Large-tonnage rotation movement hydraulic machine

A hydraulic press and large-tonnage technology, applied in the field of hydraulic presses, can solve problems such as complex structure of synchronous feeding roller table, difficulty in ensuring horizontal conveying of plates, and limitation of adjustment accuracy, so as to achieve flexible and light rotation, improve processing accuracy and production efficiency, and reduce friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

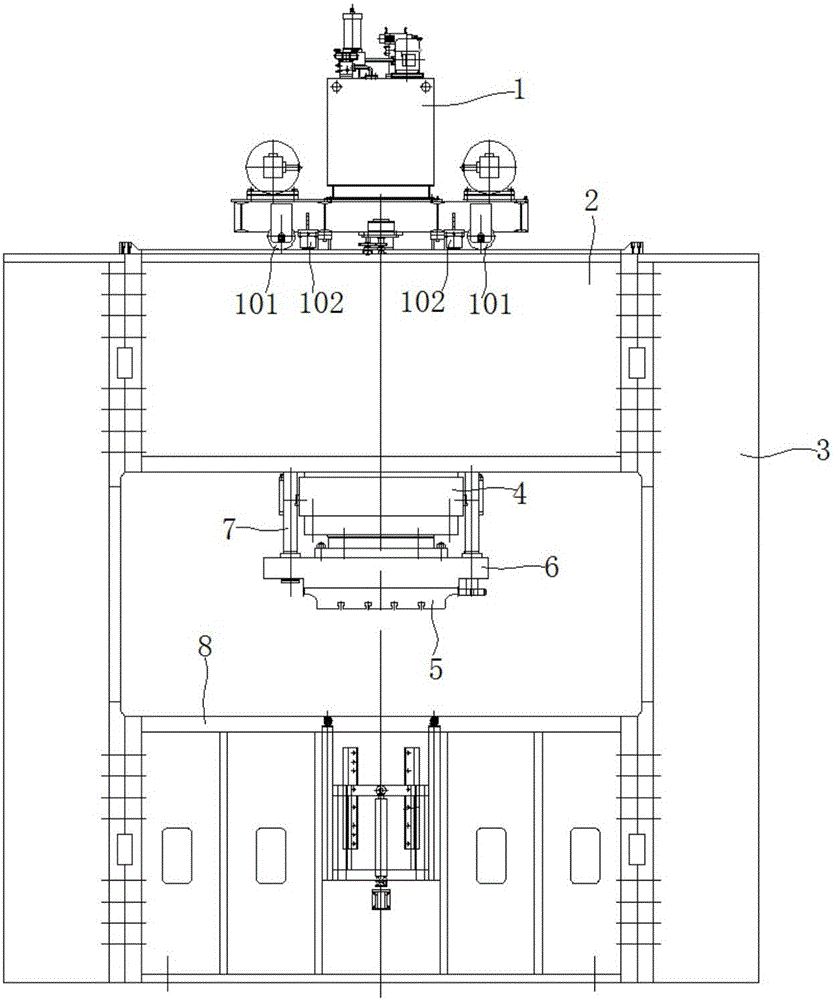

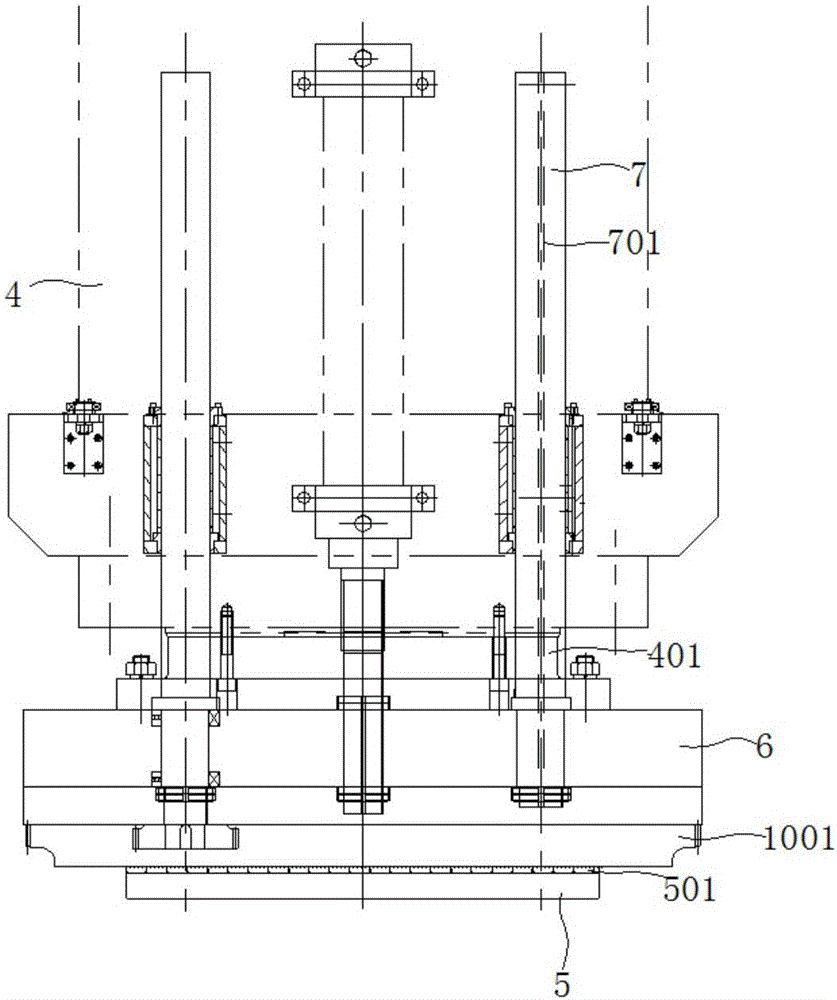

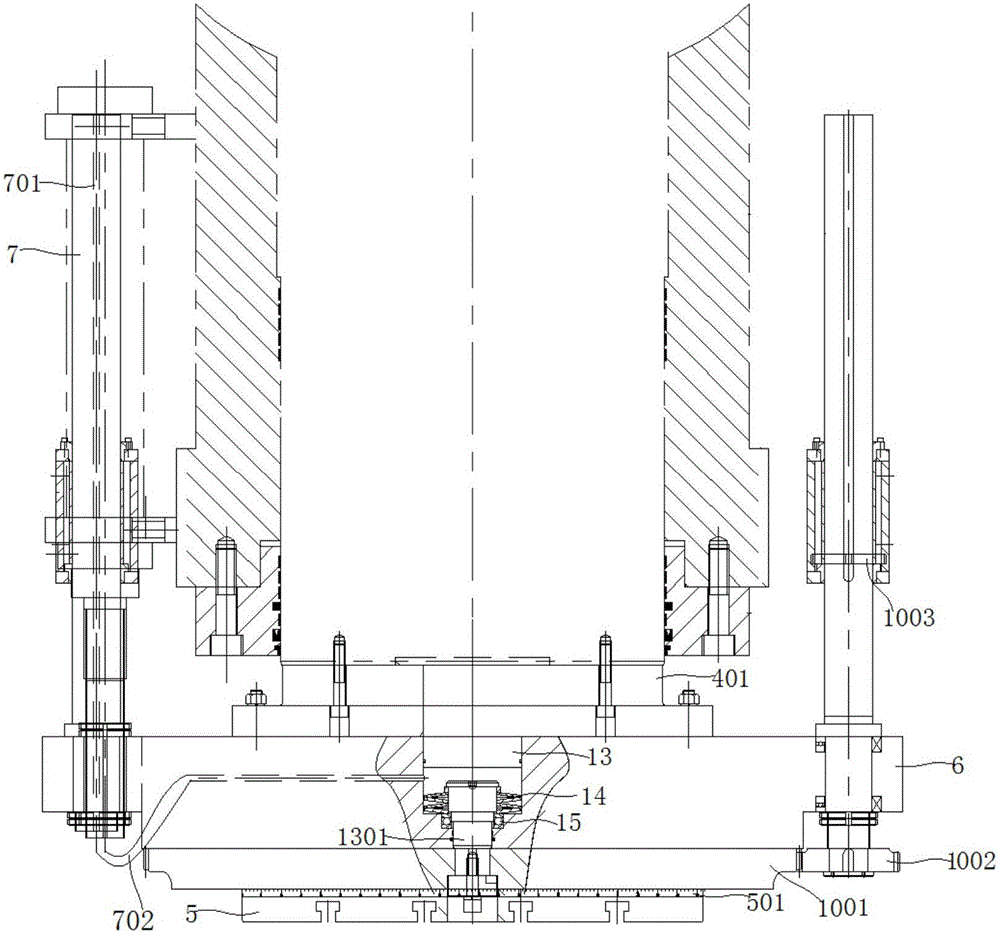

[0045] Such as figure 1 As shown, a large-tonnage rotary mobile hydraulic press of this embodiment includes a hydraulic press frame composed of an upper beam 2, a lower beam, and a column 3, a hydraulic station 1, a pressure head mechanism, and a workbench 8. The hydraulic station 1 is located at On the top of the hydraulic press frame, the pressure head mechanism is hoisted under the hydraulic station 1, and the upper beam 2 and the lower beam are processed into a rectangular box structure. Such as figure 1 As shown, the hydraulic station 1 of this embodiment is fixed on a traveling mechanism, which includes an upper trolley frame. The bottom of the upper trolley frame is provided with traveling rollers 101. The traveling rollers 101 drive the hydraulic station 1 along the rails of the upper beam 2 Move, the limit position on the left and right sides of the upper trolley frame is equipped with limit travel switches, and the bottom of the upper trolley frame is also provided wit...

Embodiment 2

[0055] A large-tonnage rotary mobile hydraulic press of this embodiment includes a hydraulic press frame composed of an upper beam 2, a lower beam and a column 3, a hydraulic station 1, a pressure head mechanism, and a workbench 8. The hydraulic station 1 is located on the hydraulic press frame At the top, the pressure head mechanism is hoisted under the hydraulic station 1, and the upper beam 2 and the lower beam are processed into a rectangular box structure. Such as figure 1 As shown, the hydraulic station 1 of this embodiment is fixed on a traveling mechanism, which includes an upper trolley frame. The bottom of the upper trolley frame is provided with traveling rollers 101. The traveling rollers 101 drive the hydraulic station 1 along the rails of the upper beam 2 Move, the limit position on the left and right sides of the upper trolley frame is equipped with limit travel switches, and the bottom of the upper trolley frame is also provided with upper trolley locking cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com