Tension-free strip steel maglev feeding device and maglev high-speed ultra-thin continuous rolling mill

A feeding device and tension-free technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of being unable to roll ultra-thin strip steel, so as to prevent bending deformation, improve quality, and have a simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

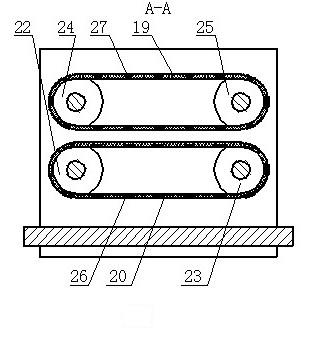

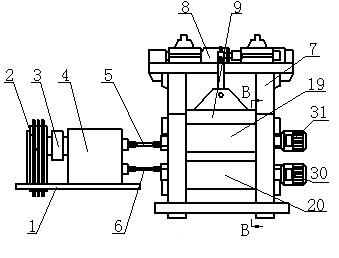

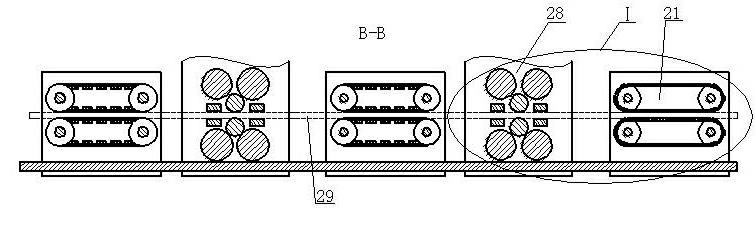

[0009] Tension-free strip steel maglev feeding device of the present invention, such as figure 1 and figure 2 As shown, the feeder frame 32 is included, and the first conveyor belt is installed on the feeder frame 32. The first conveyor belt is composed of the first lower transmission roller 22, the second lower transmission roller 23 and the first transmission belt 20. The first Several positioning magnets 26 are installed on the outer surface of the transmission belt 20; a driving device is installed on the feeding device frame 32, and the driving device is connected with the drive shaft of the first conveyor belt.

[0010] When the belt steel 29 is conveyed, the steel belt 29 is tightly adsorbed on the first transmission belt 20 under the action of the positioning magnet 26, and the driving device passes through the drive shaft of the first transmission belt, that is, the first lower transmission roller 22 or the second lower transmission roller 23. The shaft drives the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com