Label station of adhesive sticker labeling machine

A labeling machine and glue sticking technology, which is applied in the field of labeling stations in self-adhesive labeling machines, can solve problems such as unstable label spreading, label conveying instability, and label jamming, so as to improve labeling efficiency and accuracy Improve the speed and avoid the effect of card labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

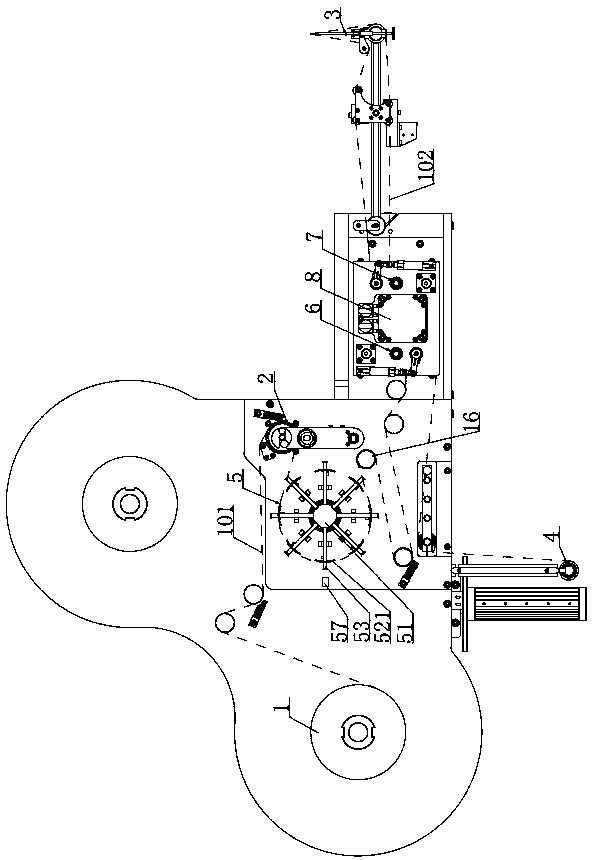

[0028] Such as figure 1 As shown, the labeling station of the self-adhesive labeling machine includes: a label roll 1, an unwinding mechanism 2, a label feeding mechanism, a peeling mechanism 3, and a winding mechanism 4 arranged in sequence along the running direction of the label. The labels to be pasted are pasted on the backing paper and rolled into rolls. The rolled labels are called label rolls 1. Usually, two label rolls 1 are placed on one labeling station for replacement. The unwinding mechanism 2 usually includes a pair of unwinding power rollers and unwinding driven rollers, the unwinding power rollers are driven by the power mechanism, and the unwinding power rollers and the unwinding driven rollers continuously roll the bottom of the label roll 1 pasted with labels. The paper keeps unrolling. The peeling mechanism 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com