Technological method for bending clamp and design and use of bending die

A bending and clamping technology, which is applied in the bending process of clamps and the design and use of bending dies, can solve complex bending parts processing and forming problems, and achieve the effect of solving bending forming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

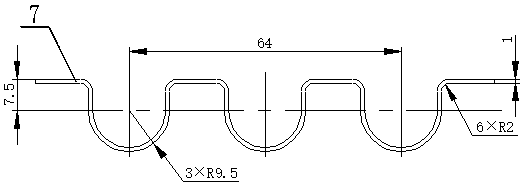

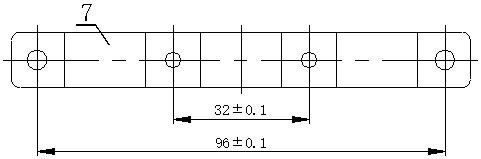

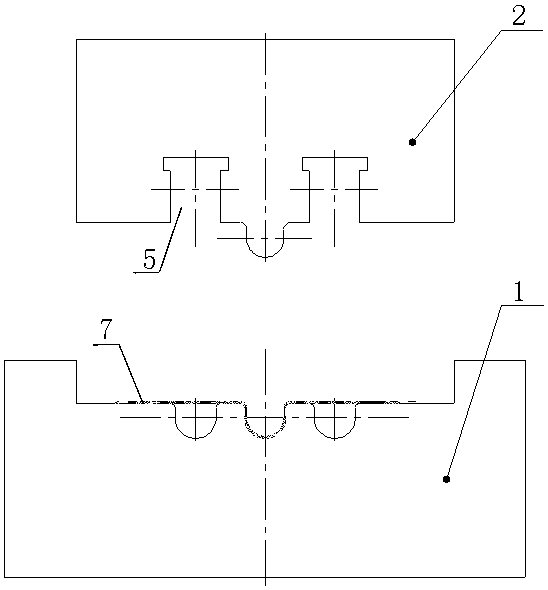

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0029] A bending process method of a clamp, the following steps are adopted:

[0030] Step 1: Place the die on the base plate of the hydraulic press, place the strip to be processed in the groove of the die; then place the punch on the strip to be processed, and place it in the slot of the die; then Put down the upper slider of the hydraulic press, pressurize the punch, make the punch press the part, make the part fully deformed, and completely fit with the die, and complete the bending of a protrusion in the middle of the part;

[0031] Step 2: Insert two movable punches into the punch respectively, and place the semi-finished parts in the die, then put down the upper slider of the hydraulic press, pressurize the punch, make the punch press the part, and fully deform the part. It fits perfectly with the die and completes the convex bending molding on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com