Fiber product winding device capable of preventing snapping

A technology for winding devices and fiber products, which is applied in the field of fiber product production, can solve the problems of excessive tension and low quality of fiber product production, and achieve the effect of improving production quality and avoiding breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments.

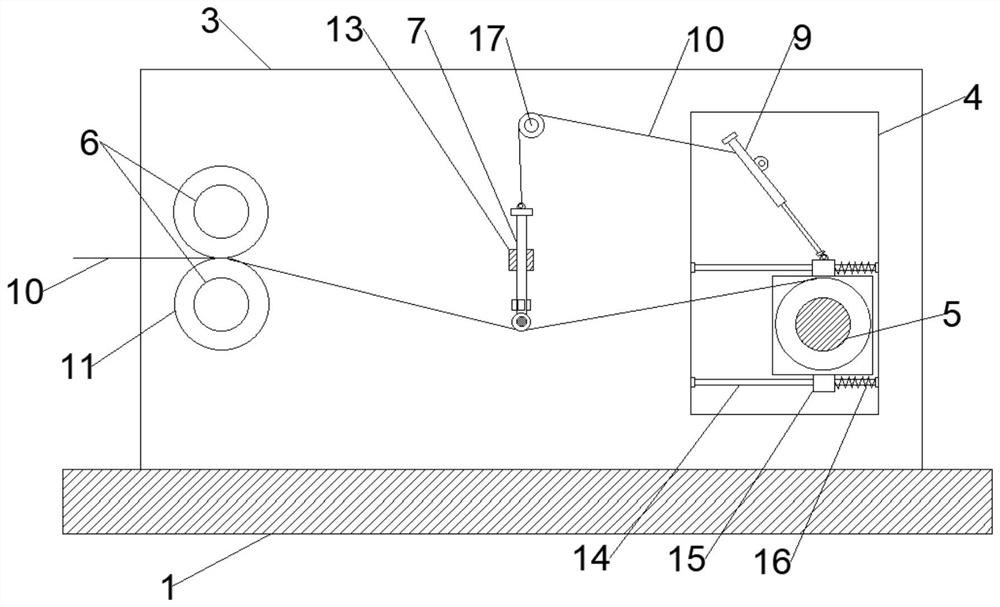

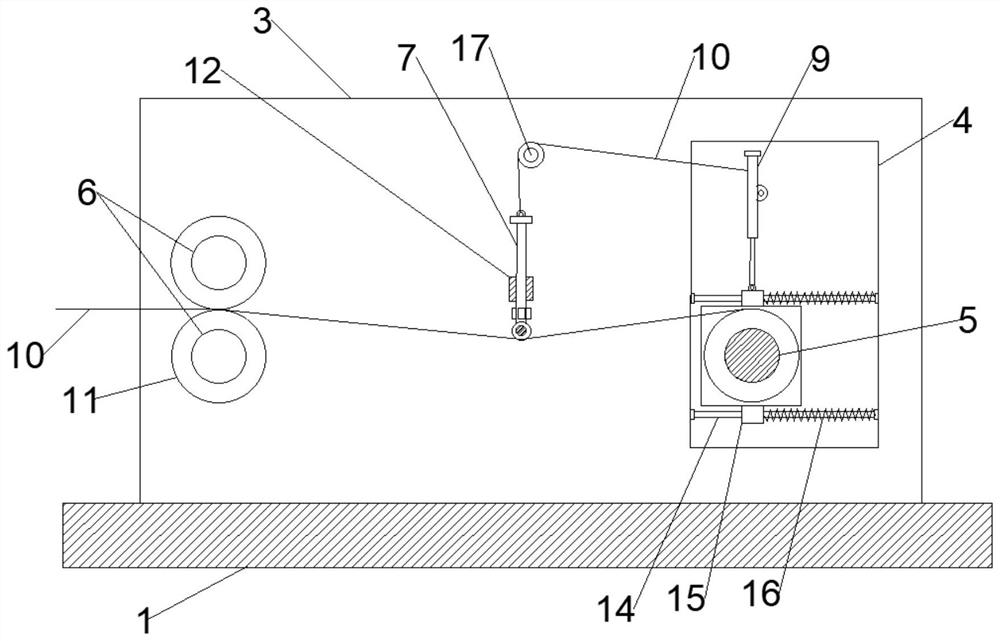

[0031] Based on the above purpose, one or more embodiments of this specification provide a fiber product winding device that can prevent breaking, which is characterized in that it includes:

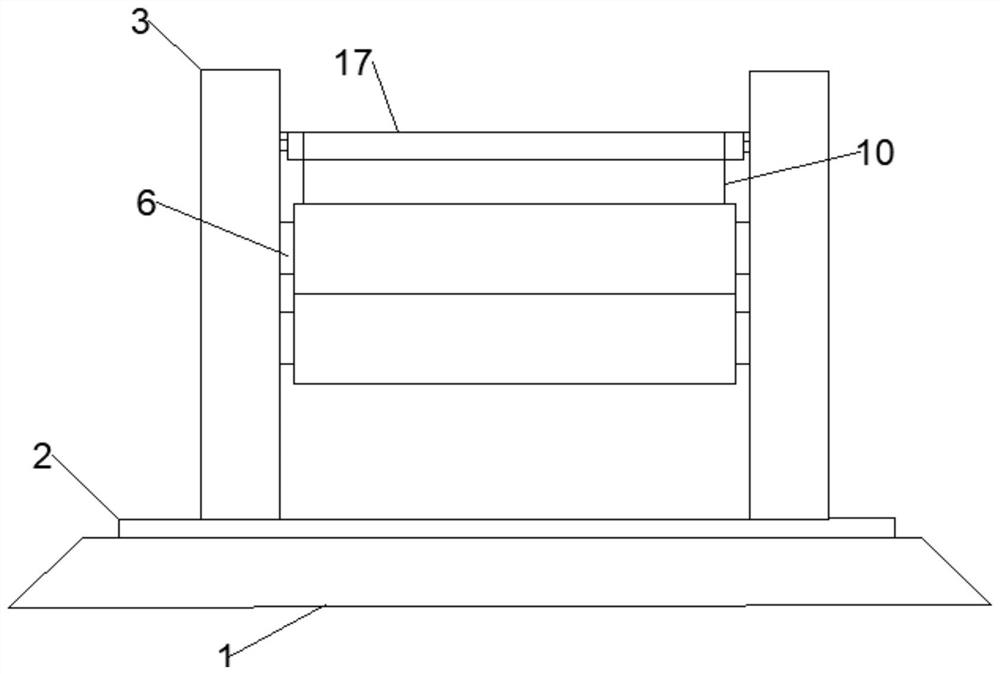

[0032] The bottom plate 1 is provided with a slide plate 2 at the upper end, and a through chute is provided inside the slide plate 2;

[0033] There are two support plates 3, and the bottom end is slidingly arranged in the chute, and the opposite surfaces of the two support plates 3 are symmetrically provided with adjustment grooves 4;

[0034] An adjustment plate, the two adjustment plates are horizontally slidably arranged in the adjustment groove 4;

[0035] The winding shaft 5 is arranged on two adjusting plates for rotating at both ends;

[0036] There are two transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com