Device for depositing individual printed products, supplied in succession, in shingle formation

a technology for printing products and shingle formation, which is applied in the direction of thin material processing, function indicators, articles, etc., can solve the problems of short drop time and no longer produced faulty shingle formation, and achieve high processing speed, reliable and flawless depositing of thicker and/or less flexible printed products, the effect of small format length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

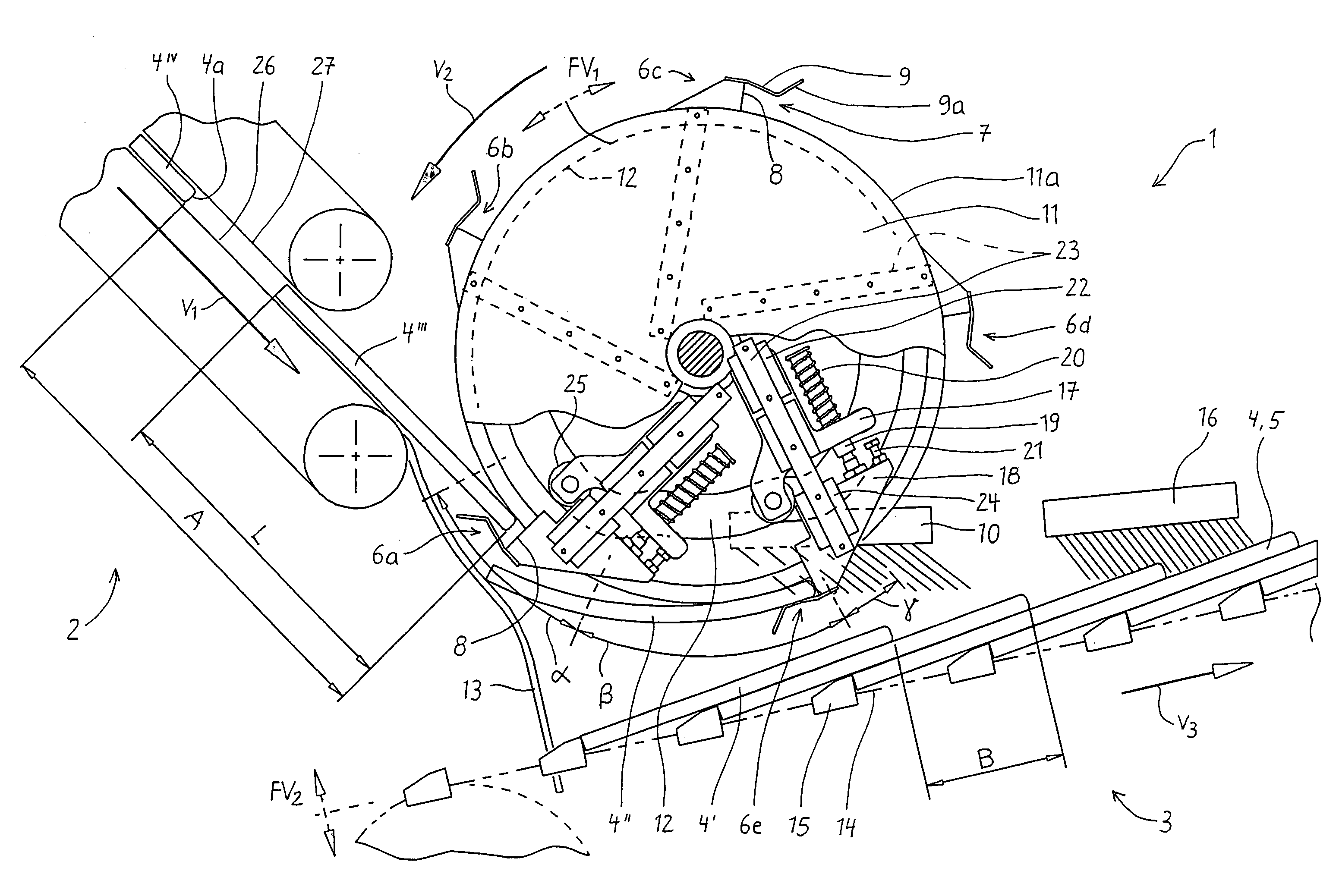

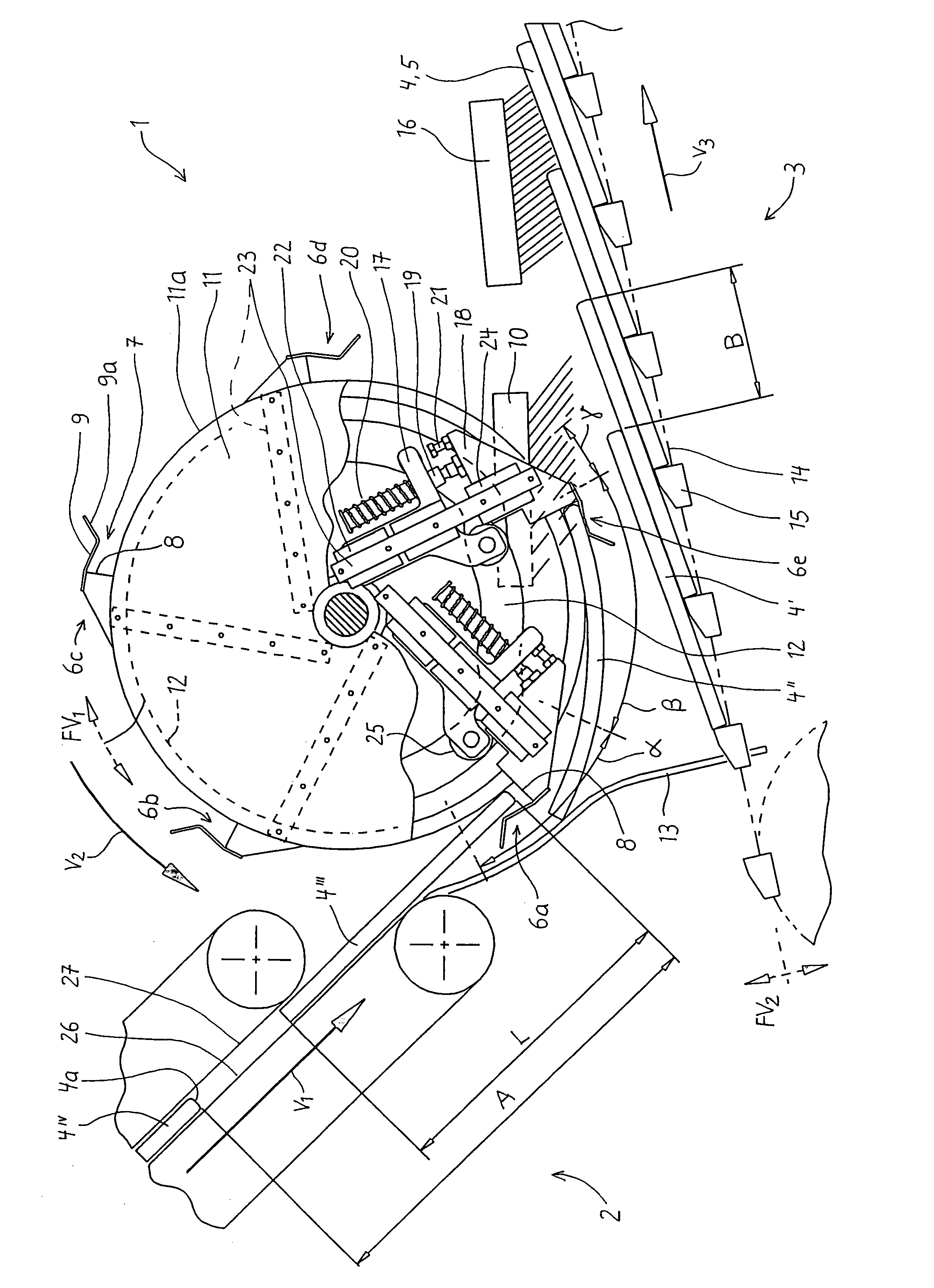

[0012]The FIGURE shows a partially schematic side view of a stream feeder 1 for depositing individual brochures 4 (4I, 4II, 4III, 4IV), supplied in succession by means of a feed conveyor 2, on a downstream conveyor 3 with a slower transport speed v3 in shingle formation 5. The brochures 4 have a format length L and are successively transported obliquely downward with a feed speed v1 by the feed conveyor 2 that clamps the brochures 4 between conveyor belts 26, 27 such that they are spaced apart from one another by a distance A, wherein the brochures are then fed to the stream feeder 1 with their spine 4a pointing forward. The bottom conveyor belt 26 extends slightly farther than the upper conveyor belt 27 such that the brochures 4 are provided with a supporting surface.

[0013]The stream feeder 1 features a plurality of rotating grippers 6a to 6e that are continuously driven in a rotative fashion with a constant gripper speed v2. The grippers 6a to 6e are respectively realized in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| feed speed | aaaaa | aaaaa |

| transport speed | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com