Prefabricated stiff concrete-filled steel tube and reinforced concrete assembled pier and construction process thereof

A technology of steel pipe concrete and reinforced concrete, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as steel pipe corrosion, and achieve the effects of high bearing capacity, low construction noise, and standardized component manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] In this embodiment, the prefabricated steel tube concrete and reinforced concrete piers are connected by grouting sleeve connectors 15, and the first bottom segment 1, the first middle segment 3, and the first top segment 4 are square columns.

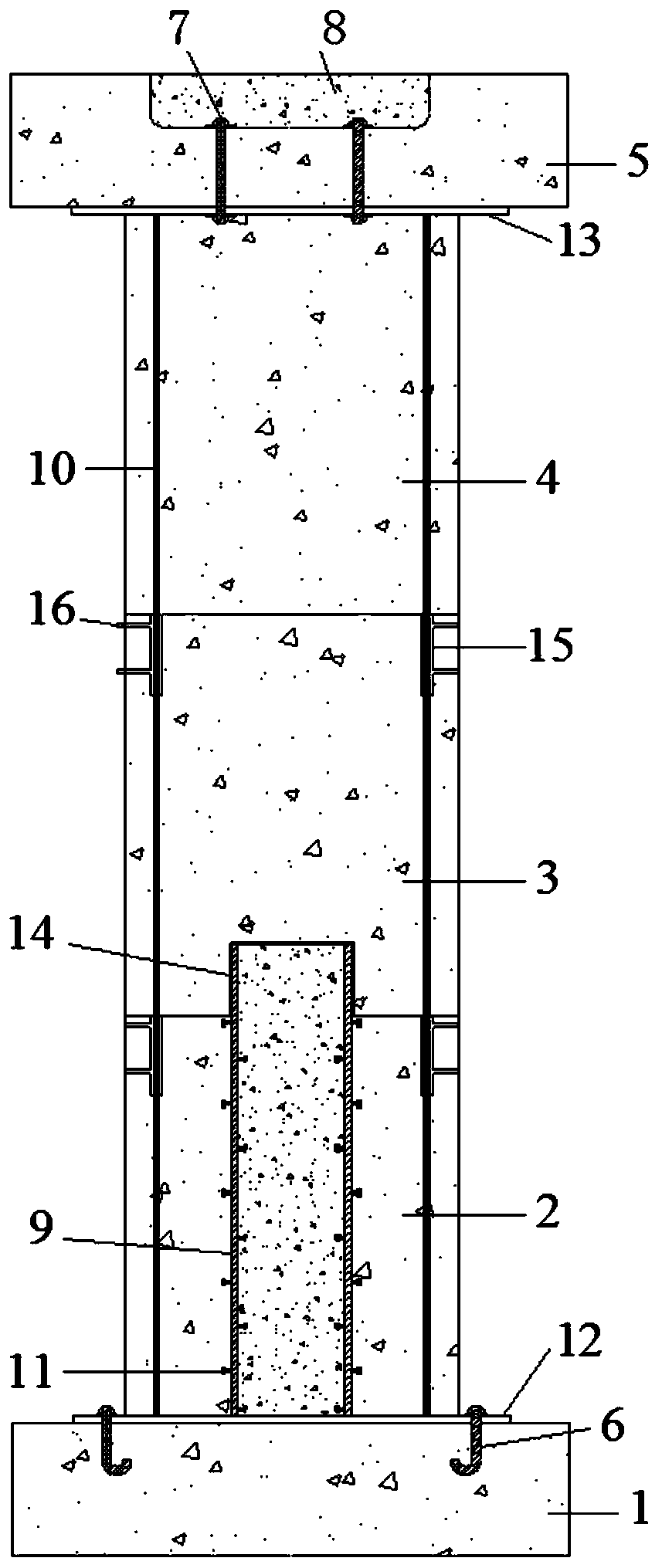

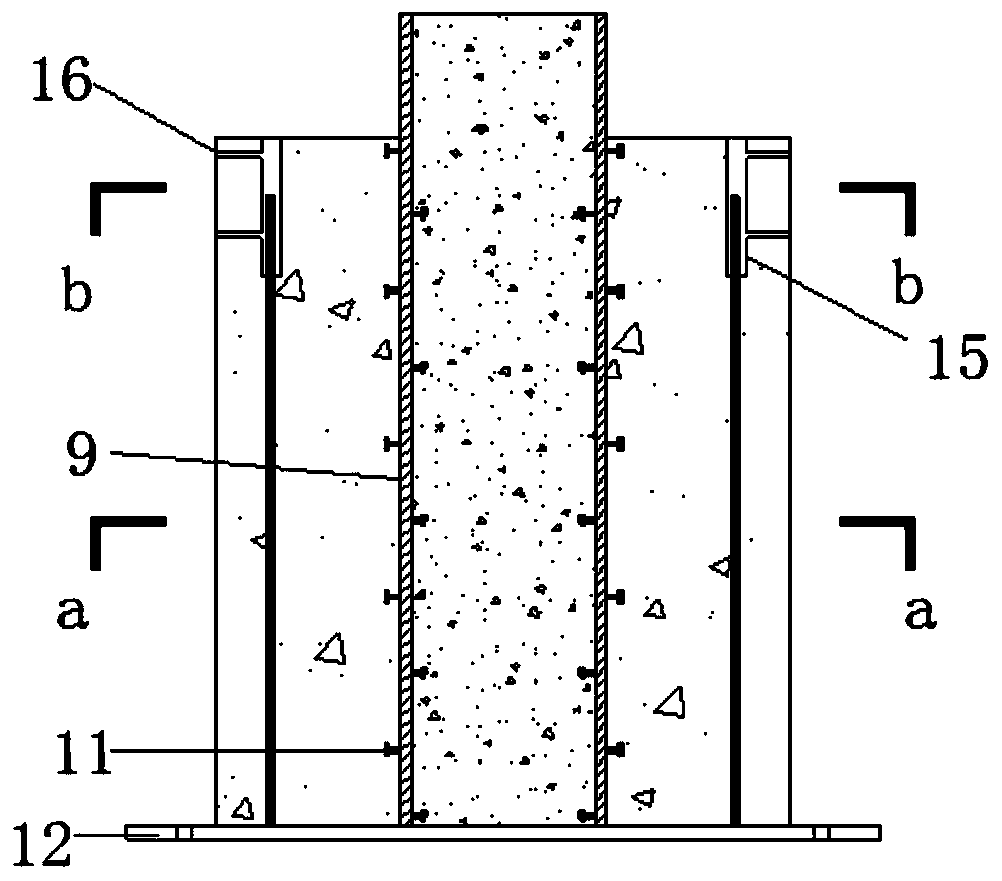

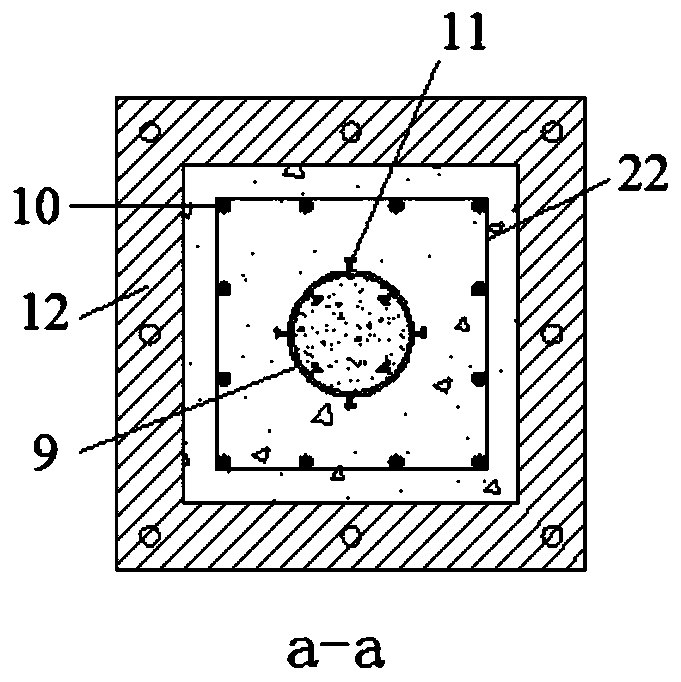

[0079] Such as Figure 1 to Figure 10 and Figure 33 to Figure 37 As shown, the prefabricated steel pipe concrete and reinforced concrete assembled bridge pier includes a foundation 1, a first bottom segment 1, a first middle segment 3, and a first top segment 4, and the foundation 1 is connected to the foundation through a bottom anchor bolt 6 The backing plate 12 is connected to one end of the first bottom segment 1, the other end of the first bottom segment 1 is connected to one end of the first middle segment 3, the other end of the first middle segment 3 is connected to one end of the first top segment 4, and the other end of the first middle segment 3 is connected to one end of the first top segment 4. The other end of a ...

Embodiment 2

[0097] The difference between this embodiment and Embodiment 1 is that the first bottom segment 1, the first middle segment 3 and the first top segment 4 adopt cylinders, such as Figure 11 to Figure 19 shown.

Embodiment 3

[0099] In this embodiment, the prefabricated steel tube concrete and the reinforced concrete assembled bridge piers are connected by connecting steel plates, and the second bottom segment, the second middle segment, and the second top segment use square columns.

[0100] Such as Figure 20 to Figure 26 As shown, the prefabricated steel pipe concrete and reinforced concrete assembled bridge pier includes a foundation 1, a second bottom segment, a second middle segment, a second top segment and a cover beam 5, and the foundation 1 passes through the bottom anchor bolt 6 and The base plate 12 is connected to one end of the second bottom segment, the other end of the second bottom segment is connected to one end of the second middle segment through embedded bolts 20, and the other end of the second middle segment is connected to the second top end through embedded bolts 20. The segments are connected at one end, and the other end of the second top segment is connected with the cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com