Bridge-cutoff self-insulation concrete block and fabrication technology thereof

A concrete block and concrete technology, applied in the field of building materials, can solve problems such as increasing the production cost of self-insulating blocks, affecting the insulation effect of the insulation layer, and weak overall strength of the block, and achieving good insulation performance, increased length, and insulation effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Attached below Figure 1-7 The present invention is further described in detail.

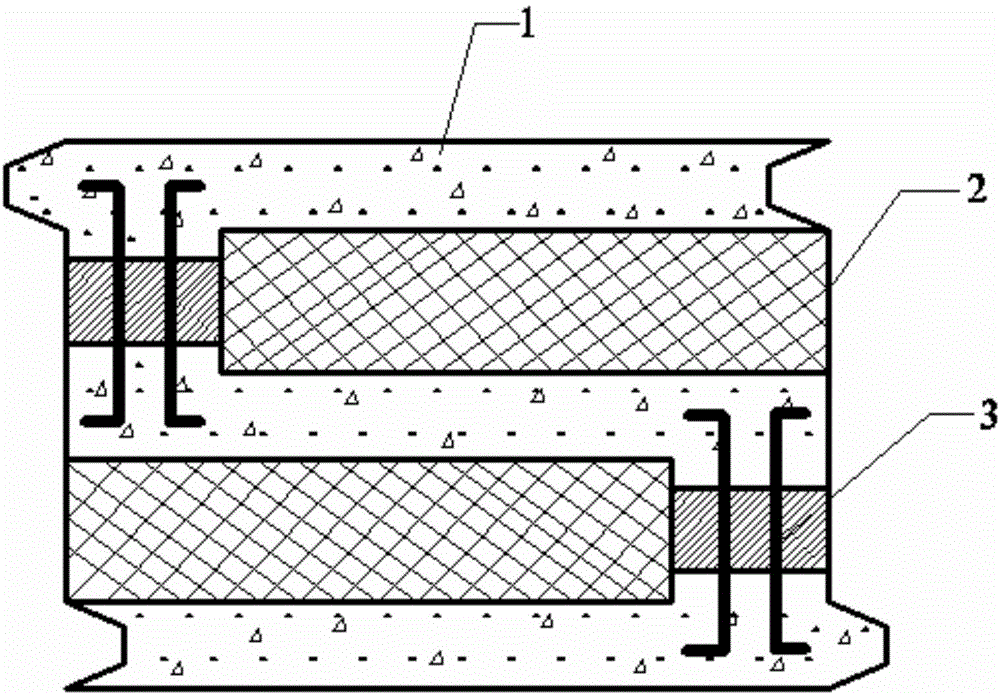

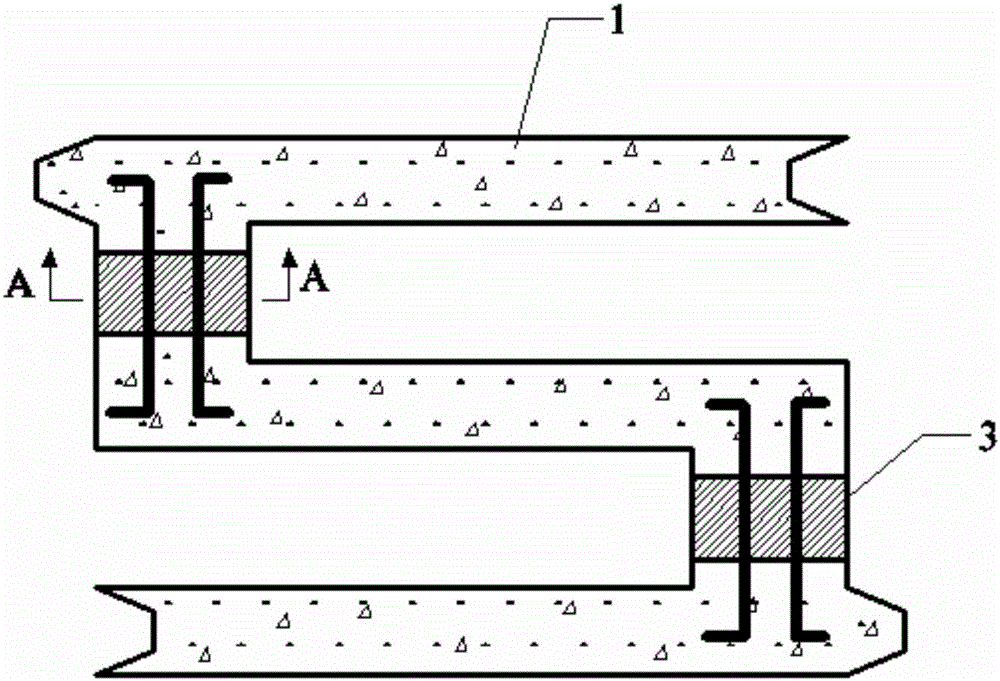

[0034] Such as figure 1 As shown, the broken bridge type self-insulating concrete block provided by the present invention is composed of a broken bridge type concrete hollow block 1 and a polystyrene insulation material 2 . The polystyrene insulation material 2 is located in the two cavities formed by the hollow blocks 1 . The upper left corner and lower right corner of the block are respectively provided with trapezoidal protrusions, and the lower left corner and upper right corner are respectively provided with trapezoidal grooves.

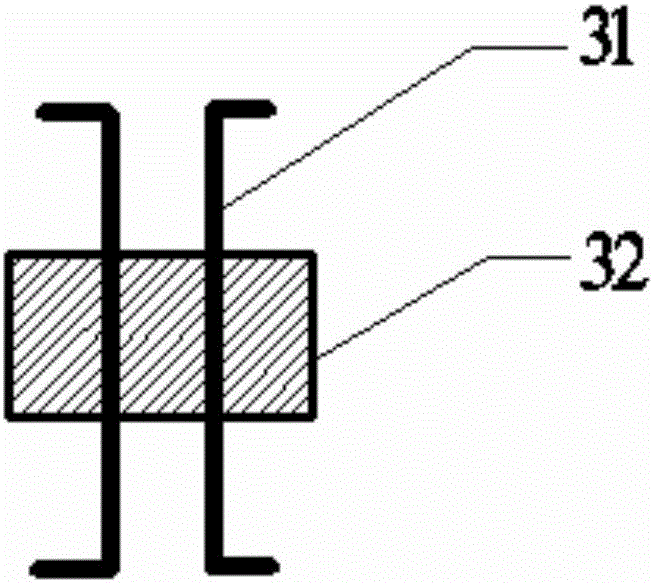

[0035] Such as figure 2 As shown, the bridge-broken concrete hollow block 1 is composed of fine stone concrete and bridge-broken connecting blocks 3 . There are two broken bridge connecting blocks 3, which connect the two ends of the broken concrete respectively, and are located on the concrete path at the left and right ends of the broken bridge concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com