Machining mechanism for bending forming of refrigerator dew eliminating tube

A technology of processing mechanism and anti-dew pipe, which is applied in the field of refrigerator parts, can solve the problems that the accuracy of the refrigerator anti-dew pipe is not easy to guarantee, cannot be adjusted, stuck in the middle beam, time-consuming and labor-intensive, etc., to achieve simple structure, strong practicability, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

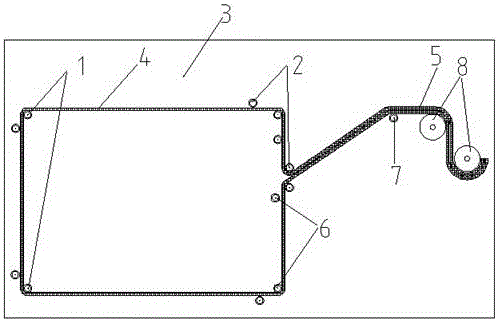

[0015] like figure 1 As shown, in order to achieve the above purpose, the technical solution adopted by the present invention is: a processing mechanism for bending and forming the anti-dew pipe of a refrigerator, which is used for bending and forming the anti-dew pipe of a refrigerator, including an inner ring positioning pin 1 and the positioning pin 2 of the outer ring, the positioning pin 1 of the inner ring and the positioning pin 2 of the outer ring are all set on the fixed plate 3, the anti-dew tube of the refrigerator is composed of the frame part 4 and the curved part 5, and the positioning pin 1 of the inner ring is located on the same anti-dew part of the refrigerator Inside the frame part 4 of the tube, the outer ring positioning pin 2 is arranged outside the frame part 4 of the same refrigerator anti-dew tube. The inner ring positioning pin 1 and the outer ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com