A composite column of lattice type steel column and reinforced concrete and its construction method

A lattice-type and lattice-type technology, applied in the field of columns of buildings, can solve the problems of insufficient strength, poor fire resistance, and high column cost, achieve small deformation of column top, reduce column self-weight, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

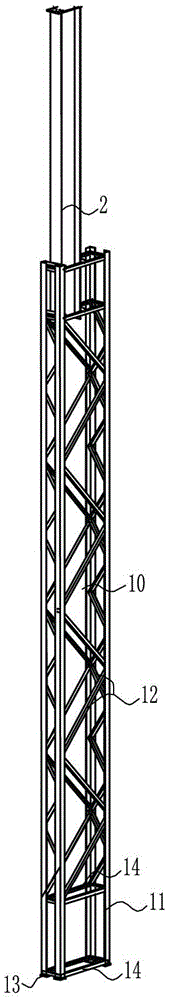

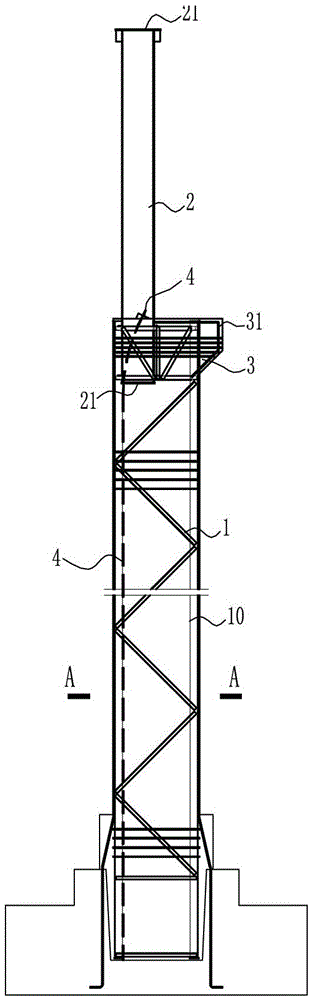

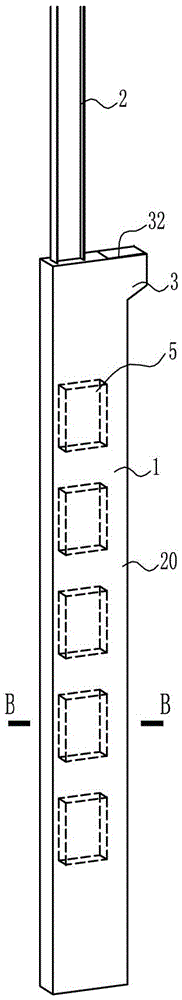

[0036] see Figure 1 to Figure 5 , an embodiment of a lattice type steel column provided in the present invention includes a lattice type lower column 1 and an H steel upper column 2, the lattice type lower column 1 is a rectangular section, and the lattice type lower column 1 It is composed of four angle steel vertical rods 11 and oblique web rods 12 located at the four corners of the rectangular cross section. The lower end of the H steel upper column 2 extends into the latticed lower column 1 for a certain length. The lattice type lower column 1 in the present invention is composed of vertical rods 11 and obliquely distributed web rods 12 connecting the vertical rods 11. This structure is stable, with high rigidity and less steel consumption.

[0037] see Figure 1 to Figure 4 , in the above embodiments of the present invention, the web 12 is located inside the upright 11 and is welded to the upright 11 . The web bar 12 is obliquely connected to the vertical bar 11, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com