Overturning clamp for large cover of crystal growing furnace

A technology of crystal growth furnace and flipping fixture, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc. It can solve the problems of personal injury accidents, high safety risks, and long growth cycle, so as to simplify the working process and solve the difficulty of flipping , the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

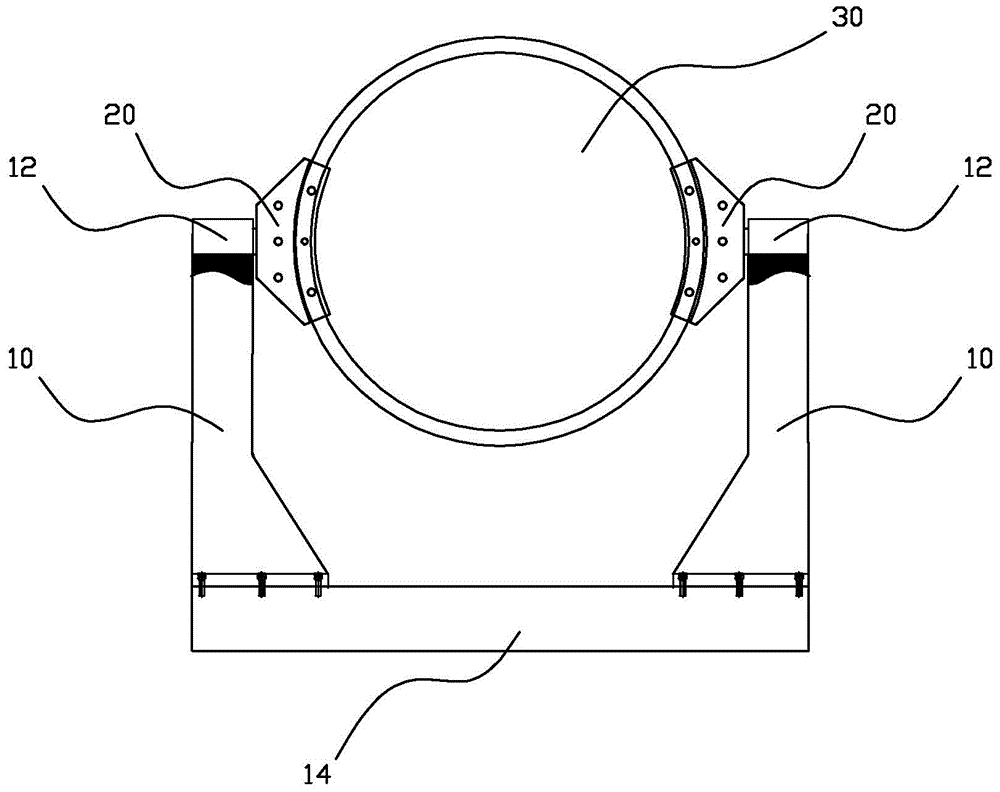

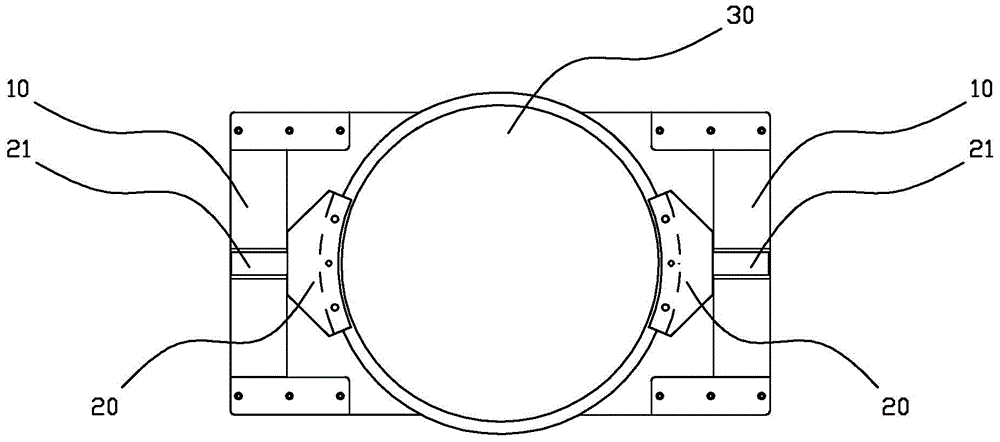

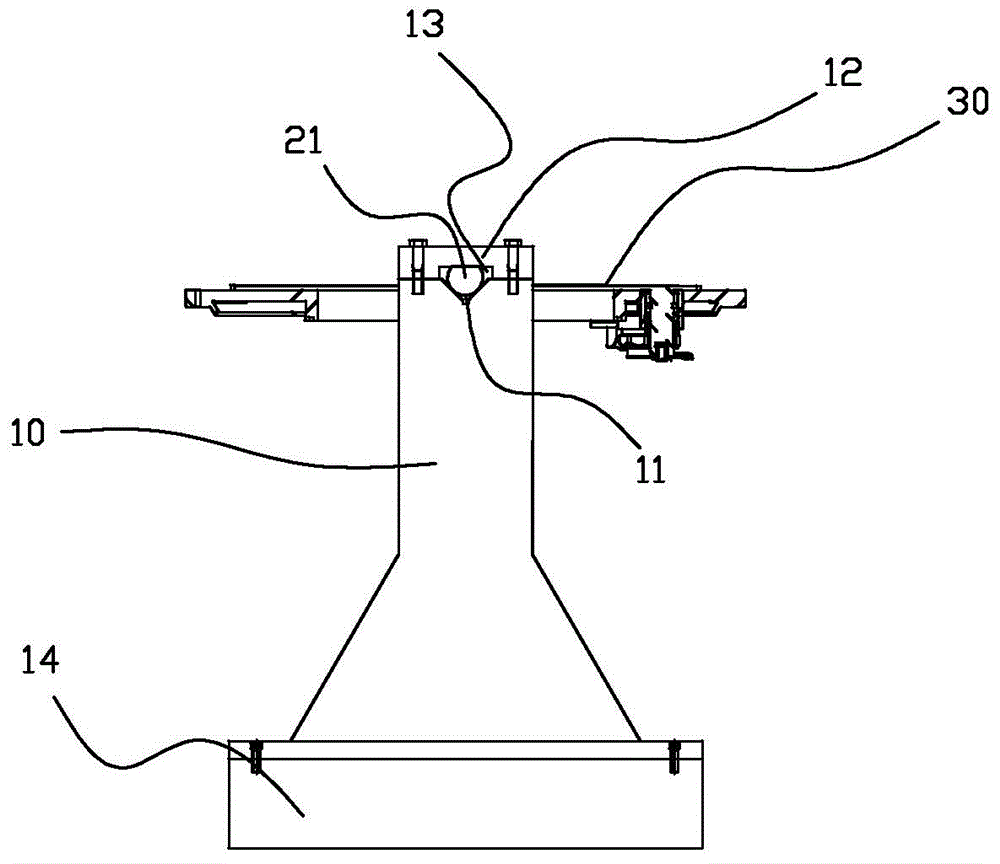

[0024] Such as figure 1 , figure 2 , image 3 The flipping jig shown for a large lid of a crystal growth furnace includes two support frames 10 arranged symmetrically, and a fixed horn 20 rotatably arranged on the support frames 10 . Such as Figure 4 , Figure 5 As shown, the fixed horn 20 includes a rotating shaft 21, a movable clamping piece 23, and a bearing block 21. One end of the rotating shaft 21 is rotatably connected to the support frame 10, and the other end of the rotating shaft 21 is connected to the bearing block 21. The bearing block 21 is connected to the movable The clamping piece 23 forms a fixed area 28, the large cover 30 is clamped in the fixed area 28, and the two rotating bearings are arranged coaxially.

[0025] In this embodiment, the bearing block 21 includes a bearing surface 24 and an installation surface 25 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com