Traction mechanism for cable processing

A technology of traction mechanism and traction motor, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc. It can solve the problems of affecting production speed, insufficient tension force, and broken cables, etc., and achieves sensitive response , Slow down the change of tension and increase the effect of buffer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

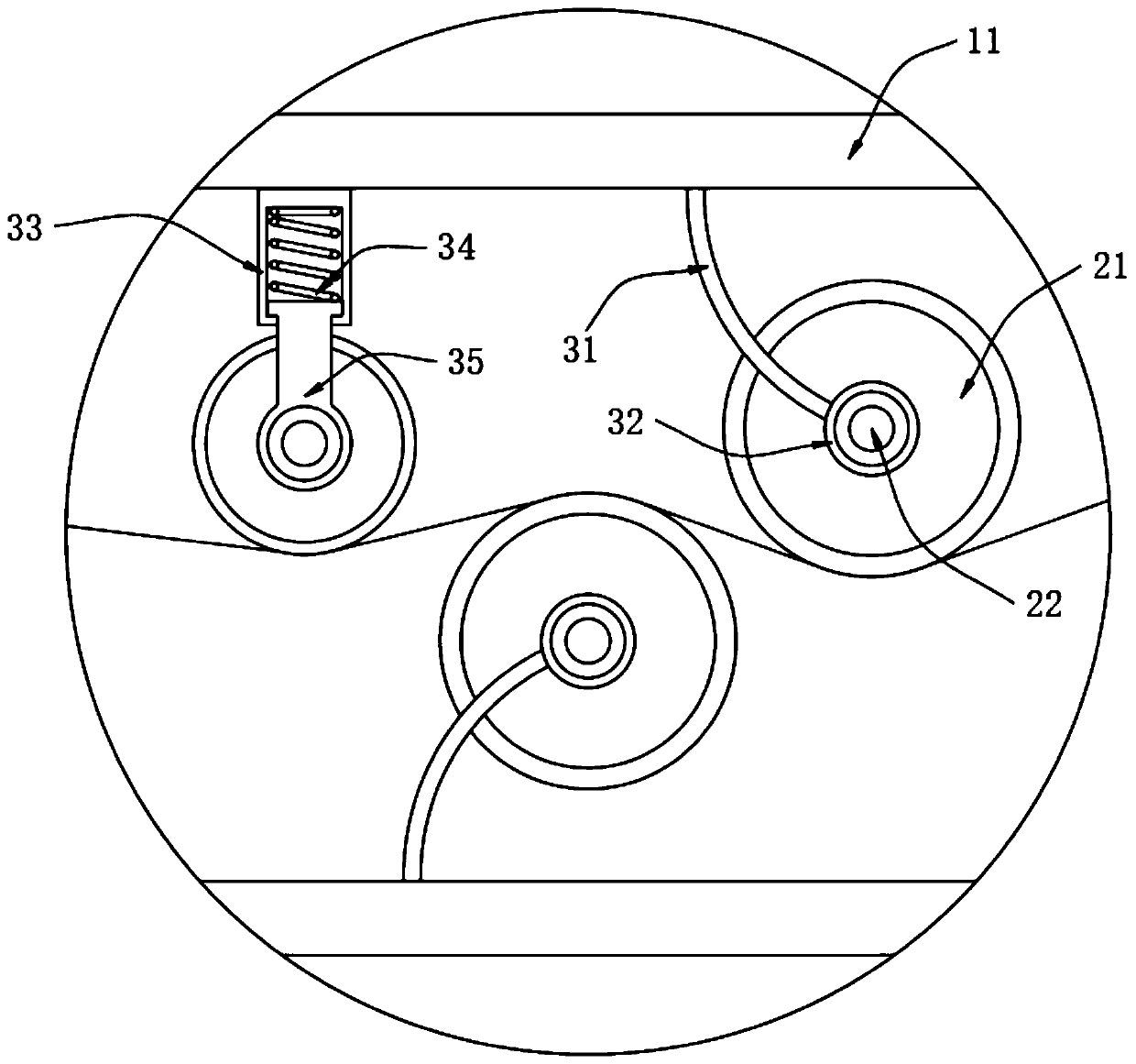

[0030] The difference from Embodiment 1 is that the first tension member 3a and the second tension member 3b each include a tension spring 31 and a connecting ring 32, and the third tension member 3c includes a spring sleeve 33, a spring 34, and a telescopic connecting ring. 35, and the bending force of the spring 34 at the third tensioning member 3c is equal to the cable breaking force, the bending force of the tensioning elastic piece 31 at the second tensioning member 3b and the first tensioning member 3a is sequentially reduced, which can increase the tension The elasticity of the 3 pairs of cables is suitable for thicker cables.

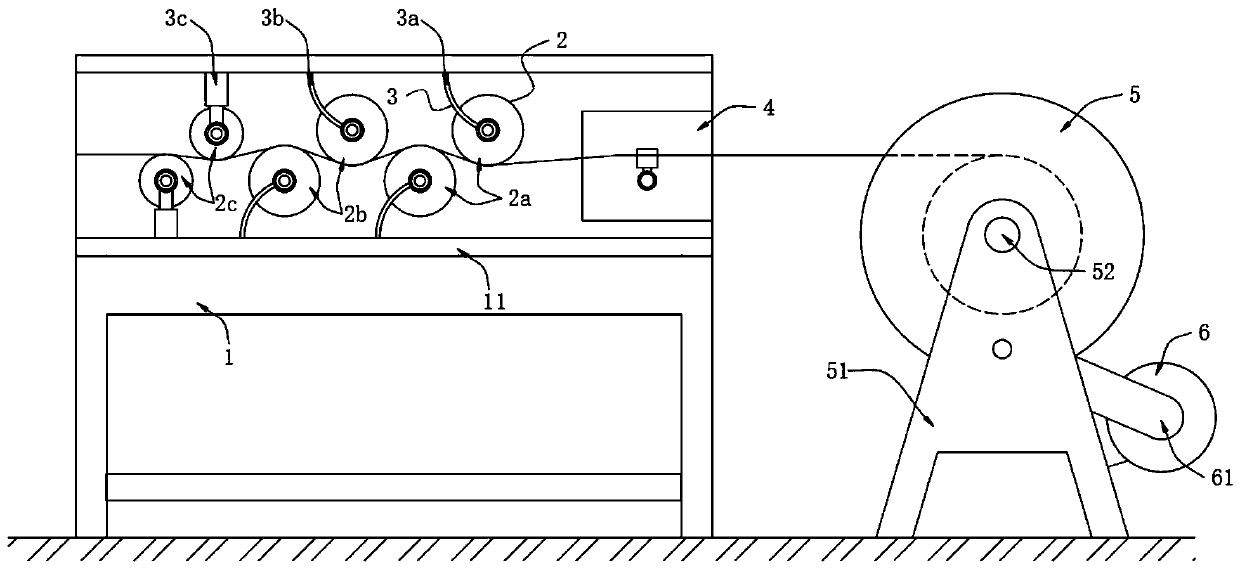

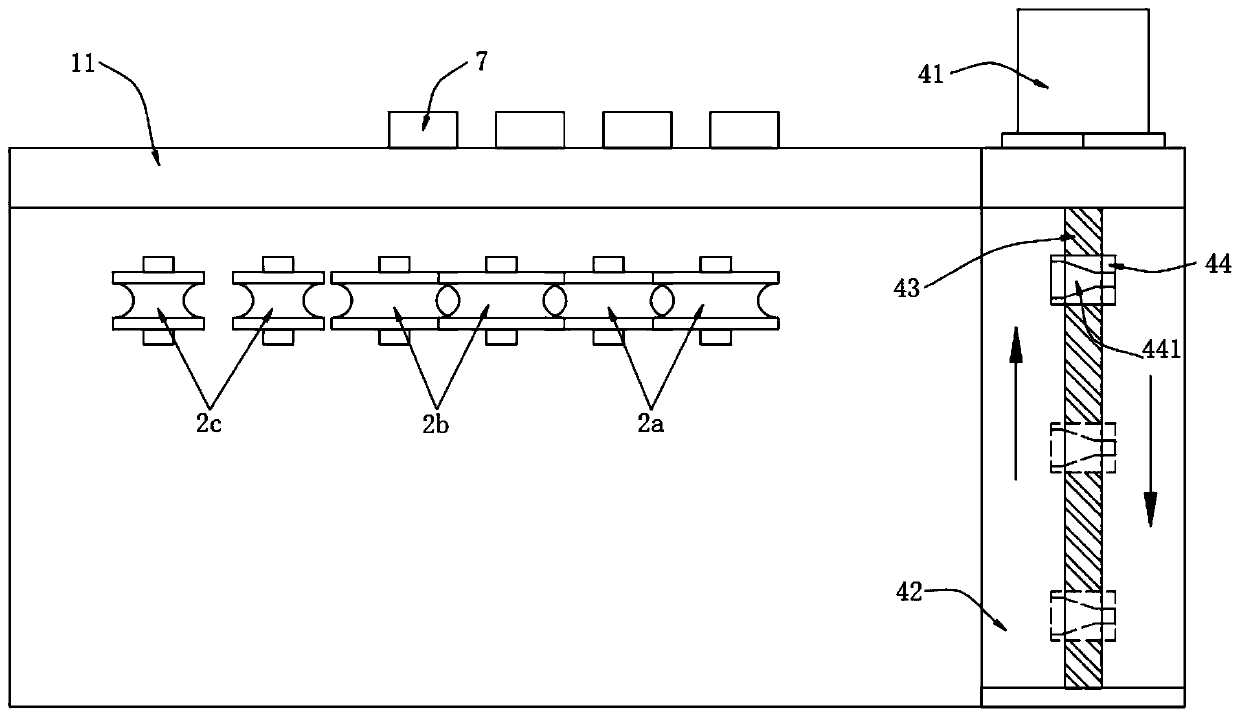

[0031] When in use, a supporting table 1 carrying the guide wheel 2, the tensioning mechanism 3 and the cable guide mechanism 4 is arranged on the input end side of the winding roller 5, and the carrying guide wheel 2, the tensioning mechanism 3 and the cable The guiding mechanisms 4 are all installed on a "dang"-shaped traction frame 11. The cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com