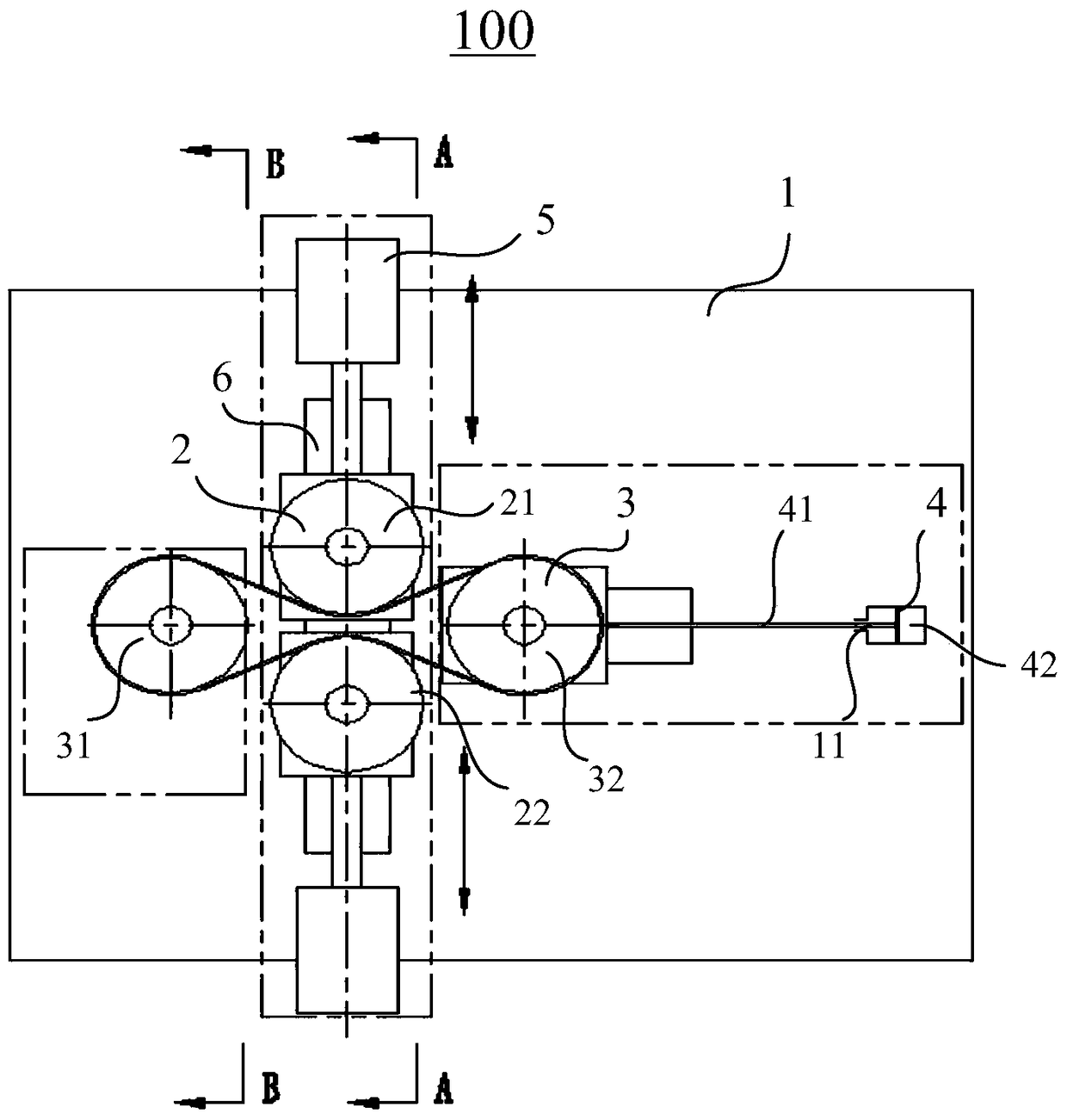

Device and method for detecting mechanical properties of cold-rolled steel strip

A technology of cold-rolled steel strip and detection device, which is applied in the direction of measuring device, using repetitive force/pulse force to test the strength of materials, scientific instruments, etc. Inaccurate strength test and other problems, to achieve the effect of accurate test and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

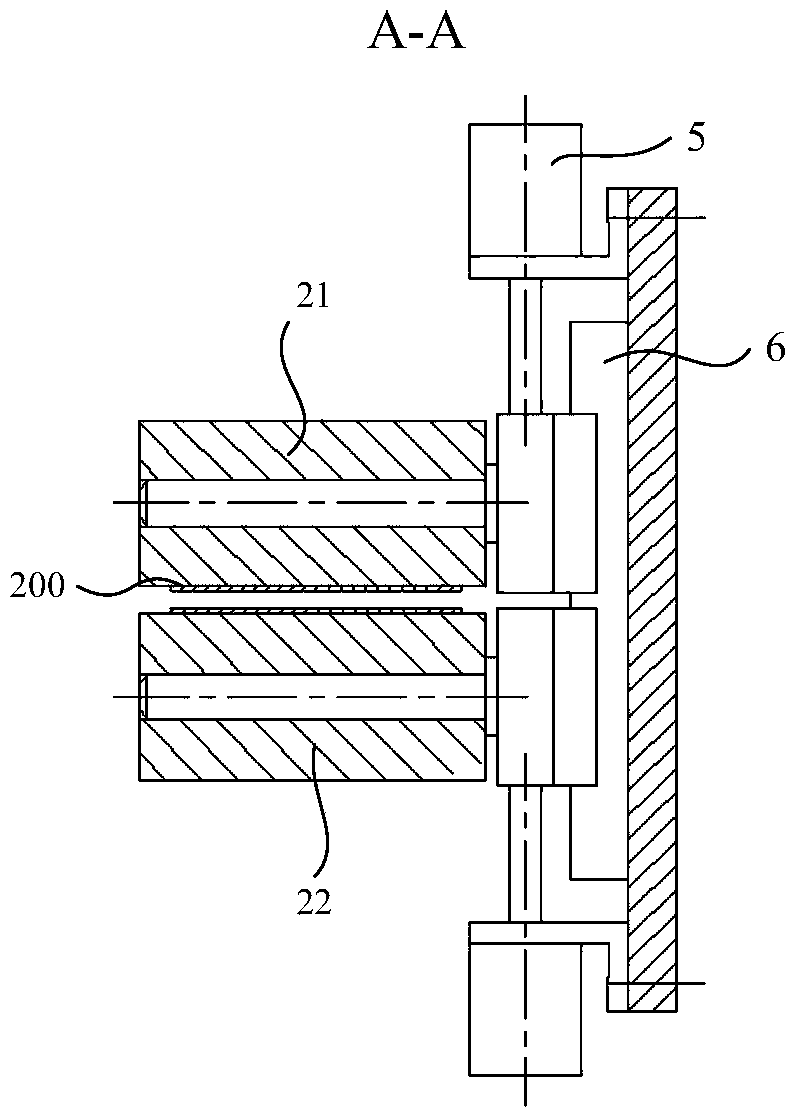

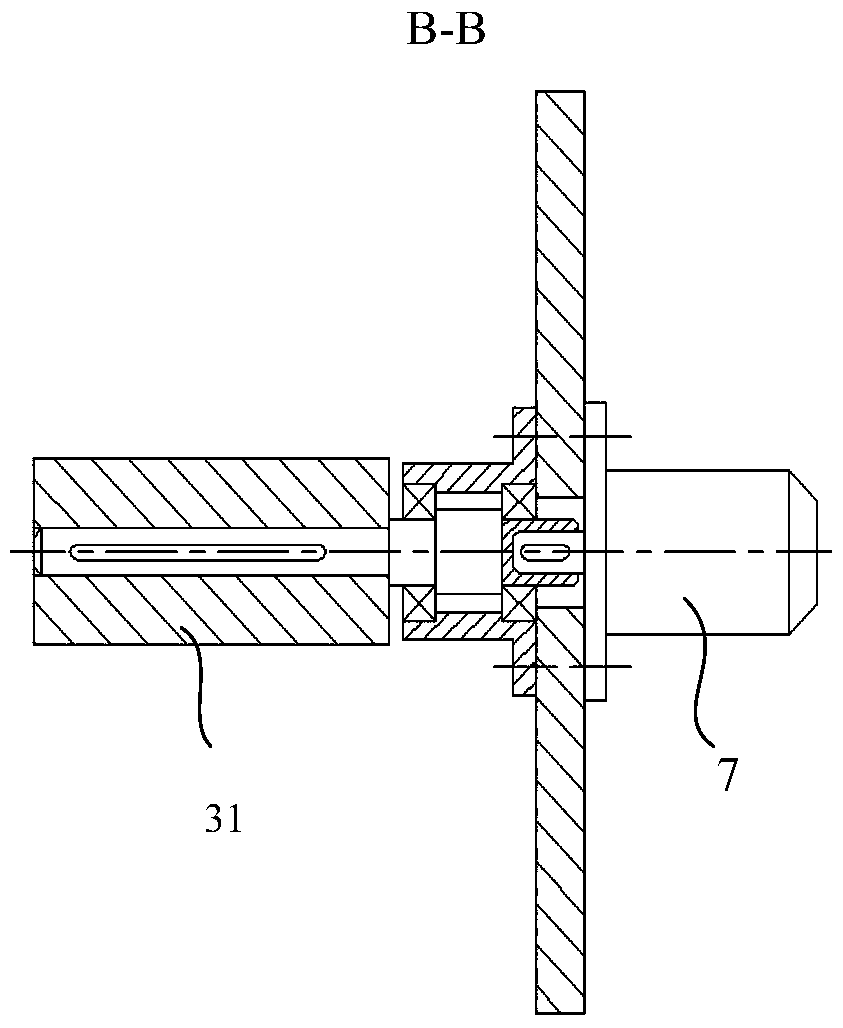

[0041] For a cold-rolling and pickling-rolling online production line in a steel plant, the radius of curvature of the driving roll 31, the bending roll 2, and the driven roll 32 is 100mm, and the tension of the cold-rolled steel strip 200 is 12kg / mm 2 , When the motor 7 rotates 15 times, the welding seam does not produce cracks or fractures, and the mechanical properties of the welding seam are qualified.

Embodiment 2

[0043] For a cold rolling continuous withdrawal production line in a steel plant, the radius of curvature of the driving roll 31, the bending roll 2, and the driven roll 32 is 200mm, and the tension of the cold rolled steel strip 200 is 8kg / mm 2 , When the motor 7 rotates 125 times, the weld does not produce cracks or breaks, and the mechanical properties of the weld are qualified.

Embodiment 3

[0045] For a cold-rolled galvanizing line of a steel plant, the radius of curvature of the driving roll 31, the bending roll 2, and the driven roll 32 is 200mm, and the tension of the cold-rolled steel strip 200 is 6kg / mm 2 , When the motor 7 rotates 72.5 times, the weld does not produce cracks or breaks, and the mechanical properties of the weld are qualified.

[0046] The beneficial effects of this application are as follows:

[0047] In the apparatus and method for detecting mechanical properties of cold-rolled steel strip provided by the present application, the bending roller slides up and down to compress the cold-rolled steel strip so that the outer side of the steel strip receives a compression force; the tension component acts on the driven roller Provide a constant dynamic load so that the tension roller provides the tension of the cold-rolled steel strip, so that the inner side of the cold-rolled steel strip is tensioned; at the same time, the driving roller is driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com