A pipe cage pipe welding construction method

A construction method and pipeline technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient welding of pipelines in narrow spaces, and achieve the effects of improving welding quality, stable movement, and high bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, for ease of description, the first section of pipeline 4 is used to refer to the first section of pipeline in the technical solution of the present invention, and the second section of pipeline 5 is used to refer to an adjacent section of pipeline in the technical solution of the present invention.

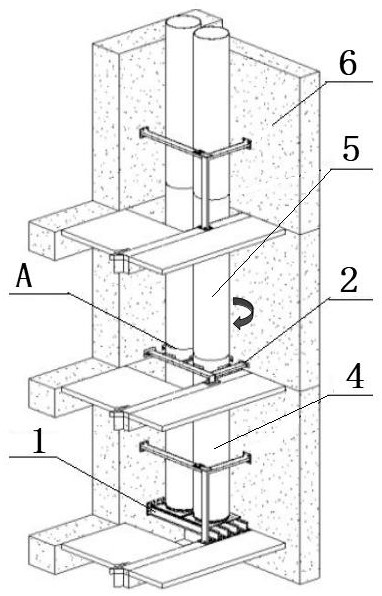

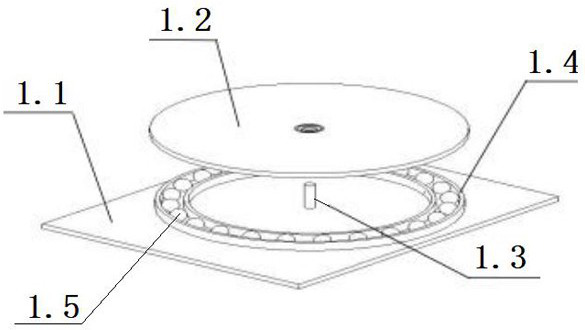

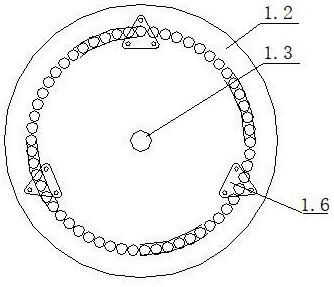

[0042] see Figure 1~Figure 7 , a pipe cage pipeline welding construction method, using a welding construction device; the welding construction device includes a rotating base 1, a pipe support 2, hoisting equipment (not shown) and a rotating force component 3; the hoisting equipment adopts electric gourd; the rotating base 1 is arranged at the lower part of the tube cage 6; the first section of pipeline 4 is installed on the rotating base 1; at least two sets of pipeline supports 2 are set, respectively sleeved on the first section of pipeline 4 and the second section of pipeline 5, The pipe support 2 is installed on the side wall of the pipe cage; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com