Load testing device and method of container crane

The technology of a test device and test method is applied in the field of hoisting and hoisting auxiliary devices, which can solve the problems of inability to adjust the position of the lifting point, single use, inconvenient loading and unloading, etc., to save test time, have a wide range of uses, and uniform force reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

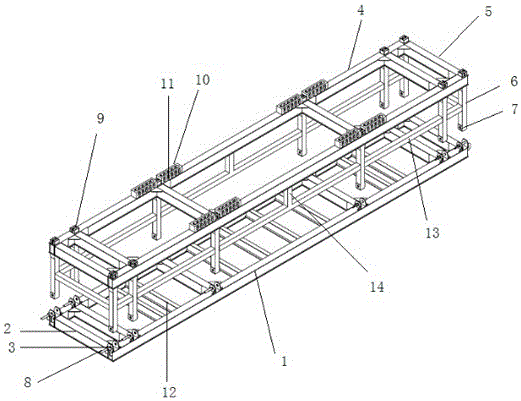

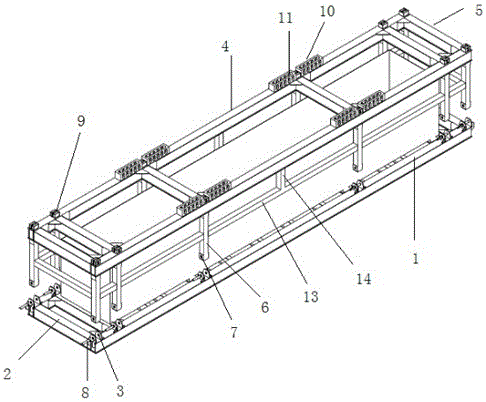

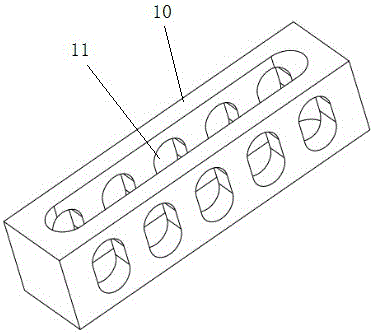

[0038] Such as figure 1 , figure 2 and image 3 As shown, a crane load test device includes a lower hanger and an upper hanger, and the device is divided into upper and lower parts to facilitate loading and unloading. Both the lower hanger and the upper hanger are left-right symmetrical structures, the lower hanger includes two first beams 1 and a plurality of first longitudinal beams 2, the first beams 1 and the first longitudinal beams 2 intersect vertically, the first beams 1 and An annulus 3 is provided at the intersecting position of the first longitudinal beam 2; the upper hanger includes two second cross beams 4 and a plurality of second longitudinal beams 5, the second cross beams 4 and the second longitudinal beams 5 intersect vertically, and the second cross beams 4 and the lower part of the intersection position of the second longitudinal beam 5 are provided with a plurality of uprights 6, and the bottom of the uprights 6 is provided with a fixing hole 7, through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com