Accumulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

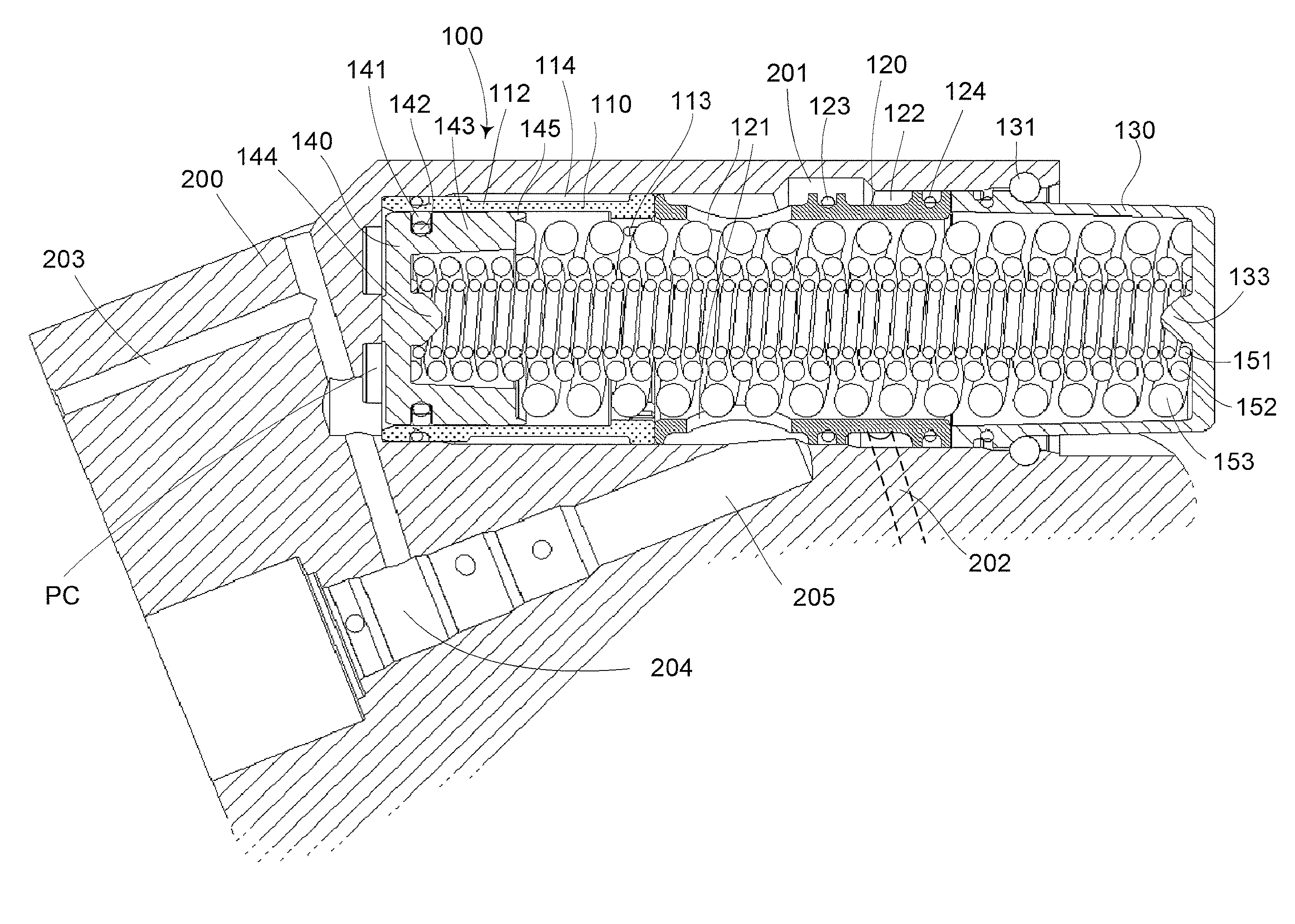

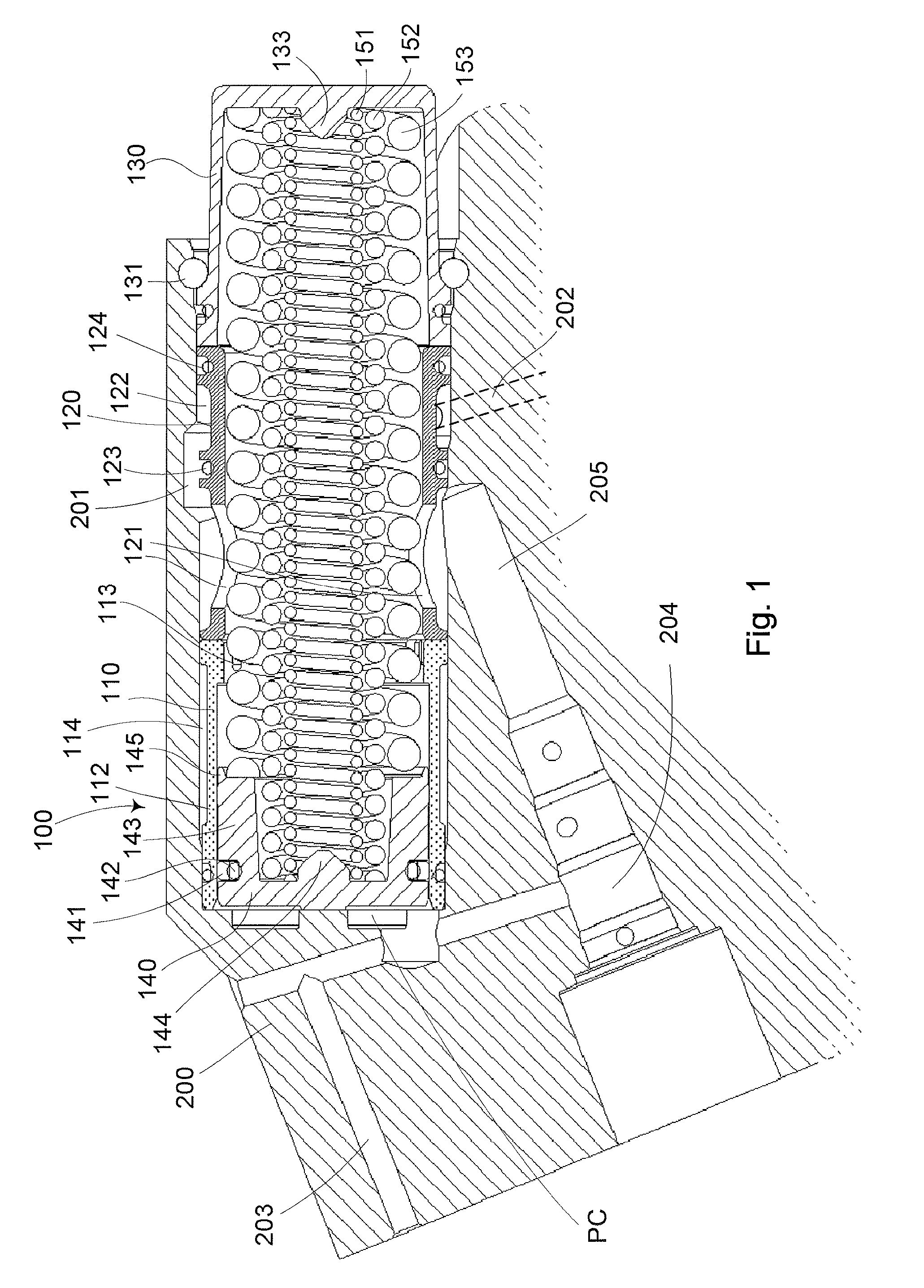

[0012]Below, several embodiments of the invention will be described with references to the drawings. These embodiments are described for illustrative purposes only, in order to enable a skilled person to carry out the invention and to disclose the best mode. However, such embodiments do not limit the invention. Moreover, other combinations of the different features are possible within the scope of the invention.

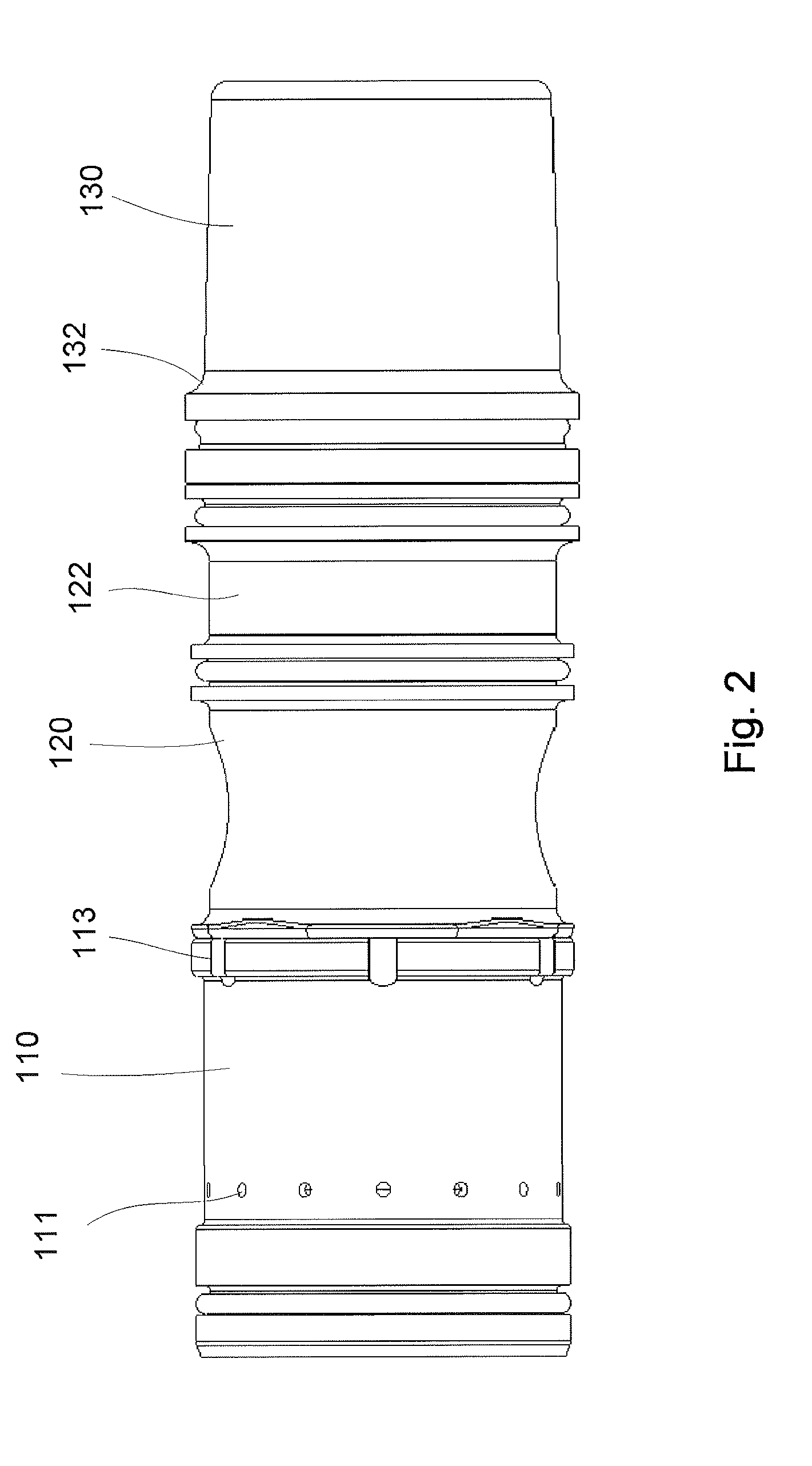

[0013]An accumulator 100 according to an embodiment of the present invention is shown in a sectional view in FIG. 1, mounted in a housing 200. The accumulator 100 includes, in the shown embodiment, a body comprising three parts, namely a liner 110, a spacer 120 and a lid 130, all being substantially cylindrical having a substantially circular cross-section. The liner 110 cooperates with a piston 140, which is adapted for reciprocating movement within the liner 110.

[0014]The liner 110 is formed with one or several outlet ports 111, see FIG. 2, which are located in a sidewall 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com