Device and method for conveying a spring serpentine

A technology of spring string and transmission direction, applied in the direction of transportation and packaging, application, household appliances, etc., can solve the problems of different spring core sizes, undesired deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

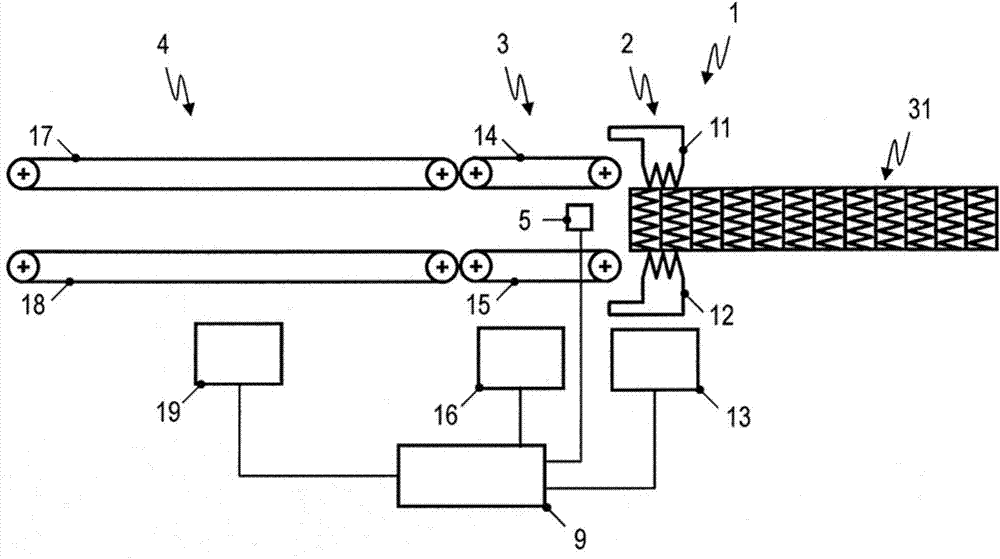

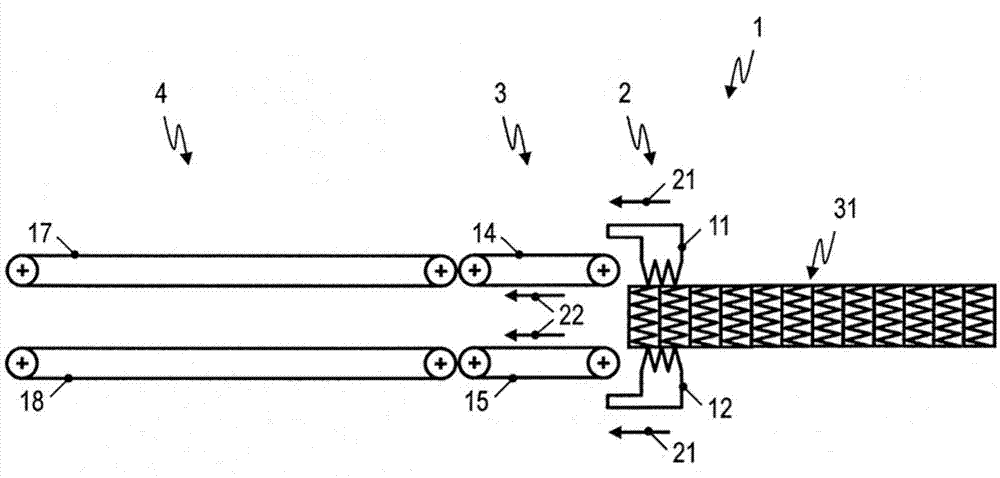

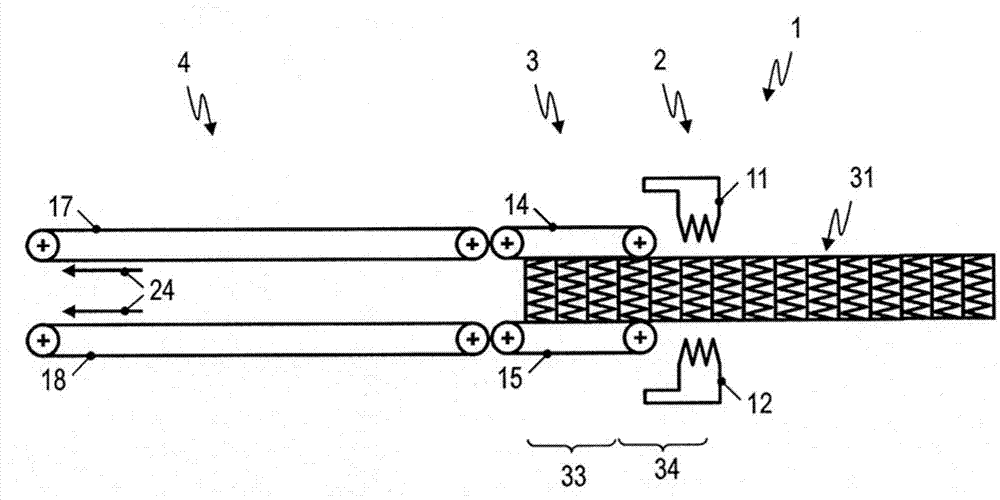

[0057] Exemplary embodiments of the present invention are described in more detail below. Features of various exemplary embodiments may be combined with each other unless this is explicitly excluded in the following description. Even if a single exemplary embodiment is described with respect to a particular application, for example in the context of an installation for supplying a continuous string of pocket springs, the invention is not limited to these applications.

[0058] In the case of the device according to the exemplary embodiment, the interconnected pocket springs of the spring string are transported in the transport direction. The transport direction can but need not be the same throughout the facility. In traditional plant engineering terms, expressions such as "arranged upstream in the direction of transport of" or "arranged downstream of" are understood to mean that the transported pocket spring passes through the corresponding element either upstream or downstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com