Cable type hydraulic jar with through line of telescopic structure

A telescopic structure and cable-type technology, which is applied in the direction of cable arrangement between relative moving parts, cable installation, electrical components, etc., can solve the problems of broken through lines, abnormal communication, power supply, etc., and achieves convenient installation and large design space. Compact and unobstructed flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

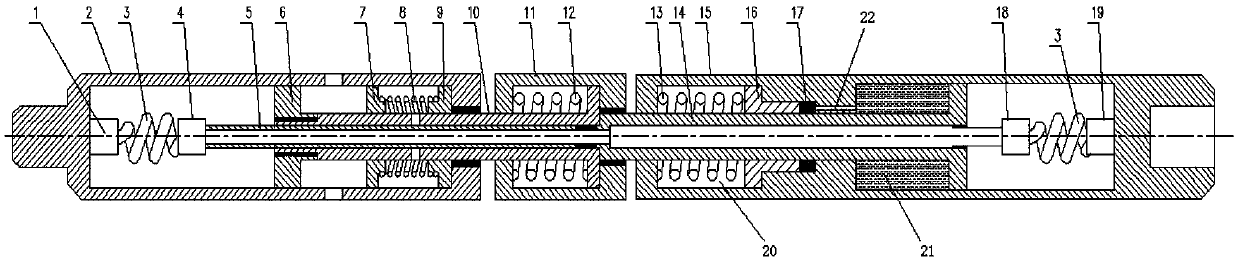

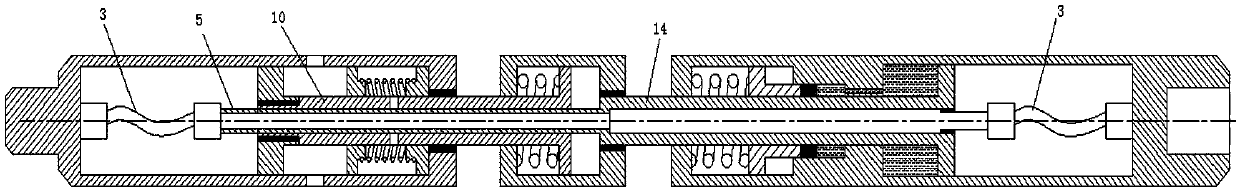

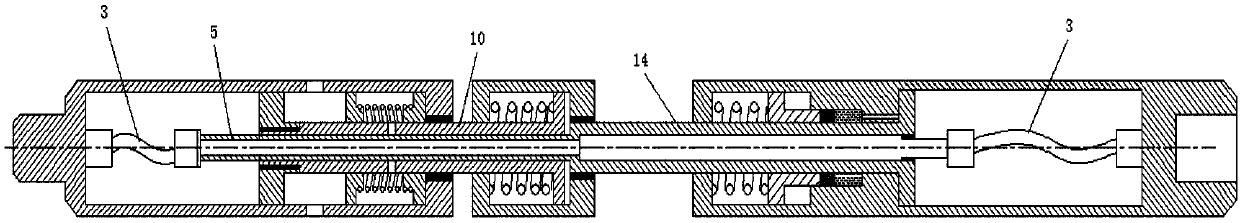

[0035] Such as figure 1As shown, the cable hydraulic jar of the present invention includes a balance assembly, an acceleration assembly, a shock assembly and a through wire 3; The assembly includes a shock shell 15 and a shock shaft 14. One end of the acceleration tube mandrel 10 is located in the balance shell 2, and the other end is located in the acceleration tube shell 11; one end of the shock shaft 14 is located in the shock shell 15, and the other end is connected to the acceleration tube The shell 11 is connected; inside the balance shell 2 there is a first high temperature resistant metal joint 1 and a second high temperature resistant metal joint 4, the first high temperature resistant metal joint 1 is fixed on the upper end of the balance shell 2; inside the shock shell 15 there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com