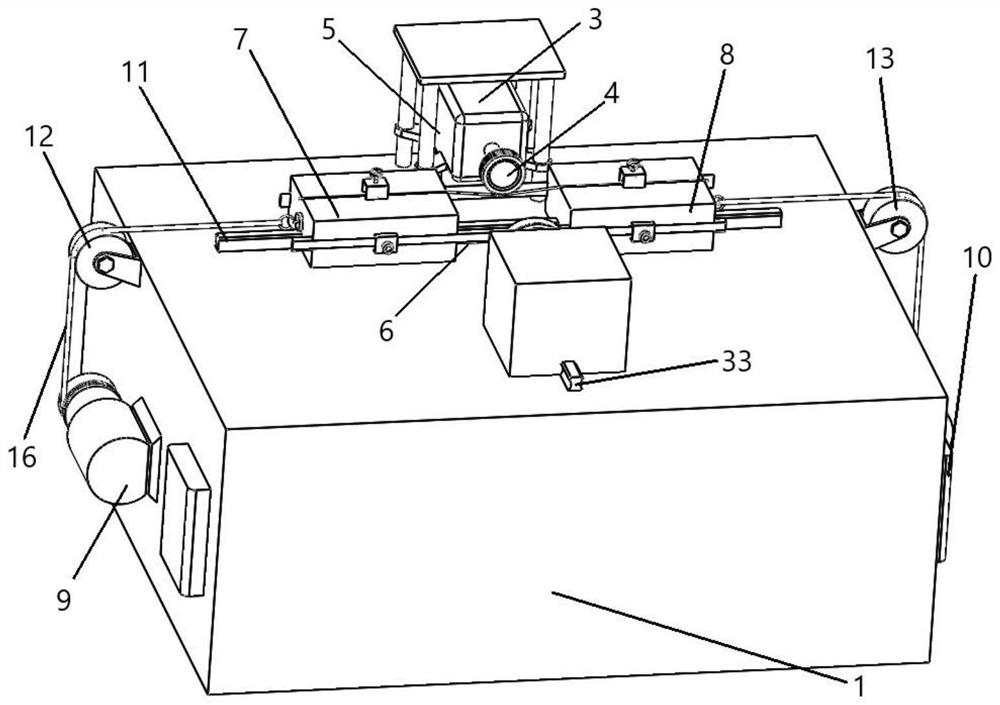

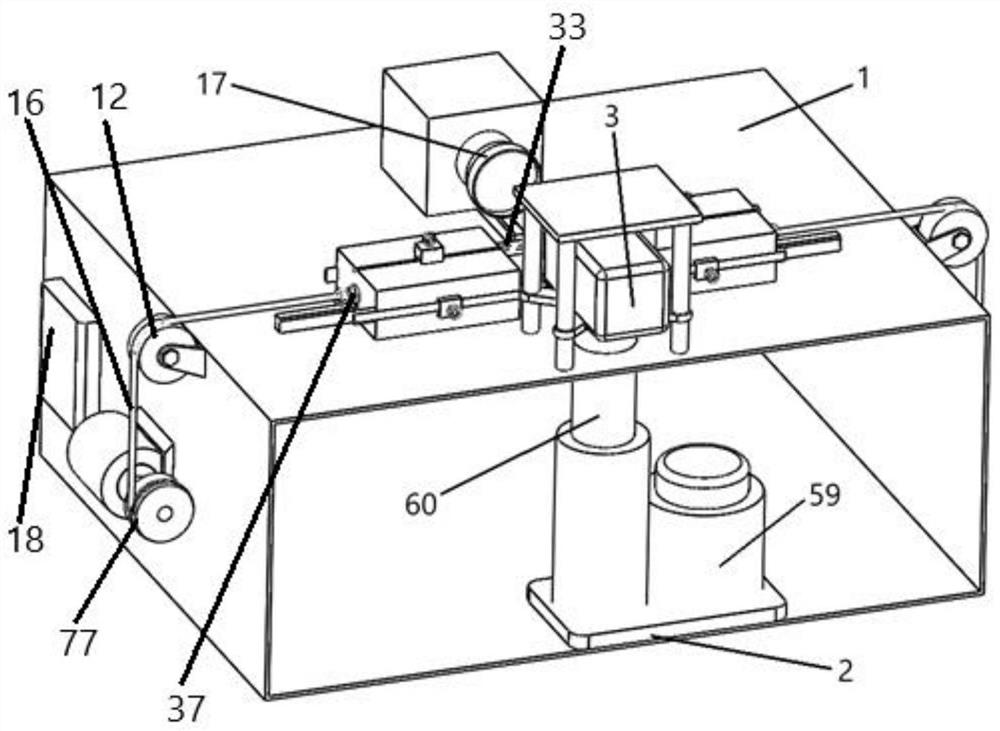

Device and method integrating polishing and tapering for preparing d-type and tapered optical fibers

A technology of tapered optical fiber and optical fiber, which is applied in the direction of automatic grinding control device, coupling of optical waveguide, optics, etc., to achieve the effect of strong stability and reliability, simple design, and solve the problem of function expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

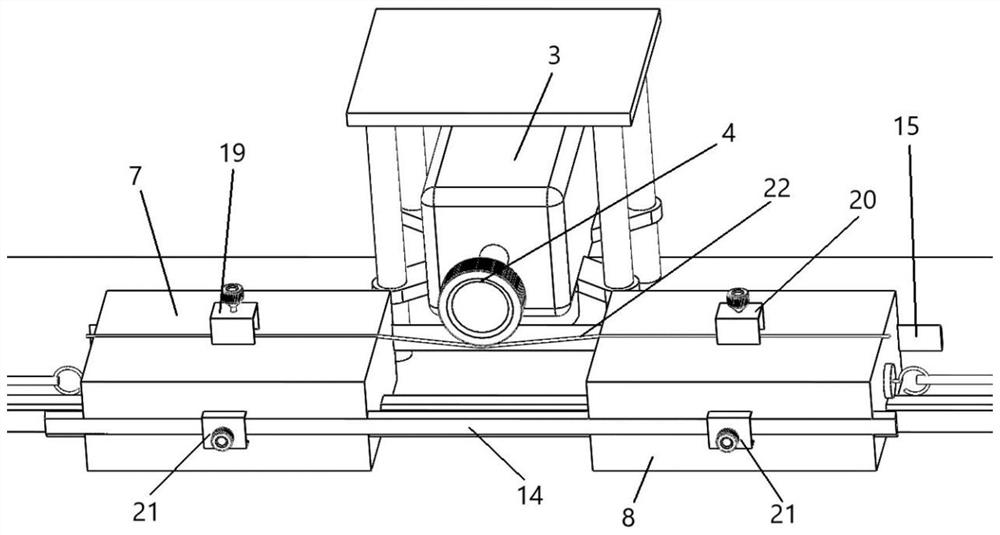

[0086]Embodiment 1: The process method of preparing D-shaped optical fiber based on an integrated device, which includes the following steps:

[0087] S1. According to the specific requirements of the polishing length processing of the optical fiber 22, adjust the fixed positions of the first connecting piece 14 and the second connecting piece 15 on the flange slider to ensure that the first flange slider 7 and the second flange slider Whether the length of the polishing work area between the blocks 8 is suitable for the length of the optical fiber 22 to be polished;

[0088] S2. Install the two ends of the optical fiber 22 on the first flange slider 7 and the second flange slider 8 respectively;

[0089] S21. Unscrew the first fixing screw 26 of the first optical fiber fixing fixture 19 on the first flange slider 7 upwards from the first threaded hole 25;

[0090] S22. Carefully lift the pressure plate 23 by hand, pass the first end of the optical fiber 22 under the pressure...

Embodiment 2

[0104] Embodiment 2: The process method of preparing tapered optical fiber based on integrated device, it comprises the following steps:

[0105] S1. Move the two flange sliders that have been fixed together by the first connecting piece 14 and the second connecting piece 15 to one side along the long guide rail 11, so that the optical fiber 22 between the two flange sliders operates in the working area The center deviates directly below the polishing wheel 3;

[0106] S2. Open the two connecting piece fixing fixtures 21 that fix the second connecting piece 15 on the side close to the optical fiber polishing module 3, and pull the second connecting piece 15 out of the dovetail slot 27 on the flange slider. The first The connecting piece 14 remains fixed;

[0107] S3. Push and move the second heating block 40 along the direction perpendicular to the long guide rail 11 from the side of the optical fiber polishing module 3 to the side of the real-time monitoring module 17 until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com