Welding method for marine low-temperature steel

A welding method and low-temperature steel technology, applied in the field of steel welding, can solve the problems of low welding strength, large welding heat input, poor toughness, and poor cold crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

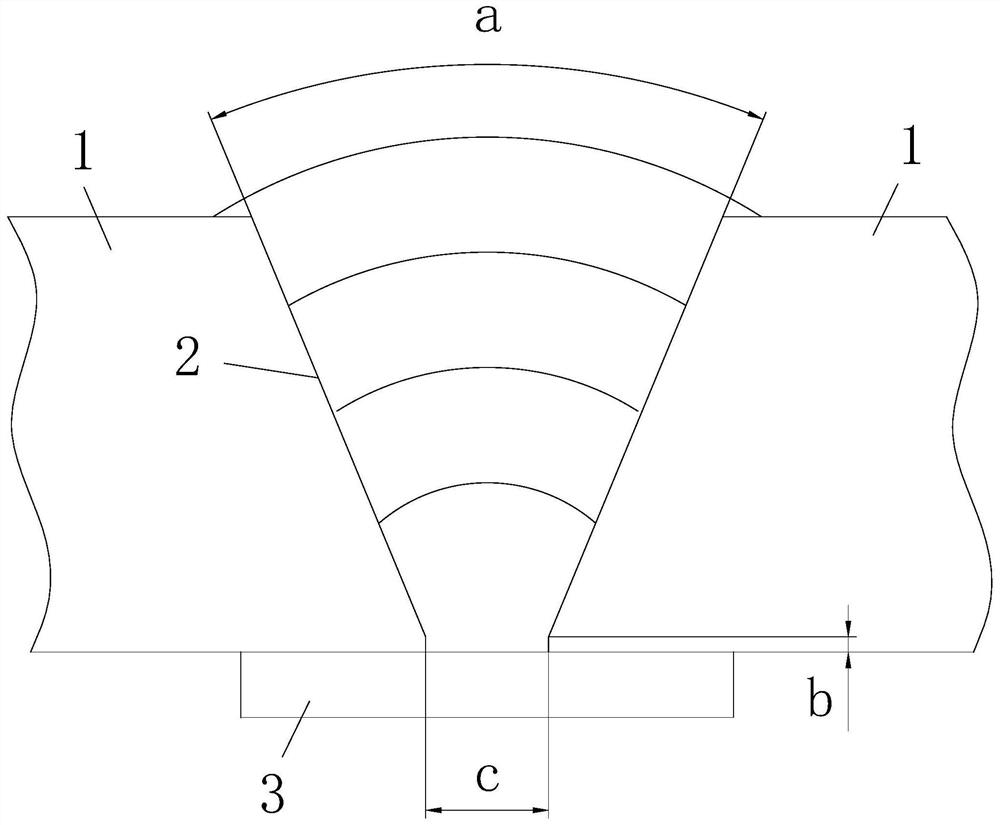

[0019] The present invention is illustrated in the following be further described in conjunction with the accompanying drawings.

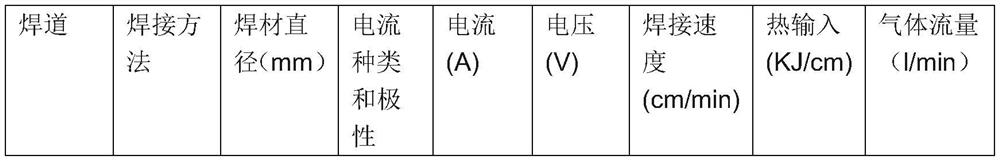

[0020] Append figure 1 Shown: one kind of marine steel welding method of low temperature, a step, is made of two marine production of low-temperature steel welding base material 1, the form of a butt weld joint, groove to form a V-groove angle of 40 ° to 50 ° port 2; step two, clear 2 V groove surface, an upper surface and a lower surface of a base material from the second edge welding V groove at least oil, rust and contamination within the range of 20mm, and polished clean exposed metallic luster; step 3. each set 3, both ends of the V-groove 2 is fixed to the spot plate 2 horse lower end a V-groove arc plate (not shown), horse plate 3, the material of the welding arc runner preform 1 same; step 4 using the multi-pass welding, the thickness of each bead is 3mm to 5mm, single-pass welding width not exceeding 25mm, the interlayer must weld by wire brus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com