Profile modeling winding technology and profile modeling winding machine

A rolling machine and process technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of air bubbles, yarn materials are not tightly bonded, etc., to achieve sufficient force, ensure clearance, and withstand Large force area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

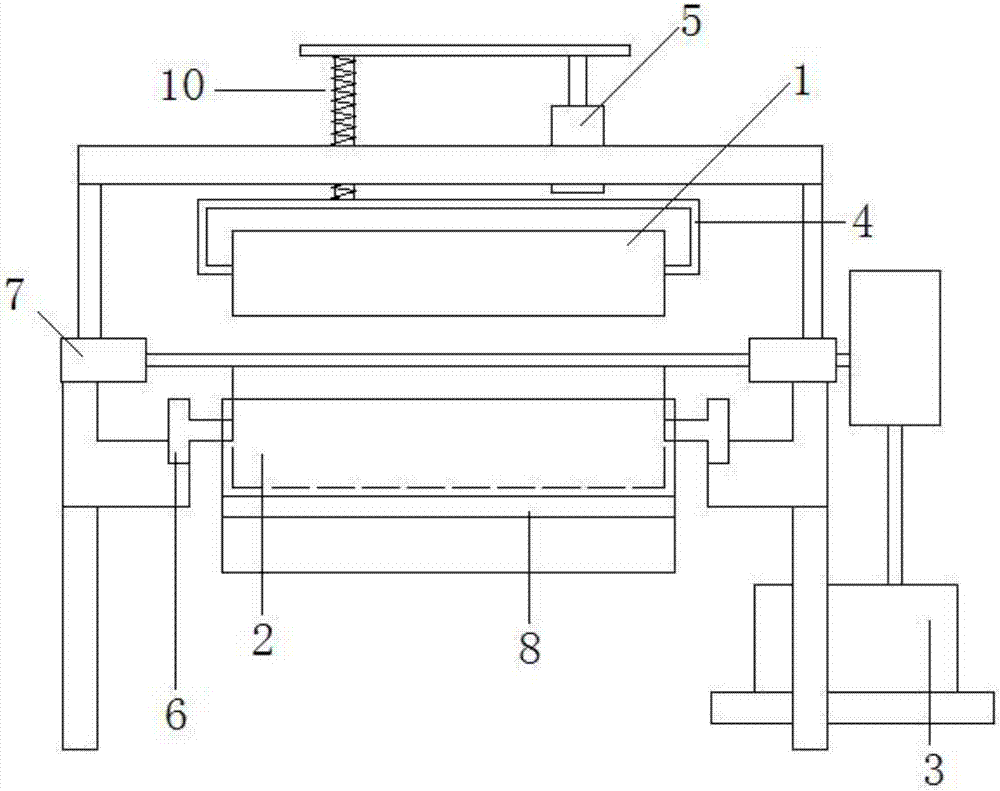

[0027] A profiling rolling process, suitable for rolling hockey stick yarn, comprising the following steps:

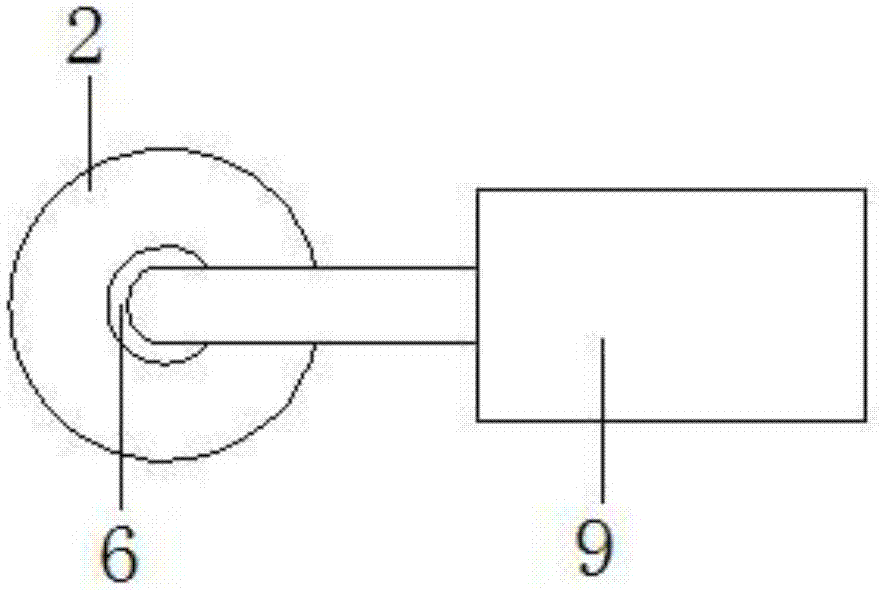

[0028] a. Set at least one heat-resistant film tube on the profiling bead corresponding to the shape of the hockey stick and having a rectangular cross-section, and fix the profiling bead on a fixed structure that can drive the profiling bead to rotate.

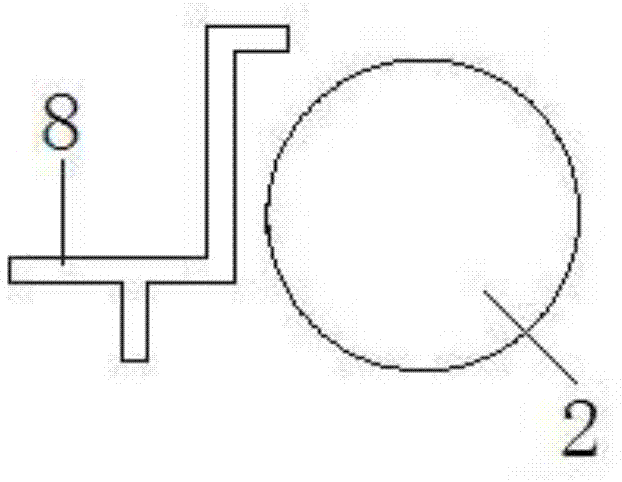

[0029] b. Use a vacuum device to suck out the air between the heat-resistant film tube and the profiling bead, so that the heat-resistant film tube and the profiling bead are tightly attached.

[0030] c. Pre-paste the dipped and viscous yarn material on the heat-resistant film tube outside the profiling bead, and the pre-pasted covering surface is one side of the profiling bead.

[0031] d. Start to rotate the fixed structure, and roll up the yarn material while rotating. During the rolling process, apply pressure to the yarn material to make it fit on the profiling bead layer by layer. The direction of force is oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com