A kind of steel sheet pile support construction method for building underground garage caisson

A technology for underground garages and construction methods, applied to sheet pile walls, excavations, caissons, etc., can solve the problems of complex construction technology, large impact on the surrounding environment, and high engineering costs, so as to reduce the risk factor, improve construction efficiency, and reduce construction difficulty and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

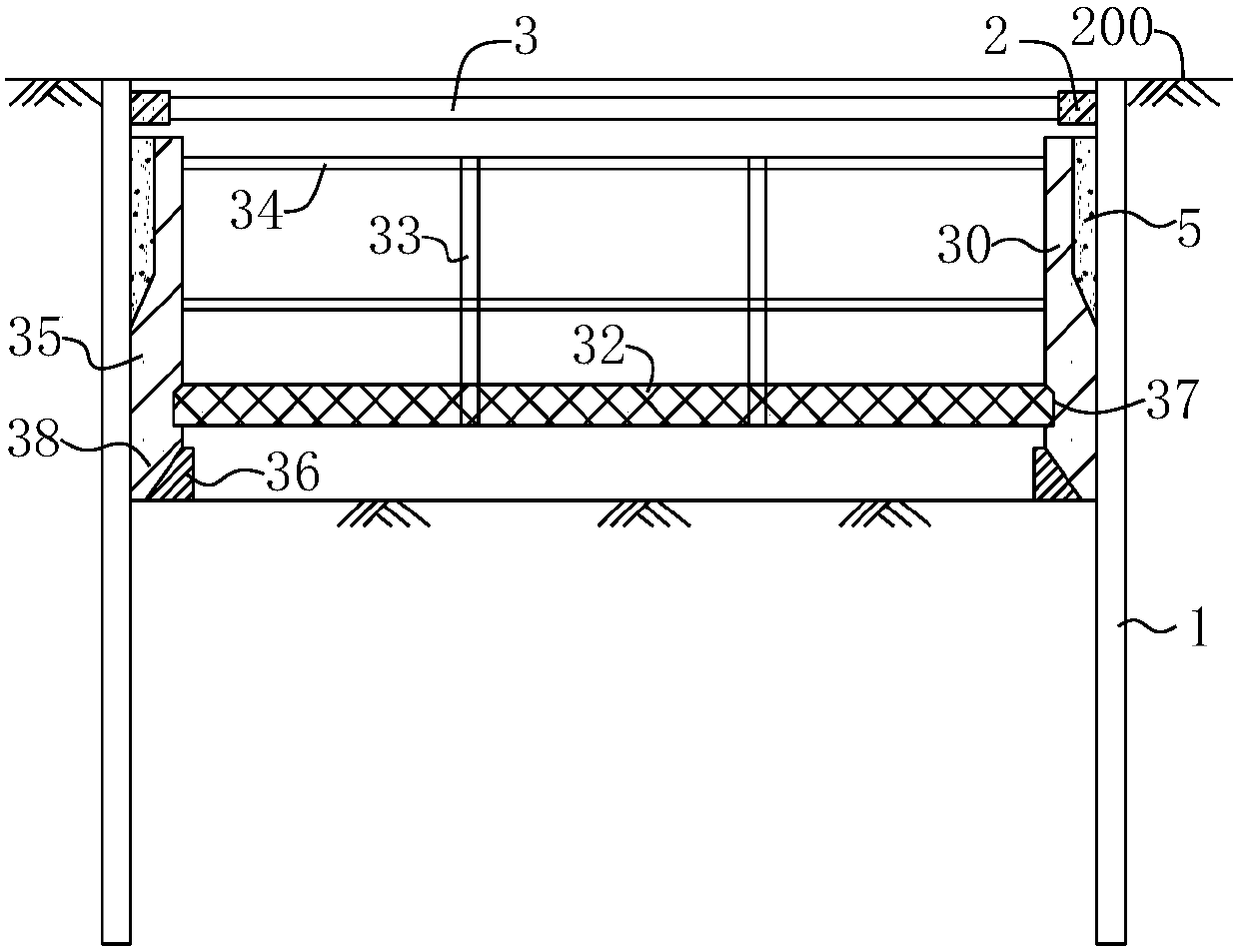

[0045] The well wall of the underground garage caisson to be built in this embodiment is a rectangular well wall, and the well wall adopts a steel-concrete structure. The design depth of the lower end surface of the well wall is 18 meters. The well wall is divided into three sections for construction. The steel sheet pile used The length is 12 meters, and the reference number 200 in the drawings is used to indicate the ground.

[0046] The following are the concrete steps that the above-mentioned underground garage caisson adopts the present invention to build:

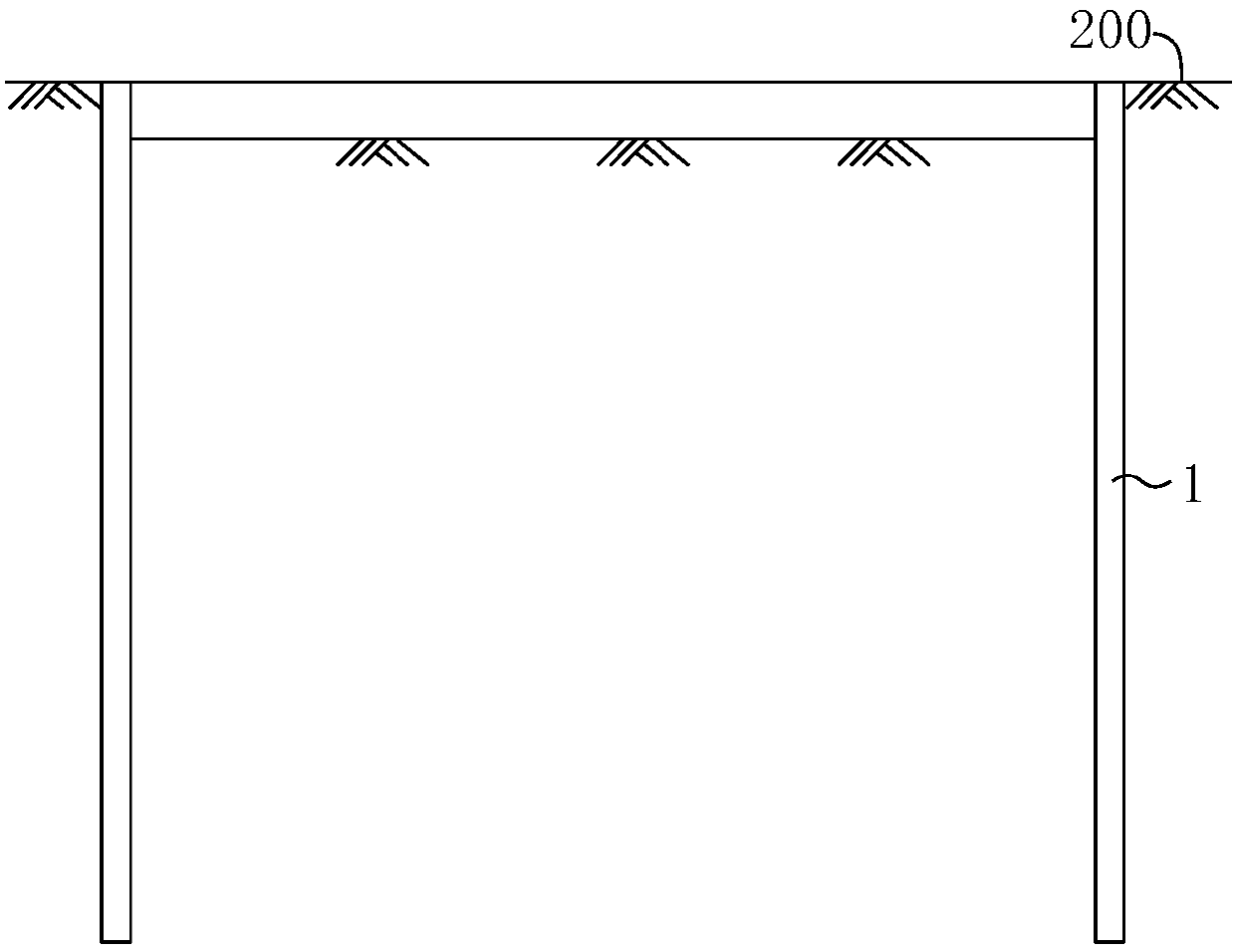

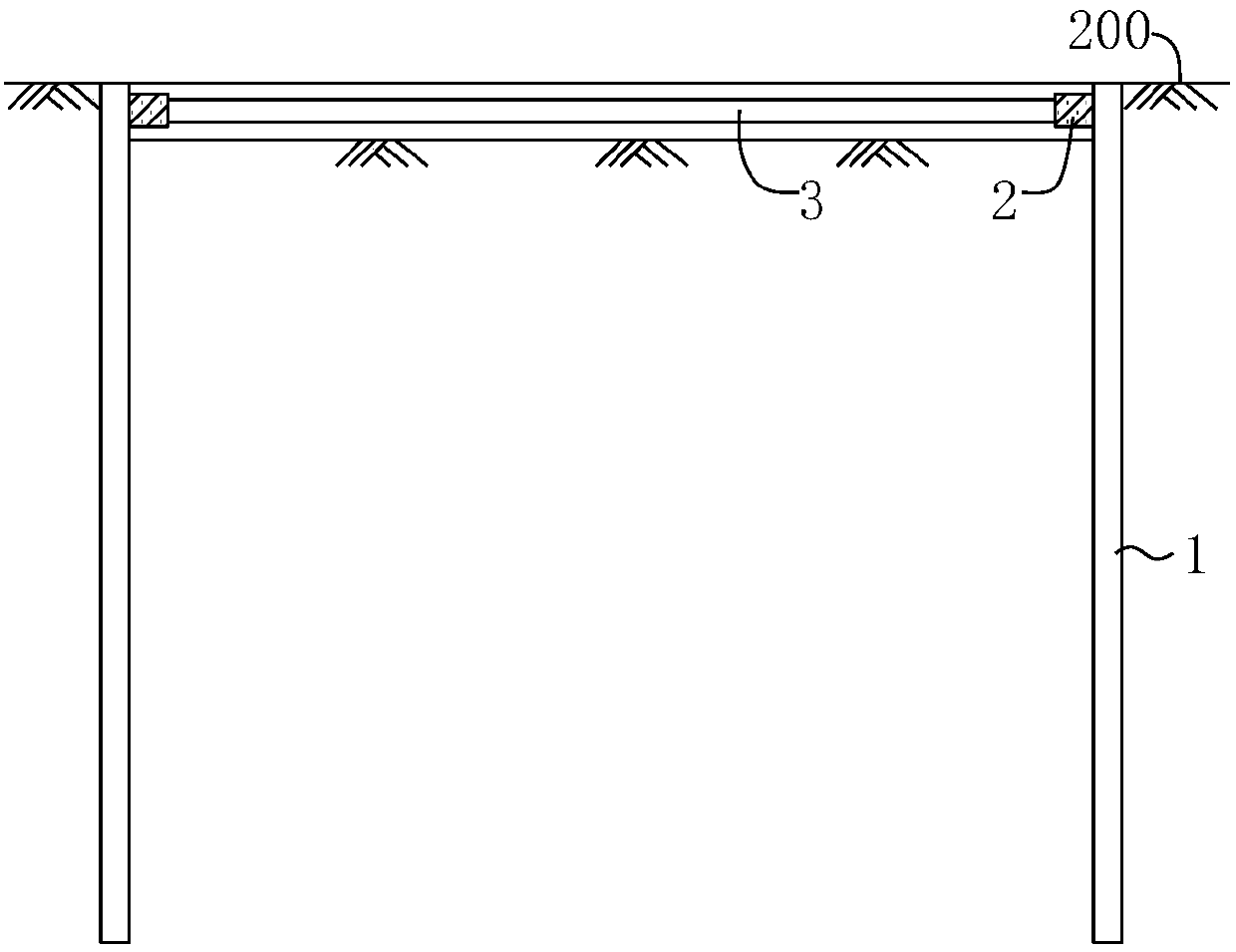

[0047] (1), see figure 1 , the steel sheet piles are sunk at the outer side of the caisson design sinking place, and the steel sheet piles are interlocked and connected to form a continuous steel sheet pile wall 1, and the bottom depth of the steel sheet pile wall 1 is 12 meters.

[0048] (2), please also refer to figure 1 and figure 2 , excavate the earth in the area surrounded by the steel sheet pile wall 1 un...

Embodiment 2

[0064] see Figure 14 , in the present embodiment, the well wall of the underground garage caisson to be built is a circular well wall, and the design depth of the lower end face of the well wall is 30 meters, and the well wall is divided into six sections for construction, Figure 14 Shown is a top view of the underground garage caisson constructed by the method provided by the present invention. In this embodiment, the bottom depth of the steel sheet pile wall 61 is 15 meters.

[0065] The steel sheet pile wall 61 indicated by the dotted line in the drawing shows the position of the steel sheet pile wall before the steel sheet pile is pulled out, and the inner side of the steel sheet pile wall 61 is the shaft wall 62 .

[0066] The construction steps in this embodiment are basically the same as those in Embodiment 1, the difference being that, in this embodiment, jacks are not used to assist the well wall to sink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com