A construction method of reverse prefabricated frame jacking of oil roof on variable slope

A construction method and oil top technology, which is used in the bottom of the road, building and other directions, which can solve problems such as slider destruction, the loss of stability of the power rod, and the destruction of prefabricated frame structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the drawings.

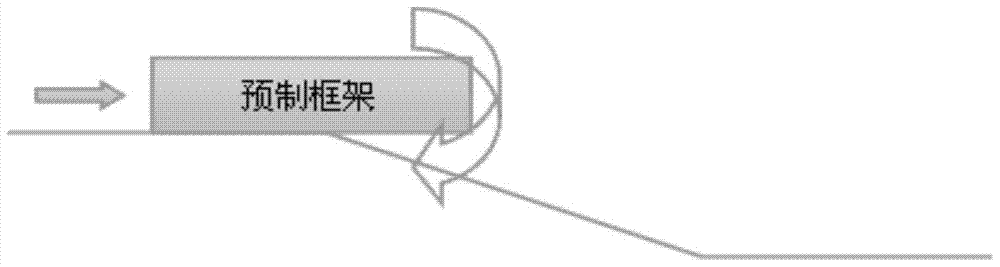

[0048] See Picture 11 , Put the oil top 2 on one end of the prefabricated frame 4, the rear seat of the oil top 2 rests on the prefabricated frame 4, the piston column of the oil top 2 is connected with the force transmission rod 3 to put the force on the back 1, through the oil The roof 2 exerts a pushing force to the back 1, and according to the principle of acting force and reaction force, the oil roof 2 rear seat pushes the prefabricated frame 4 to move forward.

[0049] according to Picture 11 It is shown that the following problems need to be solved in applying the oil top inversion technology on the variable slope slide:

[0050] ① The precast frame 4 has a top stroke of 60m, and the force transmission member 3 is inclined, which may cause the force transmission member 3 to lose stability during the jacking process; the vertical surface of the back 1 is not perpendicular to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com