Runner for francis type hydraulic turbine

a technology of hydraulic turbines and runners, applied in the field of hydraulic turbine runners, can solve the problems of increasing the cost of the manufacture of runners, and reducing the static and dynamic stress concentration of runners, so as to reduce the cost of manufacture, reduce the volume of blades, and reduce the effect of static and dynamic stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention relates to hydraulic machines and in particular to improvements in runners for Francis-type machines.

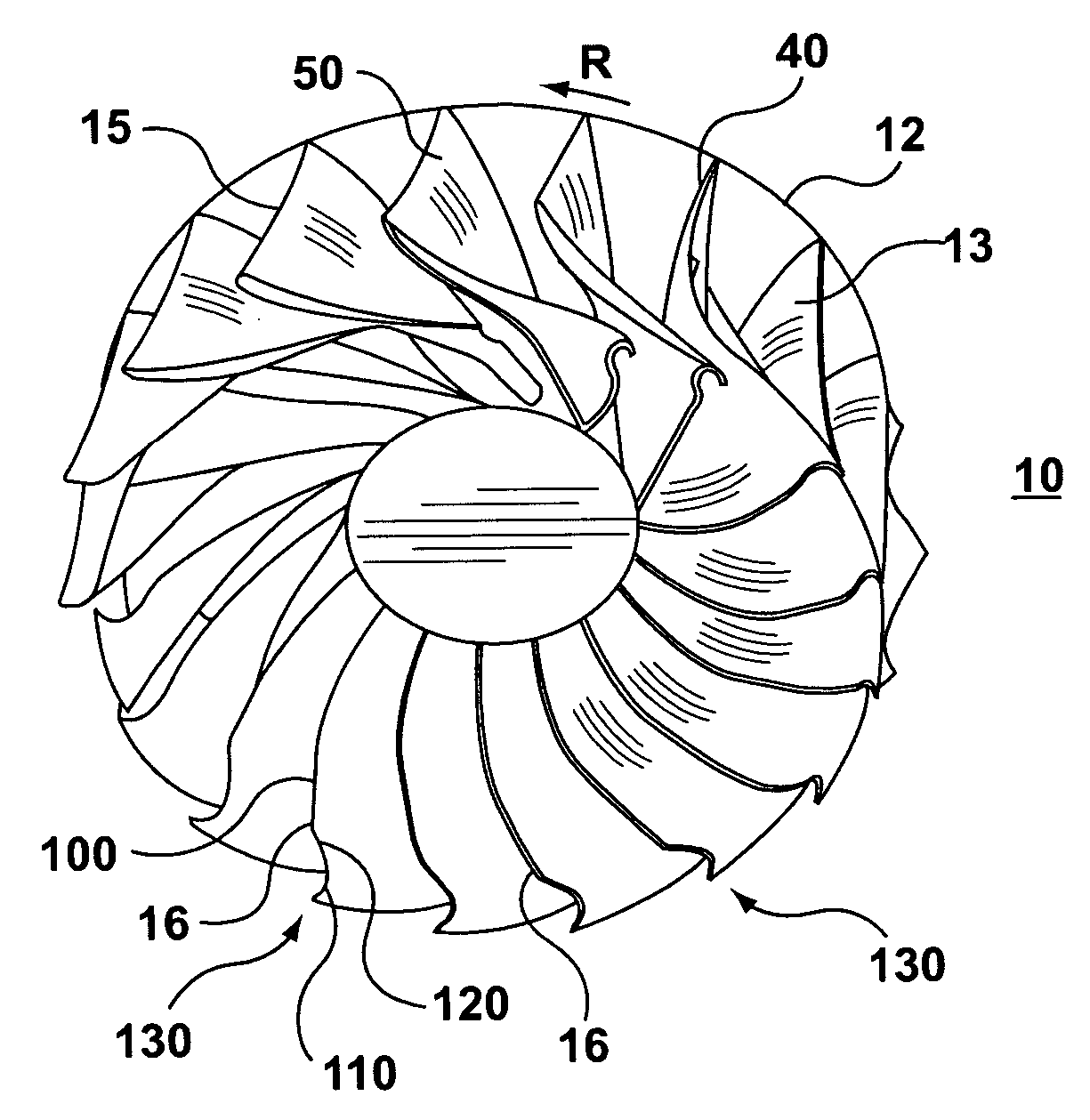

[0020]FIG. 1 schematically shows a known prior art runner 10 having a band or ring 11 and a hub or crown 12 to which the blades 13 are attached in a usual manner. The runner 10 rotates in the direction of arrow R such that each blade 13 defines a suction surface 40 leading in the direction of rotation and a pressure surface 50 trailing in the direction of rotation. It should be noted that in the blade configuration of FIG. 1, each of the blades 13 has a corner 60 adjacent where the outlet edge 16 of the blade 13 is attached or joined to the band 11. It is this corner 60, of about 90 degrees in FIG. 1, that blade 13 is subject to the static and dynamic stress concentrations mentioned above.

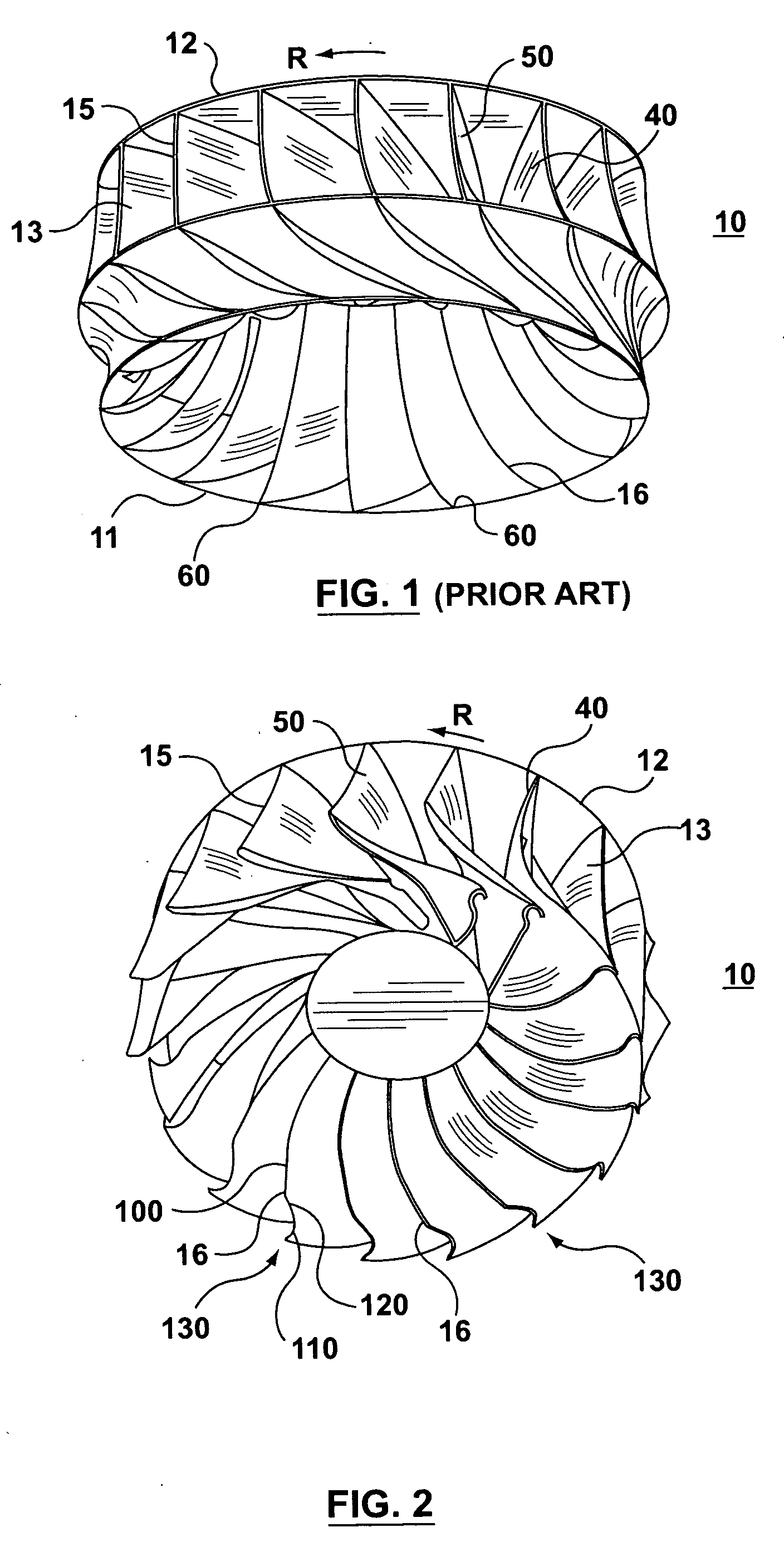

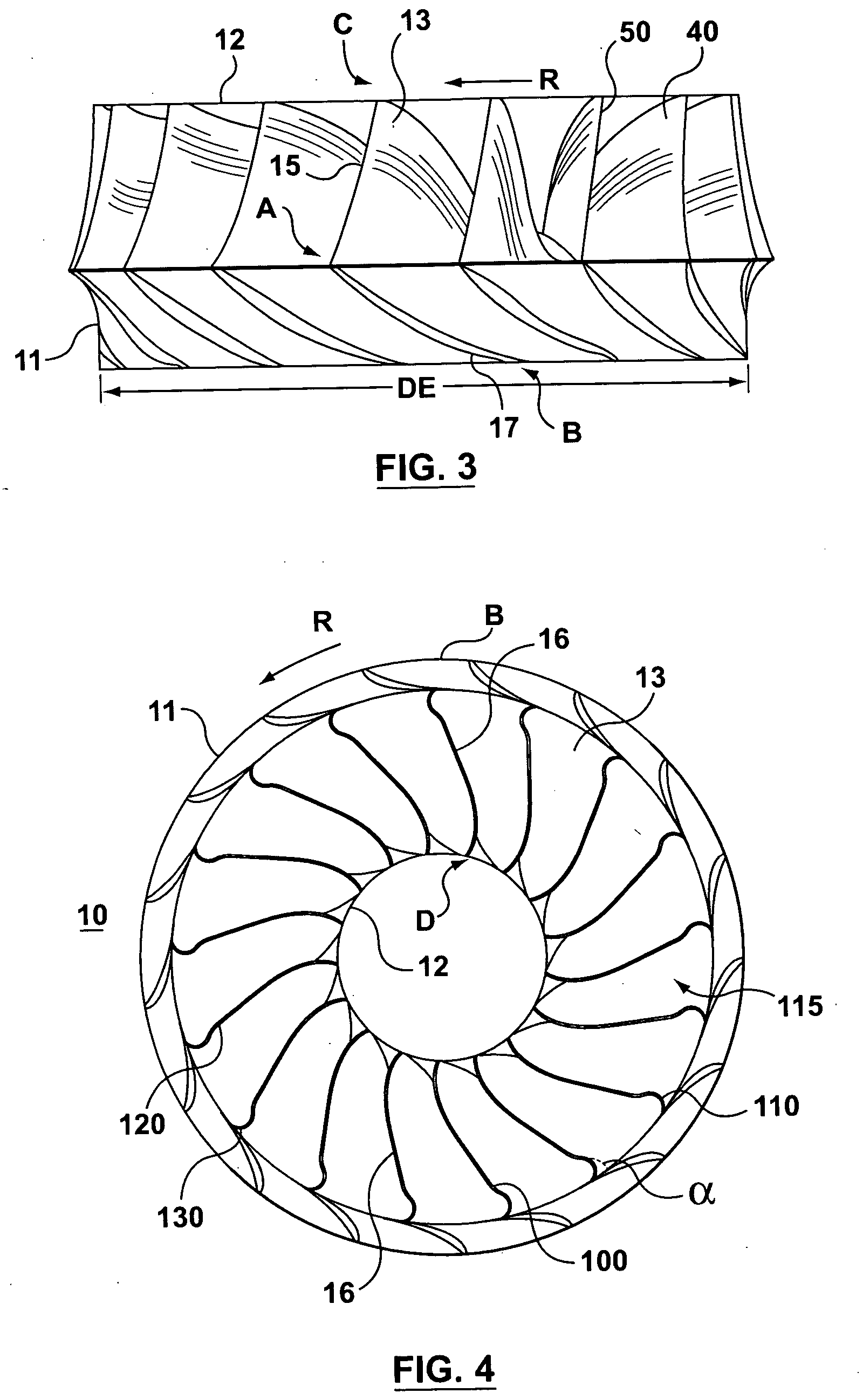

[0021] Referring to FIGS. 2 to 4, the runner 10, according to the invention is also shown with a crown 12. For clarity the actual surrounding ring or band has been omi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com