Automatic material loading and unloading mechanical arm

An automatic loading and unloading, manipulator technology, applied in the field of manipulators, can solve problems such as low efficiency, inability to quickly clamp and transport large quantities of workpieces, and achieve the effects of fast loading and unloading, reducing manual operations, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

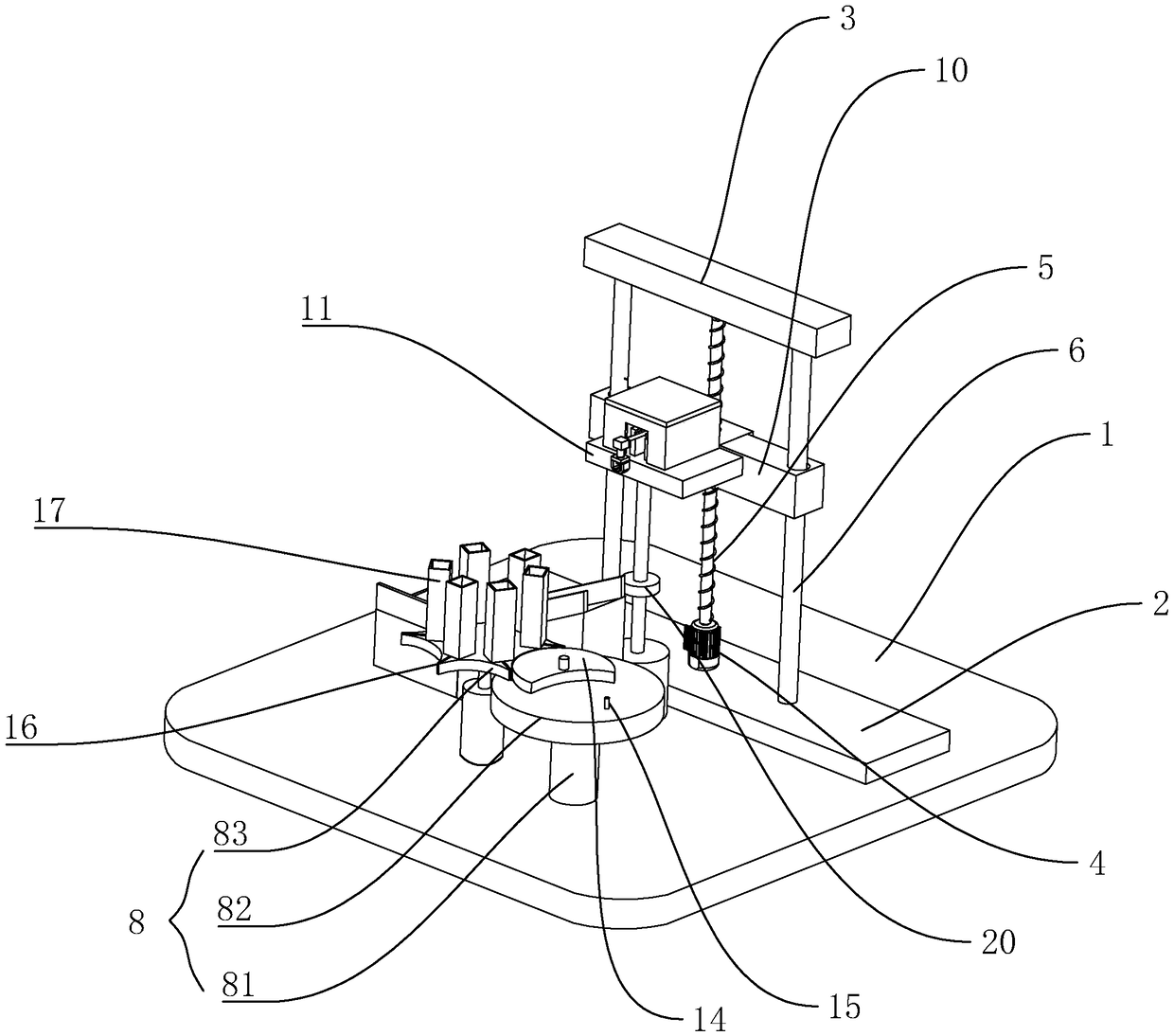

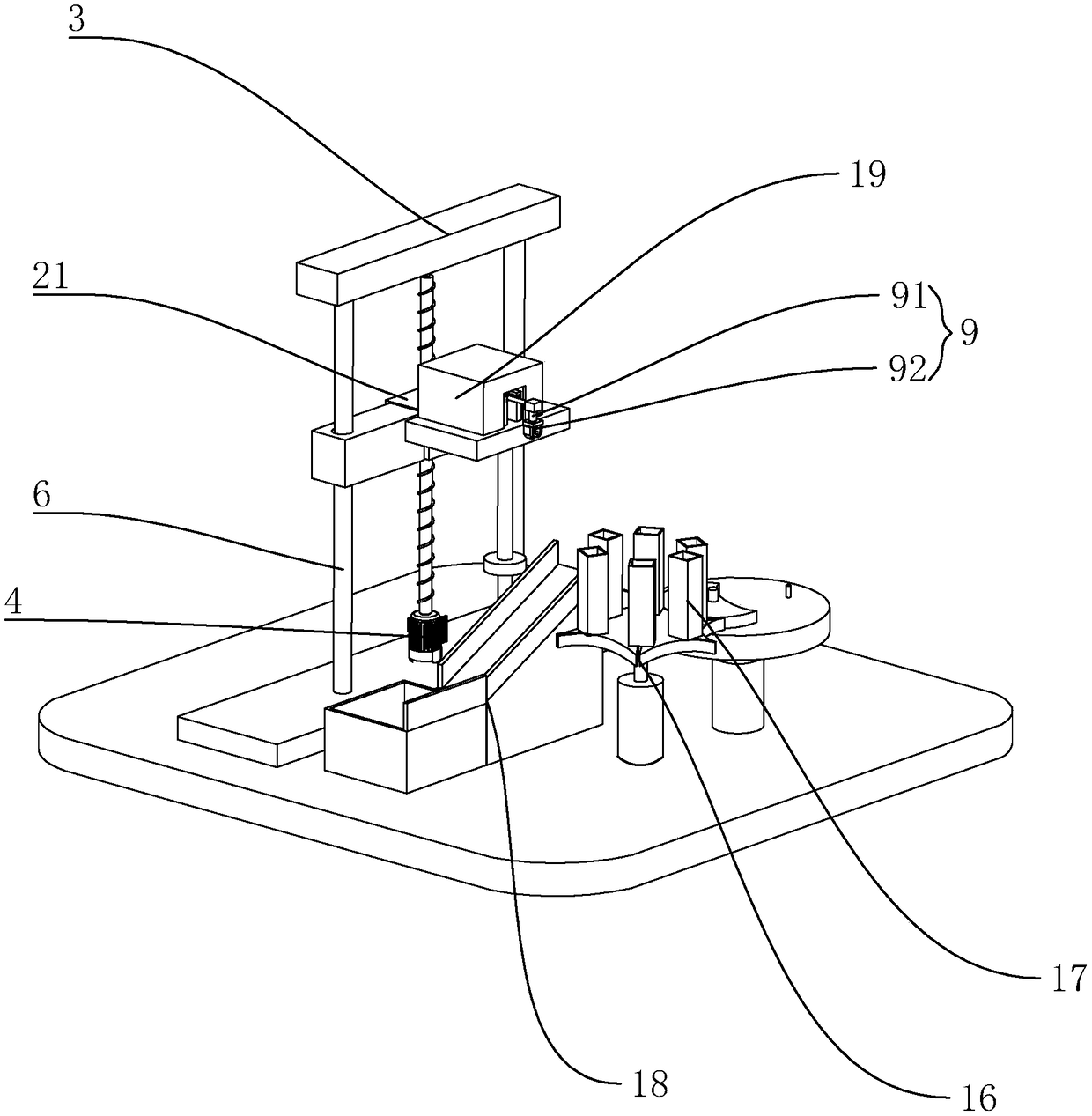

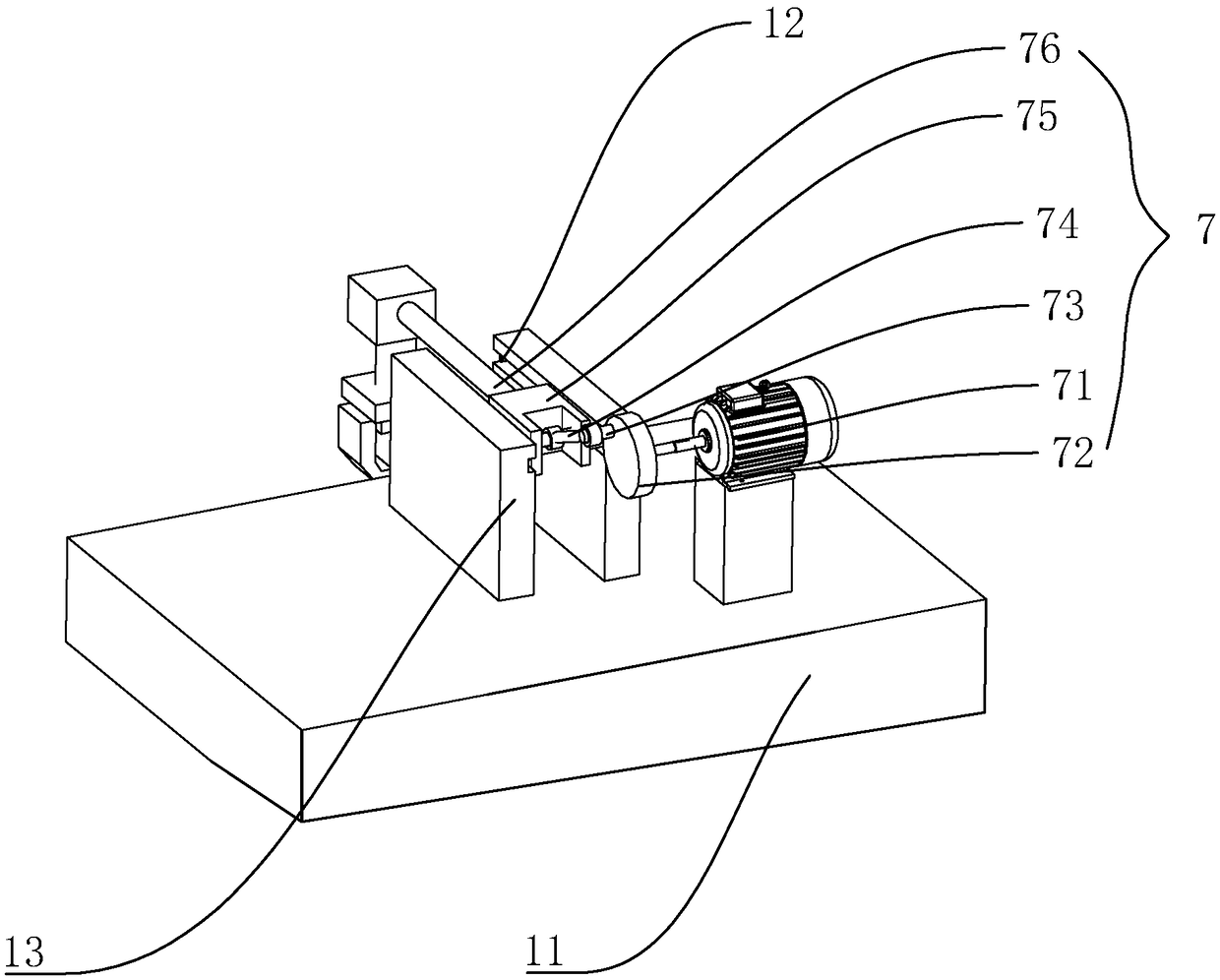

[0025] An automatic loading and unloading manipulator, such as figure 1 , graph and image 3 As shown, a base 1 is included, and a feeding mechanism 8 is provided on the base 1. The feeding mechanism 8 includes a third drive motor 81 positioned on one side of the first support plate 2, and a rotating disc 82 positioned at the output shaft of the third drive motor 81. And the hexagonal turntable 83 that is positioned at the top of the turntable 82, the turntable 82 is provided with a fixedly connected semi-disc 14, the end of the turntable 82 away from the half-disc 14 is provided with a fixedly connected guide 15, the inner arc of the hexagonal turntable 83 Just fit the outer arc surface of the half disc 14, the hexagonal turntable 83 is provided with a number of grooves 16 matching with the guide 15, and the grooves 16 are provided with a loading rack 17 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com