Method for preheating inflow water of membrane method seawater softening device

A softening device, seawater technology, applied in chemical instruments and methods, general water supply conservation, multi-stage water/sewage treatment, etc., to achieve the effects of increasing membrane flux, small footprint, and reducing thermal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

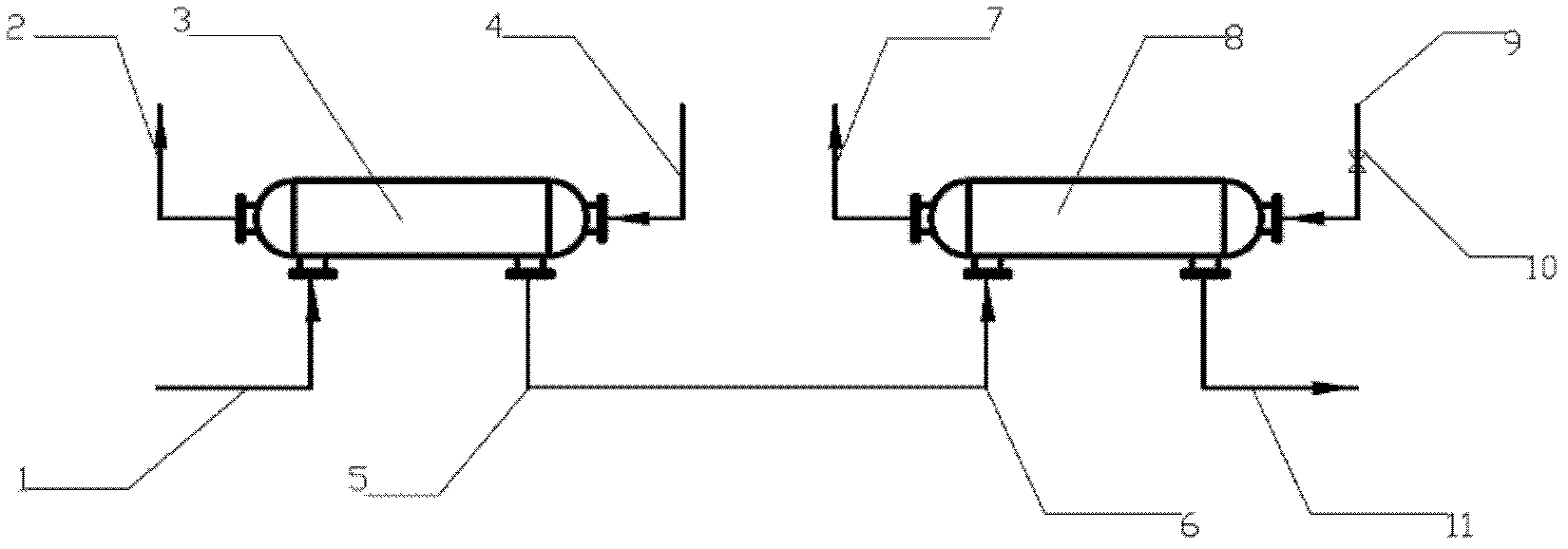

Embodiment 1

[0017] The oilfield produced water is high-temperature water, and the membrane seawater softening device adopts nanofiltration technology with ultrafiltration as pretreatment; both the primary heat exchanger and the secondary heat exchanger use titanium plate heat exchanger; the temperature of high-temperature water is 50°C, the temperature of low-temperature seawater is 2°C, and the water recovery rate of membrane seawater softening device is 60%. The device, which exchanges heat countercurrently with the concentrated brine of the membrane seawater softening device, raises the seawater temperature to 8°C, and then enters the secondary heat exchanger for countercurrent heat exchange with high-temperature water, and the seawater temperature rises after the secondary preheating After reaching 22°C, it directly enters the membrane seawater softening device; the concentrated brine from the membrane seawater softening device returns to the primary heat exchanger to exchange heat wit...

Embodiment 2

[0019] The circulating cooling water of the power plant is high-temperature water, and the membrane seawater softening device adopts reverse osmosis technology with ultrafiltration as pretreatment; both the primary heat exchanger and the secondary heat exchanger use titanium plate heat exchangers; the temperature of high-temperature water The temperature of the low-temperature seawater is 42°C, the temperature of the low-temperature seawater is 2°C, and the water recovery rate of the membrane seawater softening device is 40%. Heater, the low-temperature seawater and concentrated brine exchange heat in countercurrent, so that the seawater temperature rises to 6°C, and then enters the secondary heat exchanger to perform countercurrent heat exchange with high-temperature water, and the seawater temperature after the secondary preheating rises to 18°C After that, it directly enters the membrane softening process; the concentrated brine from the membrane seawater softening device re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com