Method for vulcanizing inflated cover tyre

A technology of heat repair and outer tire, which is applied in the field of tire repair, can solve the problems of complex structure of repair tools, cumbersome repair methods, high repair cost, etc., achieve good repair effect, easy operation, and ensure the effect of repair quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

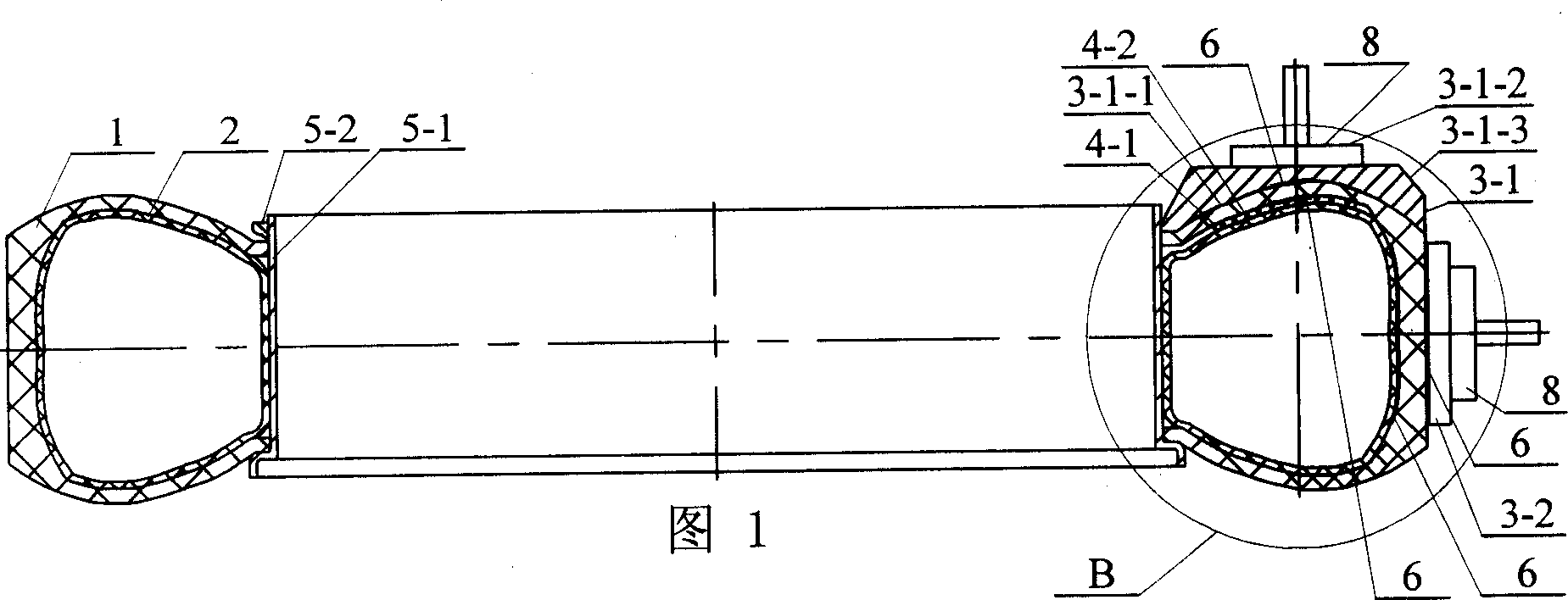

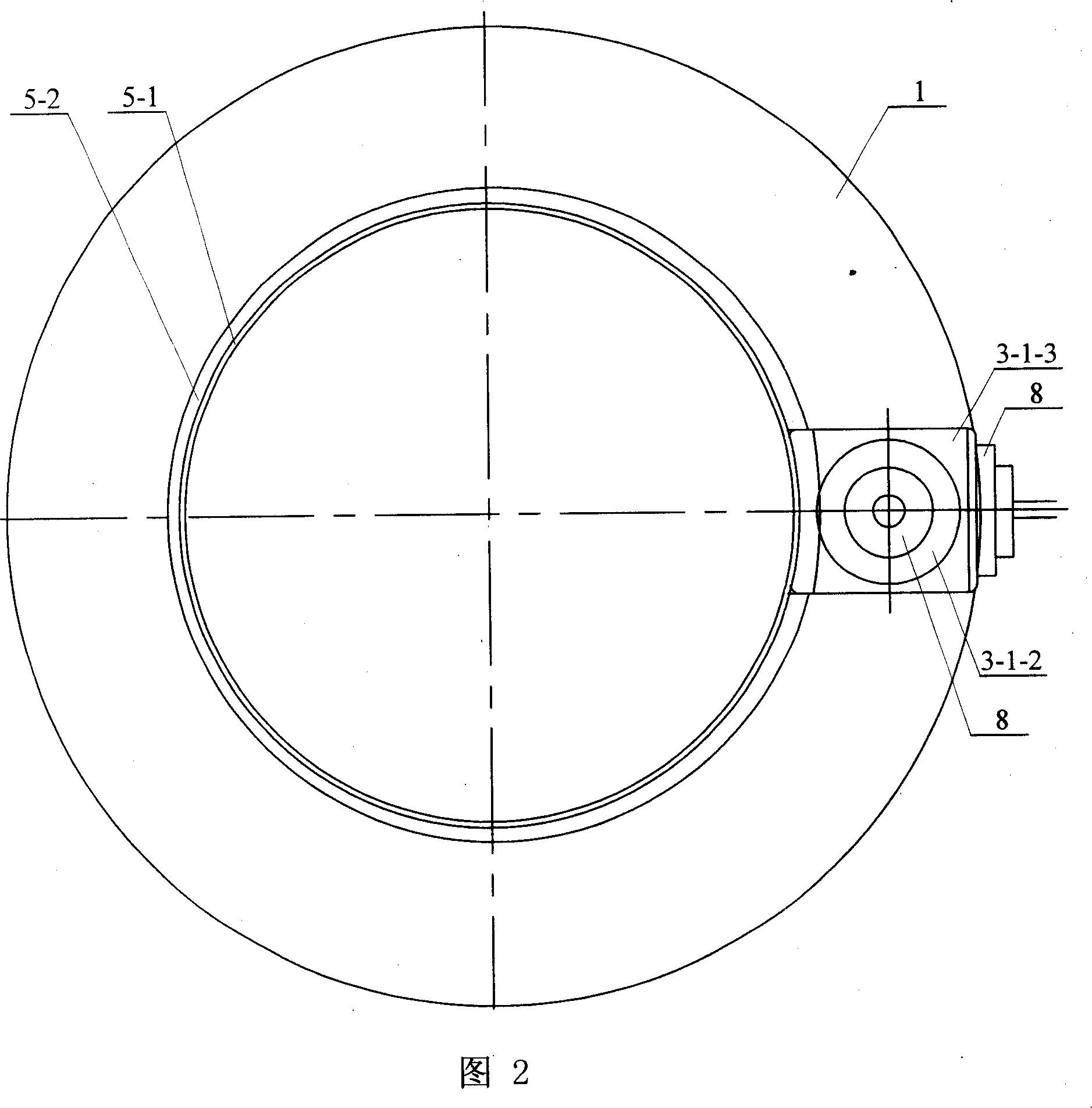

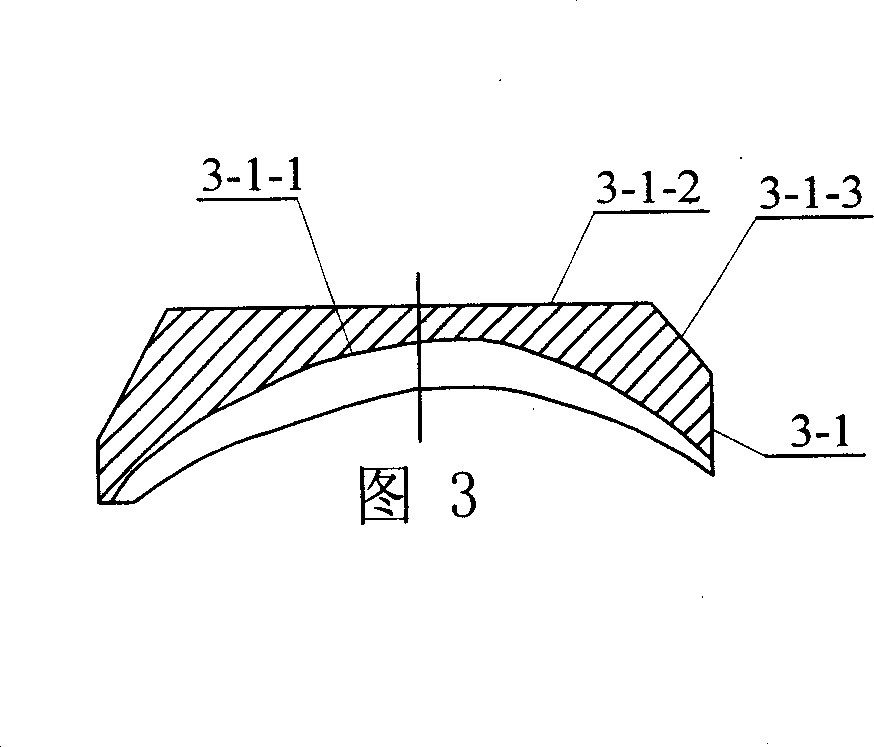

[0007] Specific embodiment one: illustrate this embodiment in conjunction with Fig. 1, Fig. 2 and Fig. 11, the thermal repair method of a kind of inflatable cover tire of this embodiment is finished like this: paste on the inside and outside surface of the inflatable cover tire 1 wound place after polishing Fire mending rubber pad 6, heating band is attached on the inner surface of the corresponding inflatable cover tire 1 of inflatable cover tire 1 wound place, then the inner tube of a tire 2 is loaded on to inflate, makes the inner surface of inner tube of a tube 2 and inflatable cover tire 1 coincide, after that, install Enter the steel basin, place a module whose contact surface matches the outer surface of the pneumatic tire 1 at the wound on the outer surface of the pneumatic tire 1, place the vulcanizer 8 on the module, and inflate the inner tube 2 until the pressure reaches 2.5-6kg / cm 2 , the heating belt is energized for 25-120 minutes, and the temperature of the heati...

specific Embodiment approach 2

[0008] Specific embodiment two: this embodiment is described in conjunction with Fig. 1 and Fig. 2, the difference between this embodiment and specific embodiment one is: in this embodiment, when the inflation pressure of inner tube 2 reaches 4.0~6.0kg / cm 2 , the heating belt is energized for 30-120 minutes, and the temperature of the heating belt reaches 145-150°C. Adopt this technical parameter to be suitable for repairing the air-filled cover tire 1 of medium-sized and large-scale automobile.

specific Embodiment approach 3

[0009] Specific embodiment three: This embodiment is described in conjunction with Fig. 1 and Fig. 2, and the difference between this embodiment and specific embodiment one is: in this embodiment, when the inflation pressure of inner tube 2 reaches 2.5kg / cm 2 , the heating belt is energized for 25-30 minutes, and the temperature of the heating belt reaches 140-145°C. Adopt the air-filled cover tire 1 that this technical parameter is suitable for repairing small car.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com