A prefabricated building exterior wall

A building exterior wall and prefabricated technology, applied in buildings, building components, building structures, etc., can solve the problems that rock wool and cement cannot be directly combined, the mechanical properties of the exterior wall are poor, and the cold bridge cannot be effectively blocked. To achieve the effect of controllable wall width, simple construction, excellent and beautiful decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

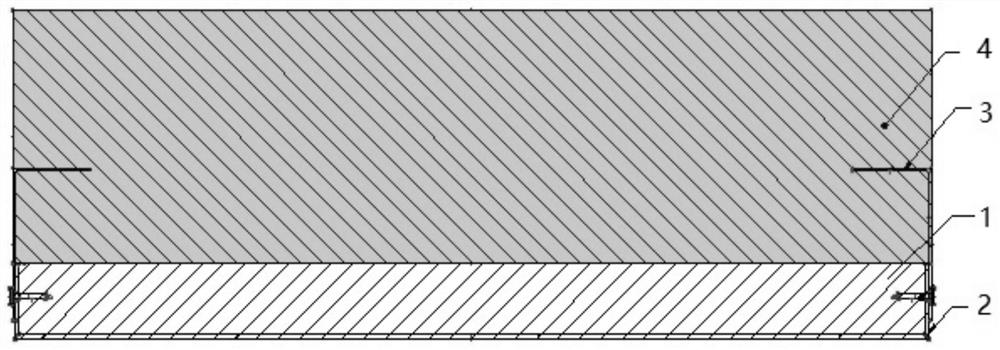

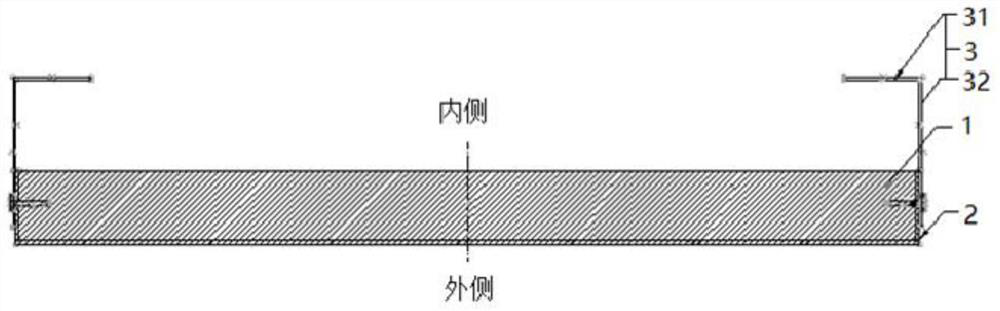

[0117] A prefabricated building exterior wall, including insulation board 1, cover layer 2, steel L-shaped embedded parts 3 and cement layer 4, cover layer 2 is a rectangular shell structure made of galvanized steel plate, and is sleeved on the insulation board On the outer surface of the insulation board 1, all the board surfaces except the inner surface of the insulation board are closed, the thickness of the insulation board 1 is equal to the thickness of the inner cavity of the cover layer 2, and two-component polyurethane is coated between the insulation board 1 and the cover layer 2 binder. The inner arm 31 and the outer arm 32 of the L-shaped embedded part 3 are vertical, the length of the outer arm 32 is greater than the thickness of the insulation board 1, the outer arm 32 is perpendicular to the thickness direction of the insulation board 1, and is attached to the outer wall surface of the cover layer 2 to connect the inner arm One end of 31 faces the cement layer 4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com