Steel pipe pile structure

A technology of steel pipe piles and steel pipes, which is applied in the direction of foundation structure engineering, foundation structure repair, sheet pile walls, etc., can solve the problems of high cost, large destructiveness, and long construction period, so as to improve end bearing capacity and improve pile The effect of bearing capacity and strengthening connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

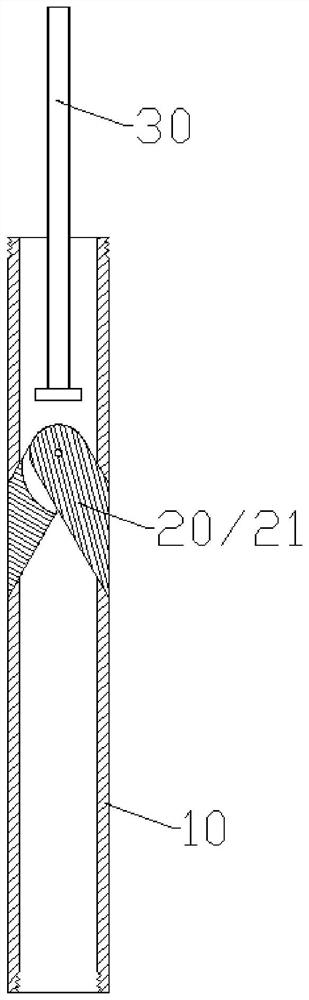

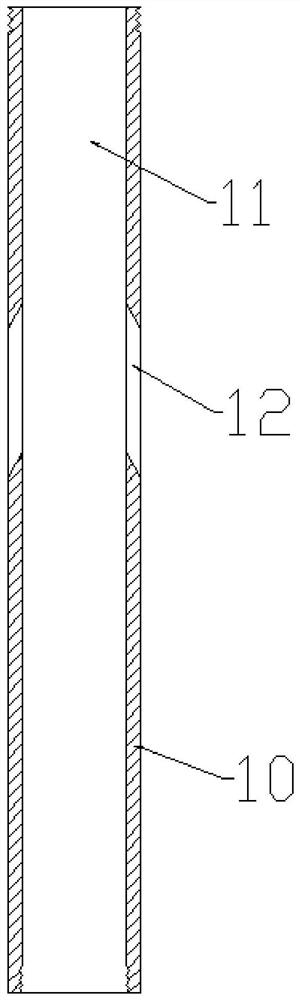

[0047] Such as Figure 1-5 As shown, a steel pipe pile structure provided in this embodiment includes: a steel pipe pile 10 and a corbel 21;

[0048] The side wall of the steel pipe pile 10 is provided with a via hole 12 connecting the inside and outside of the tube cavity 11 of the steel pipe pile 10;

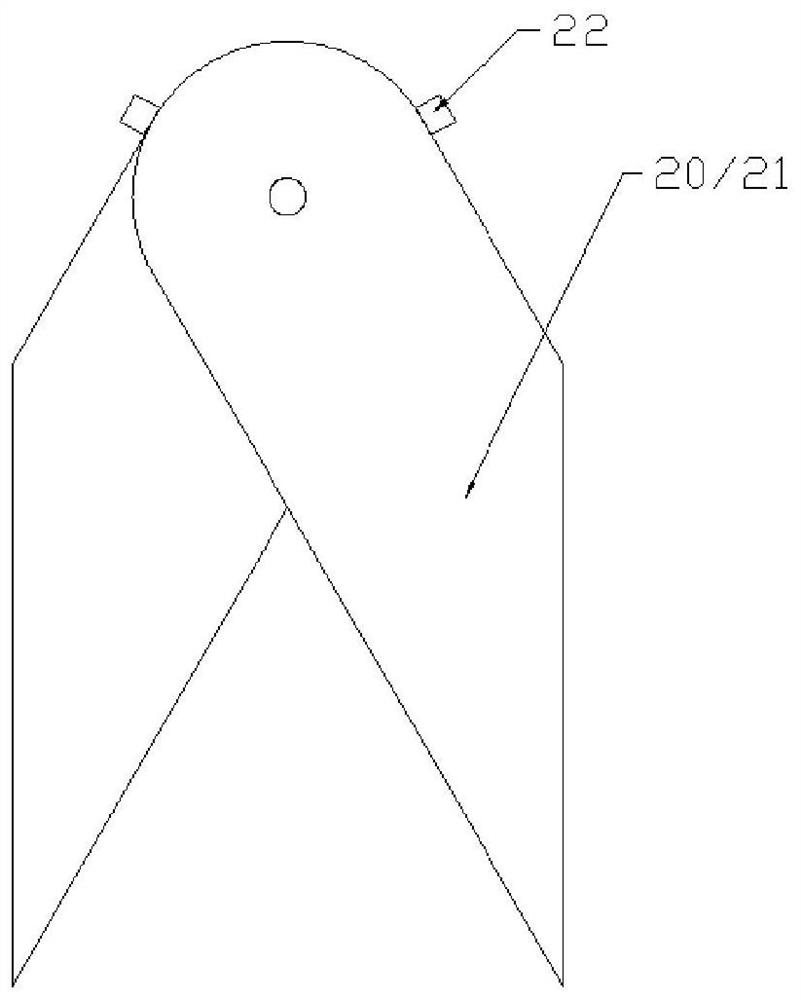

[0049] The corbel 21 is inserted into the via hole 12 so as to slide out from the lumen 11 .

[0050] The present invention is simple in structure and easy to use. After the steel pipe pile 10 is laid in place, the actuator 30 is used to push the end of the corbel 21 from the tube cavity 11 of the steel pipe pile 10 to force the corbel 21 to extend out of the steel pipe from the through hole 12. pile 10, and then form the corbel 21 structure connecting the steel pipe pile 10 and the foundation, which is convenient for construction, less destructive, and low in cost.

[0051] More preferably, this embodiment includes a corbel assembly 20, and the corbel assembly 20 includes mor...

Embodiment 2

[0061] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0062] In this embodiment, one or more corbel assemblies 20 are arranged at intervals in the lumen 11 of the steel pipe pile 10; when a plurality of corbel assemblies 20 are provided, as Figure 6 As shown, the adjacent corbel assemblies 20 are connected by intermediate connecting rods 52 .

[0063] A compression spring 60 is provided in the lumen 11 and at the bottom of the lowermost corbel assembly 20 , and both ends of the compression spring 60 are connected with the lowermost corbel assembly 20 and the steel pipe pile 10 After being compressed, the compression spring 60 tends to force the corbel assembly 20 to move upwards, thereby preventing the corbel 21 from extending out of the through hole 12 .

[0064] Before the steel pipe pile 10 is inserted into the set position of the foundation, the compression spring 60 can prevent the corbel assembly 20 from moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com