Gantry crane for large special equipment

A special equipment, gantry crane technology, applied in the direction of hoisting equipment braking device, trolley crane, load hanging components, etc., can solve the problems of uneven force, high-altitude falling objects, etc., to achieve the effect of sufficient force and solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

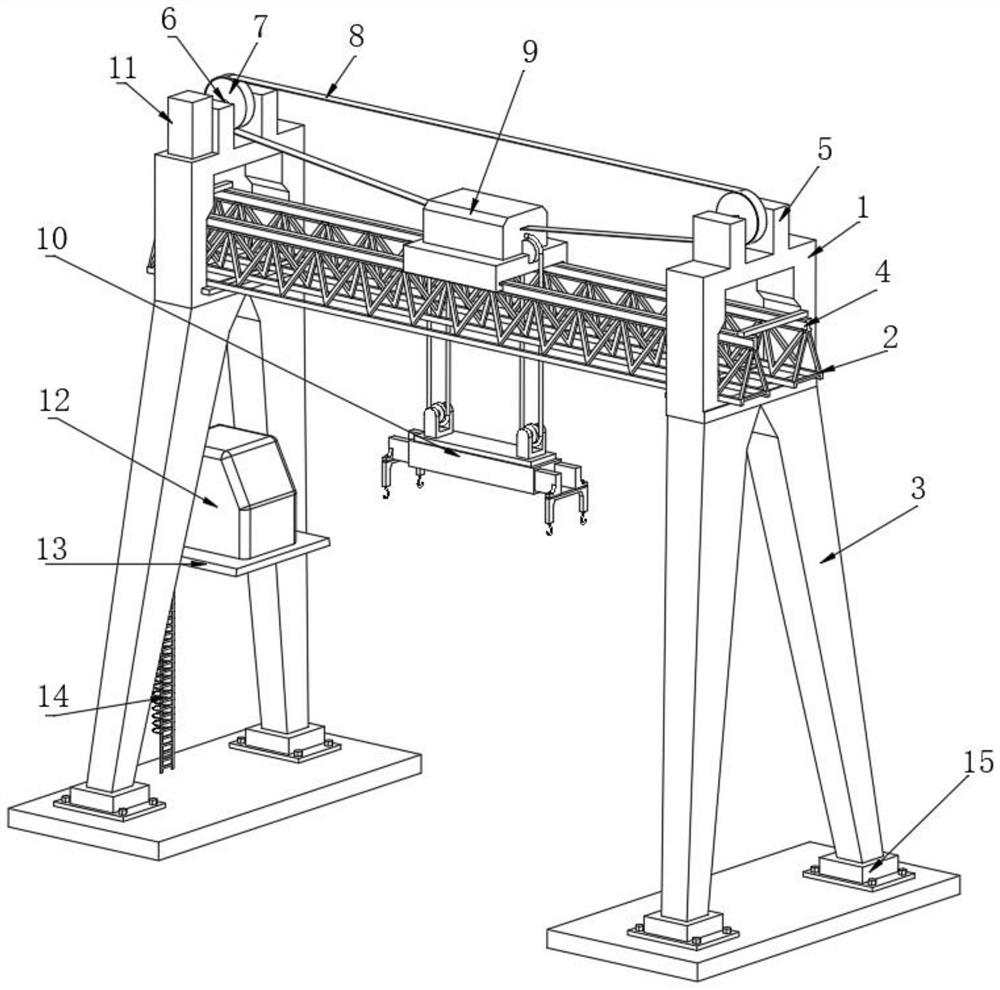

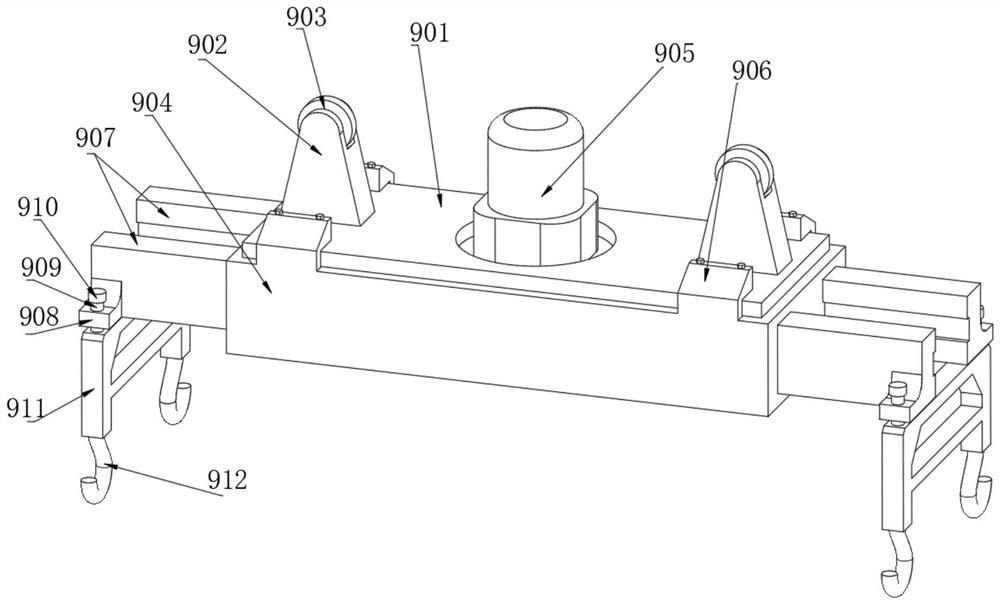

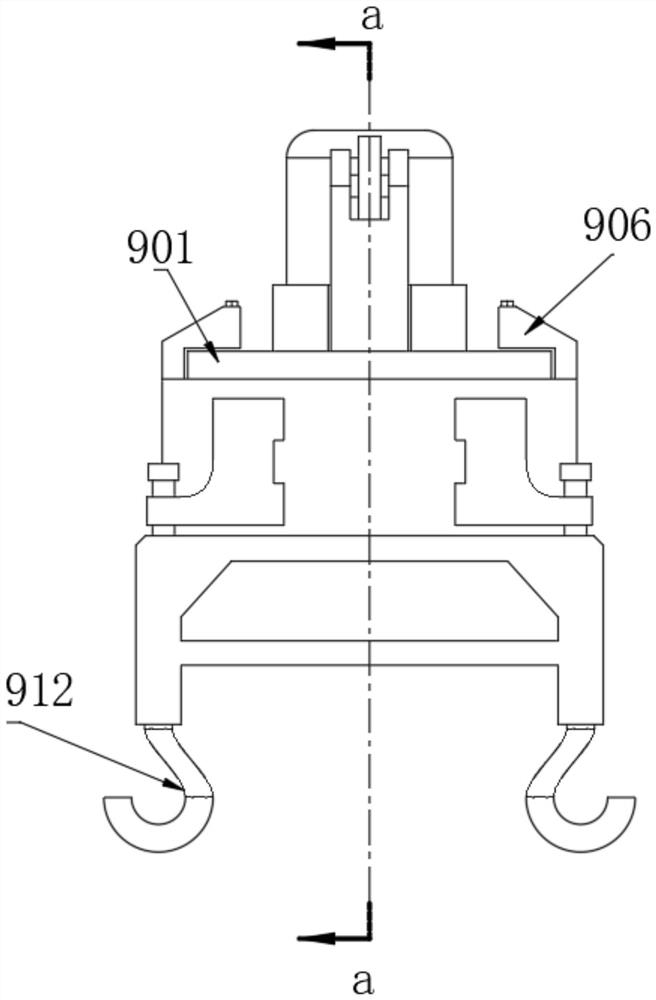

[0029] Such as figure 1 , 2 , 3, 4, 5, and 6, the embodiment of the present invention provides a gantry hammock for large-scale special equipment, including two slide rail fixing frames 1, and two slide rail fixing frames 1 run through two The triangular slide rail trusses 2 arranged in parallel, the upper ends of the two triangular slide rail trusses 2 are integrally fixedly connected with I-beam slide rails 4, and the upper surface of each slide rail fixing frame 1 is integrally fixedly connected with two A traversing turntable fixed table 5, and a traversing turntable 7 is installed between each two said traversing turntable fixed tables 5 through a traversing turntable rotation shaft 6, and a person passes between two said traversing turntables 7 The moving chain belt 8 is rotatably connected, wherein the traversing chain belt 8 is fixedly connected with a lifting assembly 9 for lifting objects, and the lower end of the lifting assembly 9 is movably connected with a claw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com