Multi-stage deblocking type water-swelling packer and method

A water-swelling and water-swelling rubber technology, which is applied in the directions of sealing/packing, earthwork drilling, wellbore/well components, etc., can solve the problems of easy-to-damage oil well well casing, solidified structure damage, wear well wall or Problems such as casing, to avoid poor sealing, eliminate suction effect, and enhance the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

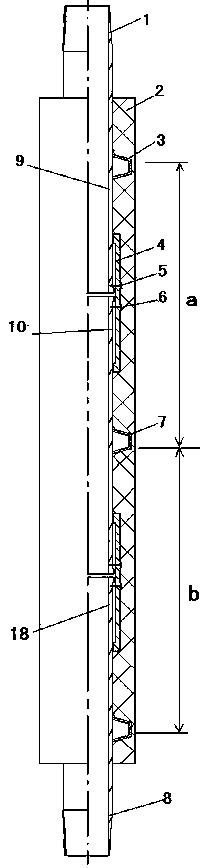

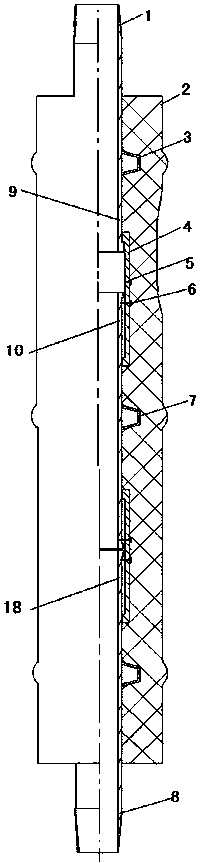

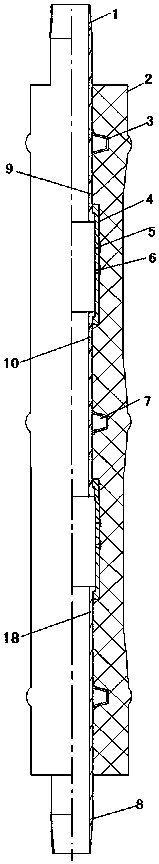

[0029] Embodiment 1, with reference to attached figure 1 and 4 , 5, a kind of multi-stage unsealable water-swellable packer mentioned in the present invention, its technical scheme is: comprise three-section center pipe, one group of water-swellable rubber and two groups of unsealing devices, water-swellable Rubber processing is on the outside of the three-section central tube and two sets of unsealing devices. There is a first set of unsealing device a between the first section and the second section of the central tube, and between the second section of the central tube and the third section of the central tube. There is a second set of unsealing devices b between them; wherein, each set of unsealing devices includes a first retaining ring 3, an unsealing liner 4, a first unsealing shear nail 5, a second unsealing shear nail 6 and a second blocking Ring 7,

[0030] The middle part of the unsealing liner 4 fixes the first central pipe 9 by the first unsealing shears 5, and ...

Embodiment 2

[0044] Embodiment 2, with reference to attached Figure 5 , the outer edge of the first shoulder 11 of the present invention is provided with a protruding outer steel ring 15, which is used to firmly cooperate with the first unblocking retaining ring 12, and the outer edge of the second shoulder 14 is provided with a protruding The outer steel ring 15 is used to firmly cooperate with the second unblocking retaining ring 13; the outer edges of the above-mentioned first unblocking retaining ring 12 and the second unblocking retaining ring 13 are respectively provided with a raised inner steel ring 16, so that The structure can better ensure the reliability of the connection between the unsealing liner and the second section of the center pipe, and avoid unsealing failure caused by falling off; Let me repeat.

Embodiment 3

[0045] Embodiment 3, with reference to attached Figure 8 , the cavities of the first, second, and third retaining rings of the present invention are filled with water-absorbing resin, and the cross-section of the retaining rings is an isosceles triangle, and the two waists are provided with communicating holes in the shape of a bell mouth, and the shape is outer width Narrow inside, this structure is more conducive to water absorption, and can also make the water-absorbent resin in the inner cavity slowly released to play a local slow-release effect. When water swells, due to the action of the water-absorbing resin in the retaining ring, the water-swellable rubber 2 will form a squeeze effect along the direction of the two sides, and further squeeze, so that the water-swellable rubber 2 will form a squeeze effect along the two sides of the waist. The extension direction forms a bulging protrusion 17, and this structure can also achieve the purpose of the present invention, en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com