Sand washing type fishing technology for sand prevention pipe string

A technology of sand control pipe and sand washing, which is applied in wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of difficulty in casing milling and small annular space between screen pipe and casing, so as to avoid operation risks and speed up operations Timeliness, the effect of controlling the cost of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

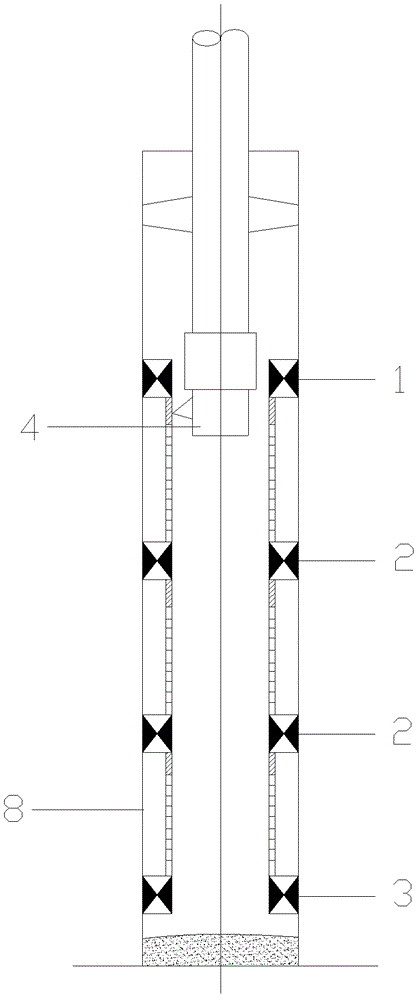

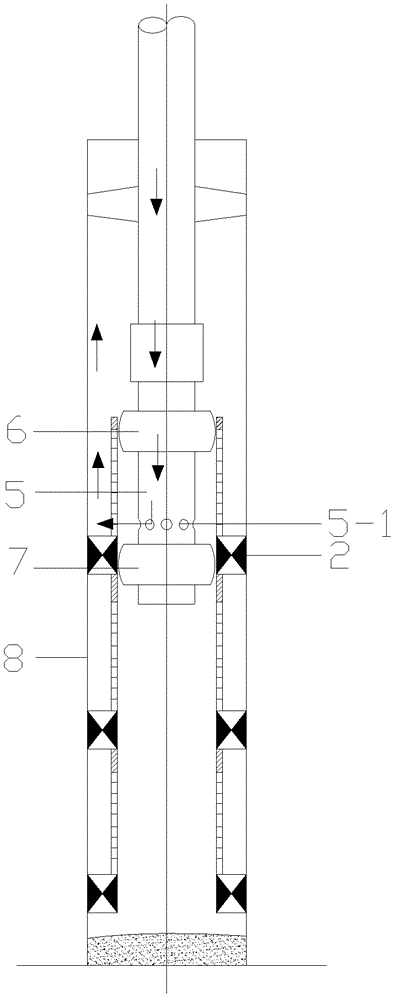

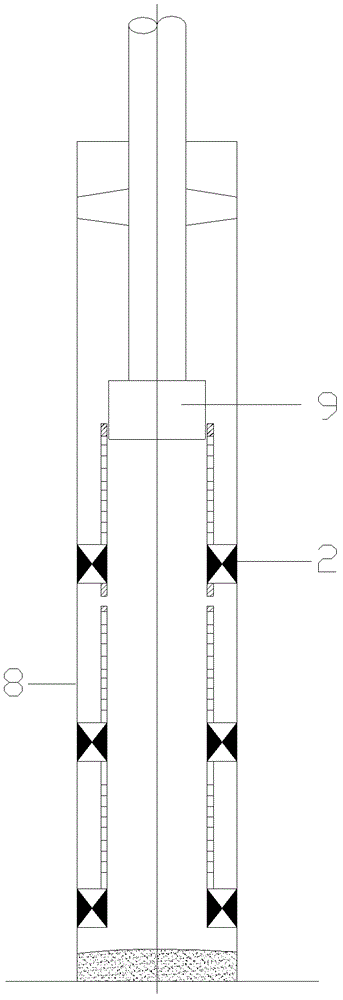

[0019] See Figure 1 ~ Figure 3 , a sand-washing type salvage process for a sand control pipe string, the sand control pipe is divided into several sets located in different oil layers by a top packer 1, at least one intermediate isolation packer 2 and a sand settling packer 3 arranged in sequence from top to bottom The sand control pipe section; the upper end of each sand control pipe section is a blind pipe, and the rest is a screen pipe; the process includes the following steps:

[0020] 1) Lower the cutting pipe string 4 into the uppermost sand control pipe section, and cut off the dead pipe of this pipe section, please refer to figure 1 ;

[0021] 2) Run in the special tool, unseal and recover the top packer 1;

[0022] 3) Lower the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com