High-speed mixer for easy opening and closing

A high-speed mixer, high-speed mixer technology, applied in mixers, mixer accessories, dissolving and other directions, can solve the problems of being smashed, time-consuming and laborious cleaning, reducing work efficiency, etc., to reduce work intensity, avoid work risks, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

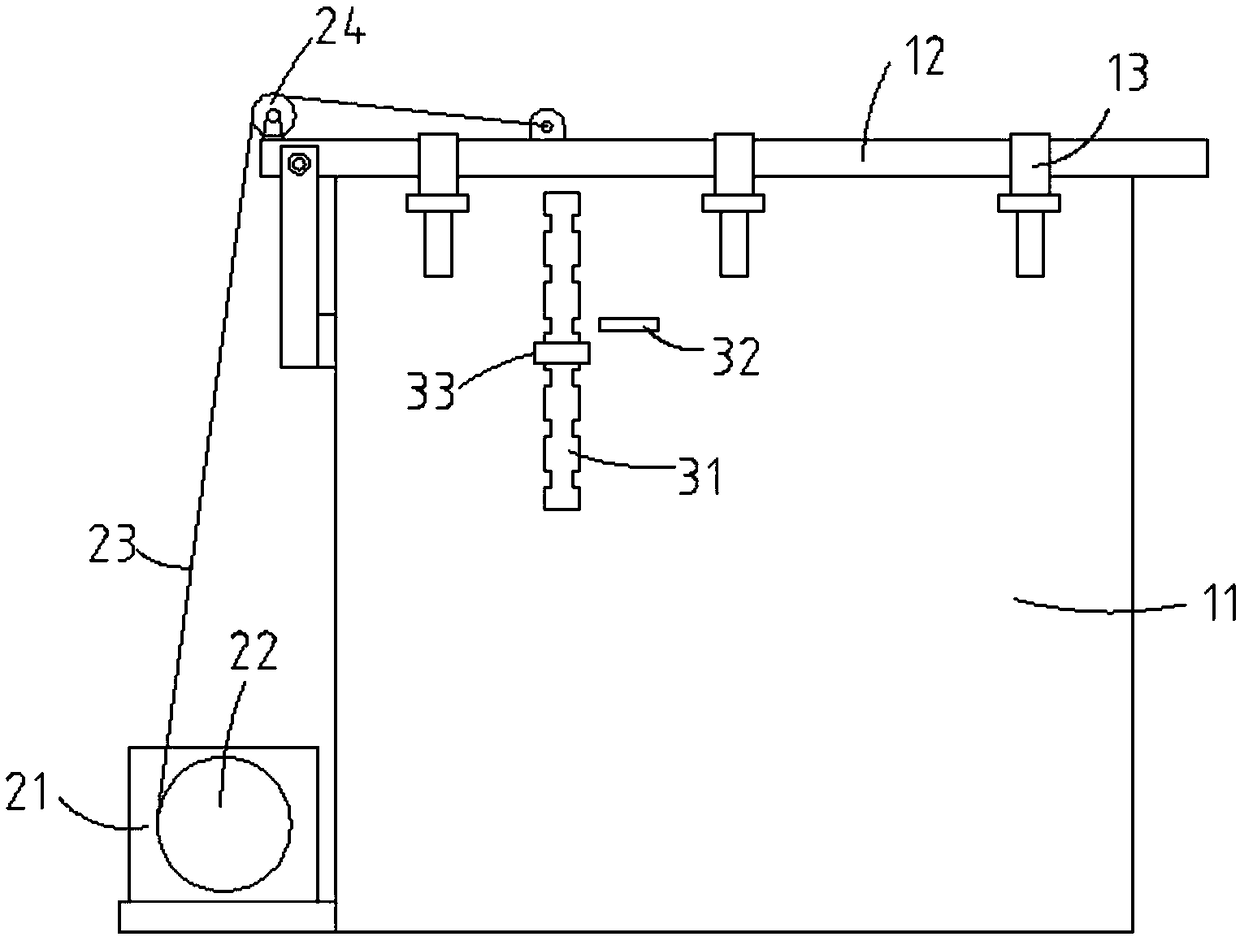

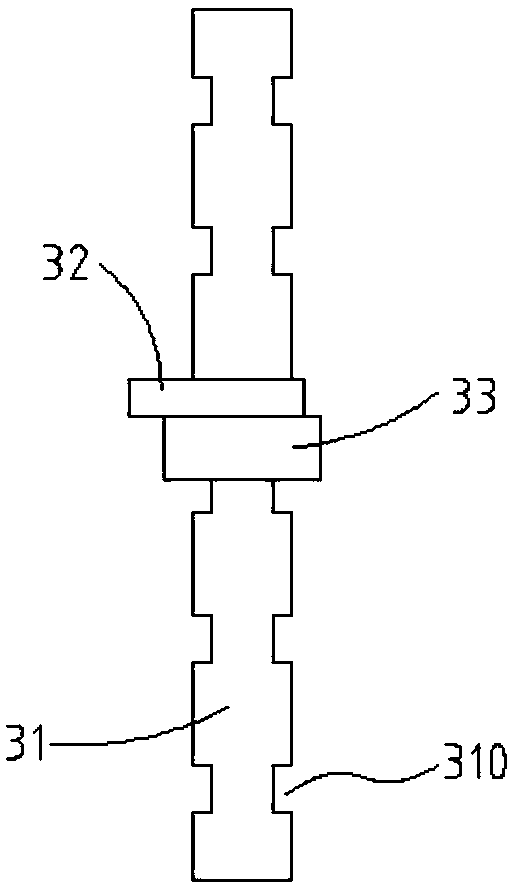

[0015] Such as Figure 1 to Figure 3 , the invention discloses a high-speed mixer that is easy to open and close, including a high-mixer barrel 11, a sealing cover 12, a buckle 13, a motor 21, a take-up reel 22, a pull cord 23, a reversing wheel 24, and a support rod 31 and the positioning insert 32 , the sealing cover 12 is hinged on the high mixer barrel 11 , and the high mixer barrel 11 and the sealing cover 12 are fixedly connected by buckles 13 . The motor 21 is placed outside the barrel 11 of the high mixer, and the rotating shaft of the motor 21 is fixedly connected to the take-up reel 22, the reversing wheel 24 is rotatably connected to the sealing cover 12, and the pull rope 23 is placed on one side of the reversing wheel 24 , and one end of the pull cord 23 is fixedly connected to the sealing cover 12 , and the other end is wound around the take-up reel 22 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com