Construction method

A construction method and a fixing method technology, applied to building components, walls, buildings, etc., can solve problems such as loss of horizontal support force, unit panels colliding with the floor, and unit panel pendulum movement is difficult to overcome, so as to slow down the pendulum movement and lift The effect of process stability and avoidance of operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

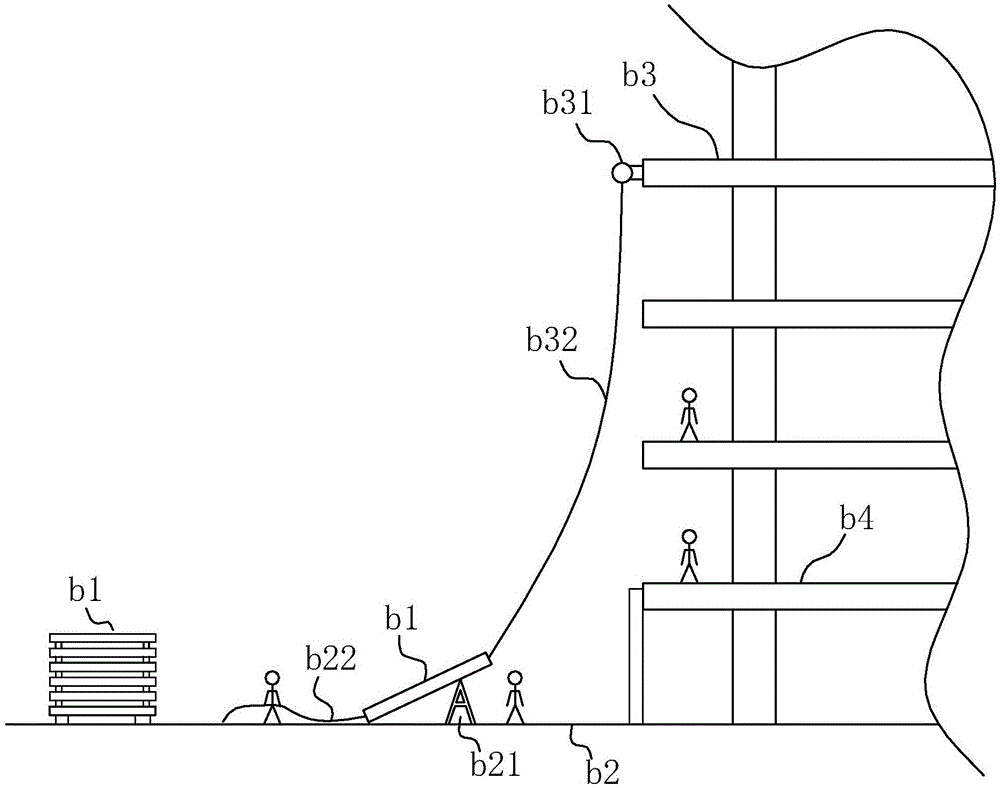

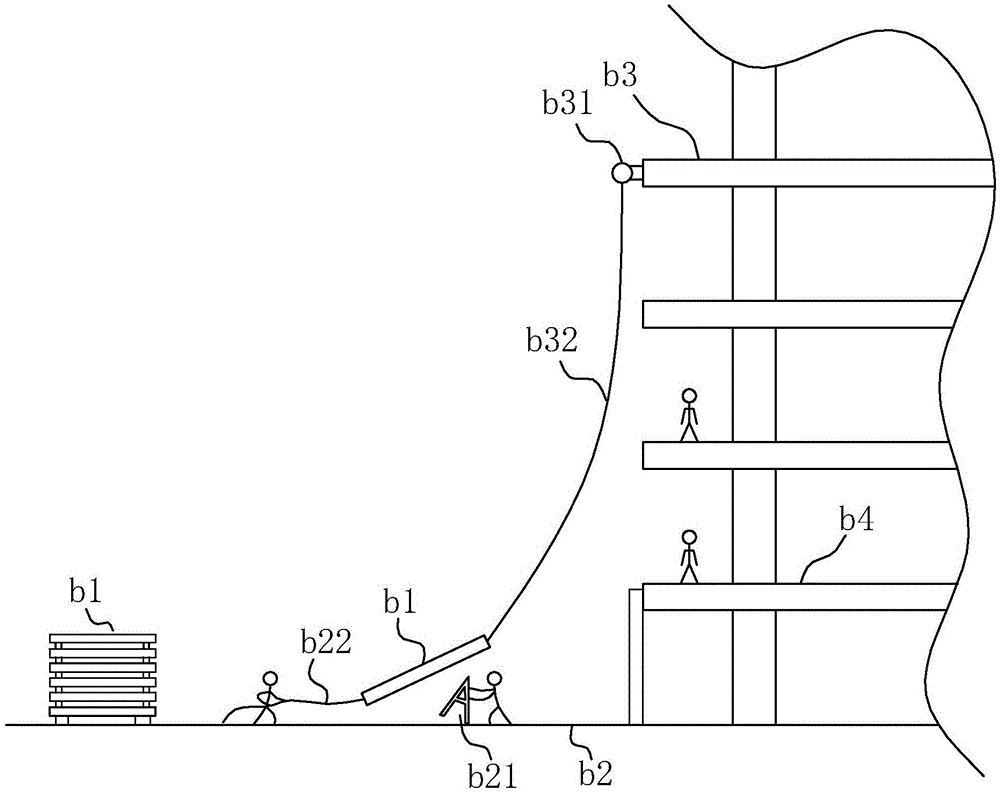

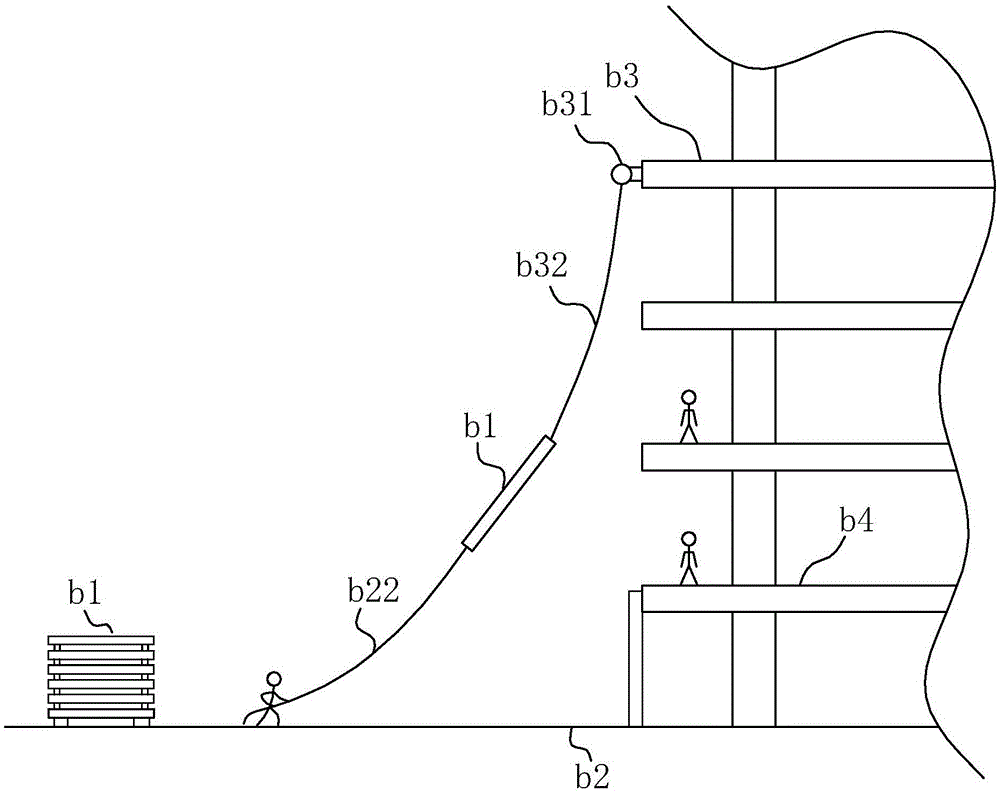

[0048] Such as Figure 10 As shown, configure a truck b5, the outward end of the fork 1 is the front end 11, and the inward end is the rear end 12, the truck b5 is pushed to the edge of the lifting layer b2, the front end 11 is facing outward and the fork 1 and the The edge is vertical, and at the same time, make the front end 11 equal to the edge position of the lifting layer b2 or exceed or be less than 10cm. At this time, record the positioning point 6 at the lateral position of the rear end 12 of the fork 1, and measure the positioning point 6 to the lifting layer with a tape measure The vertical distance from the edge of b2 and recorded as L1.

[0049] Such as Figure 13 As shown, the spreader b31 is installed outside the floor of the spreader layer b3. The spreader b31 can use an electric hoist or a crane. Measure the vertical distance between the rope entry and exit point 7 of the spreader b31 and the floor and record it as L2. Figure 10 shows the unit plate b1 hangi...

Embodiment 2

[0055] The difference between the second embodiment and the first embodiment is that the fixing method of the transport vehicle b5 can be controlled or fixed by the operator, and this embodiment can be adopted when the unit board b1 to be installed is relatively light in weight

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com