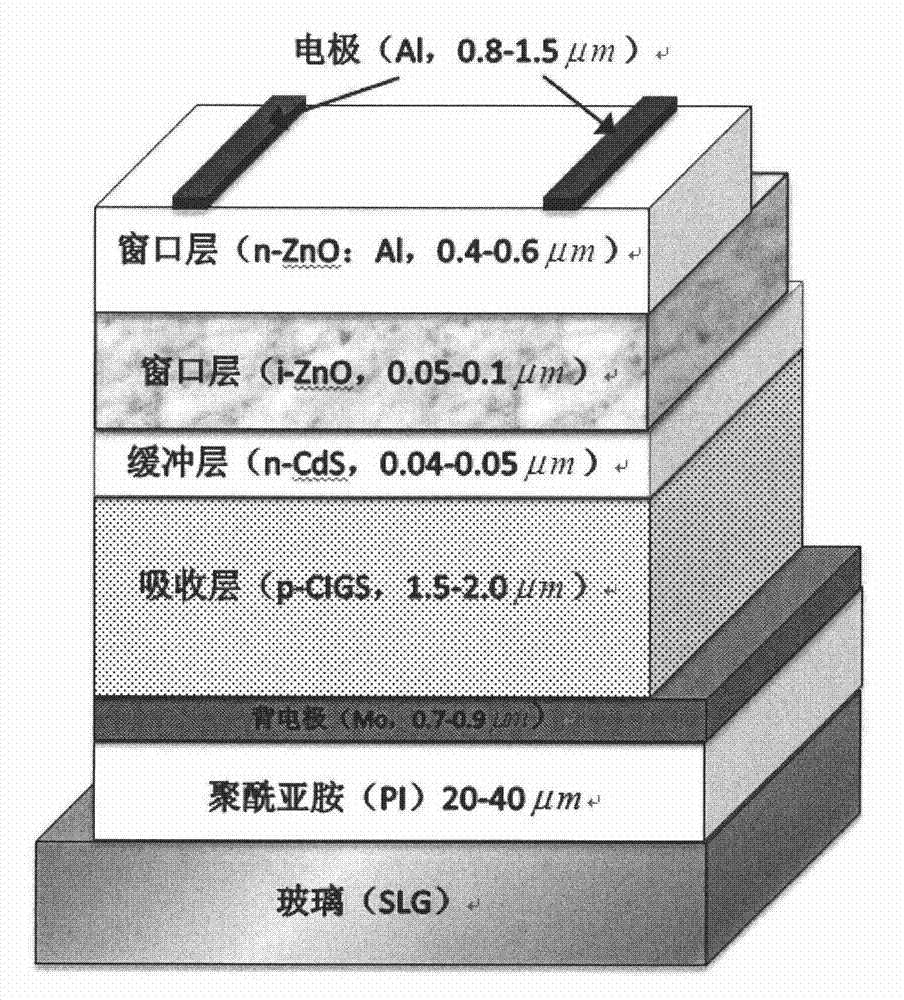

Sodium-doped copper indium gallium diselenide solar cell device and manufacturing method thereof

A technology for preparing copper indium gallium selenide and thin films, which is used in electrical components, semiconductor devices, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

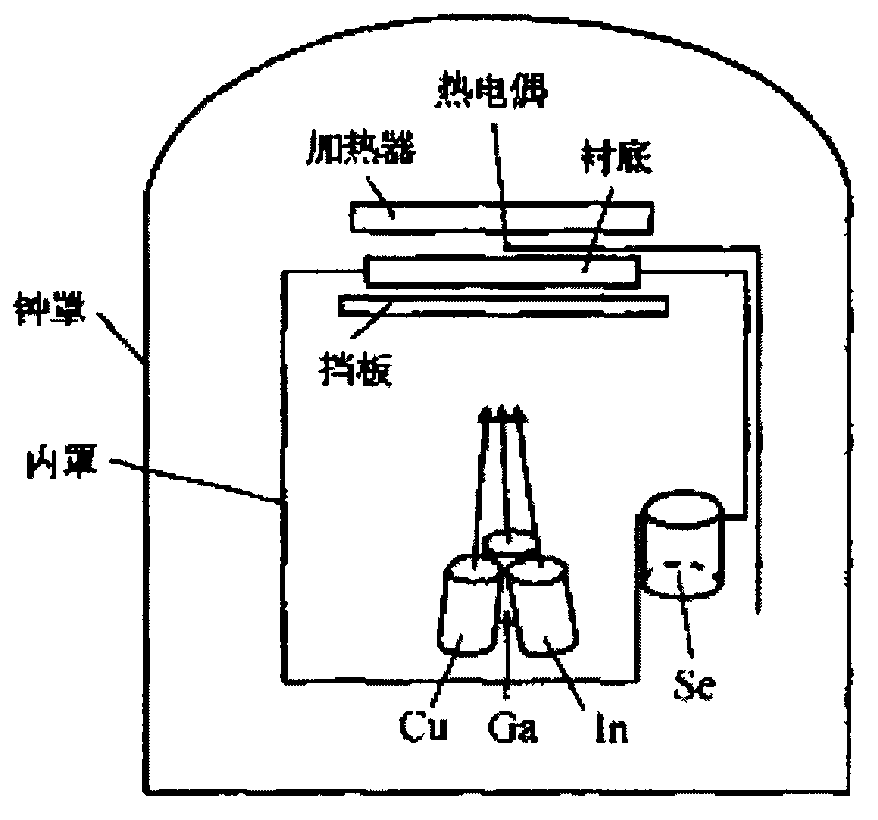

[0056] The preparation of sodium-doped copper indium gallium selenide solar cell based on polyimide film-soda glass composite substrate, the preparation steps are as follows:

[0057] 1) Cleaning of soda glass

[0058] ① Soak a 10cm×10cm soda glass in potassium dichromate solution (a solution made of 300 grams of potassium dichromate, 3 liters of concentrated sulfuric acid and 300 ml of deionized water) for 2 hours; ② Take out the soda glass Rinse with deionized water; ③Place the rinsed soda glass in an acetone solution with a concentration of 99.5%, and put it into an ultrasonic cleaning machine for cleaning (ultrasonic frequency is 20kHz, time is 25min) ④Take the soda glass out of the acetone solution , rinse with deionized water; ⑤ put the soda glass in 99.7% alcohol and put it into an ultrasonic cleaning machine for cleaning (ultrasonic frequency is 20kHz, and the time is 25min); ⑥ finally take out the soda glass from the alcohol, put Put it into a beaker filled with deio...

Embodiment 2

[0081] The preparation of sodium-doped copper indium gallium selenide solar cell based on polyimide film-soda glass composite substrate, its preparation steps are as follows:

[0082] 1) Cleaning of soda glass

[0083] ① Soak a 10cm×10cm soda glass in potassium dichromate solution (a solution prepared from 300 grams of potassium dichromate, 3 liters of concentrated sulfuric acid and 300 ml of deionized water) for 2 hours; ② Take out the soda glass Rinse with deionized water; ③Place the rinsed soda glass in an acetone solution with a concentration of 99.5%, and put it into an ultrasonic cleaning machine for cleaning (ultrasonic frequency is 30kHz, time is 20min) ④Take the soda glass out of the acetone solution , rinse with deionized water; ⑤ put the soda glass in 99.7% alcohol and put it into an ultrasonic cleaning machine for cleaning (ultrasonic frequency is 30kHz, and the time is 20min); ⑥ finally take out the soda glass from the alcohol, put Put it into a beaker filled wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com