Bulb with clamping-connection structure and special non-contact dismounting and mounting tool of bulb

A light bulb and tool technology, which is applied in the field of non-contact disassembly and assembly tools, can solve the problems of low disassembly and assembly efficiency, inconvenient operation, hidden dangers of high-altitude operation, etc., and achieves the effect of safe and convenient replacement, avoiding damage, and preventing electric shock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

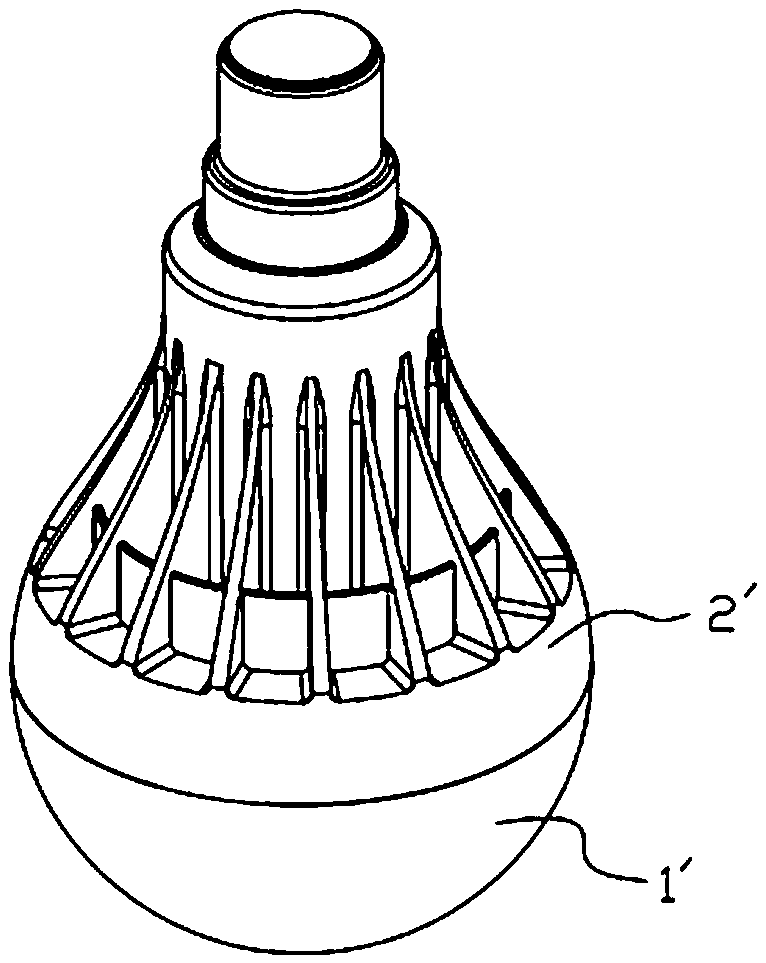

[0035] Such as Figure 5 As shown, it is a second embodiment of a light bulb with a snap-fit structure, which includes a light bulb body 1, and the outer contour of the light bulb body 1 is directly elliptical.

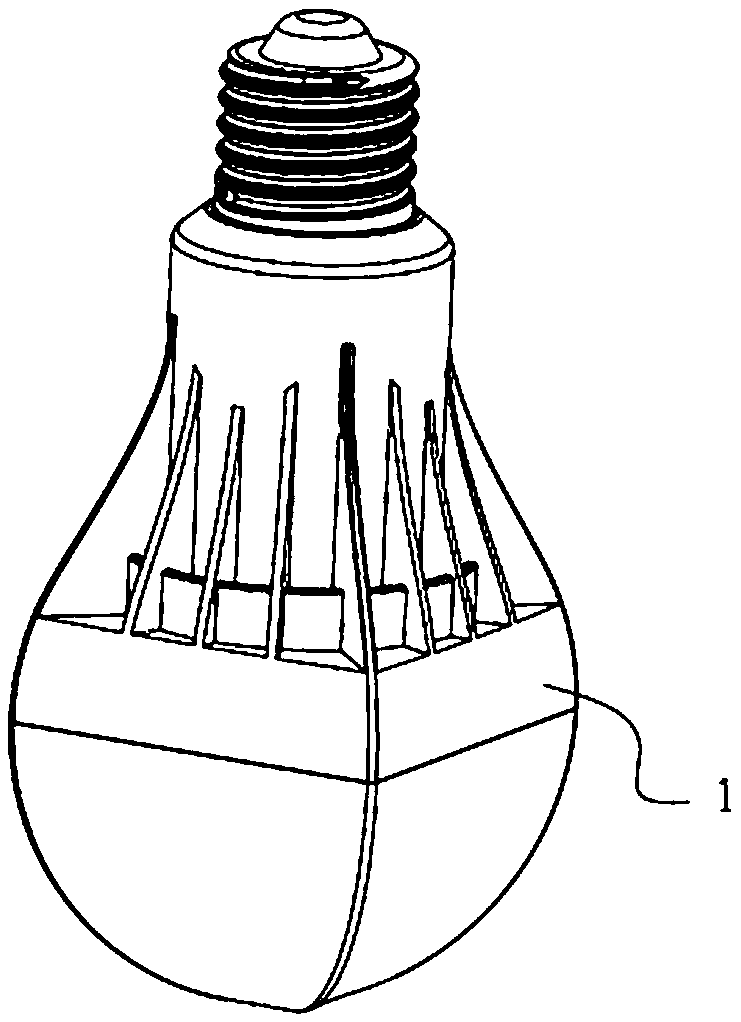

[0036] Such as Figure 6 As shown, it is a third embodiment of a light bulb with a locking structure, which includes a light bulb body 1, and a polygonal locking protrusion 11 is arranged on the light bulb body 1. In practice, the locking protrusion 11 can also be Set into an oval. In this illustration, the engaging protrusion 11 is arranged on the periphery of the bulb body 1. In practice, the engaging protrusion can also be arranged on the top of the bulb body. Its structure is as follows: Figure 7 shown.

[0037] The engaging protrusion 11 is integrally formed with the bulb body 1 or connected separately.

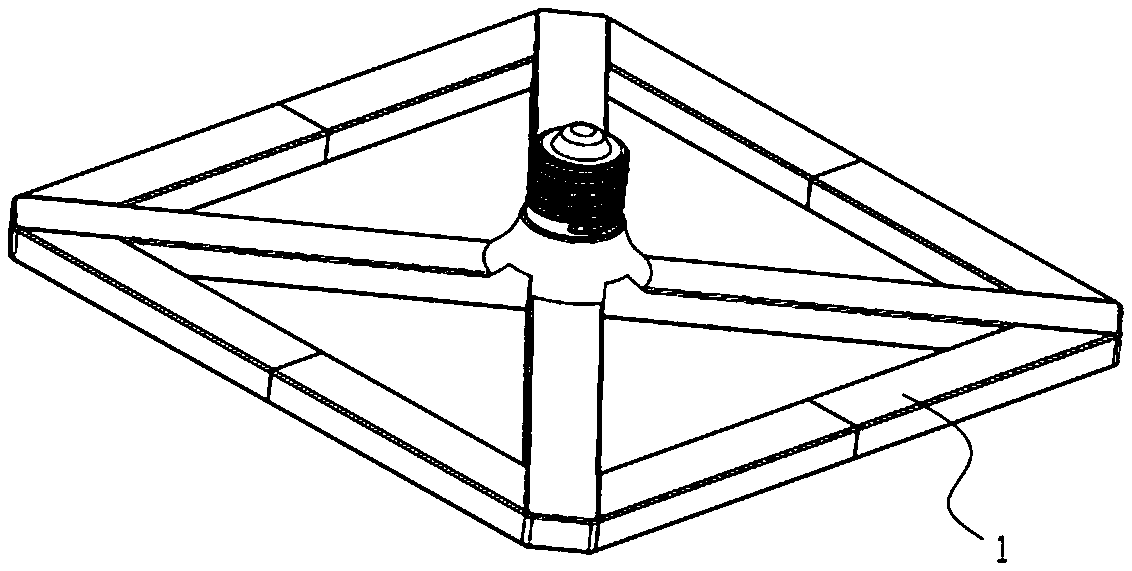

[0038] Such as Figure 8 As shown, it is a special dismounting tool for the light bulb, which includes a connecting sleeve 2, and an engaging groove 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com