Patents

Literature

35results about How to "Avoid the situation of pulling off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

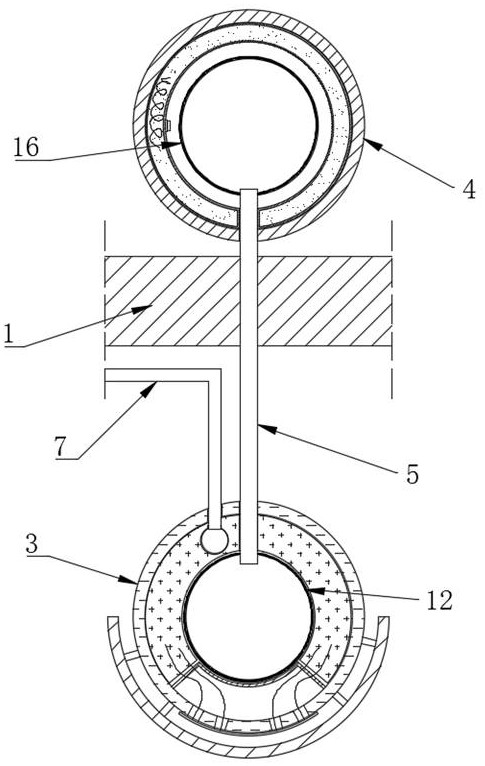

Fabricated prefabricated shear wall and laminated slab node

PendingCN107100290AAvoid the situation of pulling offImprove integrityWallsProtective buildings/sheltersSlurryShock resistance

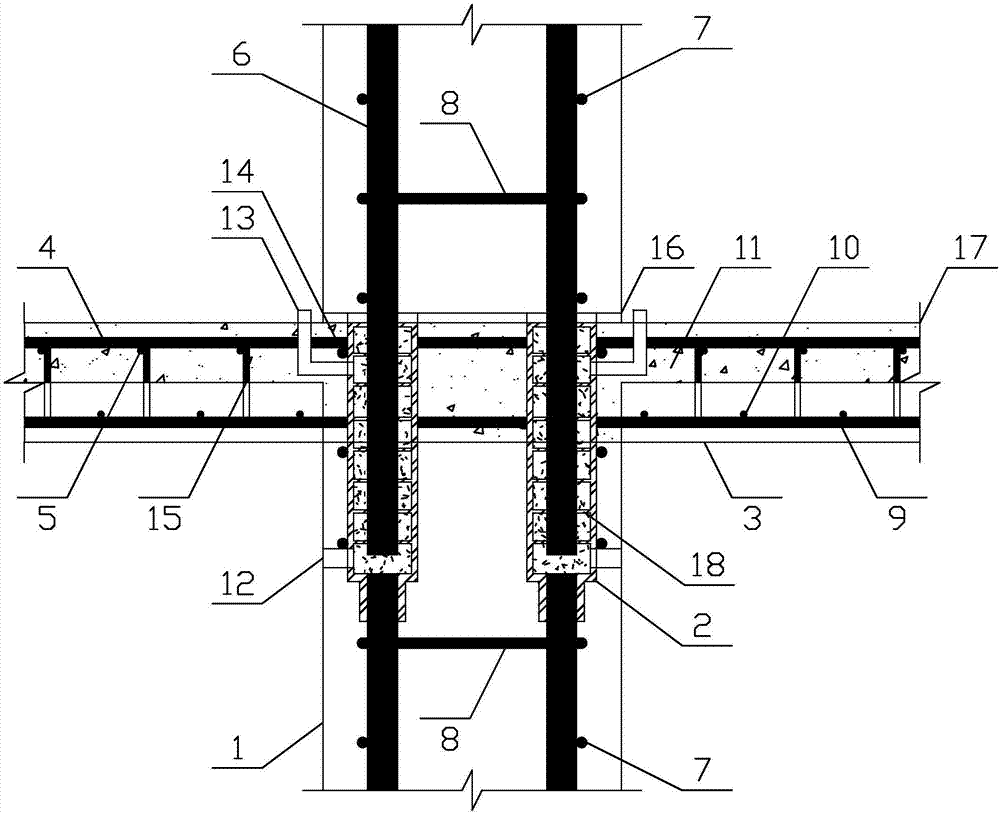

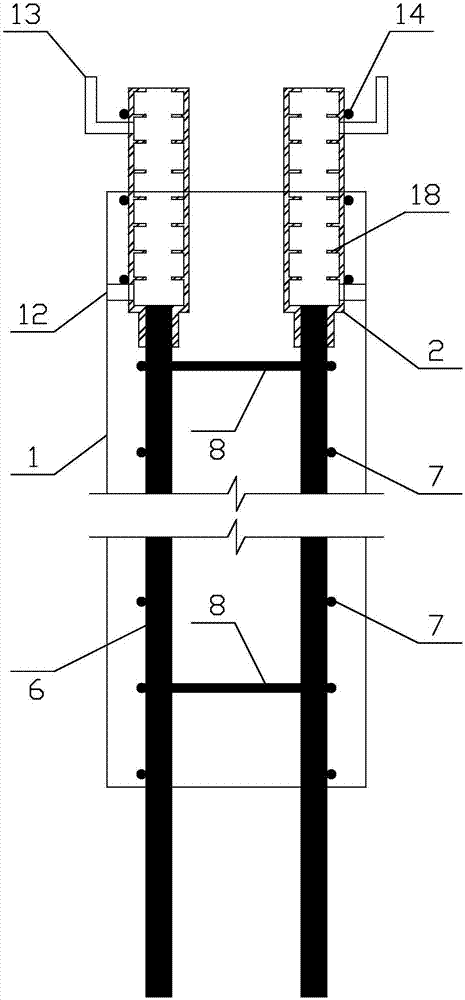

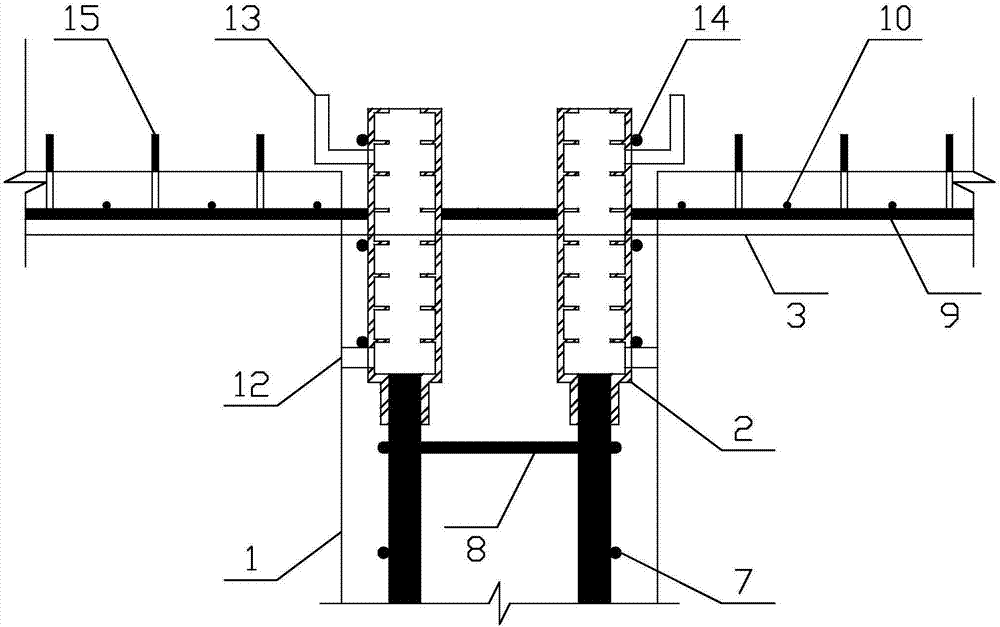

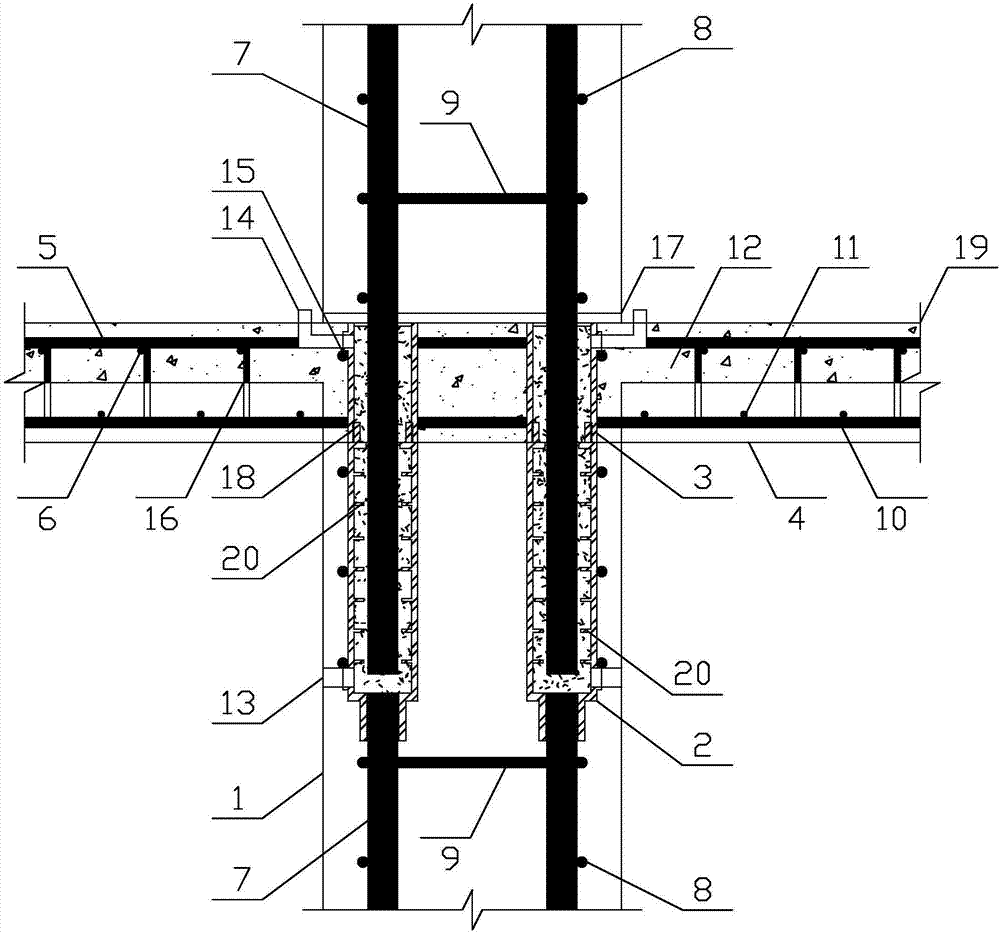

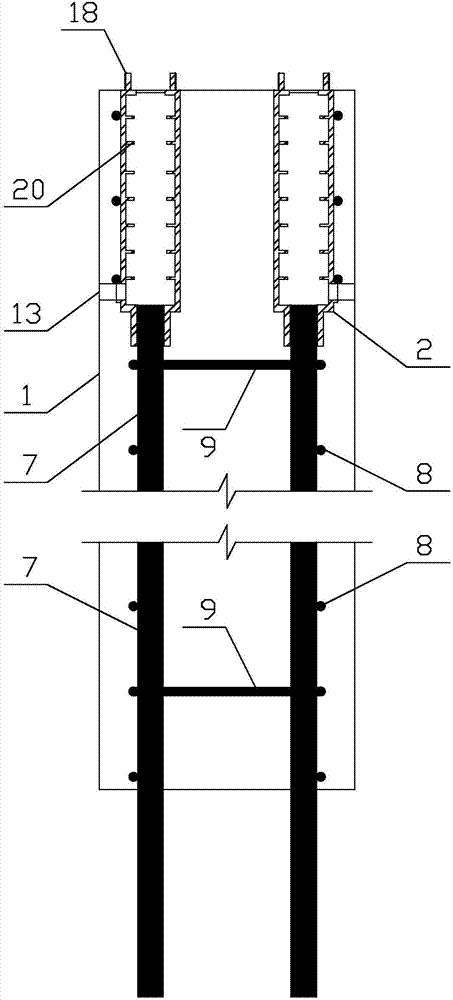

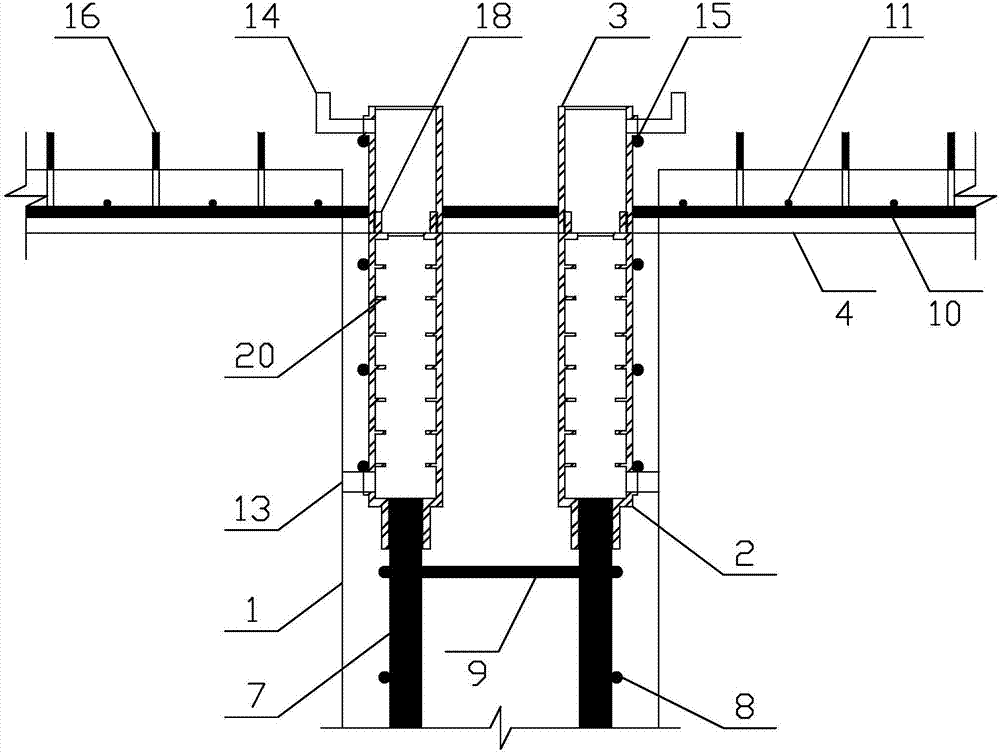

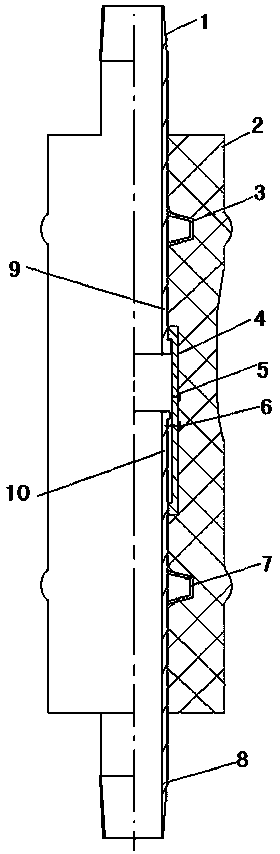

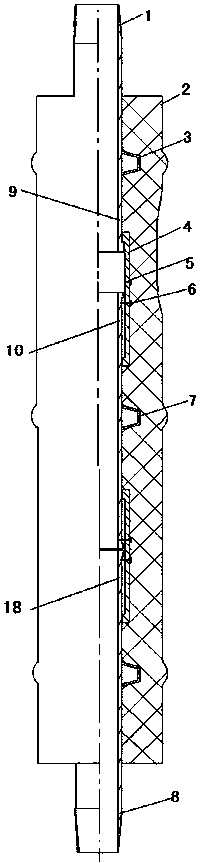

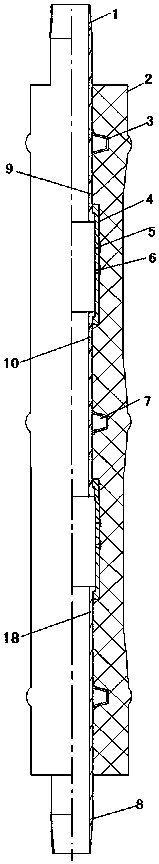

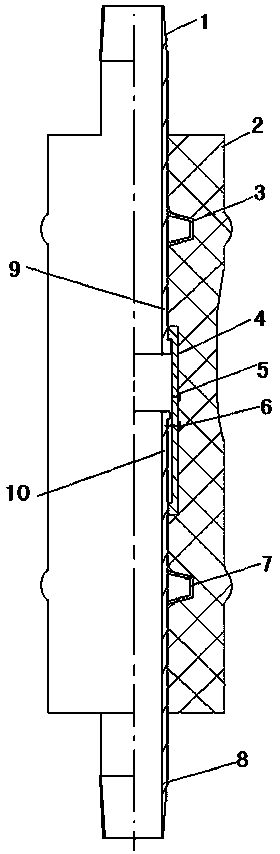

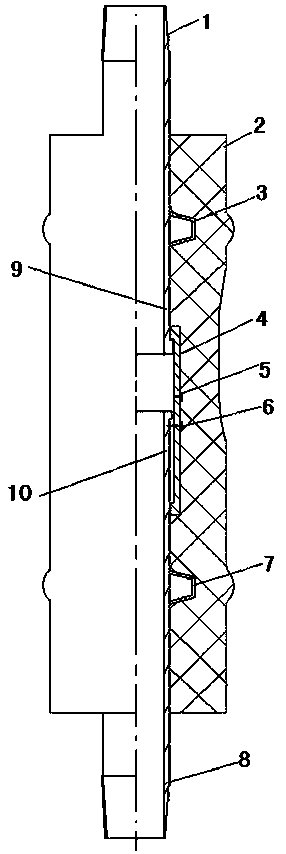

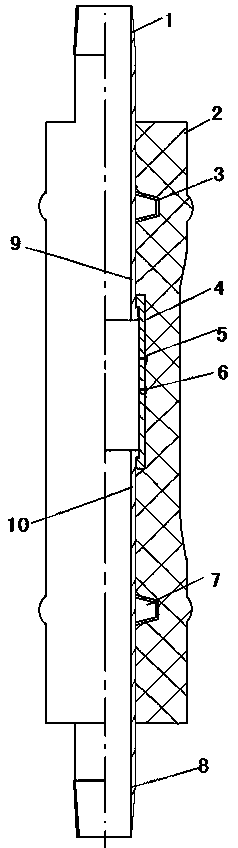

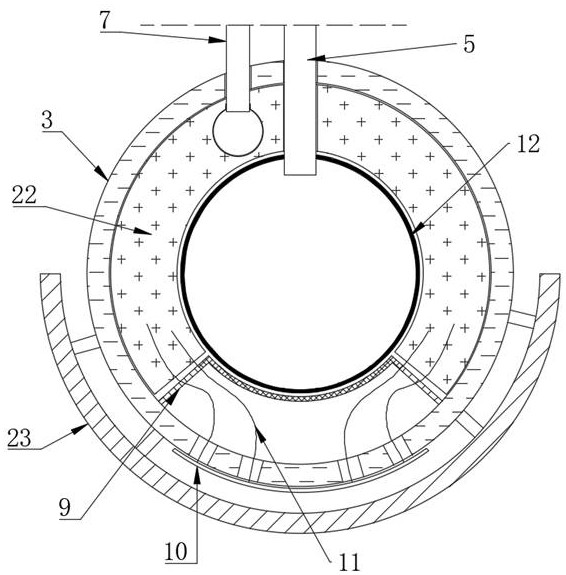

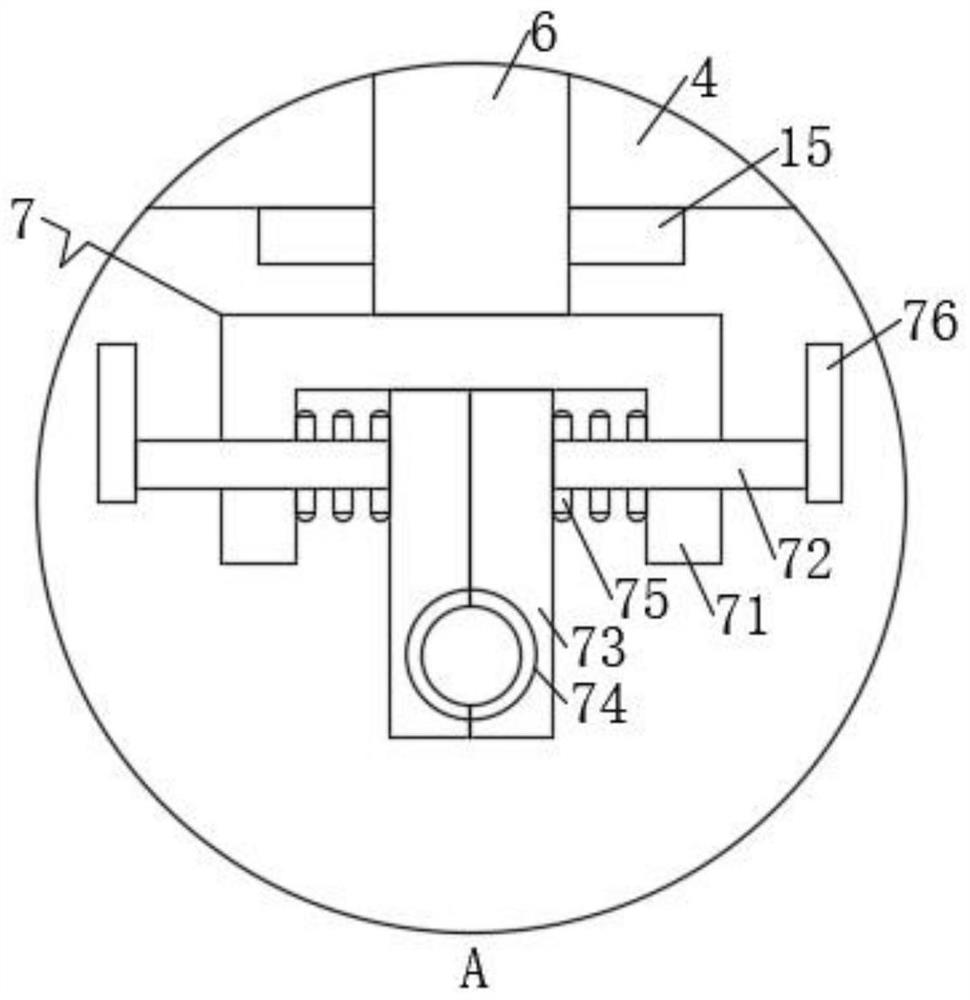

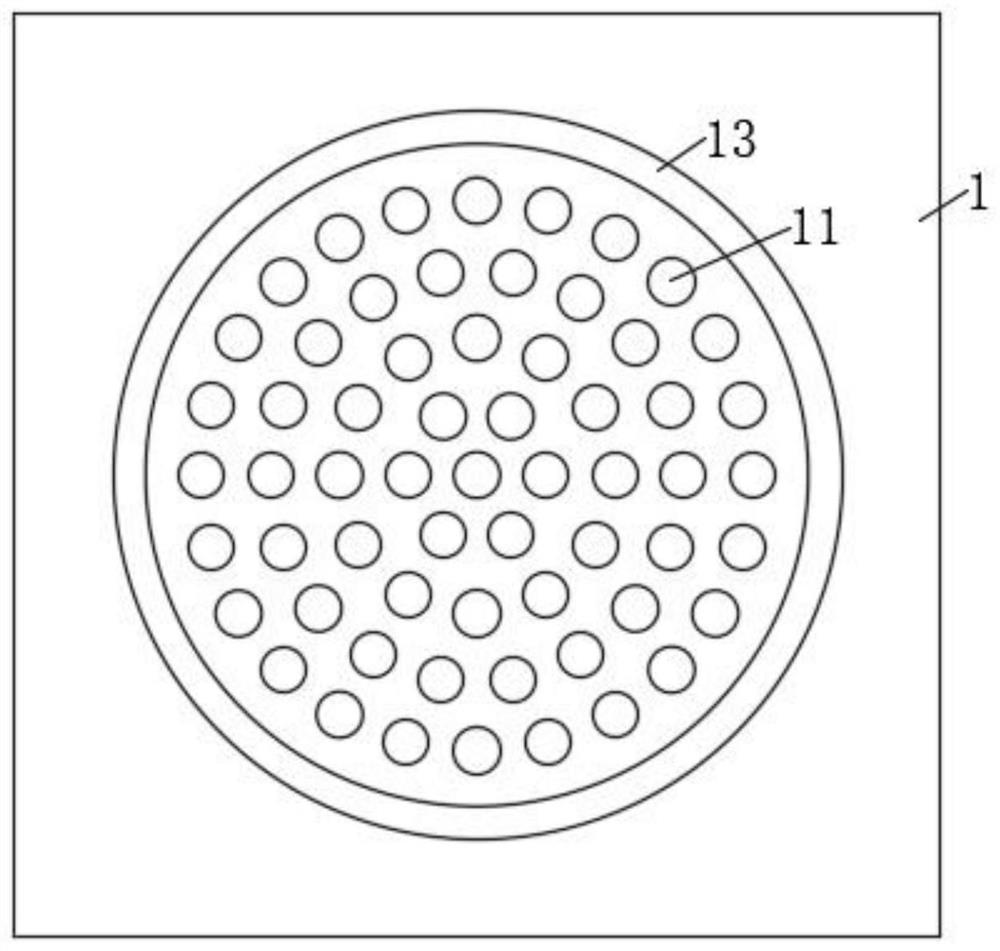

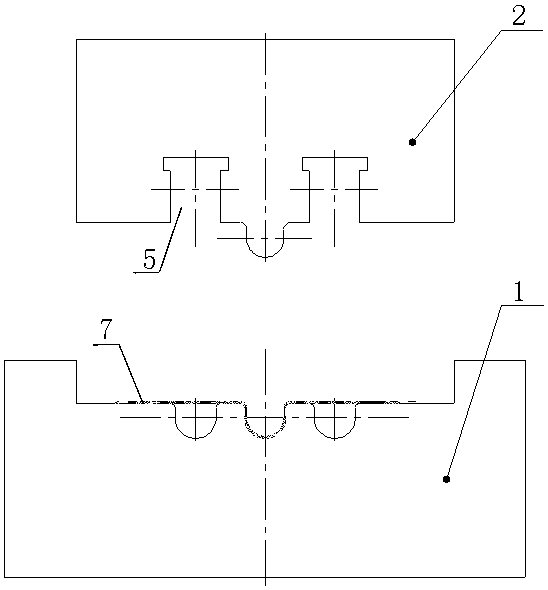

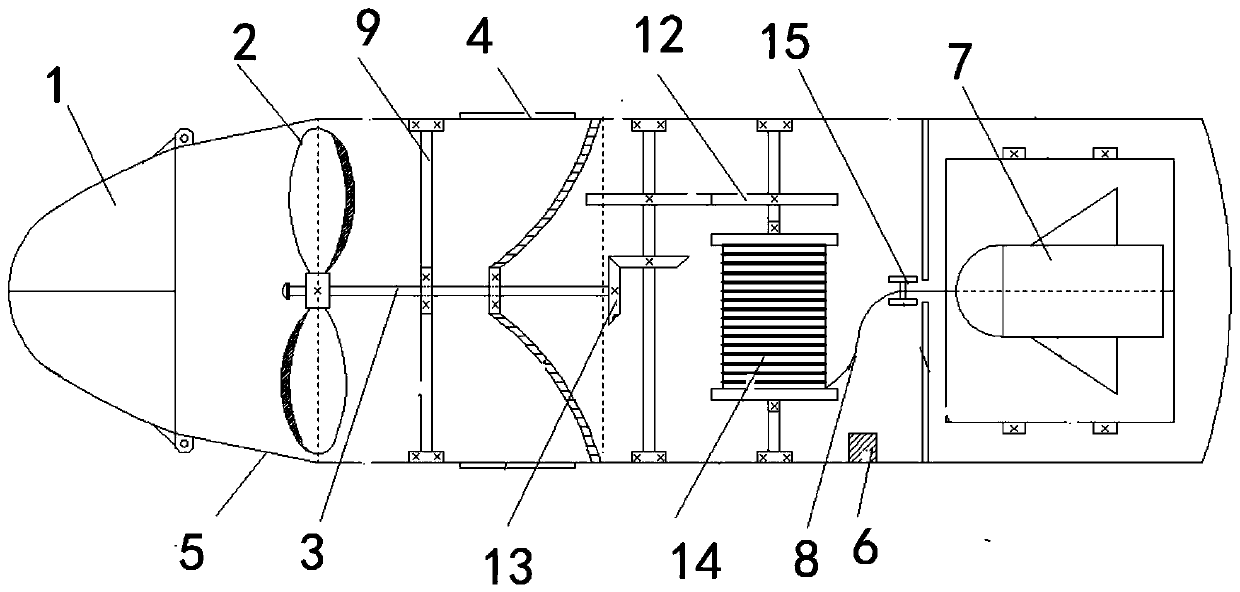

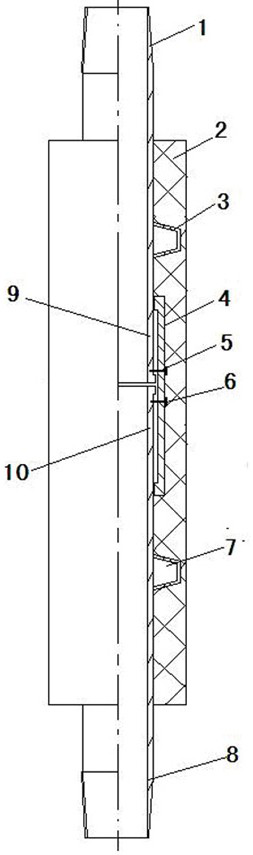

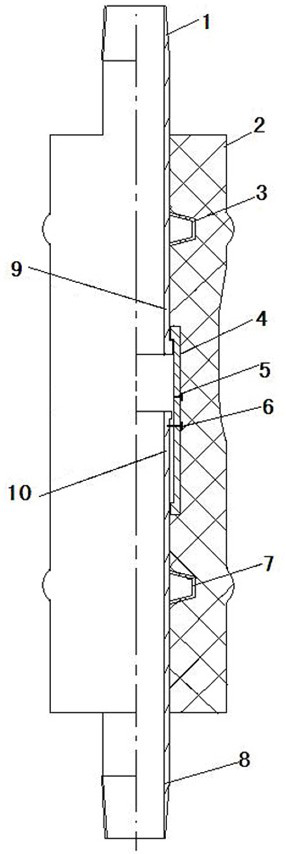

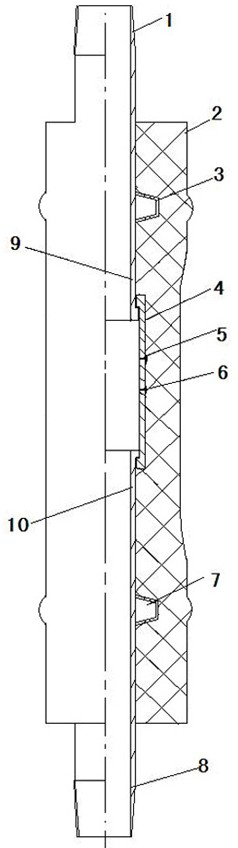

The invention discloses a fabricated prefabricated shear wall and laminated slab node. The fabricated prefabricated shear wall and laminated slab node comprises a prefabricated shear wall and a laminated slab; a grouting sleeve is arranged at a node body of the prefabricated shear wall and the laminated slab, the lower portion of the grouting sleeve is buried in the upper end of the prefabricated shear wall, and the rest part of the grouting sleeve is located in a post-poured concrete laminated layer of the laminated slab; the bottom end of the grouting sleeve is arranged at the top ends of vertical steel bars located in the prefabricated shear wall, the vertical steel bars downwards and outwards extend out of a prefabricated shear wall located on an upper floor, and the vertical steel bars are inserted into the grouting sleeve from the top end of the grouting sleeve; and a slurry discharging pipe and a grouting pipe are arranged on the upper portion and the lower portion of the grouting sleeve correspondingly, and a grouting material is poured into the grouting sleeve from the grouting pipe till the grouting material overflows from the slurry discharging pipe to enable the grouting sleeve to be completely filled with the grouting material. The grouting sleeve is a connecting piece of the upper-layer shear wall and the lower-layer shear wall, and a plastic hinge is formed at the bottom of the grouting sleeve. The prefabricated shear wall and a prefabricated plate form the wall plate node in an engaged mode through mutual connecting and binding among the grouting sleeve, a steel bar net piece and the post-poured concrete, and integrality and shock resistance of the node are improved.

Owner:广东省建科建筑设计院有限公司 +1

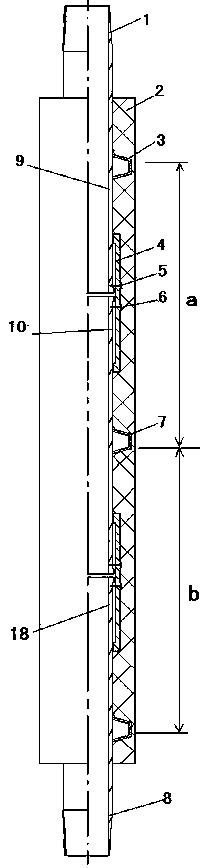

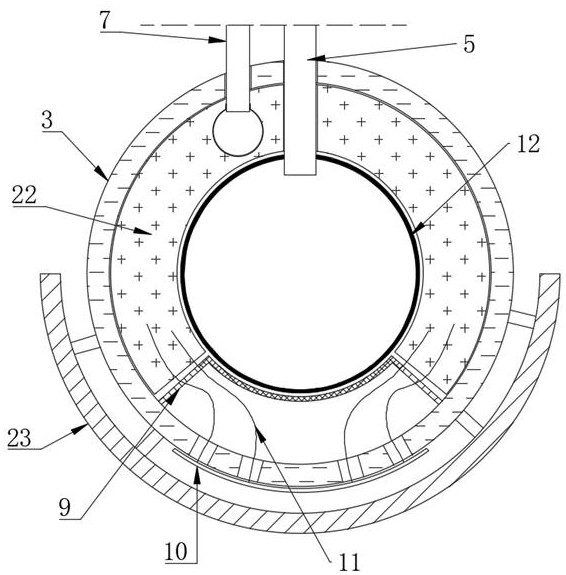

Joint of fabricated precast shear wall and laminated slab connected with fabricated precast shear wall by combined grouting sleeves

PendingCN106968381AImprove seismic performanceIncrease production capacityFloorsBuilding reinforcementsSteel barPlastic hinge

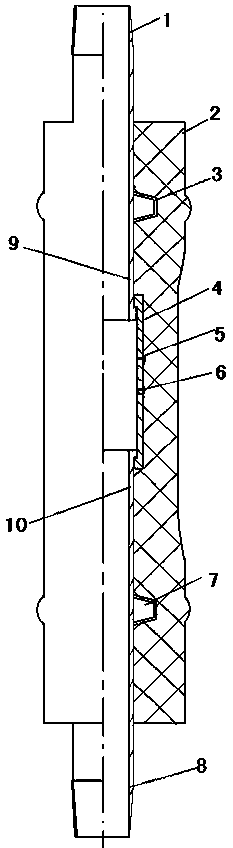

The invention discloses a joint of a fabricated precast shear wall and a laminated slab connected with the fabricated precast shear wall by combined grouting sleeves. The combined grouting sleeves are arranged at the joint. Each combined grouting sleeve comprises a first section sleeve body and a second section sleeve body; the top ends of the first section sleeve bodies are connected with the bottom ends of the second section sleeve bodies; the bottom ends of the first section sleeve bodies are connected on the top ends of vertical steel bars in the precast shear wall and completely pre-buried in the top ends of the precast shear wall, and the second section sleeve bodies are pre-buried in post-poured concrete laminated layers; the vertical steel bars extend downward out of the precast shear wall on the last storey, the vertical steel bars are inserted in the second section sleeve bodies from the top ends of the second section sleeve bodies and extend into the first section sleeve bodies; and mortar discharging pipes are arranged on the upper portions of the second section sleeve bodies, and grouting pipes are arranged on the lower portions of the first section sleeve bodies. The combined grouting sleeves serve as connecting pieces of the shear wall on the upper layer and the shear wall on the lower layer. Shear wall members form plastic hinges at the bottom. The shear wall and the precast slab form the joint through mutual connection and bonding occlusion among the sleeve bodies, steel bar meshes and post-poured concrete, and the integrity and anti-seismic performance of the joint are improved.

Owner:广东省建科建筑设计院有限公司 +1

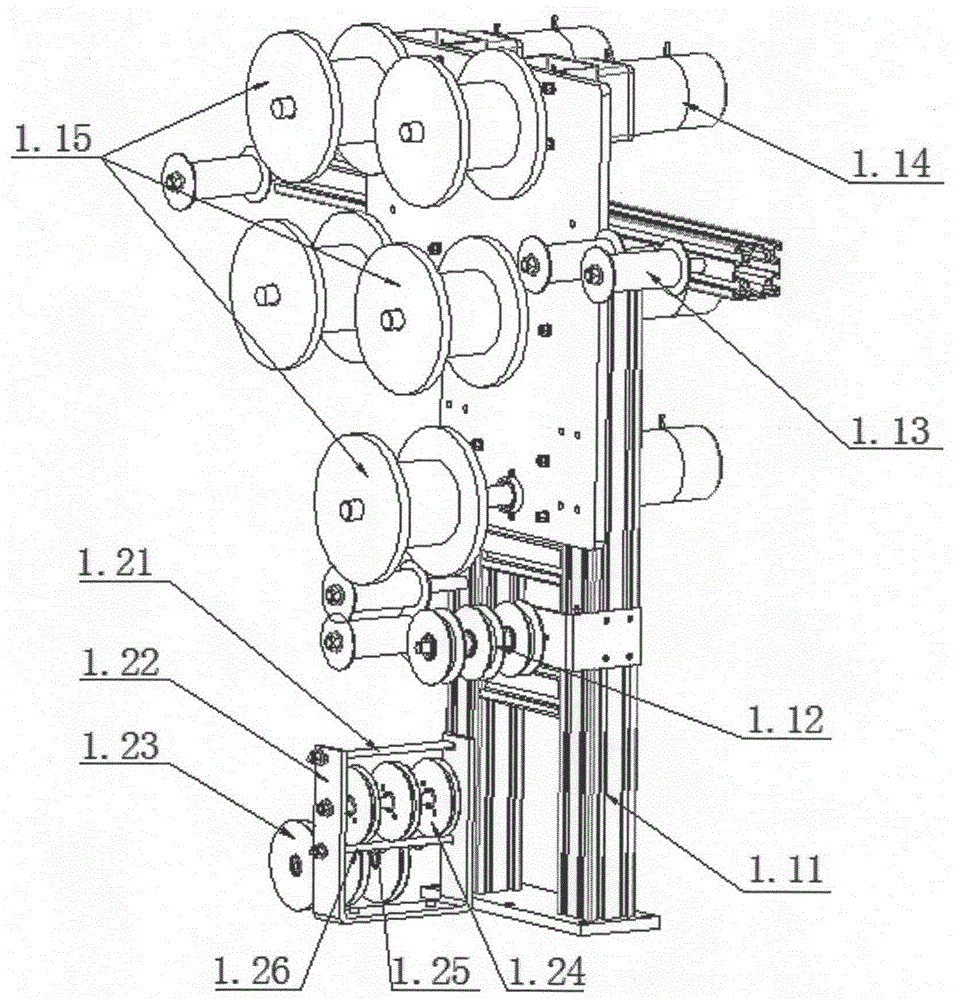

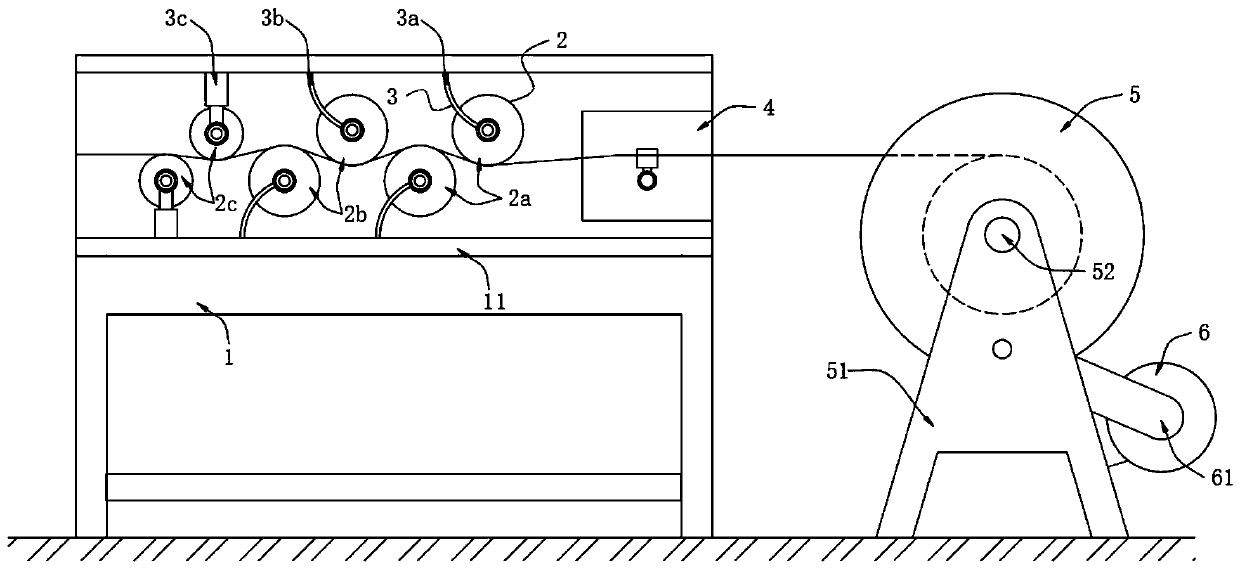

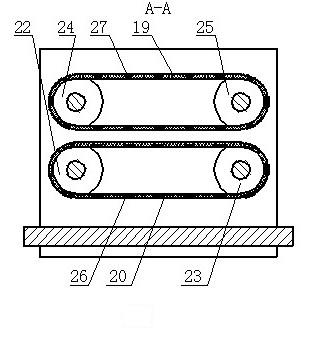

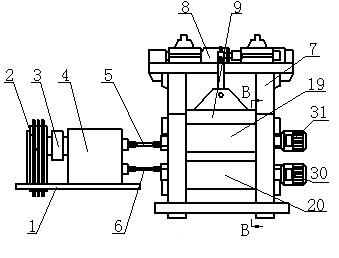

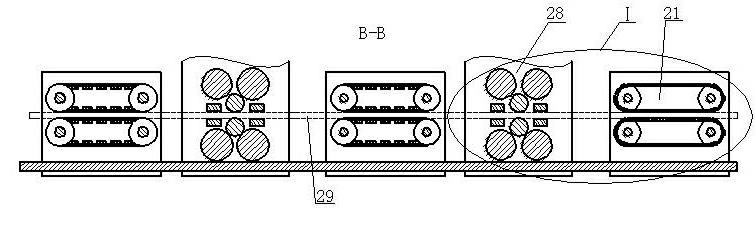

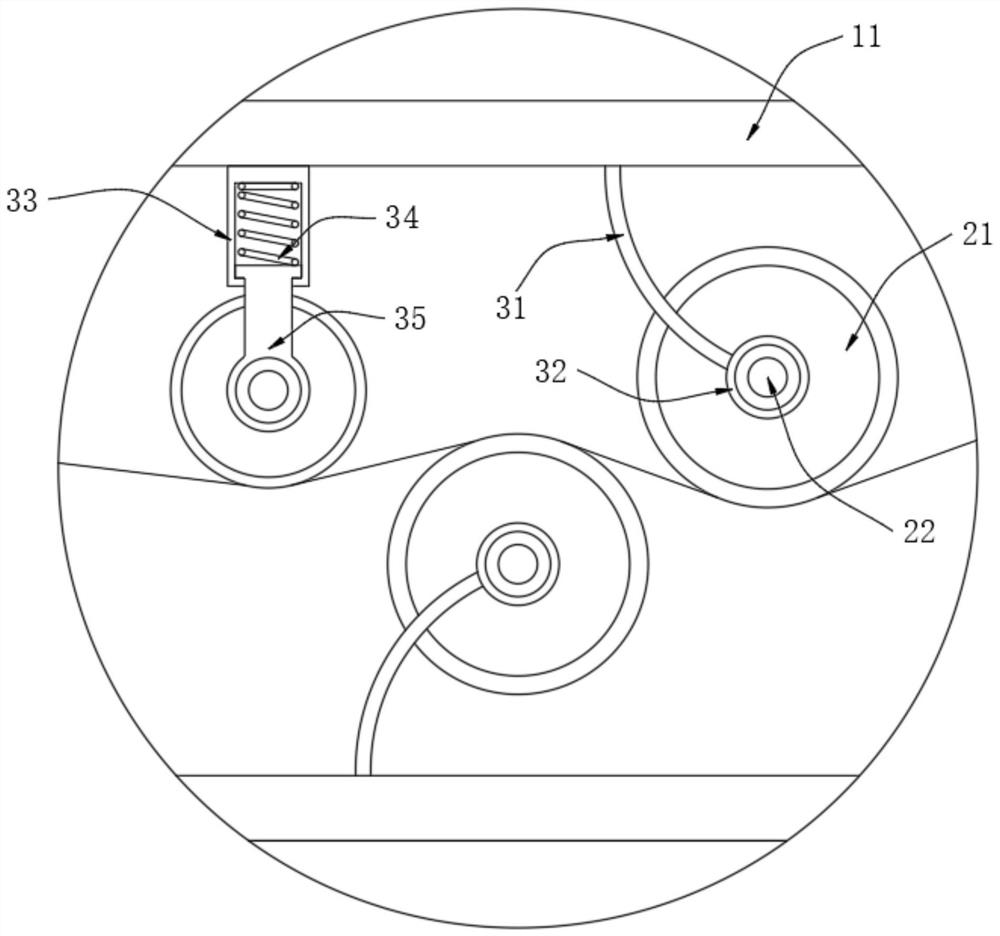

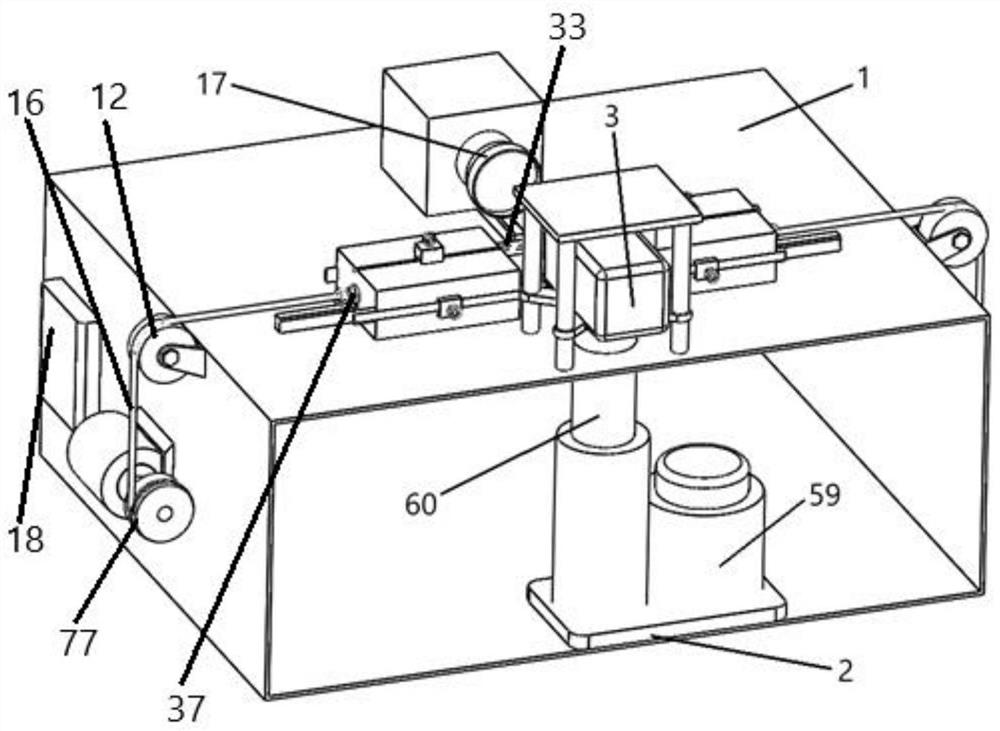

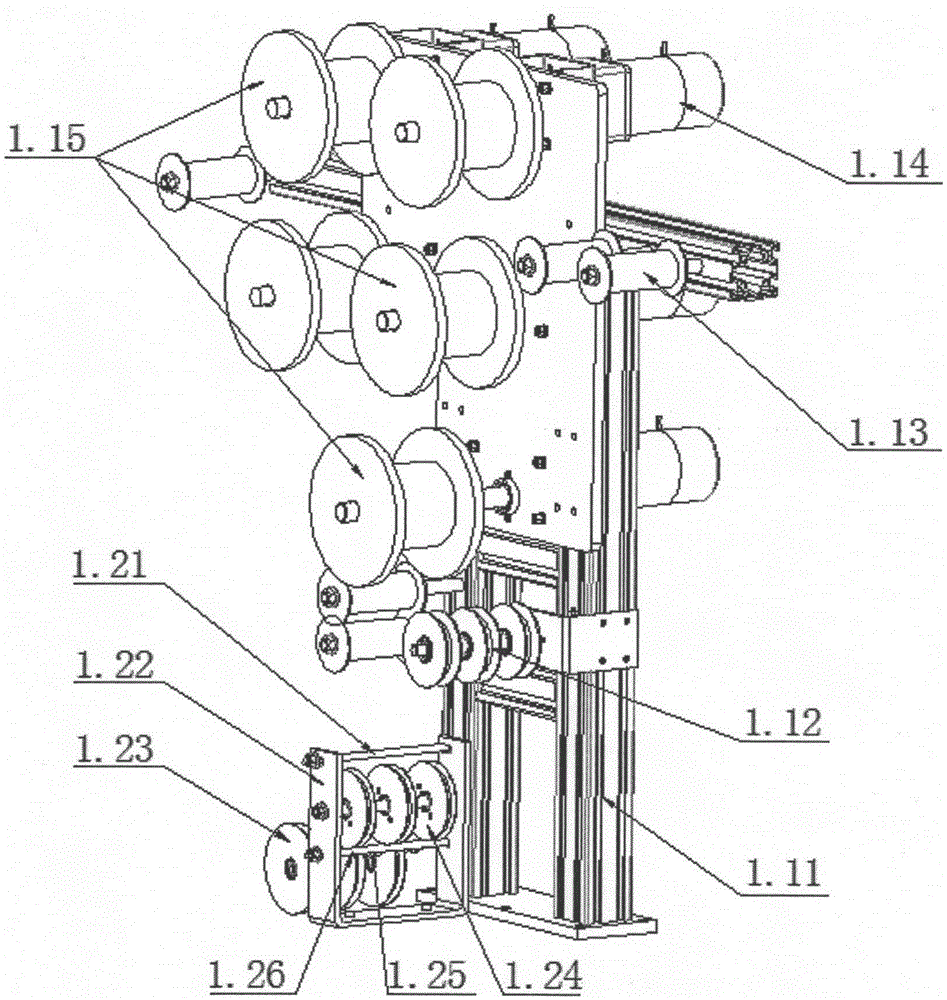

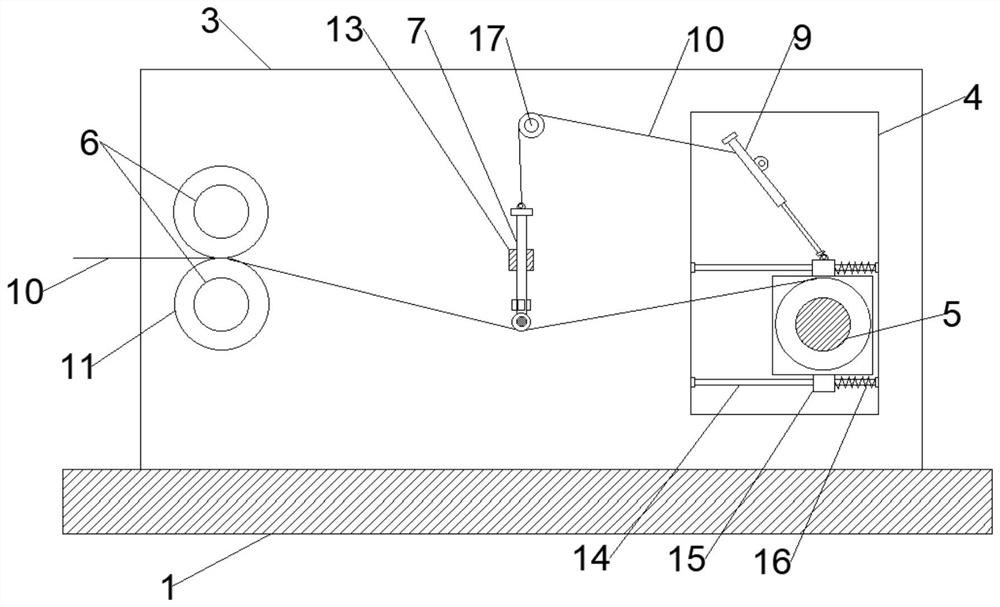

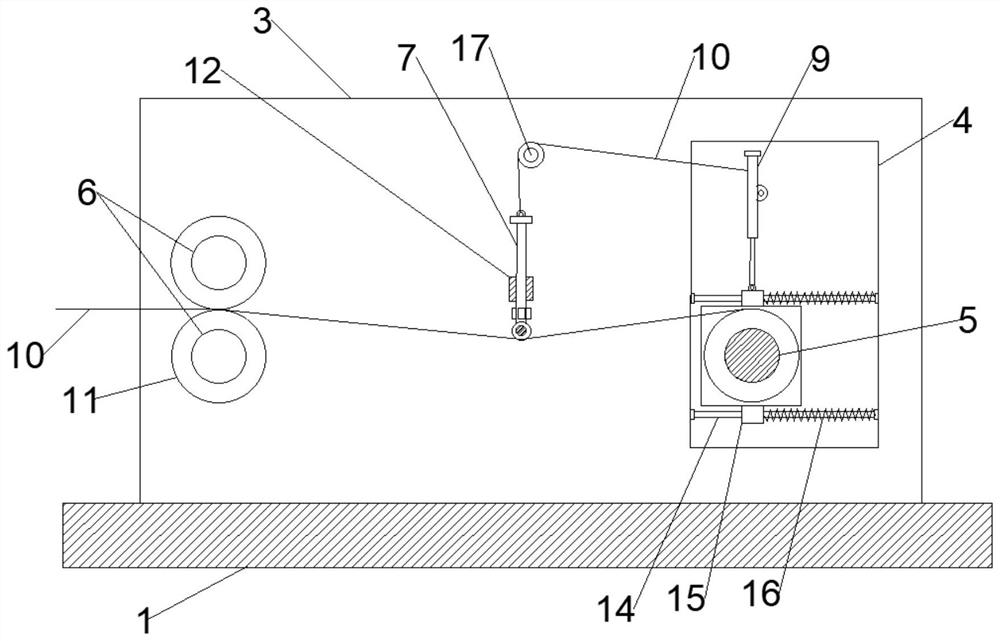

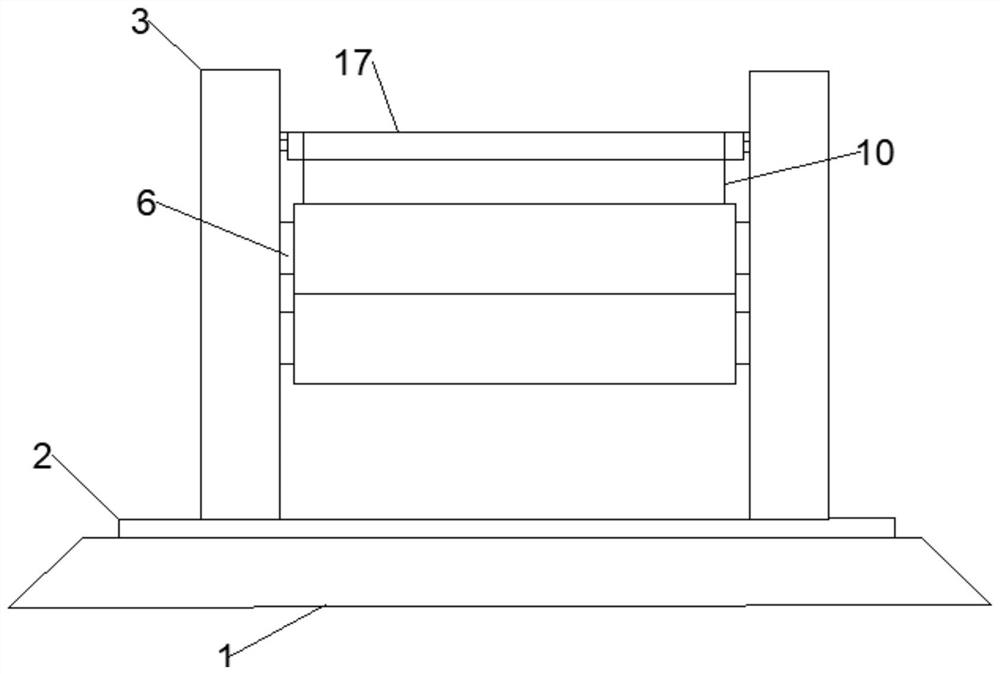

Adjustable welding strip feeding device

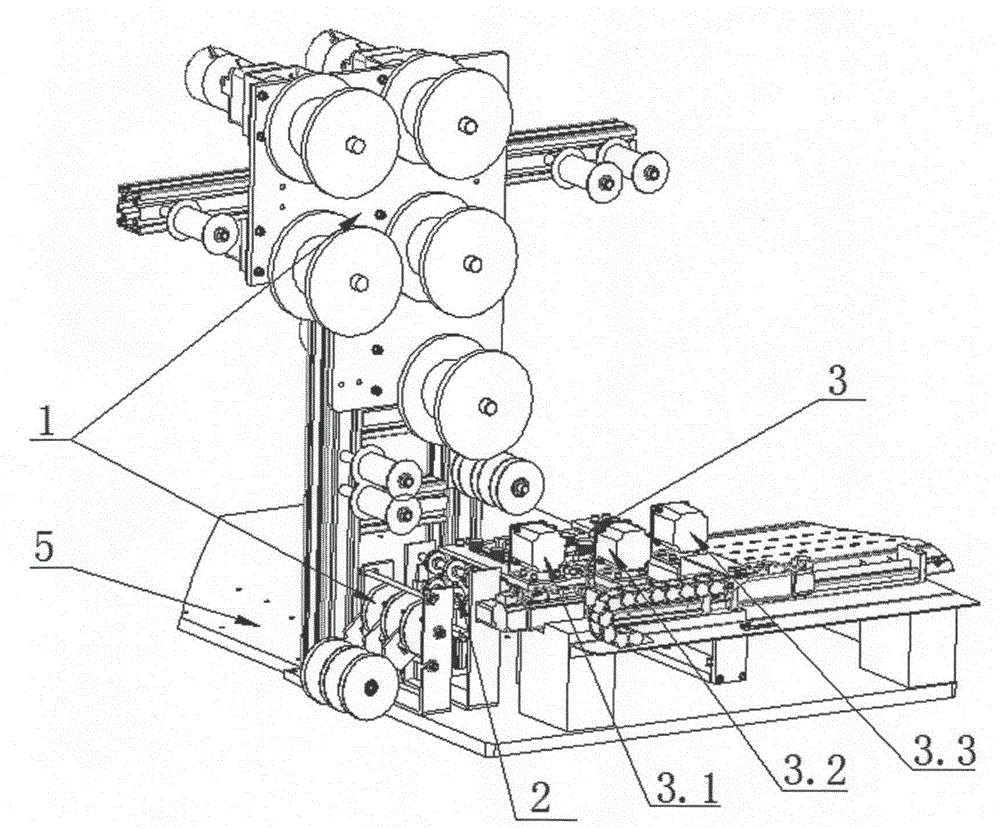

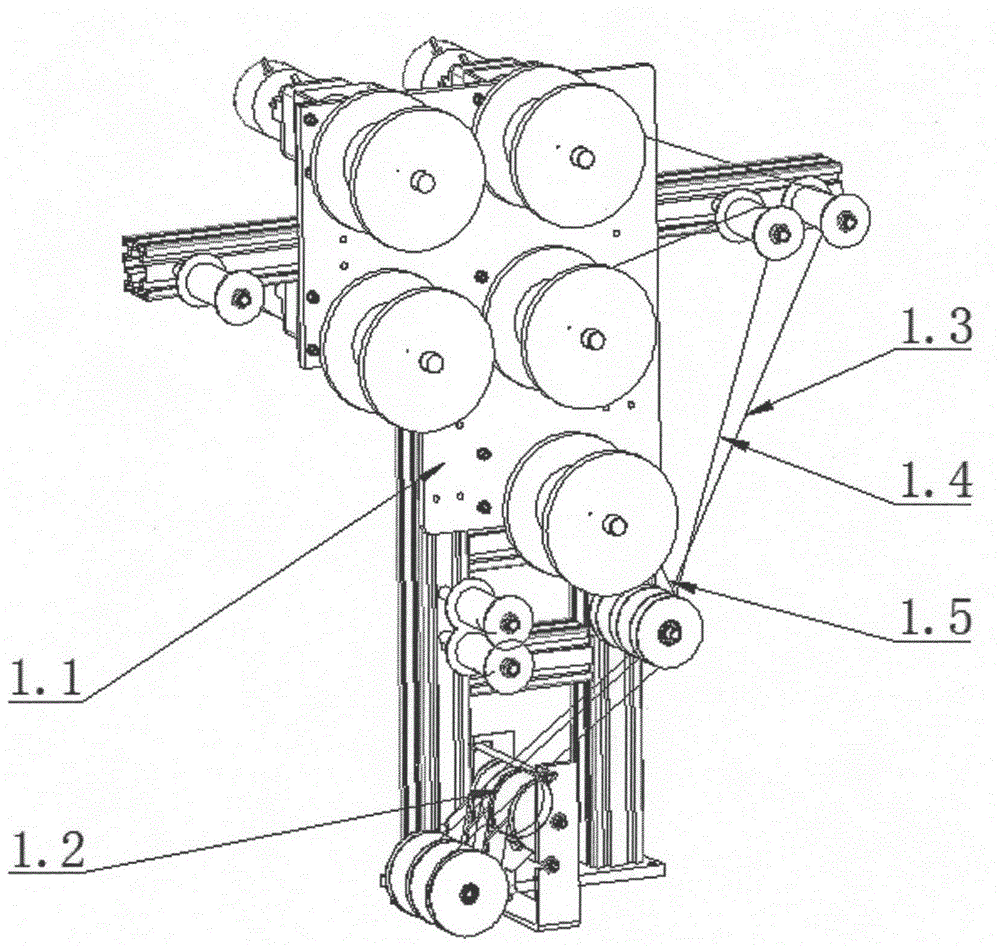

InactiveCN104668835APrevent the ribbon from being pulled offShorten laying timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

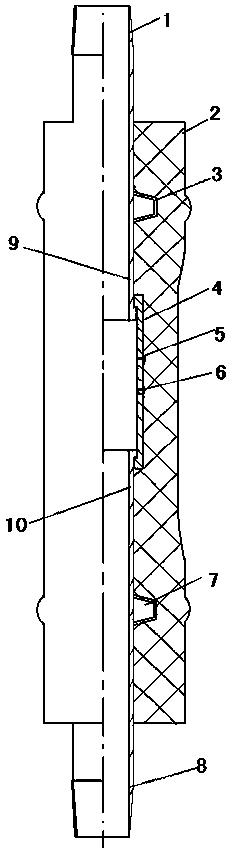

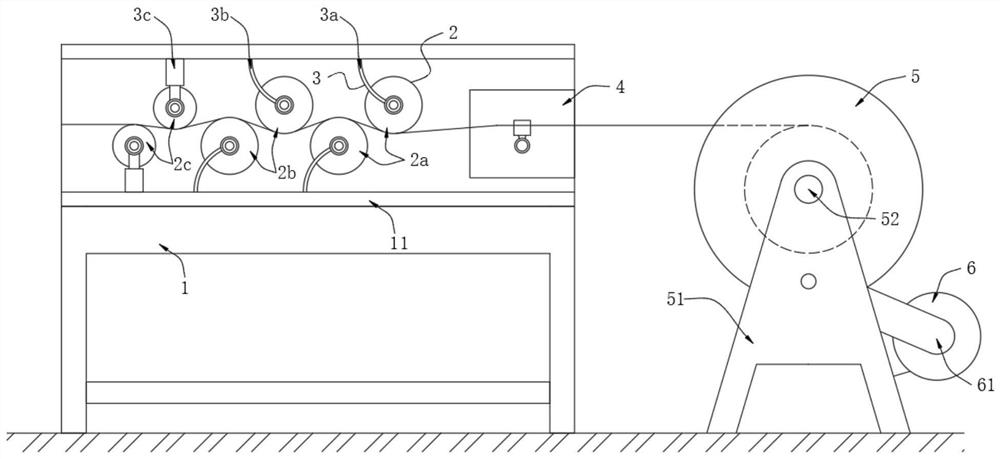

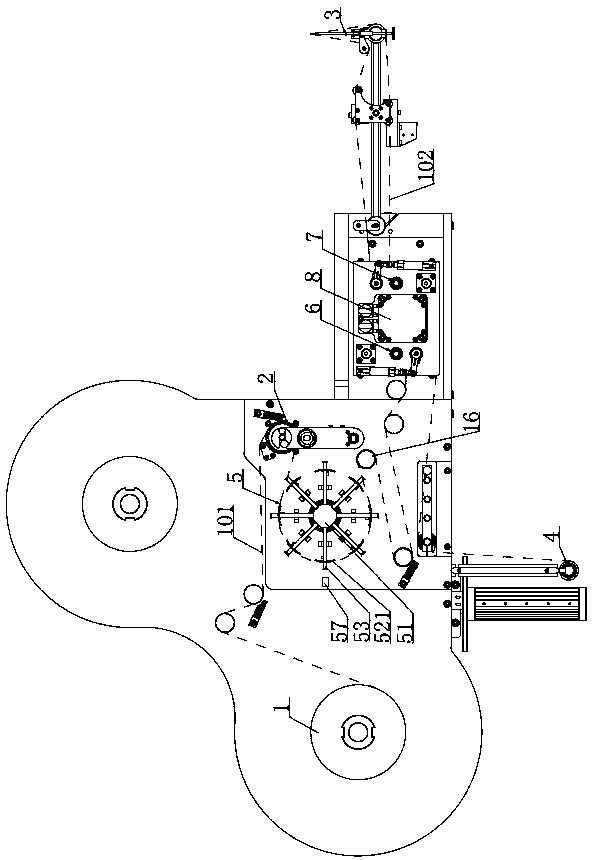

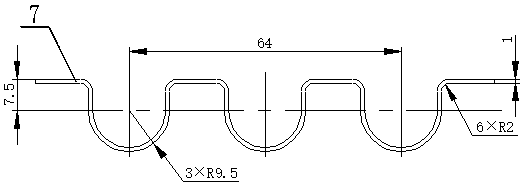

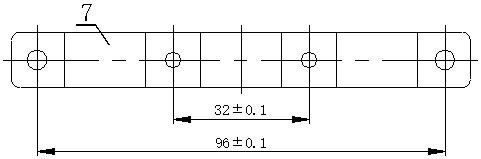

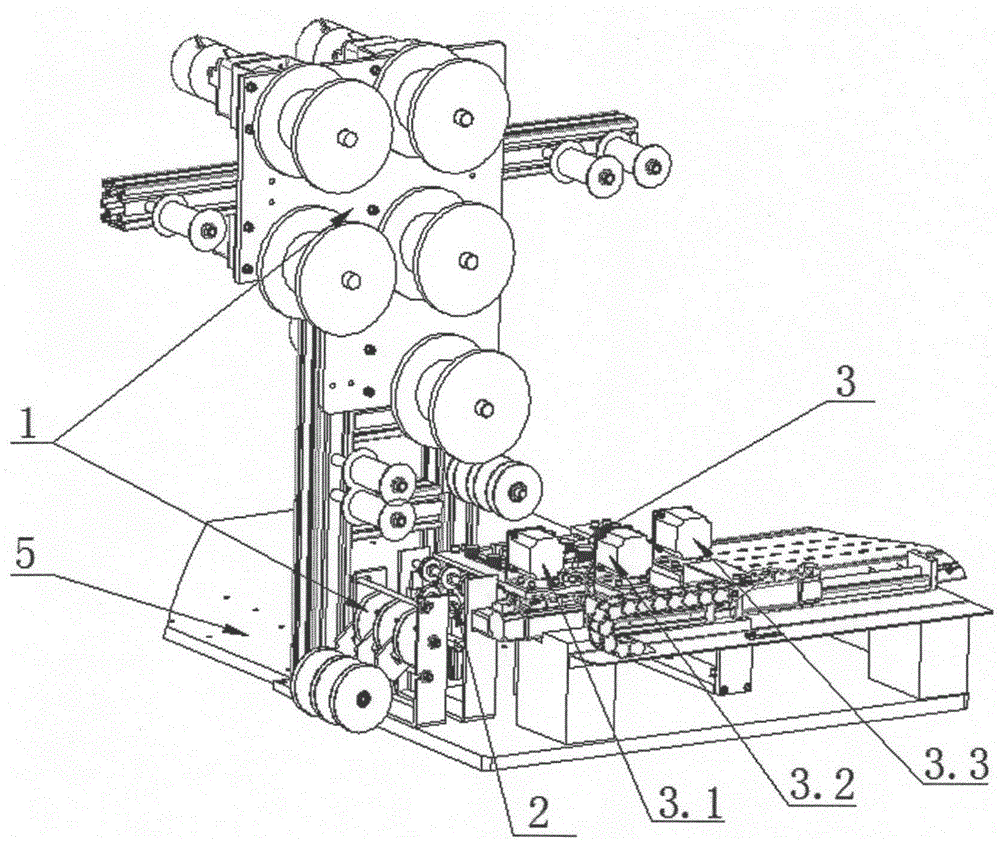

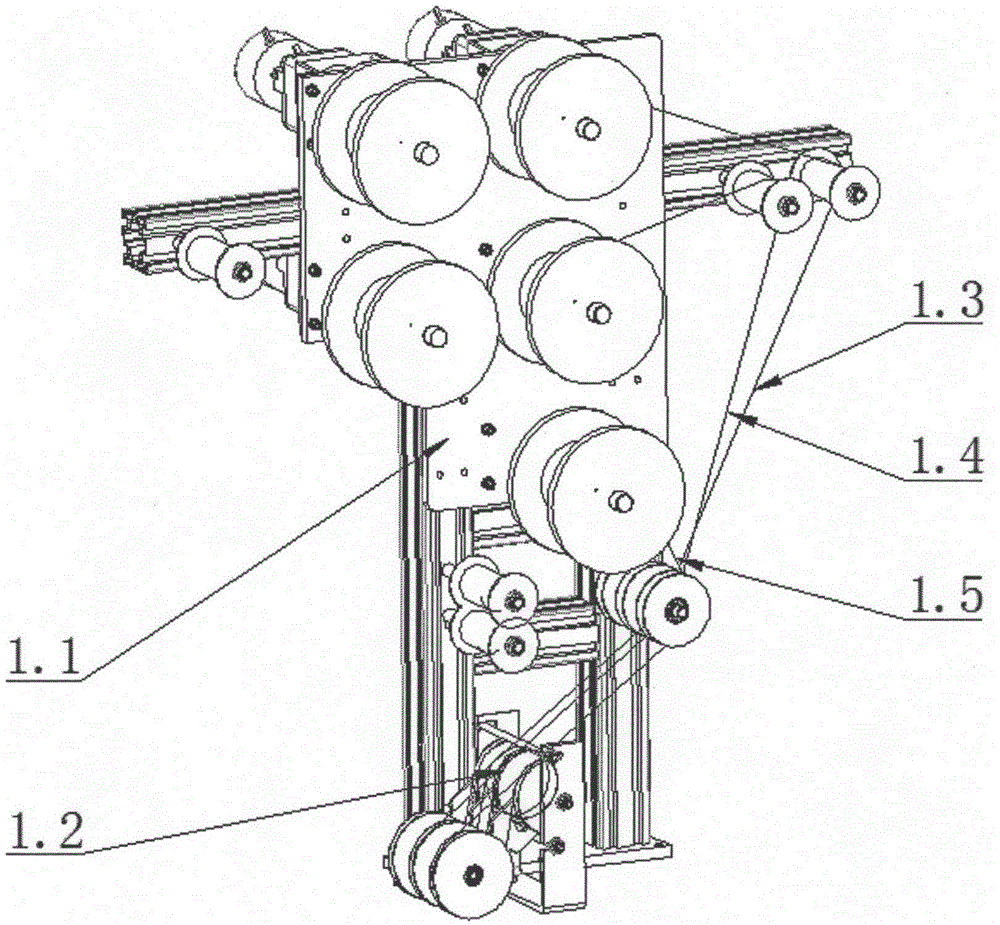

The invention discloses an adjustable welding strip feeding device which is characterized by comprising a welding strip cushioning supplying device, a welding strip feeding device and a welding strip laying device. The welding strip cushioning supplying device, the welding strip feeding device and the welding strip laying device are arranged on a mounting platform, the welding strip feeding device is arranged between the welding strip cushioning supplying device and the welding strip laying device, the welding strip cushioning supplying device comprises a winding unit and a cushioning unit, the front surface of the cushioning unit is connected with the winding unit, the welding strip laying device comprises a welding strip straightening and shaping unit, a welding strip cut-off unit and a welding strip stretching unit, and the welding strip cut-off unit is arranged between the welding strip straightening and shaping unit and the welding strip stretching unit. The adjustable welding strip feeding device has the advantages that welding strips can be quickly and effectively stretched and fed under the matching effects of the winding unit and the cushioning unit, and problems of loose winding of existing welding strips and breakage of the existing welding strips in stretching procedures can be solved; the multiple welding strips can be conveniently and quickly automatically initially fed by the welding strip feeding device instead of labor and can be simultaneously laid, and accordingly the flexibility of the adjustable welding strip feeding device can be improved.

Owner:DONGHUA UNIV

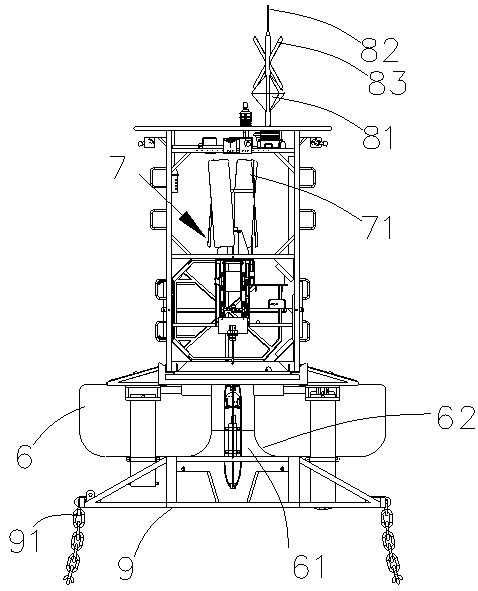

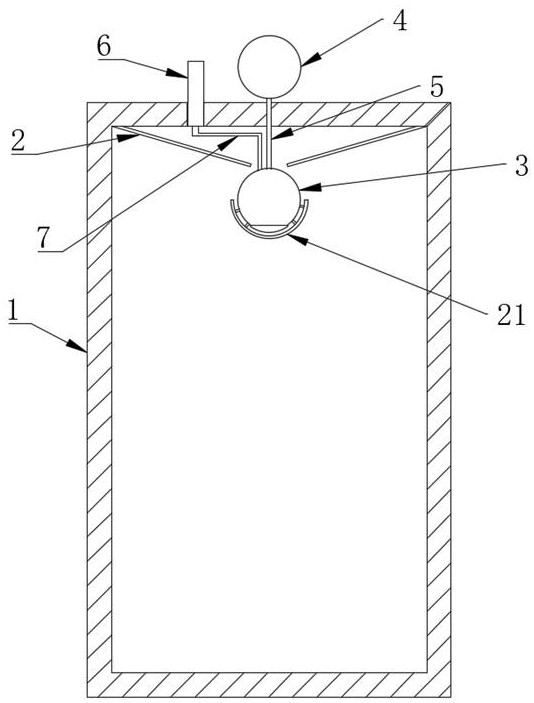

Automatic online monitoring buoy system for ocean profile

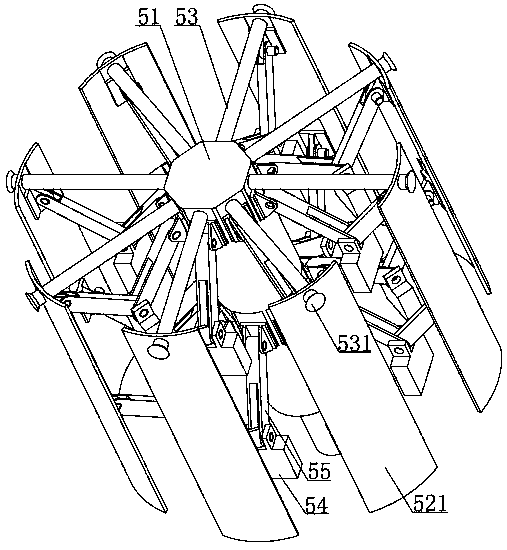

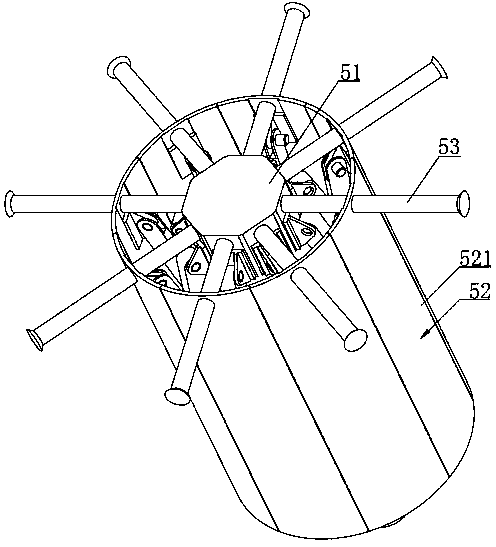

PendingCN110696967AShort response timeControl scheme is reliableCargo handling apparatusMeasurement devicesEcological monitoringBuoy

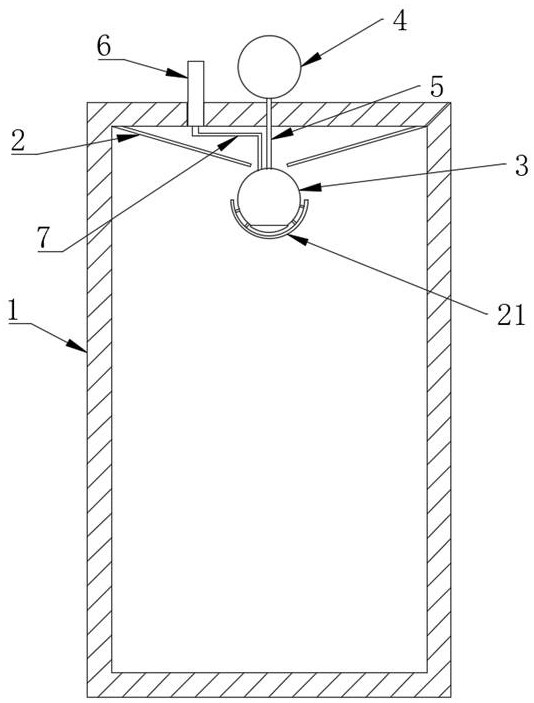

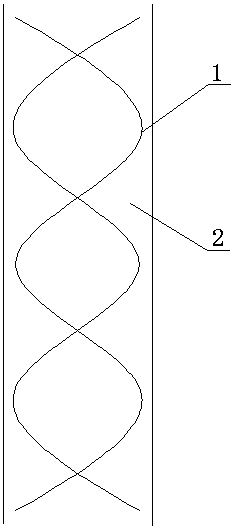

The invention relates to the technical field of marine ecological monitoring, and discloses an automatic online monitoring buoy system for a marine profile. The buoy system comprises a floating body,a wind power generation system and an instrument support, the instrument support comprises a shuttle-shaped frame composed of 2-4 supports, and a protective plate is arranged at the upper end of the shuttle-shaped frame and is connected with a balancing weight on a cable. The shuttle-shaped frame is provided with a tensile resistance piece, and the cable is fixedly arranged on the tensile resistance piece in an S shape. A winch starting and stopping device comprises a winch support and a winding drum used for winding the cable, a magnetic induction sensor is arranged below the winding drum, and a permanent magnet is arranged on the cable. When the permanent magnet approaches the magnetic induction sensor, a control signal is sent out to control the starting and stopping of a winch motor. The tensile force of the cable is dispersed in the whole line segment, so that the situation that an outer sheath or a conductor is stressed to cause skin-core separation, and even the cable is snapped, is avoided, the problem that the motor drives the instrument support to collide with the device to be damaged, is solved, and a wind-solar complementary power supply system is formed.

Owner:广州和时通电子科技有限公司 +1

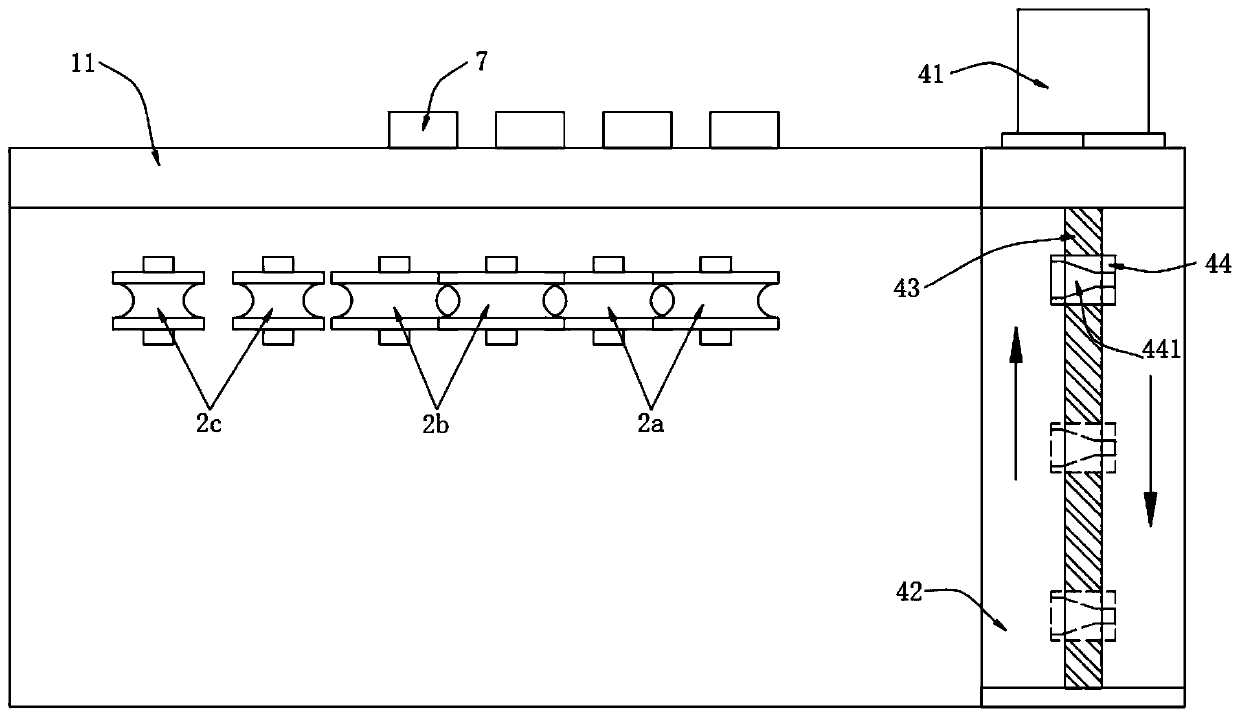

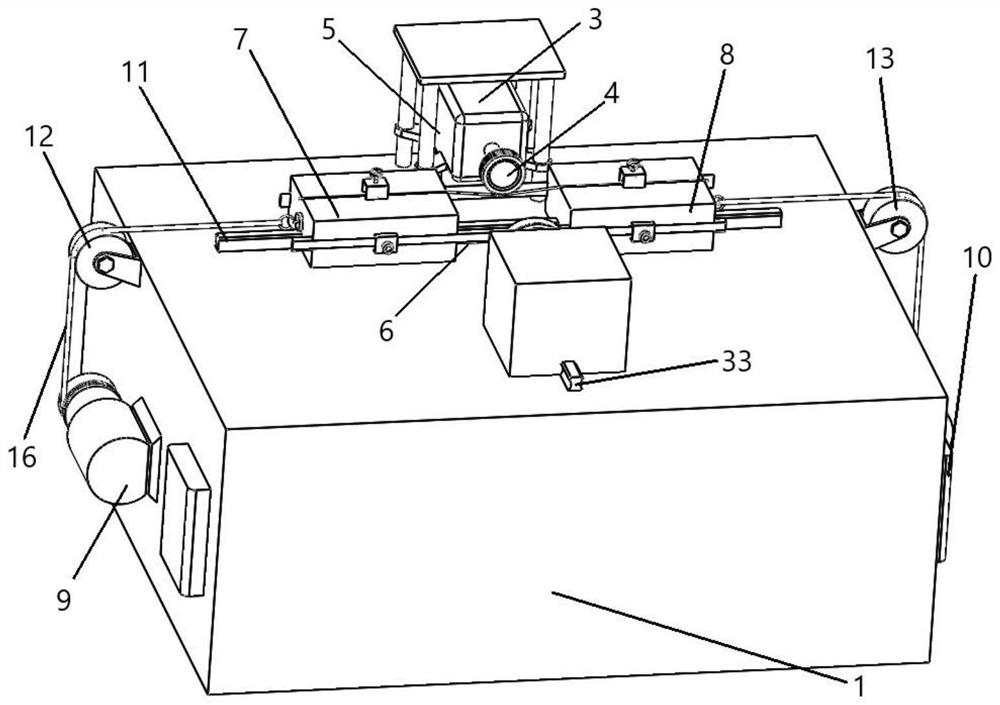

Traction mechanism for cable processing

ActiveCN110902491AIncrease buffer distanceResponsiveFilament handlingElectric machineryTraction motor

The invention discloses a traction mechanism for cable processing. The traction mechanism comprises a winding roller used for winding a cable and a traction motor used for driving the winding roller to rotate, wherein one side of the input end of the winding roller is provided with a supporting table, a traction frame is fixedly mounted on the top of the supporting table, a guiding wheel and a tensioning mechanism which are used for tensioning the cable are mounted on the inner side of the traction frame, and one end of the tensioning mechanism is rotationally connected with the guiding wheel.The tensioning mechanism correspondingly comprises a third tensioning piece, a second tensioning piece, and a first tensioning piece, elastic force of the third tensioning piece, elastic force of thesecond tensioning piece and elastic force of the first tensioning piece are sequentially reduced in the conveying direction of the cable, when speed difference appears during cable winding, and the pulling condition of the cable is generated, the first tensioning piece which is closest to the winding roller and has the smallest elastic force firstly can contract, and then the second tensioning piece and the first tensioning piece can sequentially contract so as to increase the buffering distance of the cable, so that the reaction of the tensioning mechanism is more sensitive, and the tensionchange to the cable is relieved.

Owner:SUZHOU LEMIFUN ELECTRICAL TECH CO LTD

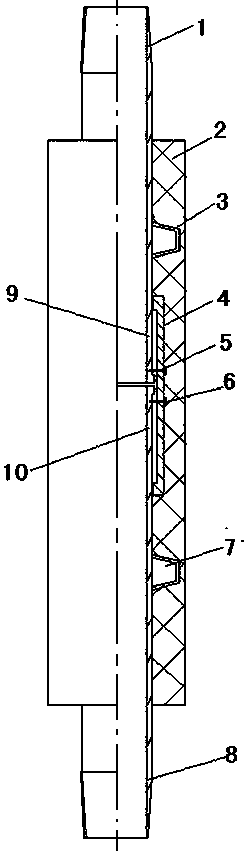

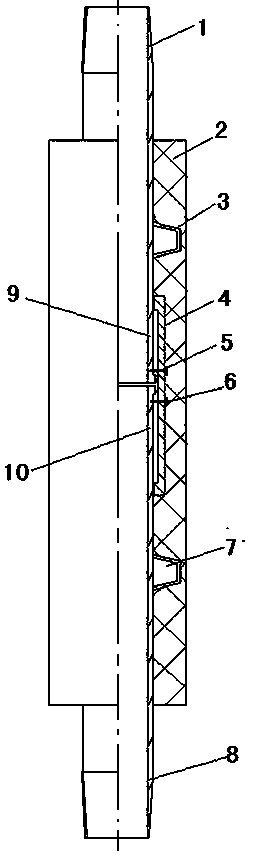

Method for using deblocking water-swellable packer

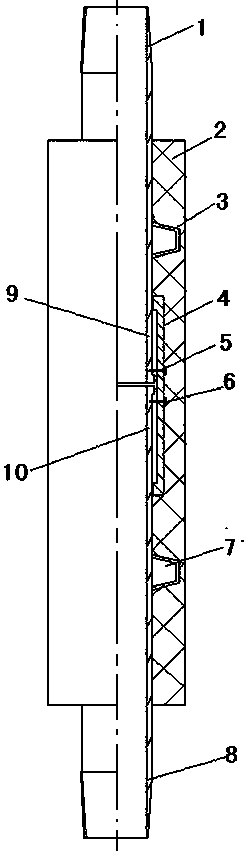

InactiveCN107724993AImprove sealingUnpacking implementationSealing/packingHigh resistanceEngineering

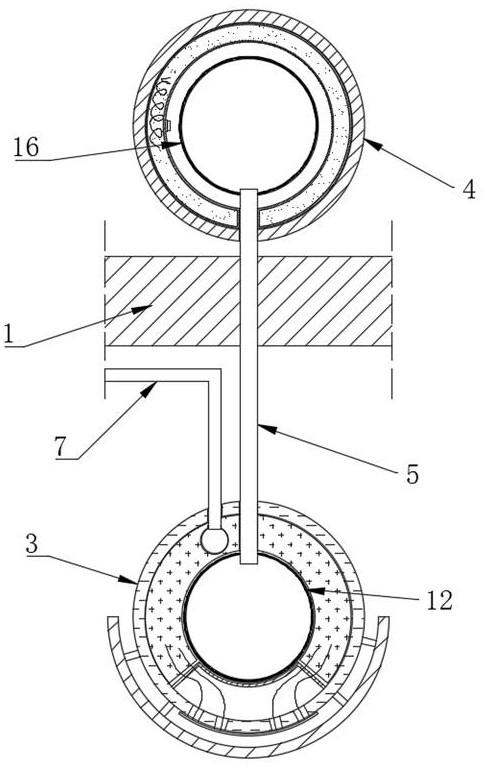

The invention relates to a method for using a deblocking water-swellable packer. The technical scheme of the method is that an upper center pipe and a lower center pipe are movably connected through adeblocking liner pipe, the upper center pipe is fixed to the middle of the deblocking liner pipe through an upper deblocking shear pin, the lower center pipe is fixed through a lower deblocking shearpin, an upper blocking ring is fixed to the outer wall of the middle of the upper center pipe, the outer end of the upper center pipe is provided with an upper connector, a lower blocking ring is fixed to the outer wall of the middle of the lower center pipe, and the outer end of the lower center pipe is provided with a lower connector. Water-swellable rubber is processed on the outer wall. The method for using the deblocking water-swellable packer has the advantages that by design of the deblocking structure, contraction of the water-swellable rubber can be achieved, deblocking is achieved,the conditions of failure in pulling caused by high resistance of the water-swellable rubber during well repair can be avoided, a huge collapsing force on a stratum caused by a suction effect of the packer when a tensile force is reinforced in a forced mode for pulling is also avoided, and the problems of high cost and long operation cycle caused by milling operation through milling shoes are alsosolved.

Owner:刘玉友

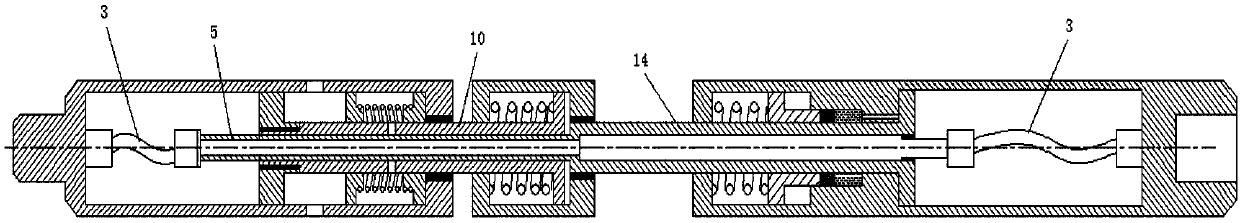

Cable type hydraulic jar with through line of telescopic structure

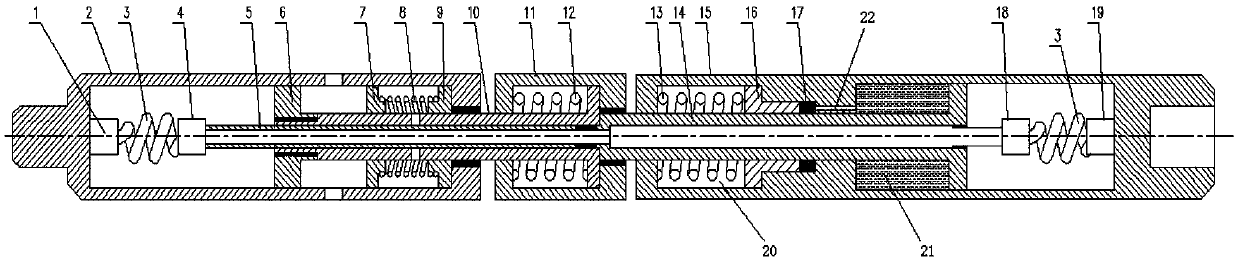

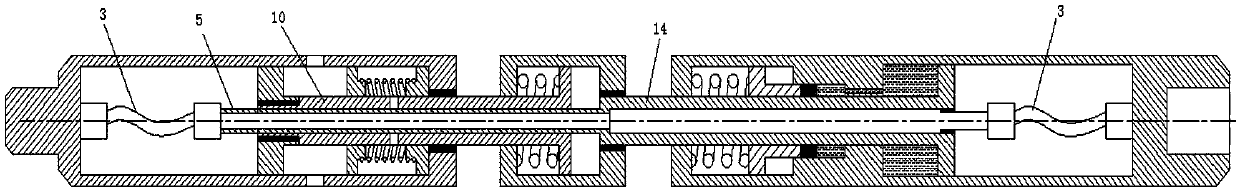

PendingCN109611048AIncrease elasticityGood oil resistanceBorehole/well accessoriesArrangements using extensible carrierPetroleumInstrumentation

The invention relates to the technical field of petroleum logging, specifically relates to a cable type hydraulic jar with a through line of a telescopic structure, comprising a first high-temperature-resistant metal joint, a balance shell, the through line, a second high-temperature-resistant metal joint, a mounting pipe, an accelerating cylinder core shaft, an accelerating cylinder shell, a jarshaft, a jar shell, a third high-temperature-resistant metal joint and a fourth high-temperature-resistant metal joint. One end of the through wire is fixed in the first high-temperature-resistant metal joint, and the other end of the through wire penetrates through the second high-temperature-resistant metal joint, the mounting pipe, the jar shaft and the third high-temperature-resistant metal joint to the fourth high-temperature-resistant metal joint. A section of through line is coiled between the first high-temperature-resistant metal joint and the second high-temperature-resistant metal joint, and a section of through line is coiled between the third high-temperature-resistant metal joint and the fourth high-temperature-resistant metal joint, so that the elongation of the through lineis compensated. Due to the compensation amount of the through line, when the instrument is moved long, the through line cannot be snapped, and therefore the whole action of the instrument cannot be affected.

Owner:XIAN CARNATION ENERGY TECH

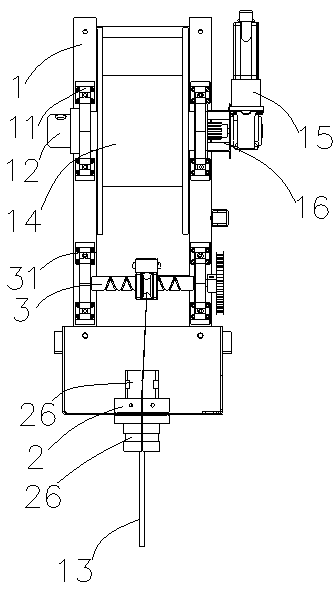

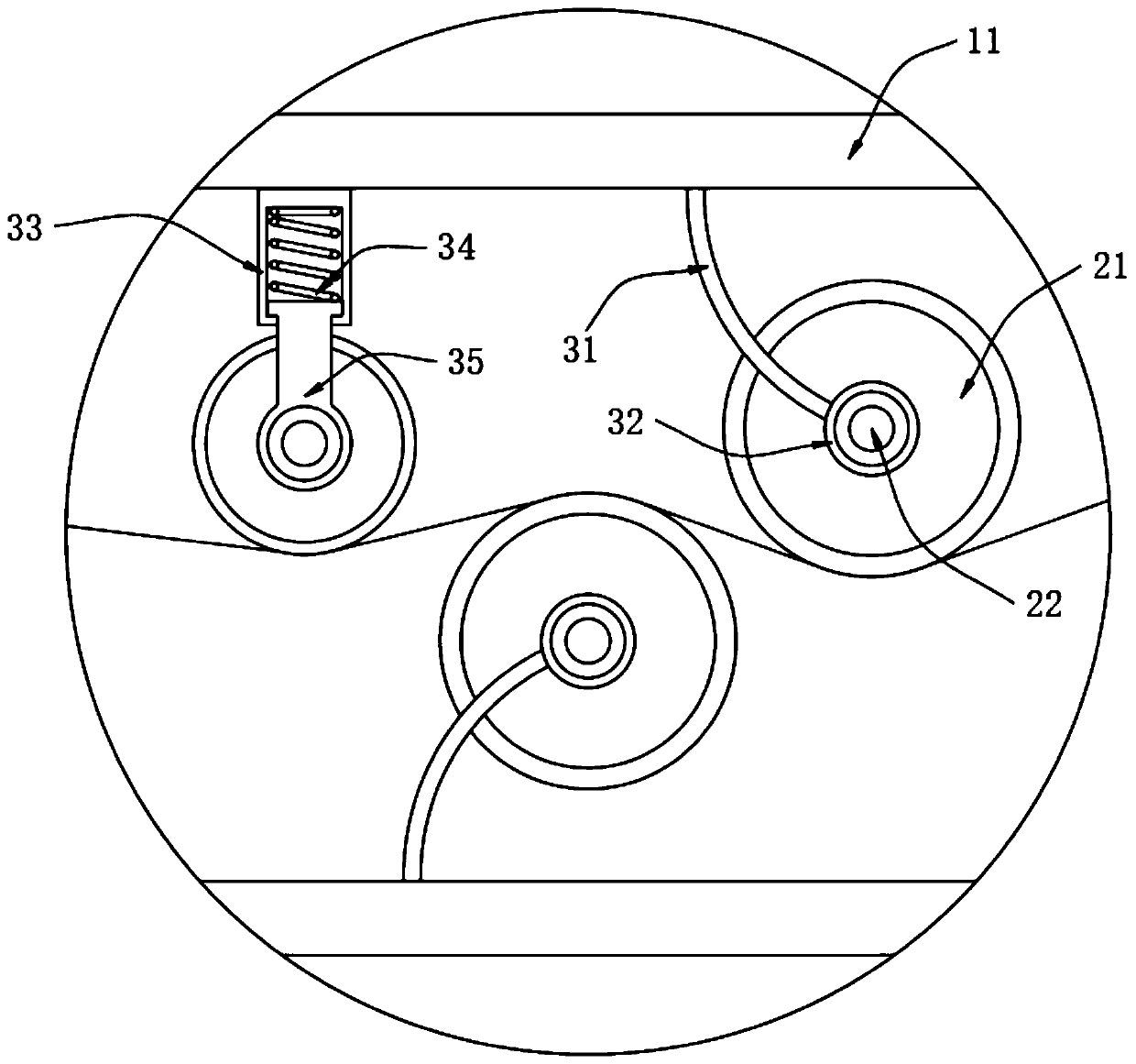

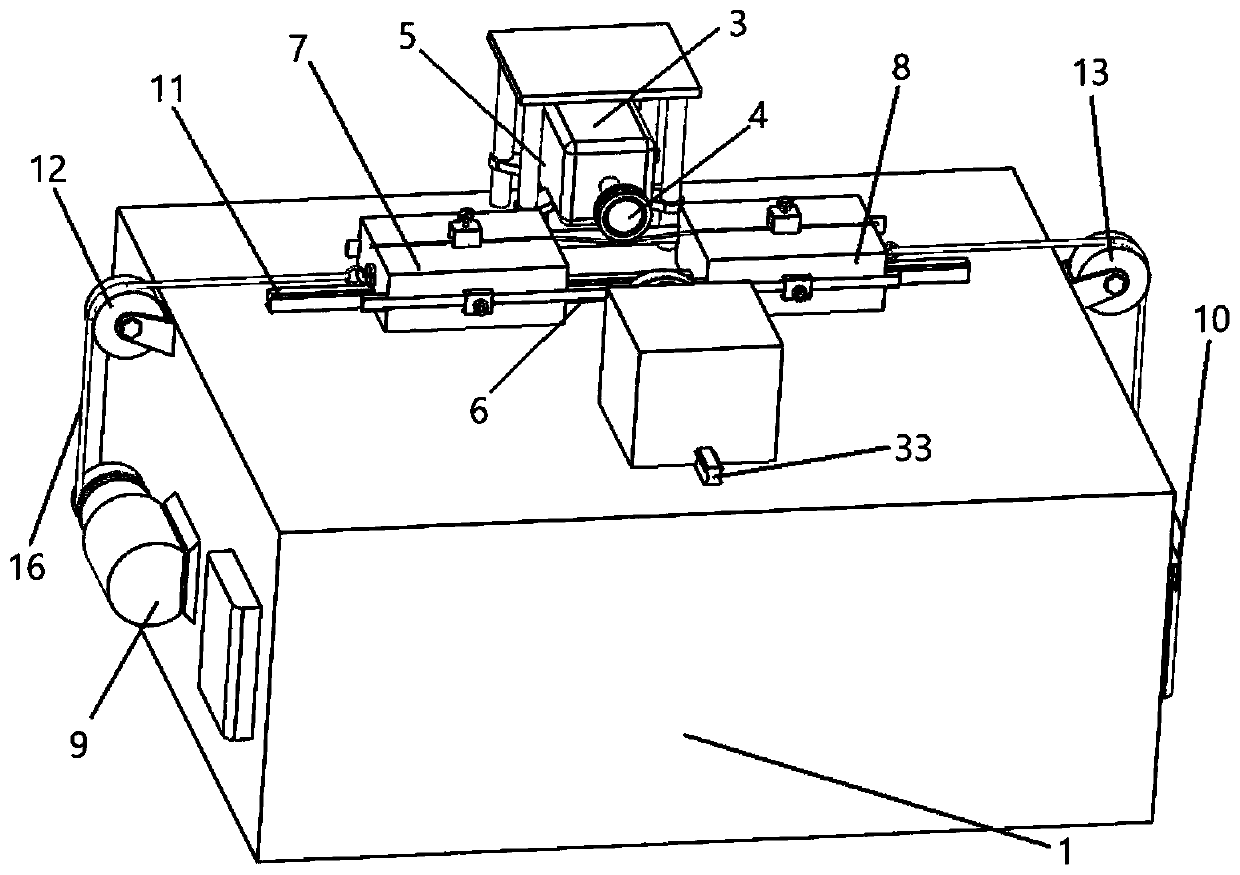

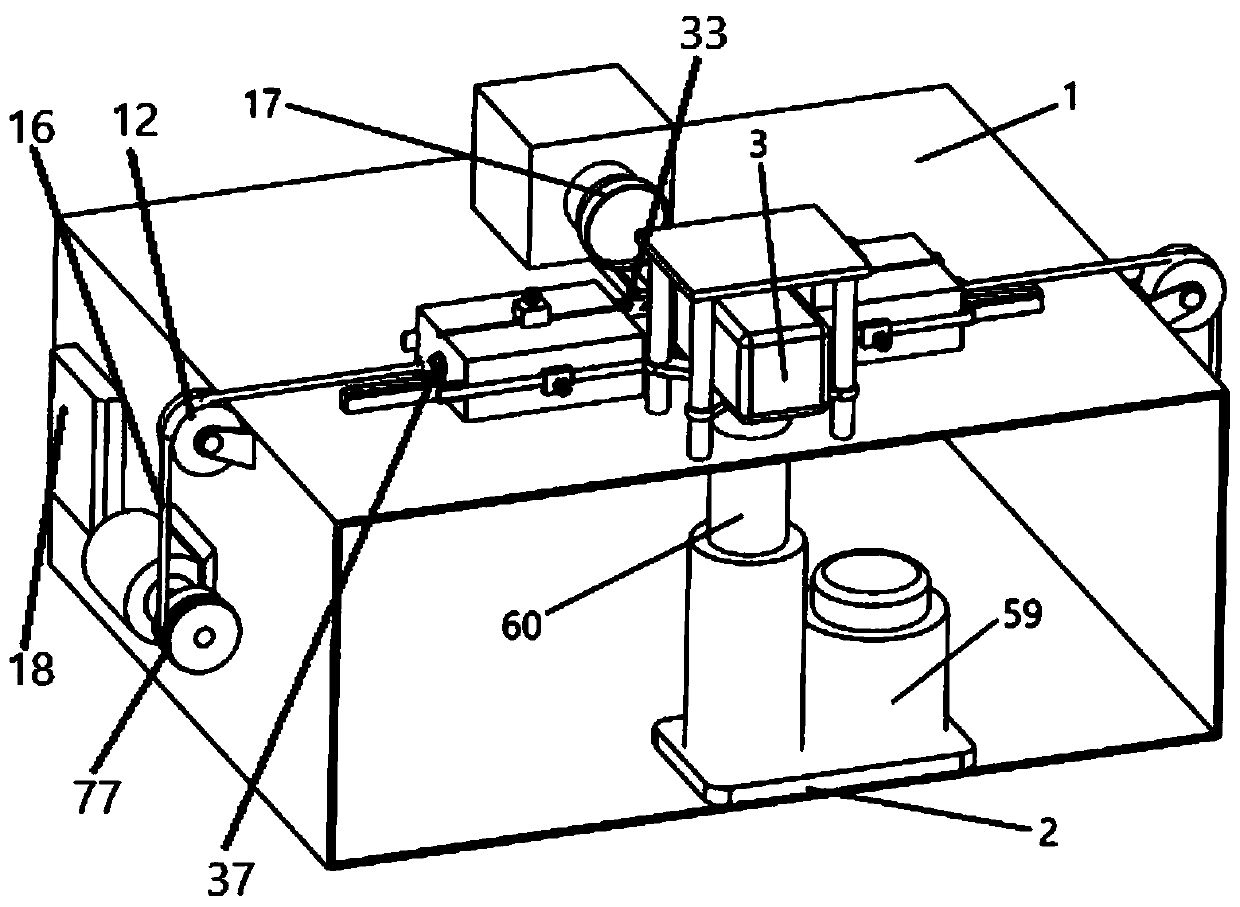

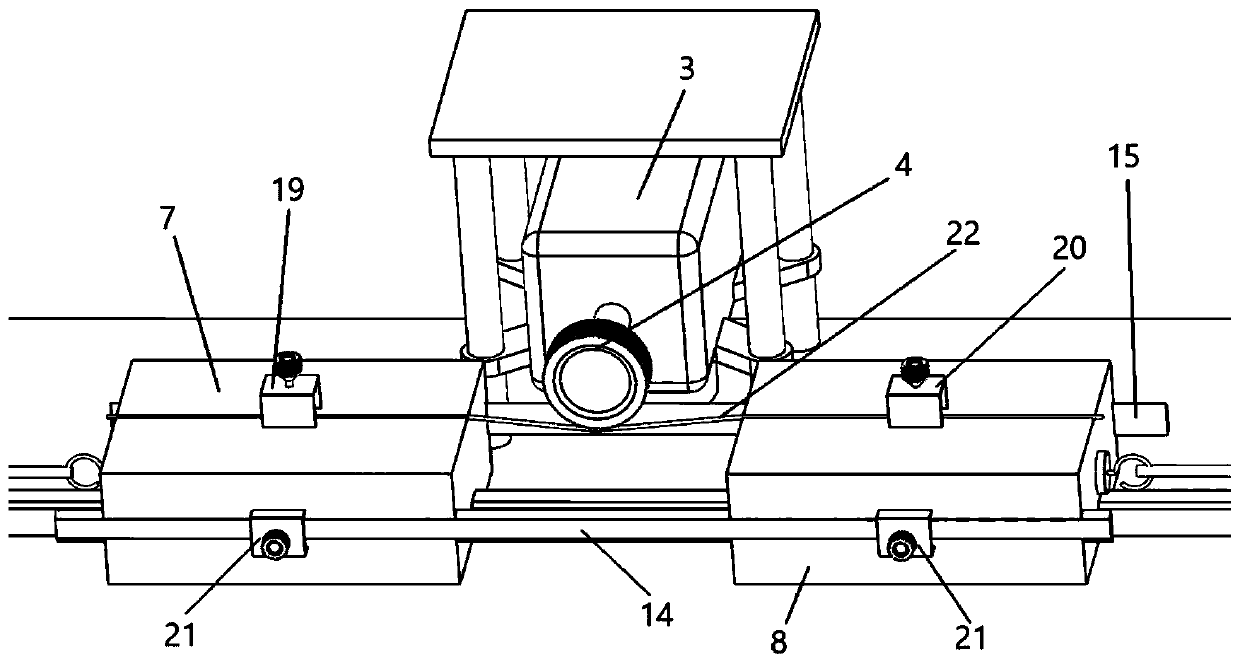

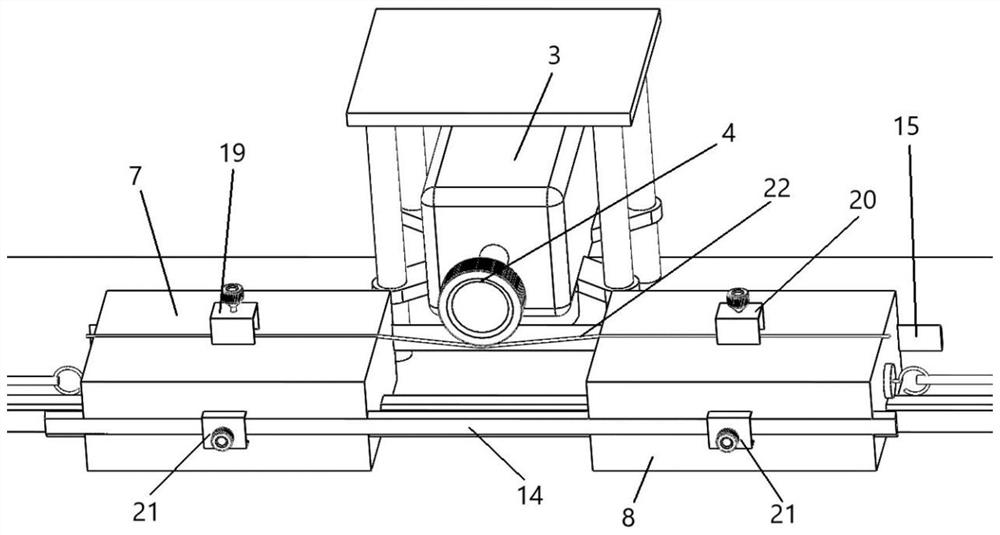

Polishing, grinding and tapering integrated device and method for preparing D-type and conical optical fibers

ActiveCN111596407AImprove stabilityStrong reliabilityGrinding feed controlCoupling light guidesFiberOptical fiber transmission

The invention provides a polishing, grinding and tapering integrated device and method for preparing D-type and conical optical fibers. The device comprises a platform main body, a lifting module, anoptical fiber polishing and grinding module, an optical fiber transmission module, a clamp module, an optical fiber heating module and the an optical fiber. The first end of the lifting module is fixedly connected with the lower end of the platform main body; the second end of the lifting module is fixedly connected with the optical fiber polishing and grinding module; the optical fiber polishingand grinding module, the optical fiber transmission module, the real-time monitoring module and the optical fiber heating module are located at the upper end of the platform main body. The optical fiber transmission module and the optical fiber heating module are both located between the optical fiber polishing and grinding module and the real-time monitoring module; a central control and communication module is located on one side face of the platform main body, a clamp module is located on the optical fiber transmission module, and the two ends of the optical fiber are fixedly connected withgrooves of flange sliding blocks through optical fiber fixing clamps respectively. Through the design of the flange sliding blocks, the problem of relative movement of the optical fiber and a polishing and grinding wheel is ingeniously solved, and side polishing and grinding of the optical fiber and tapering of the optical fiber can be implemented.

Owner:SHENZHEN GOLIGHT TECH

Tension-free strip steel maglev feeding device and maglev high-speed ultra-thin continuous rolling mill

InactiveCN102266871AReduce loadReduce in quantityMetal rolling arrangementsEngineeringContinuous rolling

The invention discloses a tension-free strip steel maglev feeding device, which comprises a feeding device frame, on which a first conveyor belt is installed, and the first conveyor belt consists of a first lower transmission roller, a second lower transmission roller and a second transmission roller. A transmission belt is connected, and several positioning magnets are installed on the outer surface of the first transmission belt; a driving device is installed on the feeding device frame, and the driving device is connected with the driving shaft of the first transmission belt. Also disclosed is a maglev high-speed ultra-thin continuous rolling mill equipped with the tension-free strip maglev feeding device, which includes at least two rolling mills, and the rolling mill and the tension-free strip maglev feeding device are installed on the same installation base. As for the feeding device, one magnetic levitation feeding device is installed on both sides of each rolling mill. The tension-free strip steel maglev feeding device can change the way of pulling and feeding the strip steel in the existing rolling mill to the way of pushing the strip steel to convey the strip steel to the rolling mill, which can fundamentally solve the problem that the existing rolling mill cannot roll ultra-thin strip steel problem.

Owner:雷亚夫 +1

Multi-stage deblocking type water-swelling packer and method

The invention relates to a multi-stage deblocking type water-swelling packer and a method. According to the technical scheme, the multi-stage deblocking type water-swelling packer comprises three sections of central pipes, a set of water-swelling rubber and two sets of deblocking devices; the water-swelling rubber is machined at the outsides of the three sections of the central pipes and the two sets of the deblocking devices, the first set of the deblocking devices is disposed between the first and second sections of the central pipes, and the second set of the deblocking devices is disposedbetween the second and third sections of the central pipes; and the outer walls of the first, second and third sections of the central pipes, the first and second sets of the deblocking devices are machined with the water-swelling rubber. The multi-stage deblocking type water-swelling packer and the method have the beneficial effects that a multi-stage deblocking structure is designed, the contraction of longer water-swelling rubber can be achieved and the deblocking can be realized, the situation in which the water-swelling rubber is too large in resistance to be moved by pulling during the well repair can be avoided, and the drawing by forcedly enlarging the tensile force can be avoided; and the problems of high cost caused by the milling operation through grinding shoes and long workingcycle can be avoided.

Owner:大庆市亚盛油田技术开发有限公司

PVC wood plastic template shaping table illumination lamp

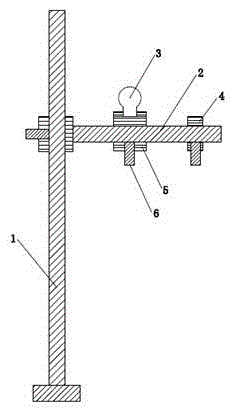

ActiveCN105570767AAvoid the situation of pulling offSimple structureLighting applicationsMechanical apparatusProduction lineEngineering

The invention discloses a PVC wood plastic template shaping table illumination lamp, belongs to the technical field of illumination lamps, and mainly solves the problem of frequent snap of plates due to incapability of meticulously observing after-pulling conditions of the plates caused by no illumination lamp on a shaping table of a traditional PVC wood plastic template production line. The PVC wood plastic template shaping table illumination lamp is characterized by comprising a fixed rod, a movable rod, an illumination lamp, a limiting mechanism, a movable clamp and a fastening nut, wherein one end of the movable rod horizontally coats the vertical fixed rod through a sleeve; a fastening screw is arranged on the sleeve; the limiting mechanism is arranged at the other end of the movable rod; and the illumination lamp is mounted at the middle part of the movable rod through the movable clamp and the fastening nut. The PVC wood plastic template shaping table illumination lamp has the characteristics of simple structure, convenience for operation and good illumination effect, and is mainly applied to illumination of a space between an upper shaping template and a lower shaping template of the shaping table on the PVC wood plastic template production line.

Owner:湖北统领建材有限公司

Deblocking water-swellable packer

ActiveCN107724992AAchieve shrinkageAvoid the problems of high cost and long operation cycleSealing/packingHigh resistanceEngineering

The invention relates to a deblocking water-swellable packer. The technical scheme of the deblocking water-swellable packer is that an upper center pipe and a lower center pipe are movably connected through a deblocking liner pipe, the upper center pipe is fixed to the middle of the deblocking liner pipe through an upper deblocking shear pin, the lower center pipe is fixed through a lower deblocking shear pin, an upper blocking ring is fixed to the outer wall of the middle of the upper center pipe, the outer end of the upper center pipe is provided with an upper connector, a lower blocking ring is fixed to the outer wall of the middle of the lower center pipe, and the outer end of the lower center pipe is provided with a lower connector. Water-swellable rubber is processed on the outer wall. The deblocking water-swellable packer has the advantages that by design of the deblocking structure, contraction of the water-swellable rubber can be achieved, deblocking is achieved, the conditions of failure in pulling caused by high resistance of the water-swellable rubber during well repair can be avoided, a huge collapsing force on a stratum caused by a suction effect of the packer when atensile force is reinforced in a forced mode for pulling is also avoided, and the problems of high cost and long operation cycle caused by milling operation through milling shoes are also solved.

Owner:DONGYING YUANJIE PETROLEUM MACHINERY CO LTD

Traction mechanism for cable processing

ActiveCN110902491BRapid responseIncrease buffer distanceFilament handlingElectric machineryTraction frame

The invention discloses a traction mechanism for cable processing. The traction mechanism comprises a winding roller used for winding a cable and a traction motor used for driving the winding roller to rotate, wherein one side of the input end of the winding roller is provided with a supporting table, a traction frame is fixedly mounted on the top of the supporting table, a guiding wheel and a tensioning mechanism which are used for tensioning the cable are mounted on the inner side of the traction frame, and one end of the tensioning mechanism is rotationally connected with the guiding wheel.The tensioning mechanism correspondingly comprises a third tensioning piece, a second tensioning piece, and a first tensioning piece, elastic force of the third tensioning piece, elastic force of thesecond tensioning piece and elastic force of the first tensioning piece are sequentially reduced in the conveying direction of the cable, when speed difference appears during cable winding, and the pulling condition of the cable is generated, the first tensioning piece which is closest to the winding roller and has the smallest elastic force firstly can contract, and then the second tensioning piece and the first tensioning piece can sequentially contract so as to increase the buffering distance of the cable, so that the reaction of the tensioning mechanism is more sensitive, and the tensionchange to the cable is relieved.

Owner:浙江省三门浦东电工电器有限公司

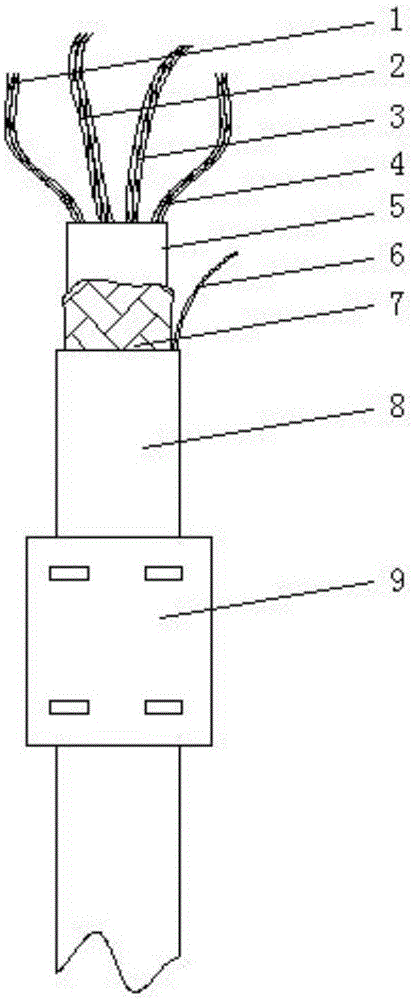

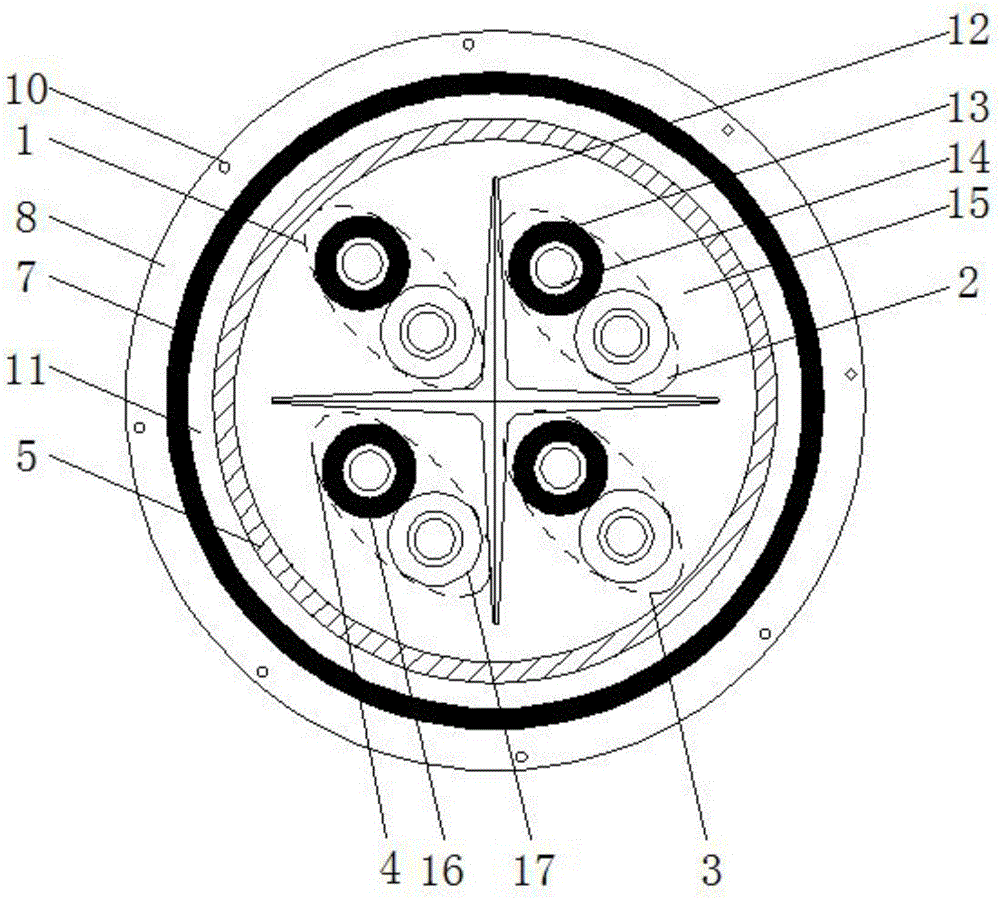

Category 5e unshielded twisted pair cable capable of operating two channels of isolation signals

InactiveCN106448876AEnhanced pulling abilityAvoid breaking the network cableInsulated cablesInsulated conductorsAluminium foilMagnesium

The invention discloses a category 5e unshielded twisted pair cable capable of operating two channels of isolation signals. The category 5e unshielded twisted pair cable comprises a polyvinyl chloride sheath, the outside of the polyvinyl chloride sheath is provided with an electromagnetic shielding device, a tearing line is arranged between the polyvinyl chloride sheath and an aluminium-magnesium braided shielding layer, a flame retardation layer is arranged between the aluminium-magnesium braided shielding layer and an aluminium foil shielding layer, a polyvinyl chloride lining layer is arranged in the aluminium foil shielding layer, a cross is arranged in the polyvinyl chloride lining layer, the upper left of the cross is provided with an A-group twisted pair, the lower left of the cross is provided with a C-group twisted pair, the A-group twisted pair is formed by a main line and a sub-line, the main line is arranged on the sub-line, the main line is formed by a polyethylene insulation sleeve and a solid copper conductor, and the solid copper conductor is arranged in the polyethylene insulation sleeve. According to the category 5e unshielded twisted pair cable, the multilayer metal layer shielding technology is employed, the influence of high electromagnetism on the operation of the category 5e unshielded twisted pair cable can be effectively prevented, and normal operation of the cable is guaranteed.

Owner:XITIANQI SUZHOU ELECTRONICS

A high and low voltage switchgear with condensation removal function

ActiveCN114361964BSpeed up evaporationPlay the role of heatingElectric heatingSubstation/switching arrangement casingsThermodynamicsLow voltage

The invention discloses a high-voltage and low-voltage switchgear with the function of removing condensation, which belongs to the technical field of switchgears. When condensation occurs on the inner wall of the top of the cabinet, the condensation will drop on the collection ball through the deflecting effect of the deflector. Above, the condensation on the collection ball will flow to the position of the water-absorbing layer along the outer wall of the collection ball. At this time, the condensation will be attracted to the inner side of the expansion layer through the function of the water guide wire, and the expansion layer will expand after absorbing water. The ball is squeezed, and when the liquid storage ball is compressed and contracted, the elastic ball will expand. After the elastic ball expands and the heating frame sticks to it, the touch switch is triggered to start the electric heating wire. At this time, the electric heating wire heats the heating frame, and the heating frame generates heat. Finally, the heat is transferred to the elastic ball, and the heat on the elastic ball is transferred to the liquid storage ball through the tube, and the liquid storage ball can heat the expansion layer, accelerate the evaporation of condensation in the expansion layer, and pass through the connecting tube. Tube discharge reduces the waste of electric energy and will not affect the components in the cabinet.

Owner:XUZHOU YILE ELECTRICAL TECH CO LTD

Label station of adhesive sticker labeling machine

PendingCN111422454AAvoid CardsImprove stabilityLabelling machinesWebs handlingLabelling machineEngineering

The invention discloses a label station of an adhesive sticker labeling machine. The station comprises a label roll, an unwinding mechanism, a label feeding mechanism, a stripping mechanism and a winding mechanism; the label feeding mechanism comprises a buffer conveying mechanism, a label feeding power roller group and a label bottom paper recovery power roller group, wherein the buffer conveyingmechanism is arranged between the unwinding mechanism and a guide roller; the buffer conveying mechanism comprises a main shaft, wherein a guide cylinder body is arranged outside the main shaft, theguide cylinder body is divided into a plurality of circular arc-shaped guide plates, each circular arc-shaped guide plate is movably supported on a guide rod, each guide rod is fixed on the main shaftand is radially arranged along the main shaft, each circular arc-shaped guide plate can move back and forth on the corresponding guide rod, and at least one counterweight mechanism is arranged between each circular arc-shaped guide plate and the main shaft. The station has the advantages that the failure of label jam is effectively avoided, the label buffering and conveying are stable, and labelbottom paper can be effectively prevented from being broken in the conveying process.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

XR equipment system

PendingCN114699765AAvoid hittingIncrease heightIncreasing energy efficiencyVideo gamesDrive wheelGear drive

The invention relates to the technical field of XR, in particular to an XR equipment system which comprises a bottom plate, a machine body is arranged on the bottom plate, a screen is arranged on the side wall of the machine body, mounting arms are arranged on the two sides of the screen, a bottom shell is connected to the ends of the mounting arms, an adjustable mounting mechanism is connected to the lower portion of the bottom shell, and a sensing handle is connected to the mounting mechanism. Due to the arrangement of the adjustable installation mechanism, when the induction handle is installed, the clamping assembly is arranged, installation is convenient, and taking-out is convenient, when a player takes down the induction handle to play games, a motor can control starting to drive a driving wheel, the driving wheel drives a driven wheel to rotate through a belt, and then a first gear drives a second gear to rotate; and the second gear can drive the third gear to rotate, so that the player can be prevented from hitting the equipment during operation, and accidental injury is avoided.

Owner:三一智造(深圳)有限公司

Device and method integrating polishing and tapering for preparing d-type and tapered optical fibers

ActiveCN111596407BImprove stabilityStrong reliabilityGrinding feed controlCoupling light guidesFiberMechanical engineering

The invention provides a device and method integrating polishing and tapering for preparing D-shaped and tapered optical fibers. The device includes a platform main body, a lifting module, an optical fiber polishing module, an optical fiber transmission module, a fixture module, and an optical fiber heating module. and fiber optics. The first end of the lifting module is fixedly connected to the lower end of the platform main body, and the second end of the lifting module is fixedly connected to the optical fiber polishing module. The optical fiber polishing module, optical fiber transmission module, real-time monitoring module and optical fiber heating module are located at the upper end of the platform main body. In addition, the optical fiber transmission module and the optical fiber heating module are located between the optical fiber polishing module and the real-time monitoring module. The groove of the flange slider is fixed. The invention cleverly solves the problem of relative movement of the optical fiber and the polishing wheel through the design of the flange slider, and can implement both side polishing of the optical fiber and tapering of the optical fiber.

Owner:SHENZHEN GOLIGHT TECH

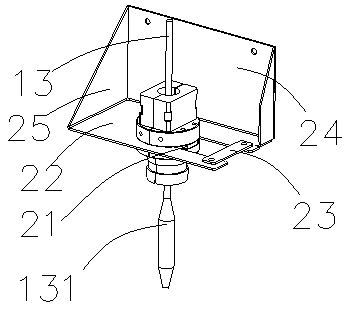

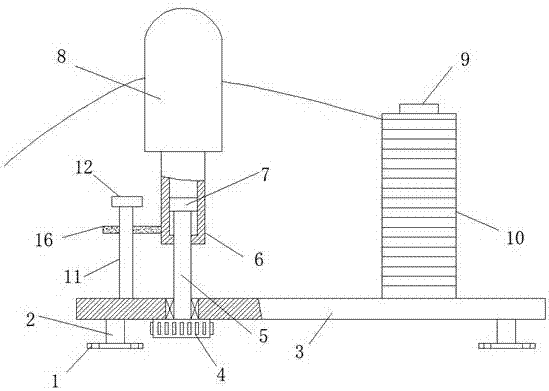

Lead drawing device for embroidering machine

InactiveCN107488951AReduce frictionAvoid the situation of pulling offEmbroidering machines apparatusBobbinEngineering

The invention discloses a lead wire device for an embroidery machine, which comprises a fixing block fixed on the embroidery machine, a pole is fixed on the top of the fixing block, and a mounting plate is fixed on the end of the pole far away from the fixing block. The top of the board is fixed with a plurality of lead wire units along the length direction, and the lead wire unit includes a wire barrel fixing column and a guide rod fixed on the top of the installation board, and the guide rod is located on one side of the wire drum fixing rod, and the guide rod is far away from the installation board A limit block is fixed at one end of the mounting plate, and a knob is provided under the bottom of the mounting plate. The present invention can adjust the height of the lead block and the lead hole through the cooperative use of wire barrels, fixing columns, knobs, connecting rods, internal thread sleeves and external thread blocks, and can then match with wire barrels of different lengths. The lead hole is adjusted to a proper position to achieve the purpose of reducing the lead angle, so as to avoid the situation that the embroidery thread is broken due to the excessive lead angle.

Owner:陈钦楠

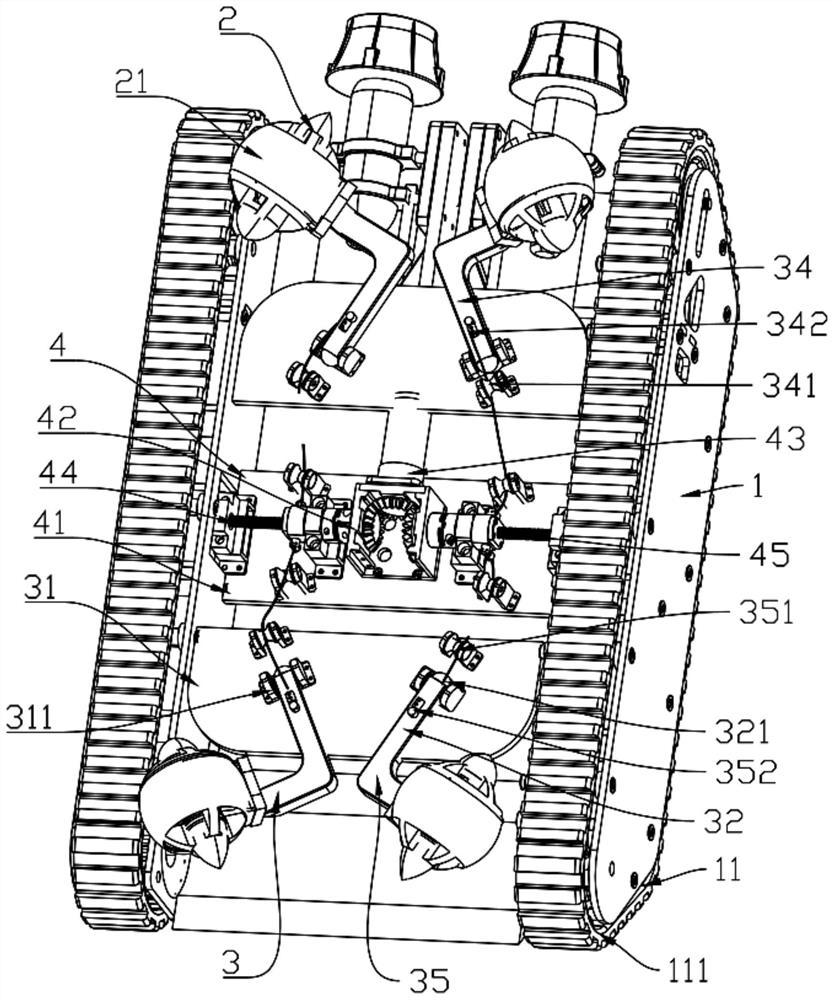

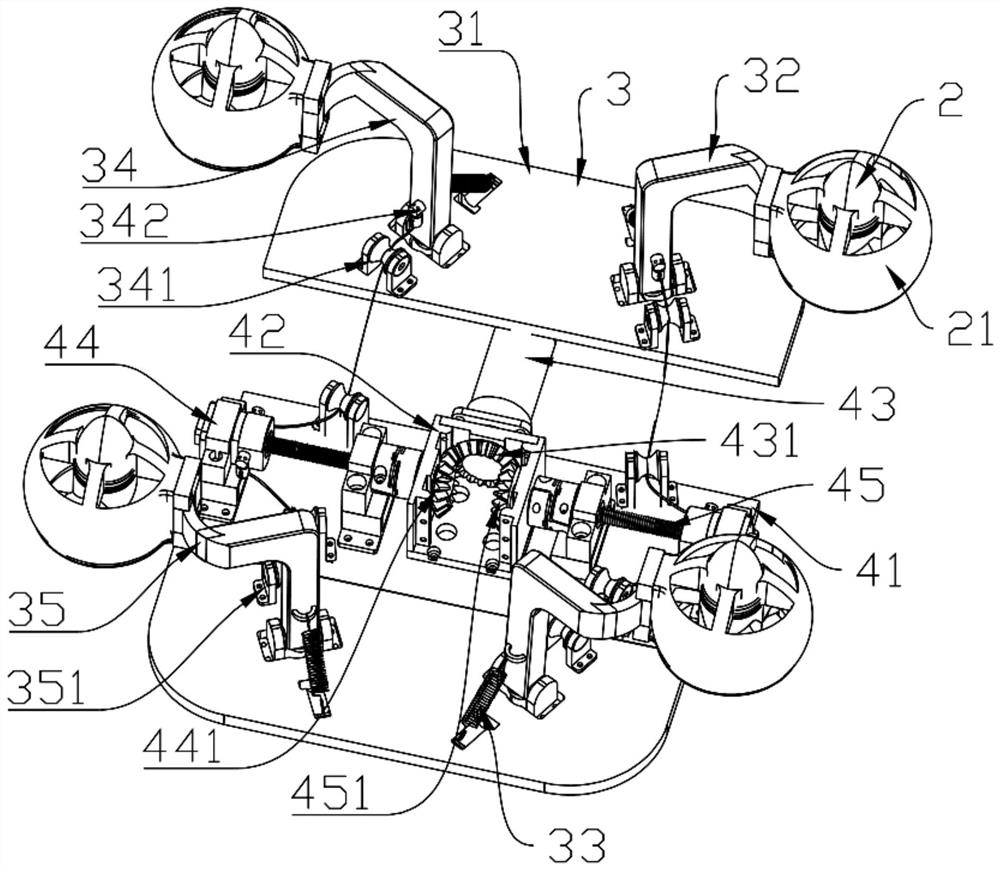

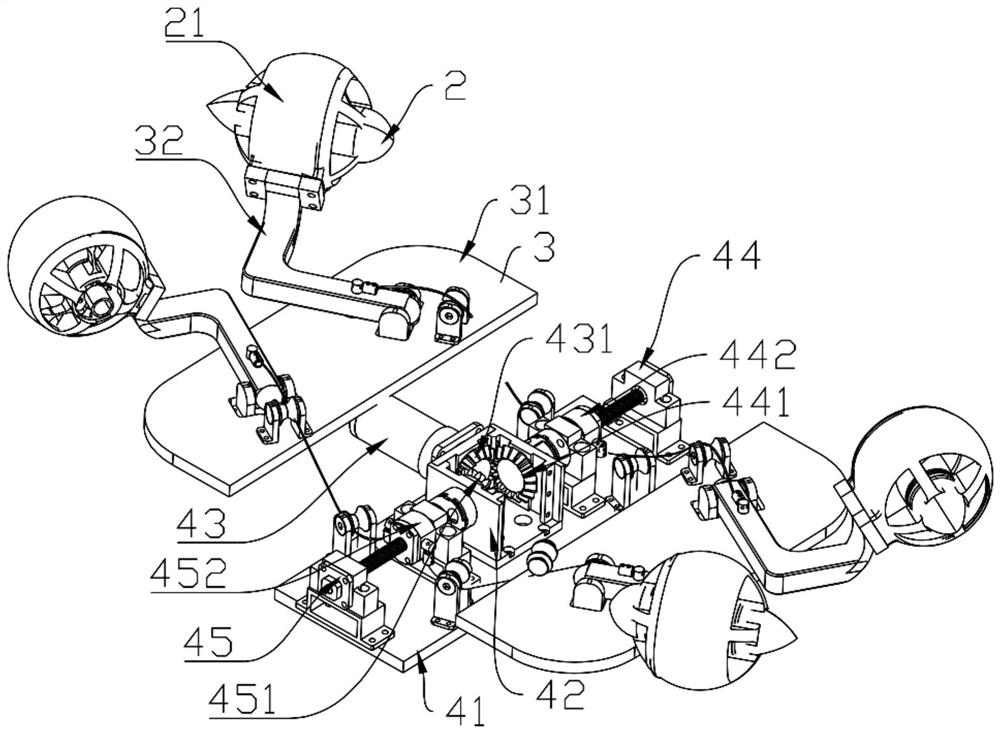

Unmanned system flexible transmission variable structure underwater propulsion device

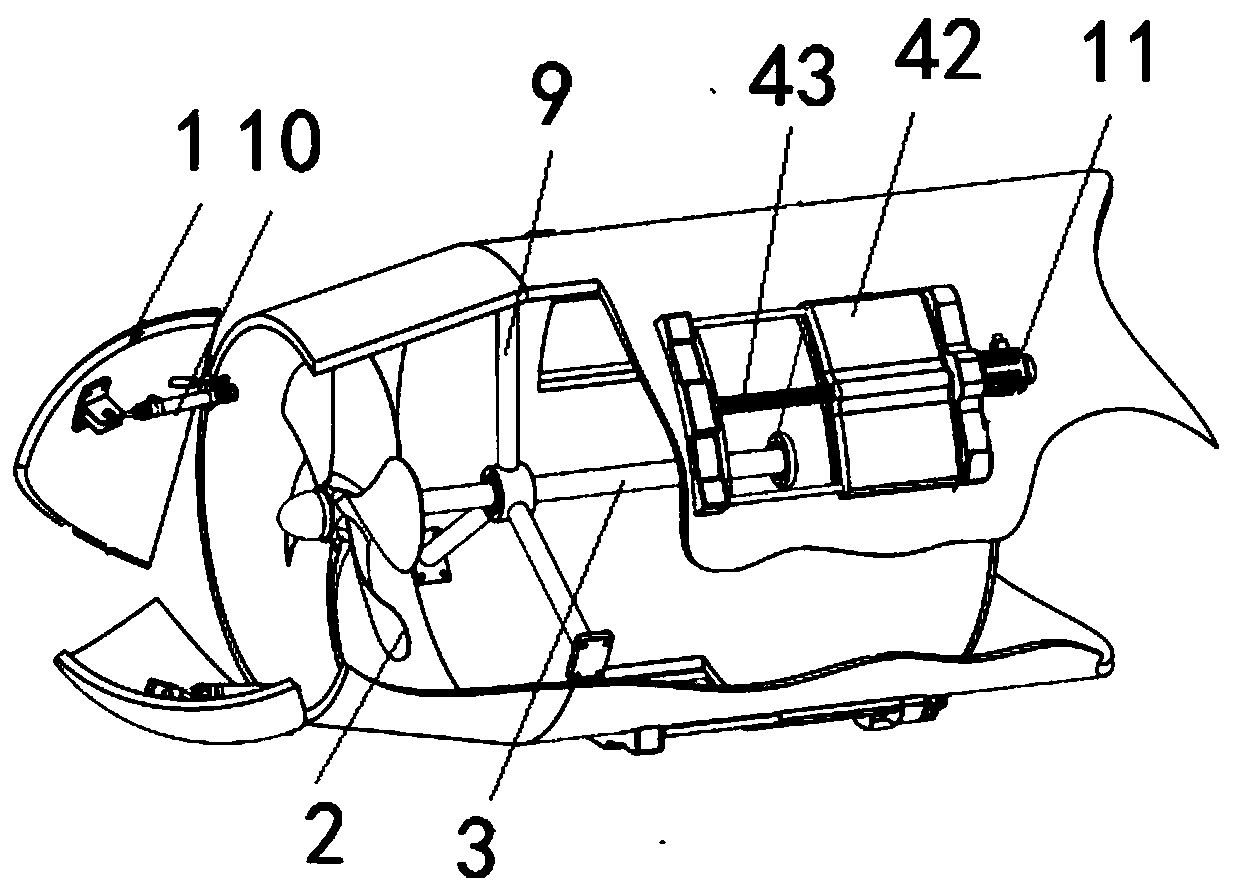

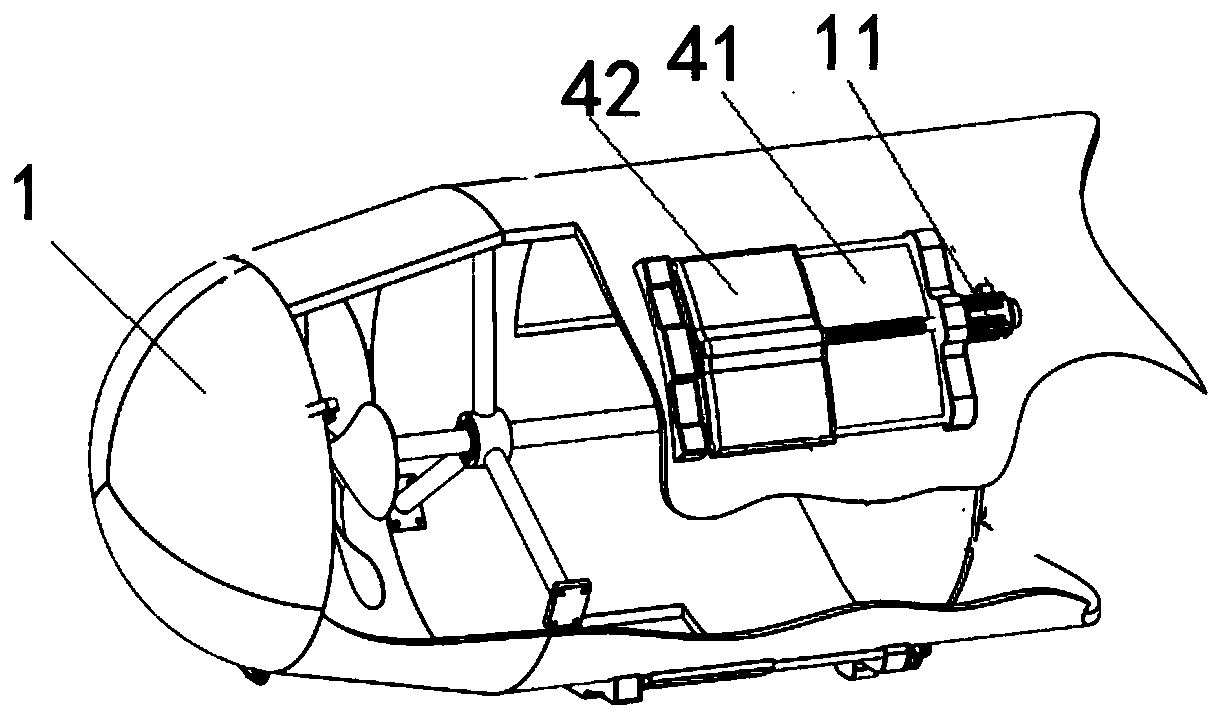

ActiveCN114056016ARealize spatial structure transformationReduce widthAmphibious vehiclesControl systemWorking environment

The invention relates to the technical field of amphibious robots, in particular to an unmanned system flexible transmission variable structure underwater propulsion device which comprises a vehicle body, a propeller, a propeller lifting mechanism and a flexible transmission mechanism, the propeller is arranged on the propeller lifting mechanism, the vehicle body is provided with an unmanned control system and a land action system, the unmanned control system is connected with the land action system, the flexible transmission mechanism and the propeller, transmission of non-parallel shafts is achieved in the sailing process, the height of the propeller can be remarkably reduced on the premise that the width of the vehicle body is not changed, the height of the propellers can be increased according to actual requirements, the distance between the propellers can be extended outwards, the width of the vehicle body does not need to be increased, and space structure transformation of the propellers is achieved so as to be suitable for running on land or passing through various complex working environments such as pipelines with limited underwater height and narrow areas.

Owner:GUANGDONG INTELLIGENT ROBOTICS INST

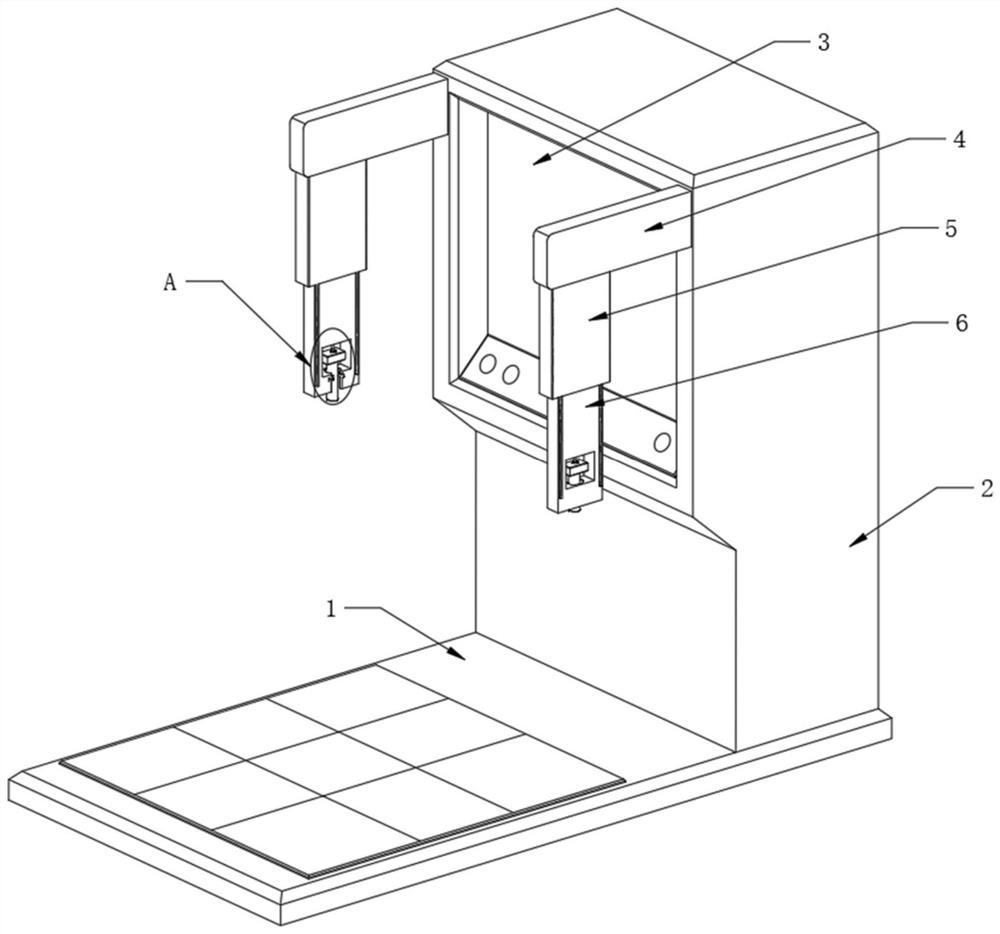

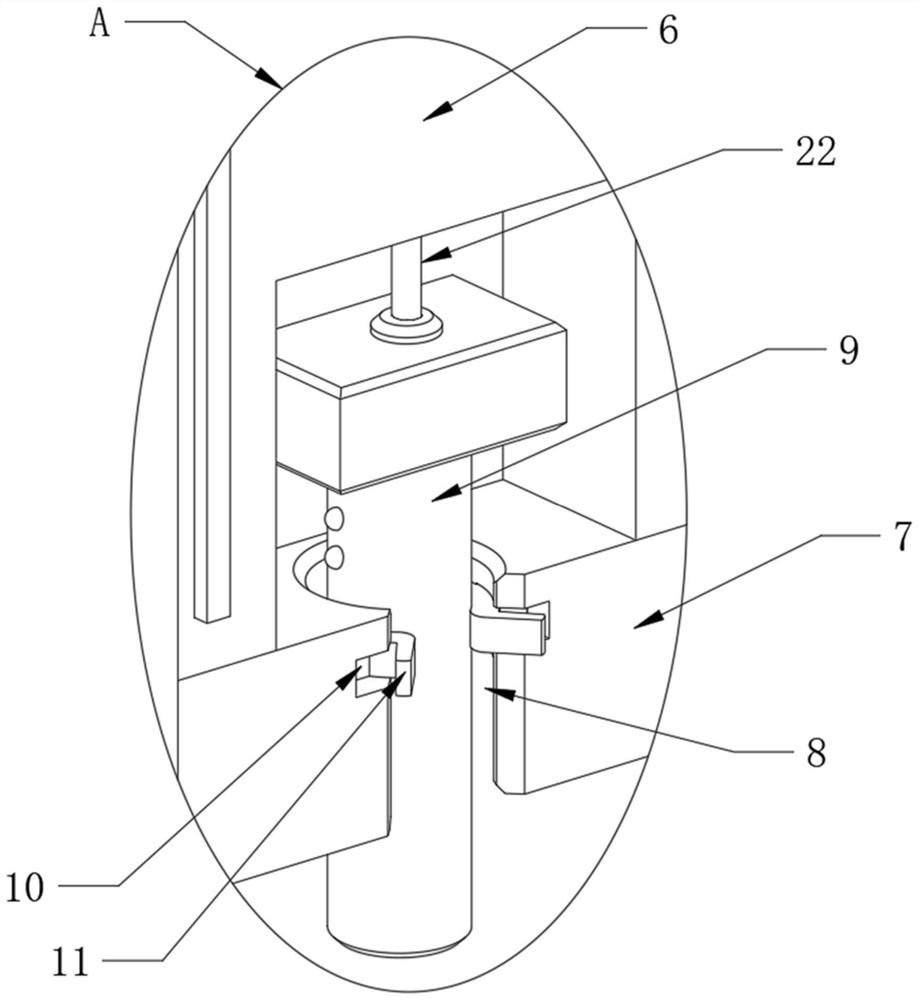

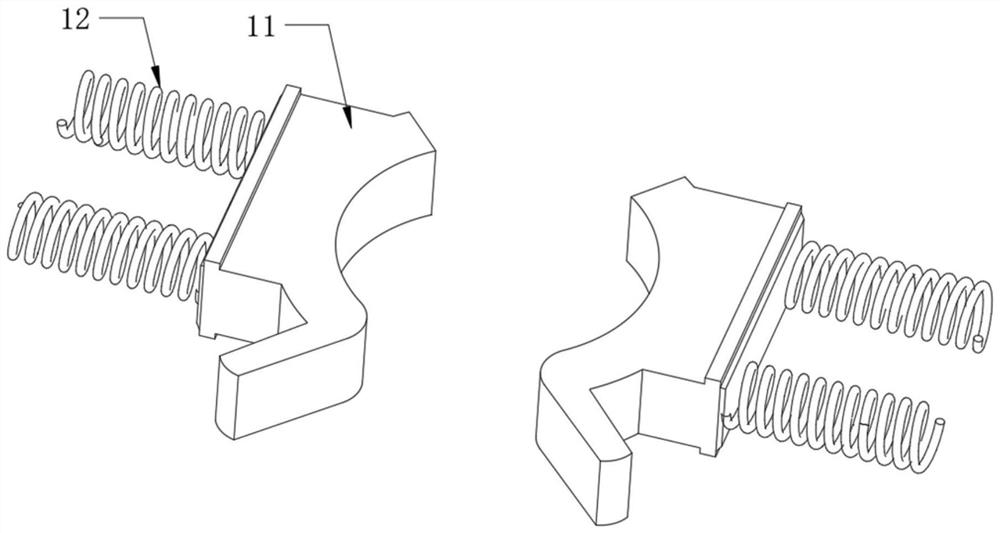

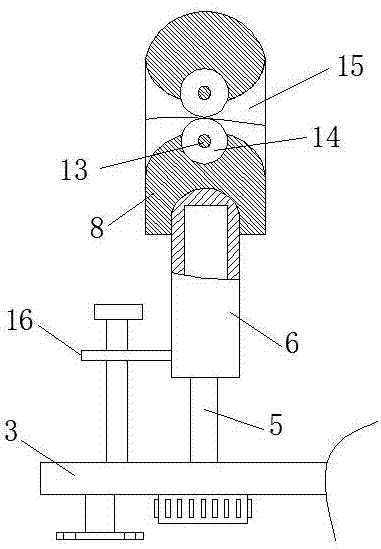

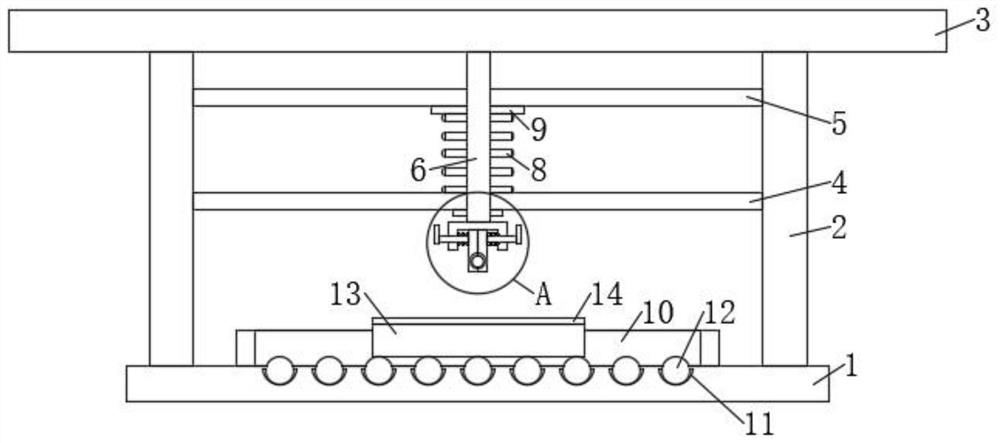

Pseudo soldering detection device for circuit board welding

InactiveCN113607636AAvoid the situation of pulling offWelding/cutting auxillary devicesUsing mechanical meansPhysicsSoldering

The invention discloses a circuit board welding pseudo soldering detection device. The device comprises a base plate, wherein supporting plates are fixedly connected to the two sides of an upper end of the base plate, a first transverse plate and a second transverse plate are jointly and fixedly connected between upper ends of the two supporting plates, and the second transverse plate is located above the first transverse plate; a vertical rod jointly penetrates through the middle of the first transverse plate and the middle of the second transverse plate and is slidably connected with a vertical rod, and a clamping mechanism is mounted at a lower end of the vertical rod. The device is advantaged in that the clamping mechanism is arranged on the vertical rod, a second spring is arranged at a part of a vertical plate between the first transverse plate and the second transverse plate, during use, the clamping mechanism is used for clamping a wire, the wire is pulled through the elastic force of the second spring, whether pseudo soldering occurs or not is detected, the vertical rod is provided with a first baffle ring, it can be guaranteed that the pulling positions of the vertical rod each time are the same, and conditions of detection failure and direct breaking of the wire are avoided.

Owner:深圳市建宏达照明电路有限公司

Technological method for bending clamp and design and use of bending die

InactiveCN110640044ASolving Bending Forming ProblemsAvoid the situation of pulling offShaping toolsStructural engineeringTwo step

Owner:GUIZHOU TIANYI ELECTRICAL

A kind of high elasticity fitness stretcher

InactiveCN106039649BIncrease elasticityElastic footResilient force resistorsActive polymerNitrile rubber

Owner:SHANGLUO UNIV

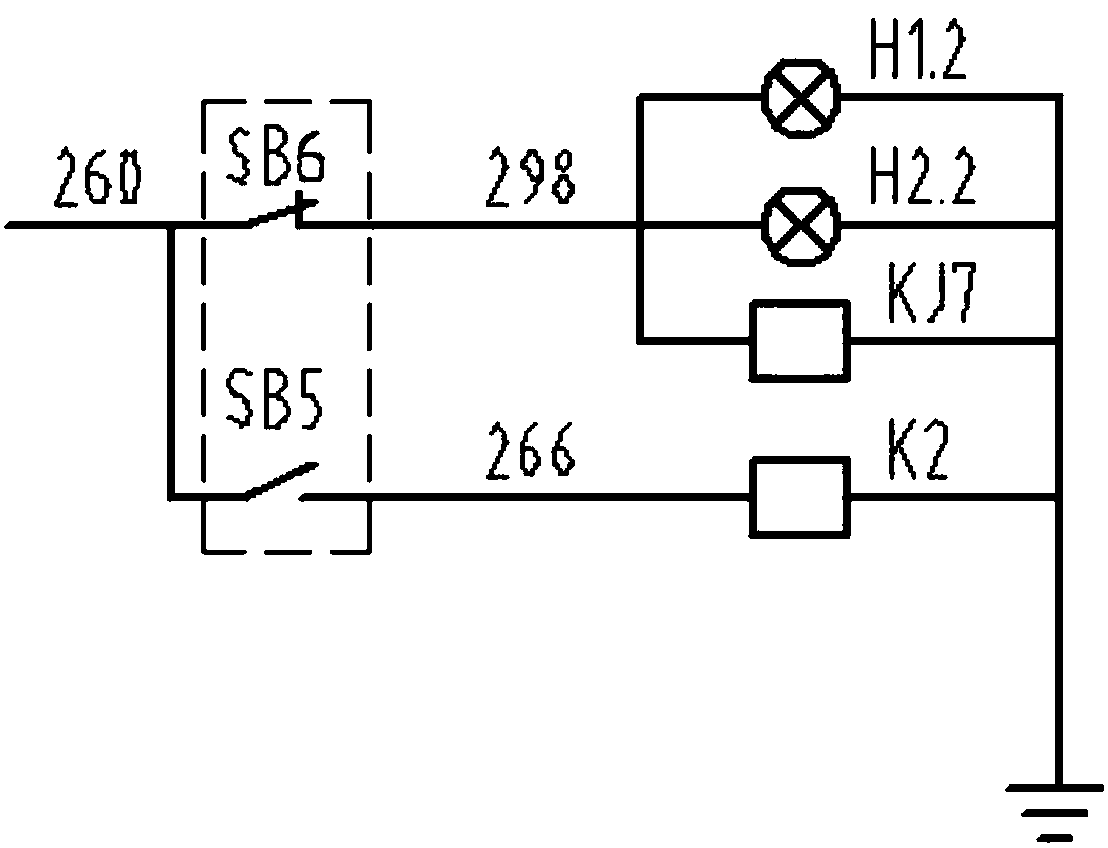

Anti-misoperation protective device for position-fixing pin of platform of catenary operation car

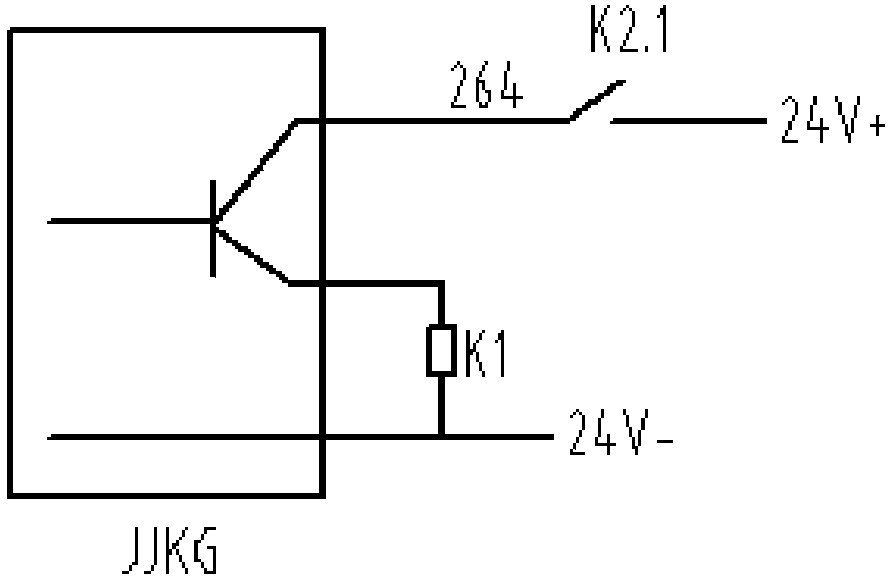

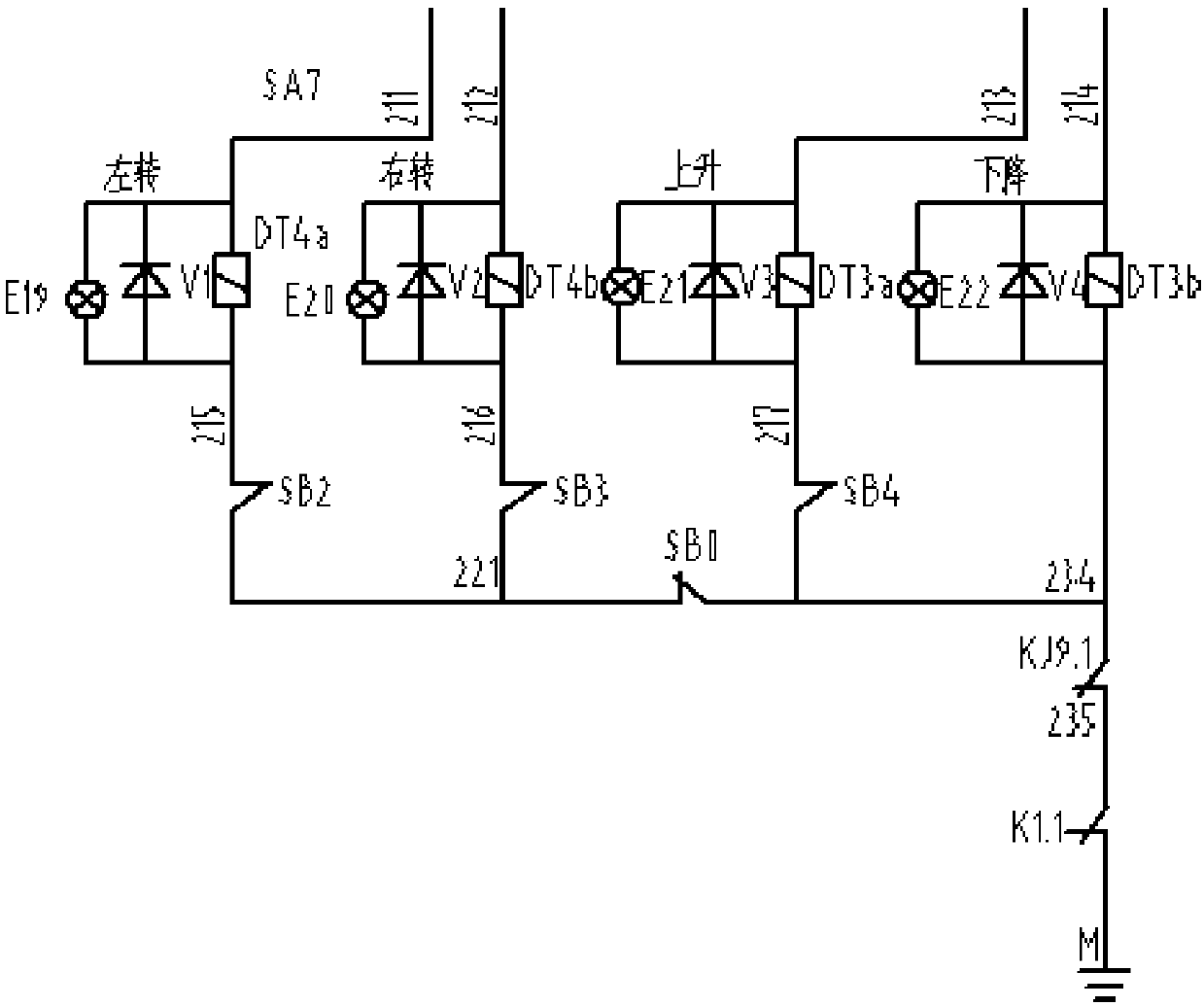

The invention provides an anti-misoperation protective device for a position-fixing pin of a platform of a catenary operation car. The anti-misoperation protective device comprises a power supply, a position-fixing pin inductive switch, a position-fixing pin relay, a hydraulic system normally closed contact and a hydraulic system electrical circuit, wherein the power supply end of the power supplyis connected with the power input end of the position-fixing pin inductive switch; the output end of the position-fixing pin inductive switch is connected with the input end of the position-fixing pin relay; the output end of the position-fixing pin relay is connected with the input end of the hydraulic system normally closed contact; the output end of the hydraulic system normally closed contactis connected with the input end of the hydraulic system electrical circuit; the position-fixing pin inductive switch is fixed on a position-fixing pin mounting seat; and the position-fixing pin inductive switch is connected with the hydraulic system electrical circuit by the position-fixing pin relay. When the position-fixing pin inductive switch senses the position-fixing pin, a high electricallevel is outputted so as to cut off the hydraulic system electrical circuit and the platform can not work; and when the position-fixing pin inductive switch does not sense the position-fixing pin, a low electrical level is outputted so as to close a hydraulic system electrical circuit and the platform can work normally.

Owner:太原中车时代轨道工程机械有限公司

High-low voltage switch cabinet with condensation removing function

ActiveCN114361964ASpeed up evaporationPlay the role of heatingElectric heatingSubstation/switching arrangement casingsThermodynamicsLow voltage

The invention discloses a high-low voltage switch cabinet with a condensation removing function, and belongs to the technical field of switch cabinets. When condensation is generated on the inner wall of the top end of a cabinet body, the condensation drops on a collecting ball through the flow guide effect of a flow guide plate, and the condensation on the collecting ball flows to the position of a water absorbing layer along the outer wall of the collecting ball; at the moment, the condensation is attracted to the inner side of the expansion layer under the action of the water guide wire, the expansion layer expands after absorbing water and extrudes the liquid storage ball, when the liquid storage ball is pressed and contracts, the elastic ball expands, the elastic ball is attached to the heating frame after expansion and triggers the touch switch to start the electric heating wire, and at the moment, the electric heating wire heats the heating frame; after the heating frame is heated, heat is transferred to the bouncy ball, the heat on the bouncy ball is transferred to the liquid storage ball through the through pipe, the liquid storage ball can heat the expansion layer, evaporation of condensation in the expansion layer is accelerated, the condensation is discharged through the connecting pipe, waste of electric energy is reduced, and components in the cabinet body cannot be affected.

Owner:XUZHOU YILE ELECTRICAL TECH CO LTD

A kind of wind damping device applied to aviation dragging system

ActiveCN107554790BAvoid the situation of pulling offHigh feasibilityAircraft componentsLaunching weaponsAviationImpeller

The invention discloses a wind force damping device, and belongs to the field of damping devices in an aviation drag system. The wind force damping device comprises air inlet dampers, fan impellers, an impeller shaft, exhaust air dampers, a cabin body, a decoy, a traction cable, a transmission steering device and an impeller shaft support, wherein the air inlet dampers are arranged at the front end of the cabin body; the fan impellers are arranged at the rear end of the air inlet dampers; one end of the impeller shaft is connected with the fan impellers and the other end of the impeller shaftis connected with the transmission steering device; the impeller shaft is fixed to the impeller shaft support; two ends of the impeller shaft are fixed to the cabin body; the decoy is released and isconnected with the transmission steering device through the traction cable, and the fan impellers are driven to rotate through the impeller shaft; and the air inlet dampers and the exhaust air dampersare opened at the same time, so that airflow which acts on the surfaces of the fan impellers is formed, torque for allowing the fan impellers to reversely rotate is generated, and the decoy can be decelerated or recovered. According to the wind force damping device disclosed by the invention, by using the wind force simply, the damping effect of slowing down the releasing speed of the traction cable can be generated and the situation that the traction cable is broken by pulling at the end of releasing can be effectively avoided.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

An oil well operation tool

The invention relates to a petroleum underground operation tool. According to the technical scheme, an upper central pipe and a lower central pipe are movably connected through an unsealing liner pipe, the upper central pipe is fixed in the middle part of the unsealing liner pipe through an upper unsealing shear nail, the lower central pipe is fixed through a lower unsealing shear nail, an upper retaining ring is fixed on the outer wall of the middle part of the upper central pipe, an upper joint is arranged at the outer end of the upper central pipe, a lower retaining ring is fixed on the outer wall of the middle part of the lower central pipe, a lower joint is arranged at the outer end of the lower central pipe; the outer wall is processed with water-swellable rubber. The petroleum underground operation tool has the advantages that, by designing the unsealing structure, the shrinkage of the water-swellable rubber and the unsealing can be achieved, the situation that the pulling cannot be carried out due to the large resistance of the water-swellable rubber during work over can be avoided, the problem that the drawing must be carried out by forcedly increasing the pulling force isalso avoided, the great destructive force is generated to the stratum due to the pumping action of the packer, and the problems of high cost and long operation period caused by grinding and milling operation by grinding shoes can be avoided.

Owner:山东浮来春生物化工有限公司

An adjustable welding ribbon feeding device

InactiveCN104668835BQuick and effective pulling and feedingAvoid the situation of pulling offWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

Owner:DONGHUA UNIV

Fiber product winding device capable of preventing snapping

PendingCN113602875AReduce tensionAvoid the situation of pulling offWebs handlingStructural engineeringManufacturing engineering

One or more embodiments of the invention provide a fiber product winding device capable of preventing snapping. The fiber product winding device comprises an adjusting plate, a winding shaft, a conveying shaft, adjusting rods and a telescopic rod. According to the fiber product winding device capable of preventing snapping, the adjusting rods are arranged between the winding shaft and the conveying shaft, an adjusting roller is rotationally arranged between the two adjusting rods, the adjusting roller is pressed on a wound fiber product, and when the tension of the fiber product is too large, the adjusting roller is driven to move upwards, so that the adjusting rods move upwards, the telescopic rod rotates around a rotating piece, the adjusting plate drives the winding shaft to slide in the direction of the conveying shaft, the tension on the fiber product is reduced, the situation that the fiber product is snapped due to the fact that the tension on the fiber product is too large is avoided, and the production quality of the fiber product is improved.

Owner:ANHUI HEBANG TEXTILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com