Patents

Literature

80results about How to "Simple connection process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

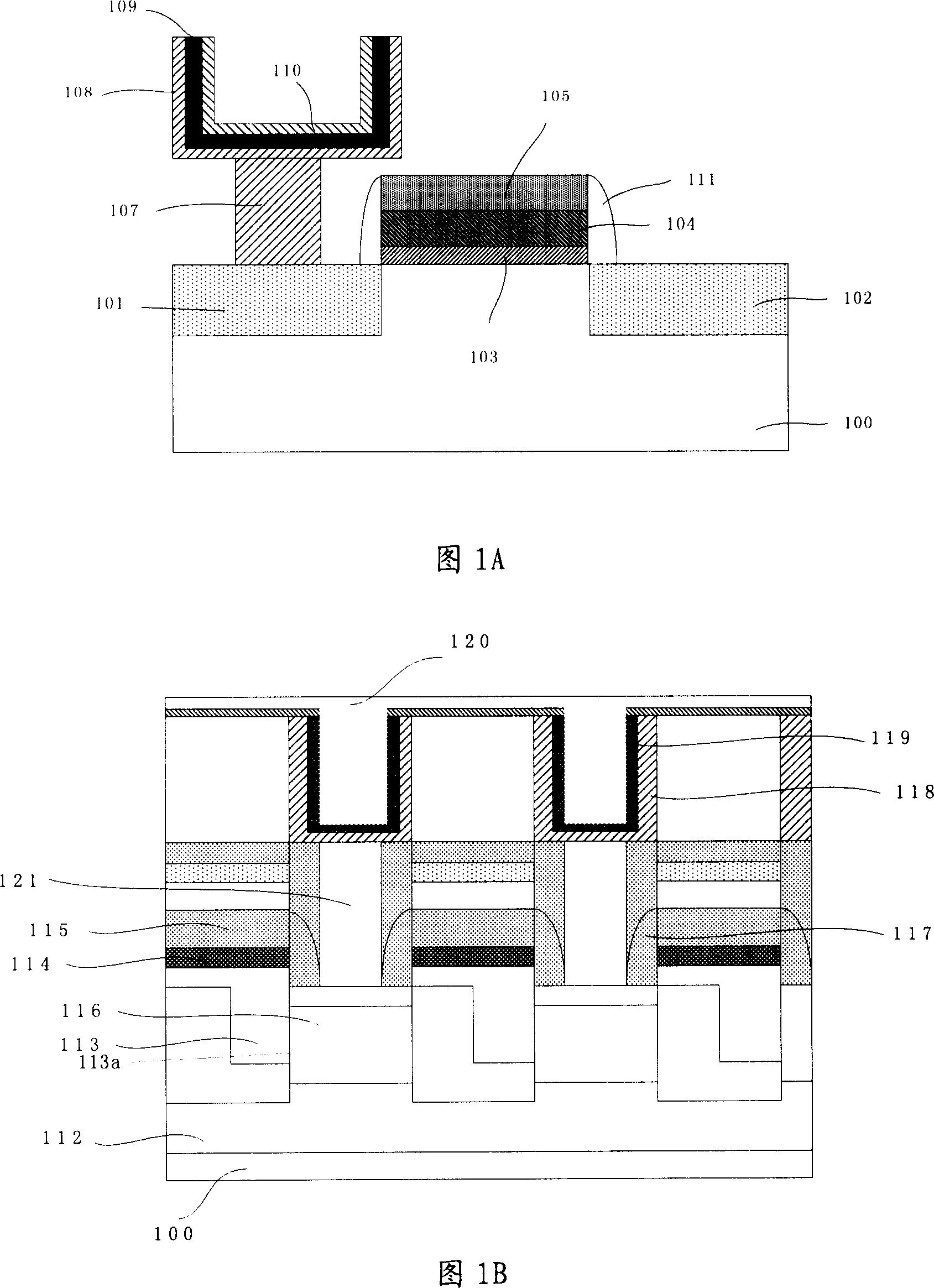

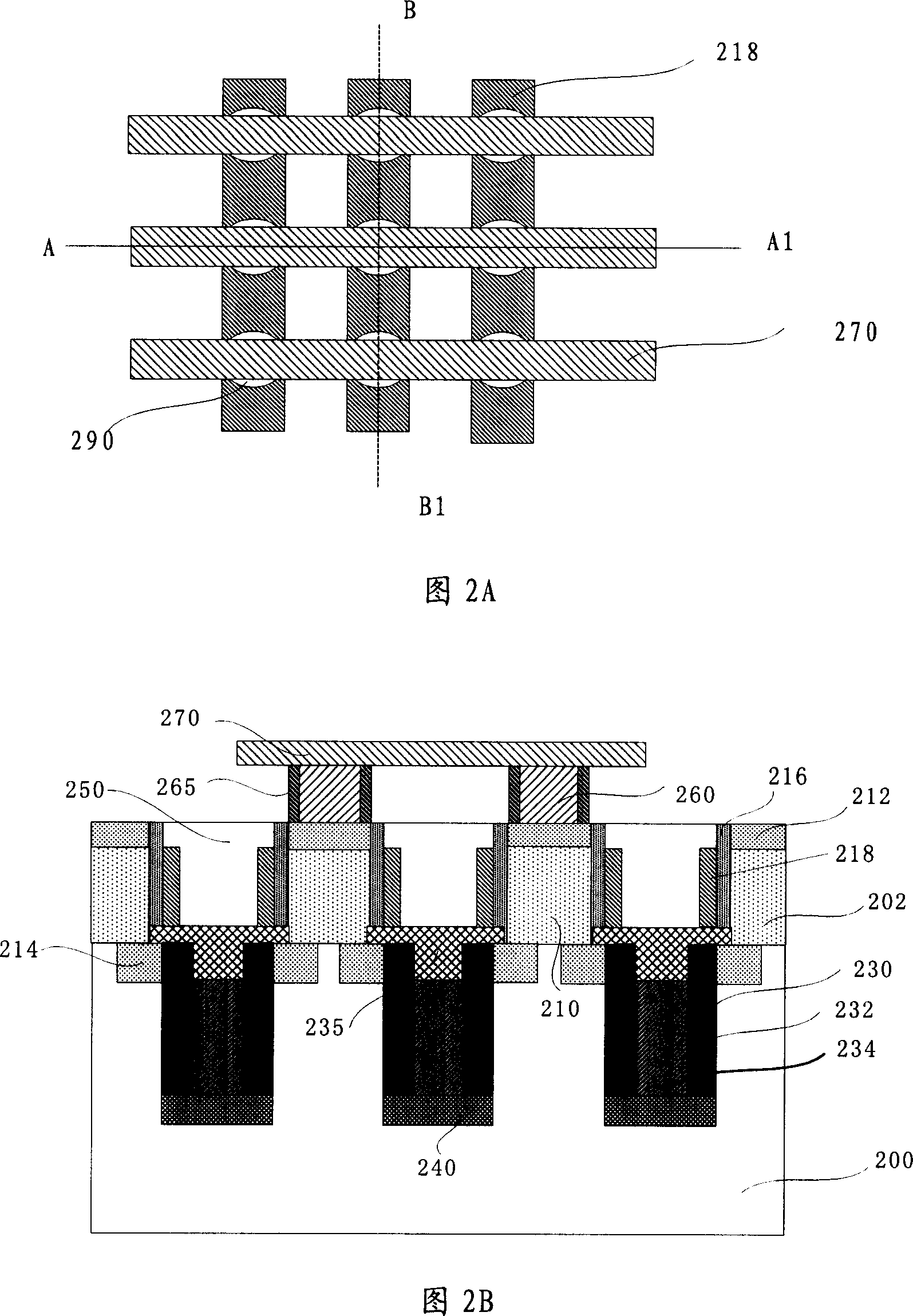

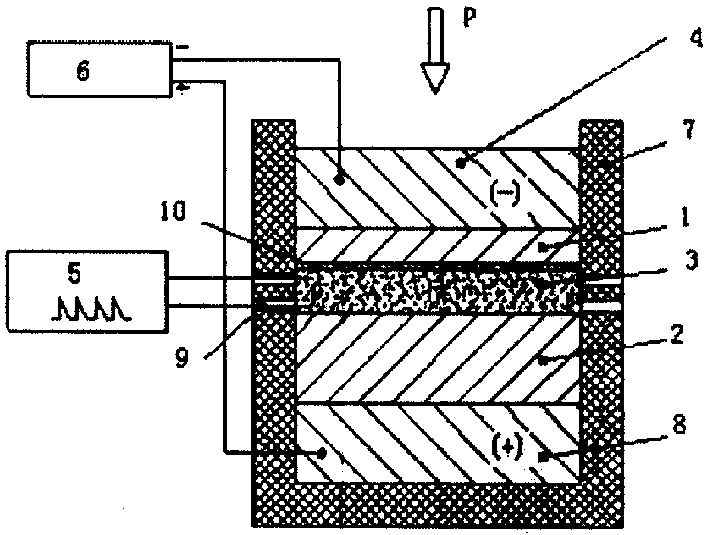

Semiconductor storage device and manufacturing method thereof

ActiveCN101090117AReduce areaSimple connection processTransistorSemiconductor/solid-state device manufacturingCapacitanceTransistor array

This invention discloses a semiconductor circuit and its manufacturing method, in which, said circuit includes a storage unit array and a peripheral loop, and the storage unit includes a vertical ciculating grid transistor and a groove capacitor under the transistor, the peripheral loop is composed of conventional plane transistors, the menufacturing method includes: forming a vertical circulation grid transistor array on the substrate of the semiconductor and forming a storage capacitor under the transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

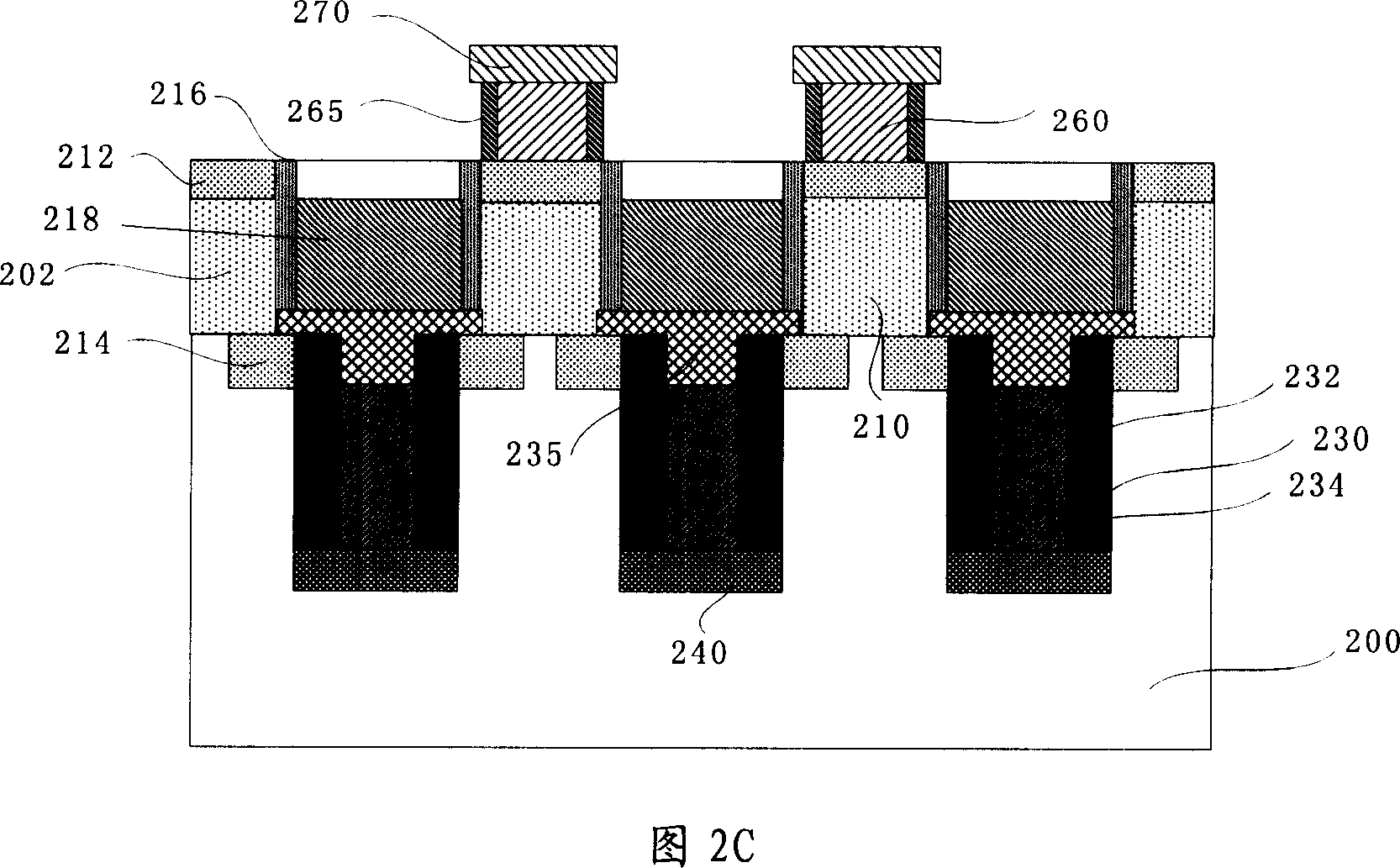

Ceramic and metal field self extending combustion connecting method

A field self-progressing combustion method for attaching a protecting ceramic layer onto high-temp abrasive surface of metal features that the self combustion at the interface between ceramic and metal can generate local high temp to sinter the interface, an external electrostatic field can help the immigration and diffusion of ions, and the nickel infiltration on the interface of ceramic can fill the interface gap. Its advantages are high adhesion and low cost.

Owner:TAIYUAN UNIV OF TECH

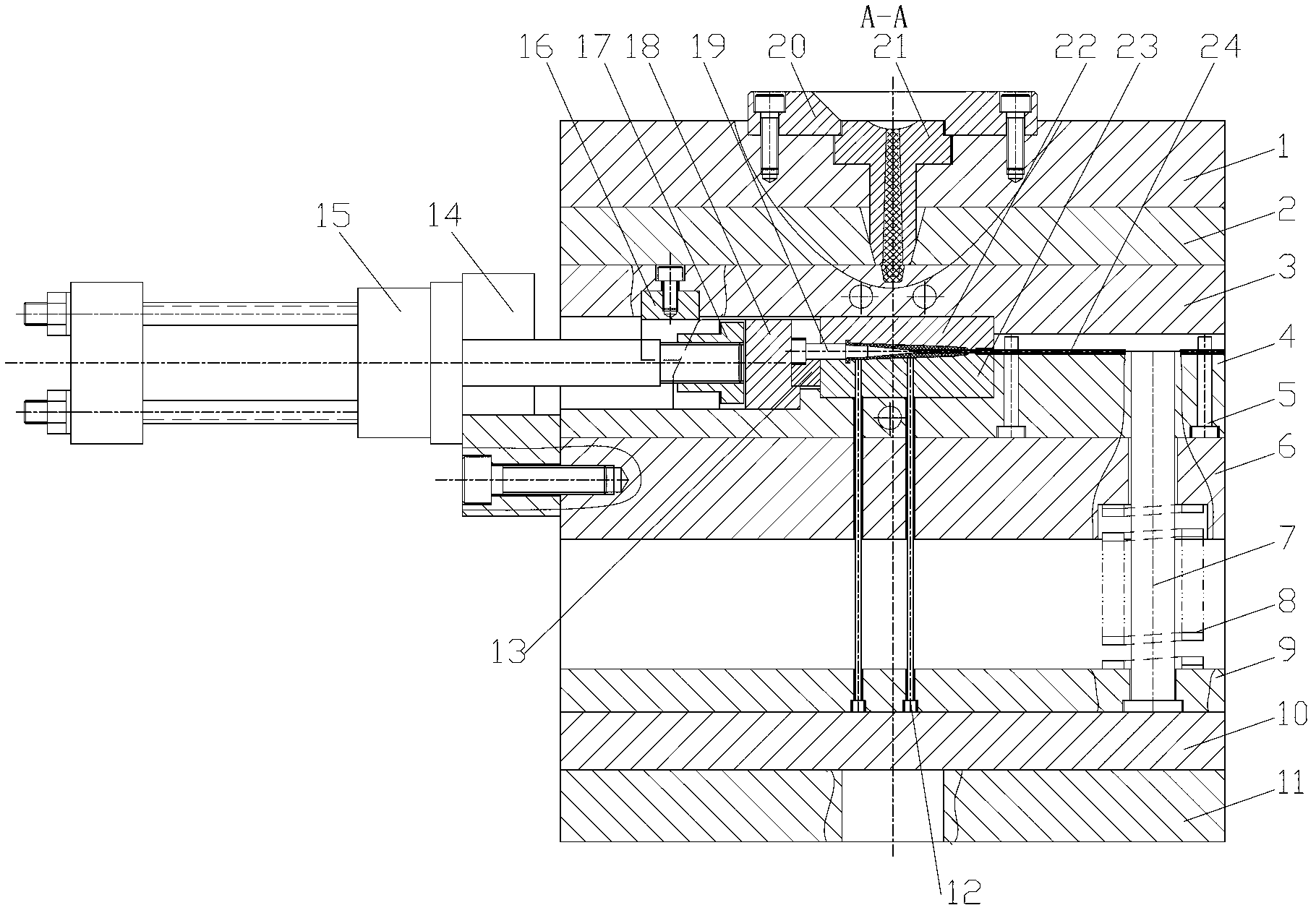

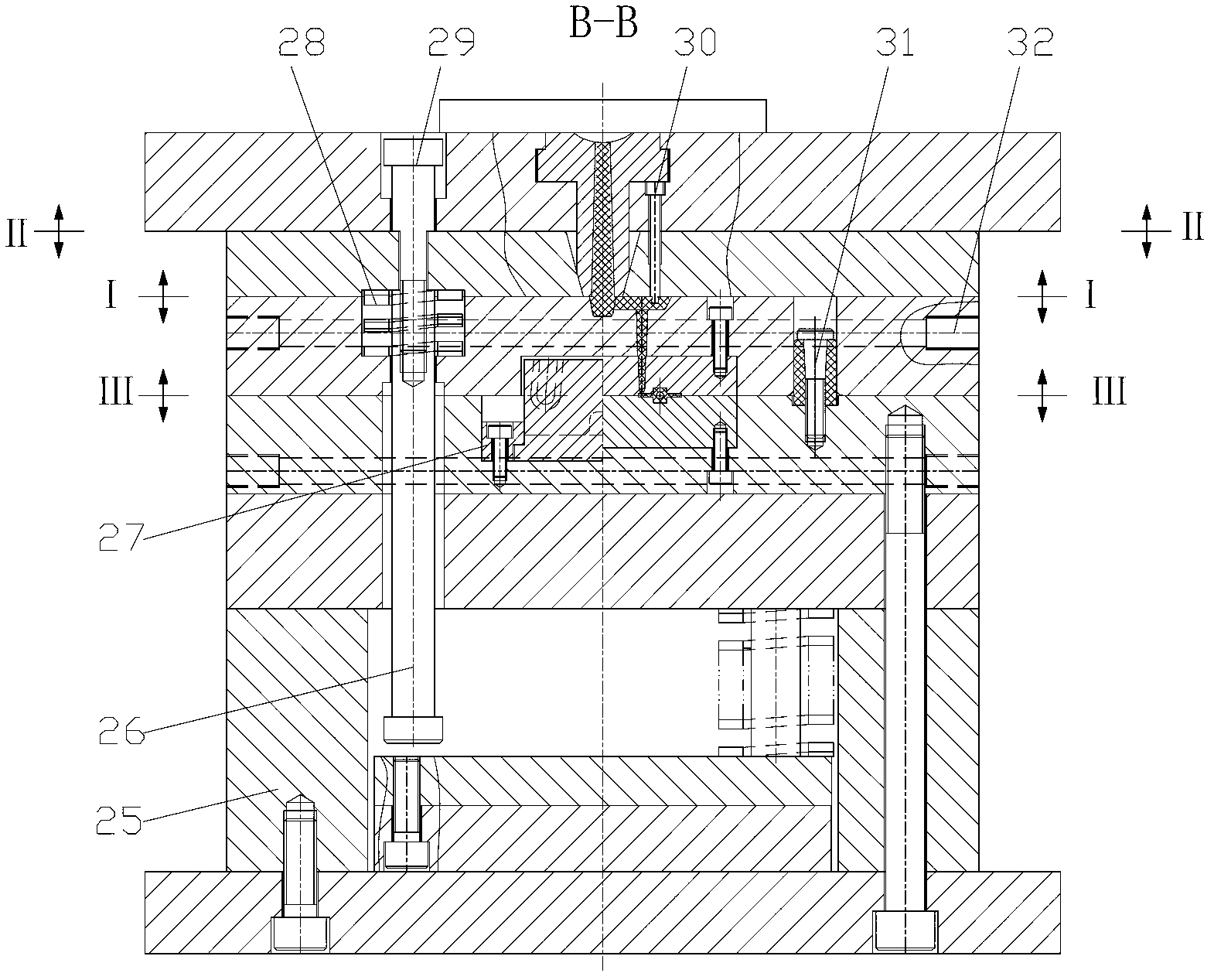

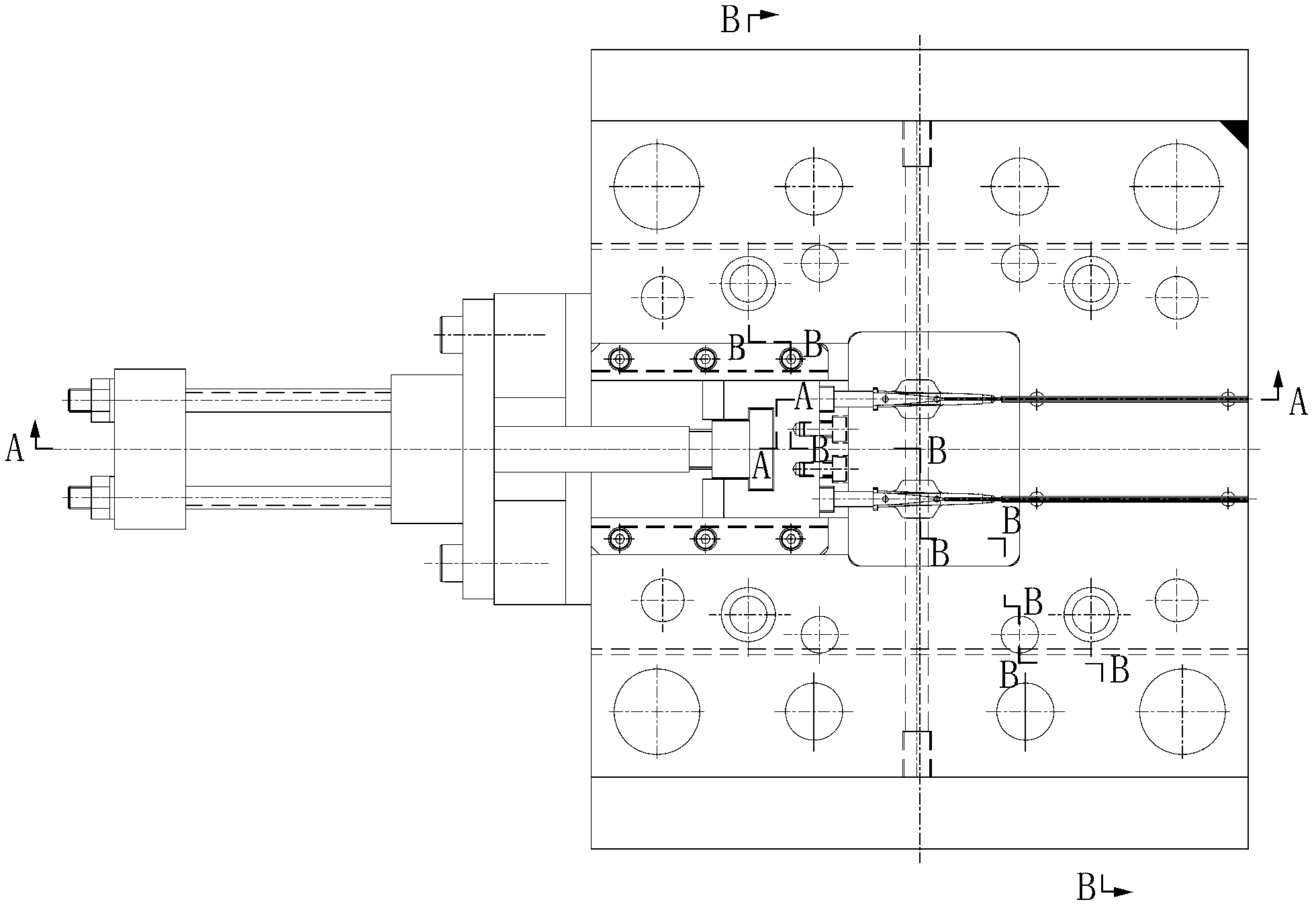

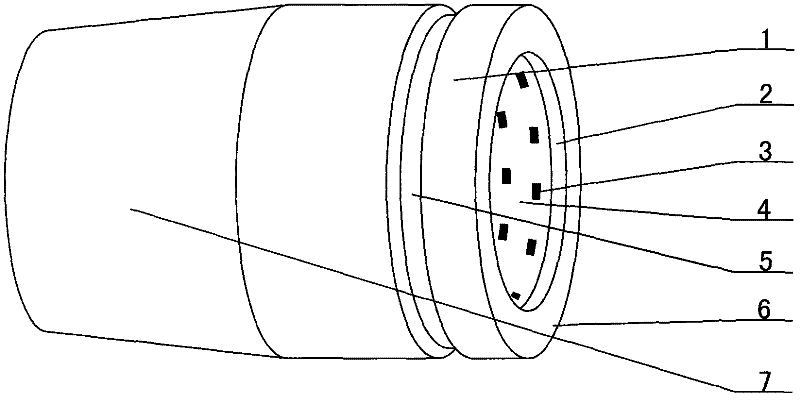

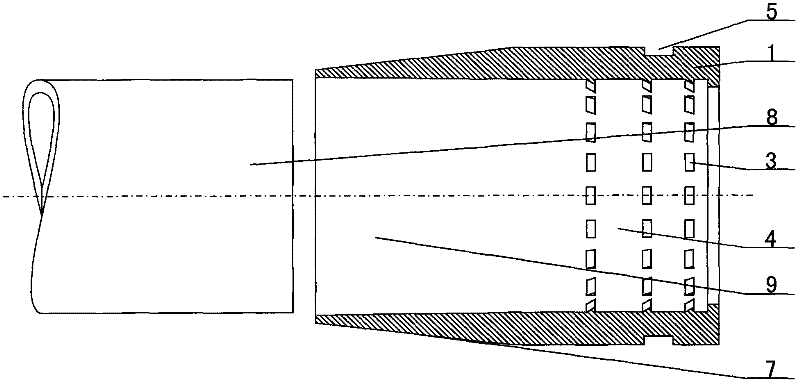

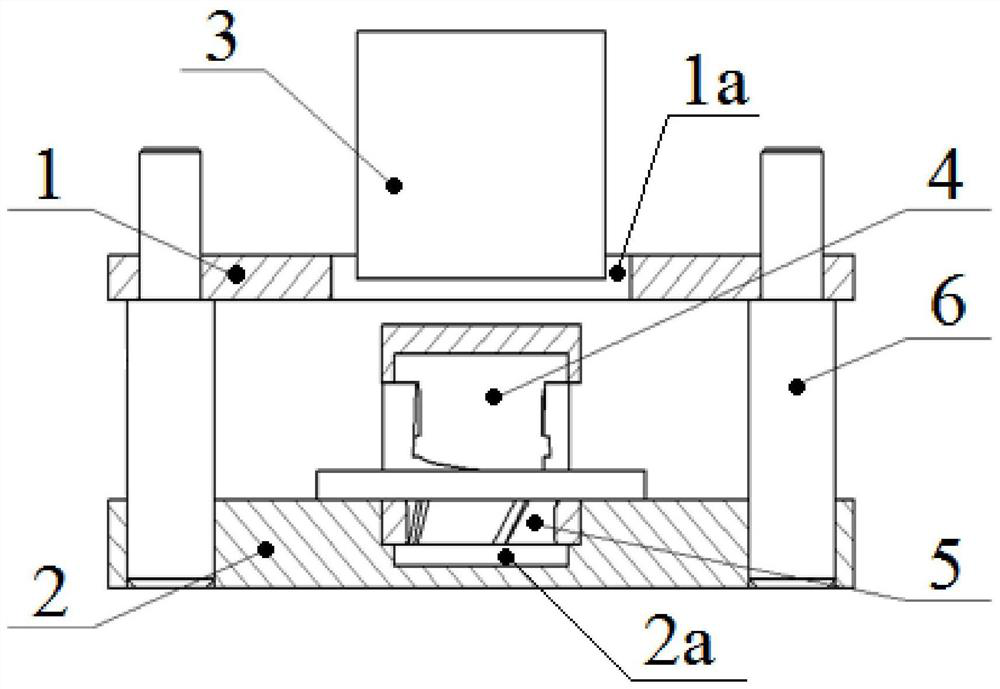

Injection mold of medical intervention catheter adapter

InactiveCN103213251AReduce manufacturing costAchieve connectionCoatingsCATHETER ADAPTERHydraulic cylinder

The invention discloses an injection mold of a medical intervention catheter adapter, belonging to the technical field of polymer injection molds. The injection mold is characterized in that a polymer catheter is used as a two-cavity three-plate type injection mold of an insert, and comprises a three-plate type injection mold base, a hydraulic cylinder side core-pulling mechanism, a catheter installing mechanism and a cooling water channel. The injection mold mainly comprises a stationary mould fixing plate, a stripper plate, a fixed mould plate, a movable mould plate, a catheter fixing nail, a movable mould base plate, a reset rod, a top rod retaining plate, a top rod pushing plate, a movable mould fixing plate, a core pressure block, a hydraulic cylinder fixing plate, a hydraulic cylinder, a locking block, a hydraulic cylinder connecting sleeve, a sliding block, a core, a stationary mould cavity insert, a movable mould cavity insert, a cushion block, a sliding block pressure block, a pulling nail, a nylon nail and a cooling water channel. The injection mold has the effects and advantages that the polymer intervention catheter is used as the insert for injecting and forming the catheter adapter, the catheter is connected with the inside of a mould of the catheter adapter, the connecting process of the catheter and the catheter adapter is simplified, and the manufacture cost of the intervention catheter is lowered.

Owner:DALIAN UNIV OF TECH

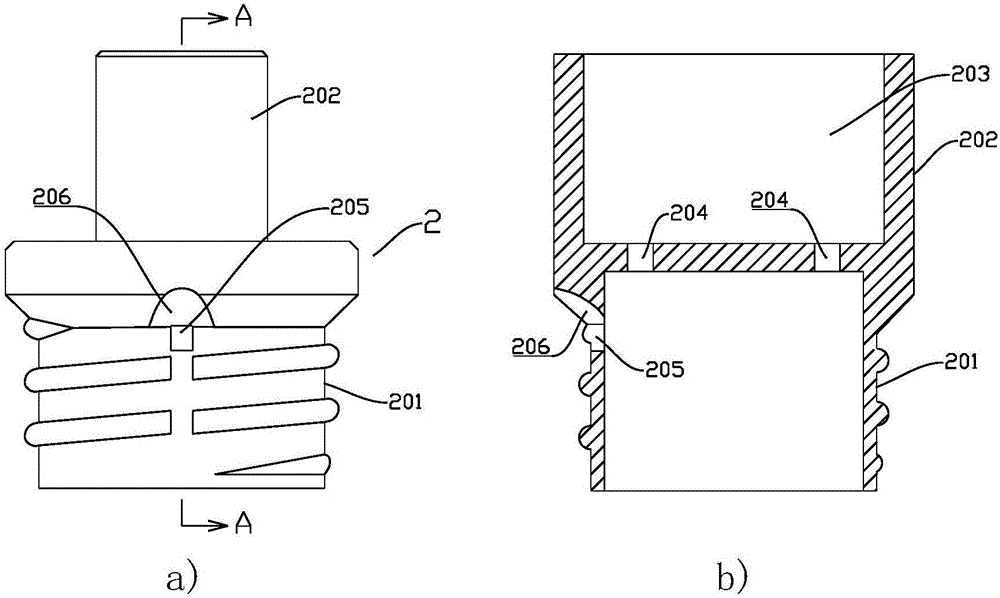

Quick connection joint for plastic pipeline

InactiveCN102654224AOvercome sheddingOvercome the breakPipe connection arrangementsPlastic pipeworkEngineering

The invention provides a quick connection joint for plastic pipeline, relating to a connection structure of the plastic pipeline. The connection joint is made of a hard material, wherein a connection head (1) is a section from one external end to the middle part of the connection joint; a round-about groove (5) is arranged on the outer edge face of the connection head; an opening part stopping ring (2) is arranged on an inner wall (4) at one end inside an end face (6) at one end of the connection joint; clamps which are clamped with the external face of a rubber pipe (8) and are circularly distributed are arranged on the inner wall at one end; and a section from an inner face at the other end to the middle part of the connection joint is a horn opening (9) with a large external part and a small internal part at the other end. The quick connection joint provided by the invention is locked at an end head of the plastic pipeline through a mechanical effect, and forms a tight quick connection structure through the annular-distributed clamps. The quick connection joint ensures the good sealing property due to the specific structural design, so as to achieve rapid, efficient and convenient mounting, dismounting and maintenance. Therefore, the phenomena of releasing, breaking, and water and gas leakage of the pipeline, caused by the conventional connection manner, can be effectively overcome.

Owner:山东鼎鑫矿用新材料有限公司

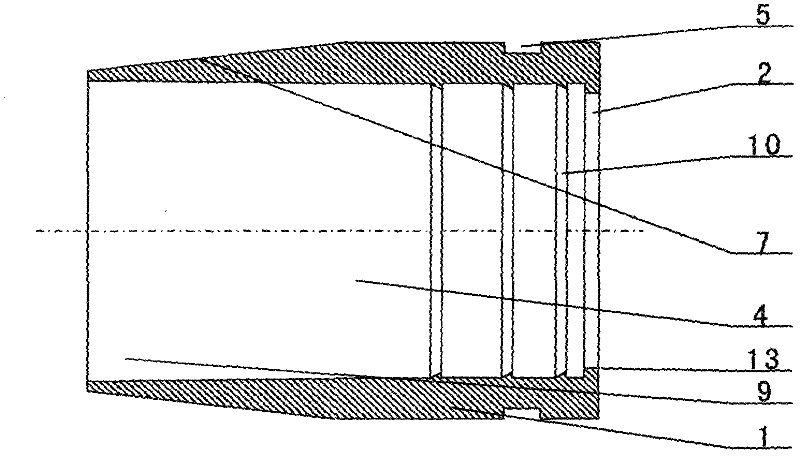

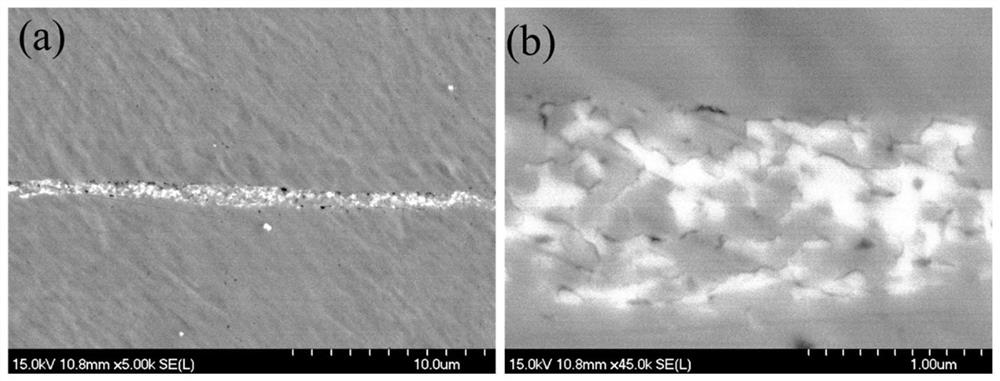

Silicon carbide ceramic connection method and silicon carbide cladding

The invention discloses a silicon carbide ceramic connection method and a silicon carbide cladding, and the silicon carbide ceramic connection method comprises the following steps: S1, taking liquid polycarbosilane as a precursor, and adding a curing agent for curing treatment; S2, enabling the cured polycarbosilane to be subjected to heating pretreatment, and forming precursor powder; S3, mixing the precursor powder and an organic solvent to prepare slurry; S4, smearing the slurry between a SiC cladding tube and an end plug which are matched with each other, and forming a sandwich connection structure; and S5, performing high-temperature curing and cracking treatment on the sandwich connection structure, so that the slurry forms a connection layer which is tightly connected between the SiC cladding tube and the end plug. According to the silicon carbide ceramic connection method, high-strength connection of the SiC cladding and the end plug at a low temperature (less than or equal to 1500 DEG C) and without pressure is realized, filler does not need to be added, the pore defect of a middle connection layer is reduced, and the air tightness of a formed joint is improved; and the connection process is simple and has low requirements on equipment, and the cost is reduced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

Medical sterilization packaging bag

The invention relates to a medical sterilization packaging bag which is formed by a closed cavity formed by connecting the corresponding parts of medical flexible sheet material; content is positioned inside the closed cavity; and the medical flexible sheet material at least comprises two pieces, wherein one piece is a transparent high-temperature-resistant medical composite plastic film, and the other one is medical non-woven. Every two opposite sides of the transparent high-temperature-resistant medical composite plastic film and the medical non-woven are connected with each other by hot melting or high-temperature-resistant bonding agent, so that the closed cavity can be manufactured. The medical non-woven is polypropylene fiber medical non-woven with three-layer structure, or terylene medical non-woven or polyurethane fiber medical non-woven. The medical sterilization packaging bag is provided with a sterilizing effect chemical indicating mark. By adopting the medical sterilization packaging bag, packed medical appliance can be sterilized by various conventional methods and can be maintained in a sterile state for a long time, so that the medical sterilization packaging bag has low cost and convenient use, and is beneficial to improve the sterile level of operation and all medical treatment operations.

Owner:THE SECOND AFFILIATED HOSPITAL OF CHONGQING MEDICAL UNIV

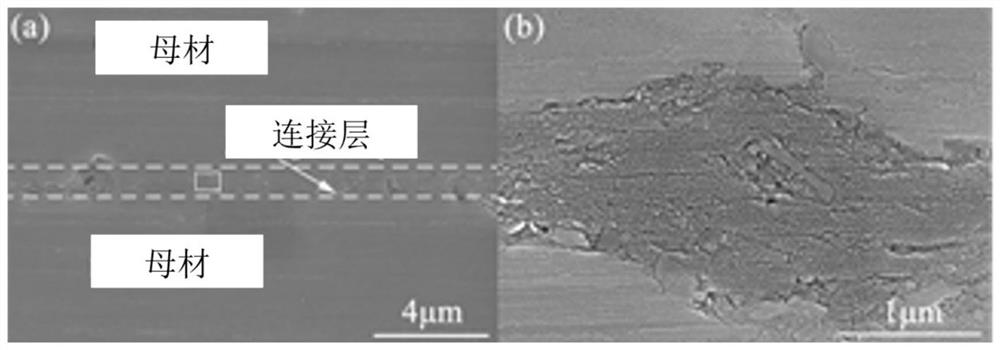

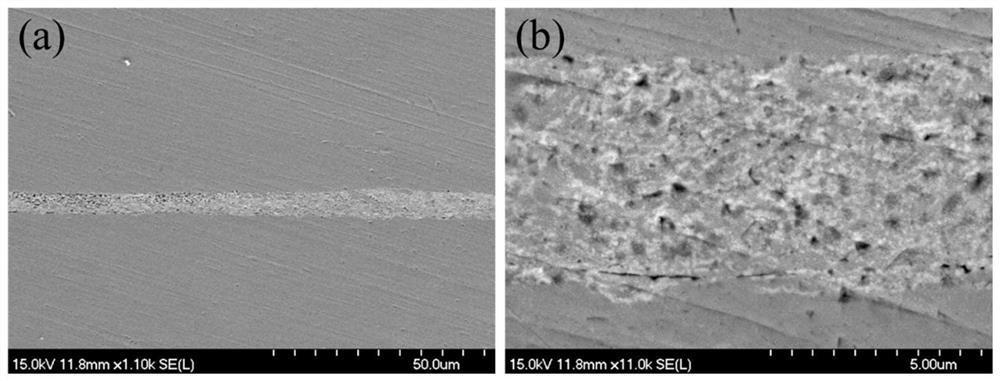

Ultrasonic soldering method for fast forming ceramic-metal interconnection

InactiveCN106563861AQuality improvementAddress reliabilitySoldering apparatusWelding/soldering/cutting articlesMolten stateSurface oxidation

The invention belongs to the technical field of welding, and particularly relates to a simple, fast and easily-implemented ultrasonic soldering method for fast forming ceramic-metal interconnection. The ultrasonic soldering method for fast forming ceramic-metal interconnection is characterized by including the following steps that surface treatment is carried out on base materials to be interconnected; then, the base materials to be interconnected are assembled into a sandwiching structure of the first base material / the middle layer / the third base material and placed on a heating table; the structure in the second step is heated and pressurized so that the middle layer can melt; and ultrasonic application is stopped, ballasting on a test piece is canceled, the test piece is taken down after the test piece is cooled, and the interconnection process is completed. Compared with the prior art, the ultrasonic soldering method for fast forming ceramic-metal interconnection is advantageous in that a joint compact and uniform in structure can be obtained in extremely short time, and the reliability problem caused by too long isothermal holding time is avoided; and in addition, oxide films on surfaces to be interconnected are destroyed by the ultrasonic effect, wetting and spreading of the middle layer in a molten state on the base materials are facilitated, and the quality of the joint is improved.

Owner:HARBIN INST OF TECH AT WEIHAI

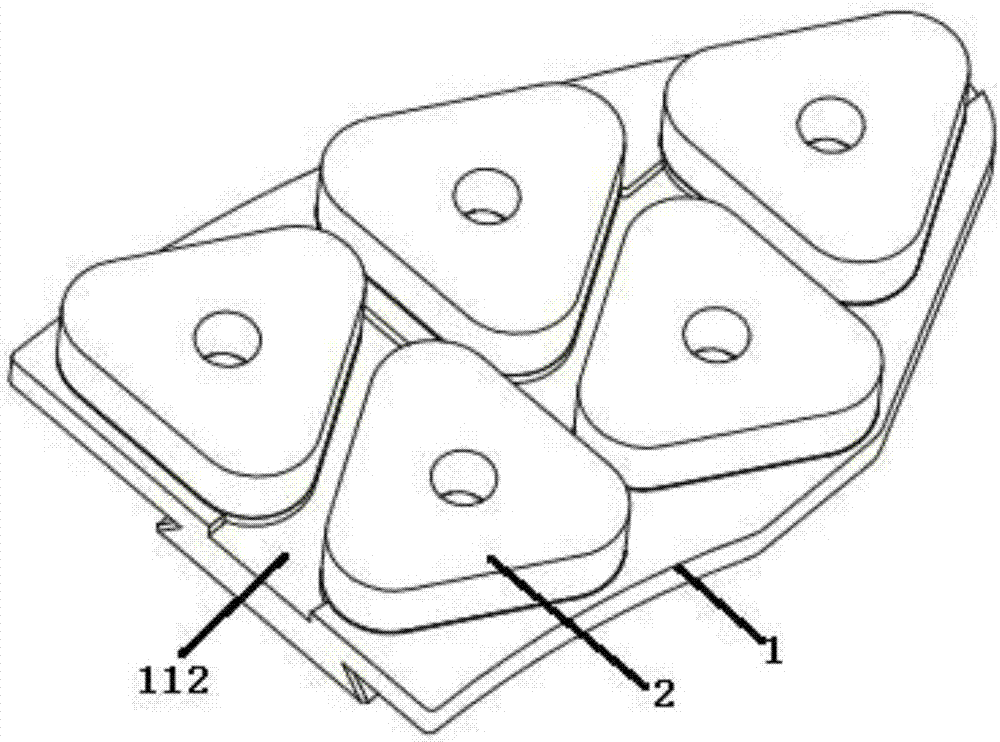

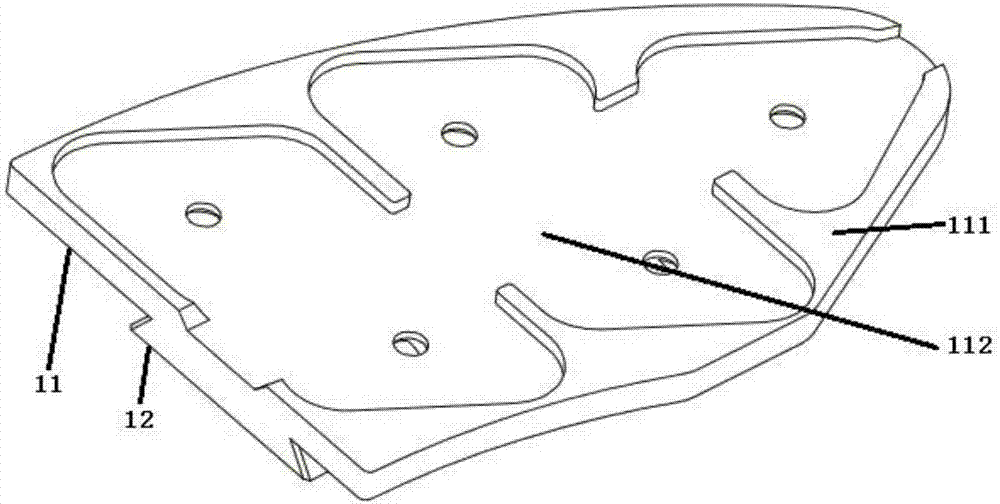

Powder metallurgy brake pad for D-series high-speed train set

PendingCN107061576AIncrease stiffnessImprove stress distributionFriction liningEngineeringMachining process

The invention discloses a powder metallurgy brake pad for a D-series high-speed train set. The powder metallurgy brake pad comprises a steel backboard, a dovetail block and a plurality of brake pad friction bodies. The steel backboard and the dovetail block are of an integrated forming structure, any brake pad friction body is fixed to the steel backboard through a big gasket and a rivet, each big gasket is located between the corresponding brake pad friction body and the steel backboard, and the positions, located on the edges of the brake pad friction bodies, of the steel backboard are provided with flanges matched with the brake pad friction bodies in shape. According to the brake pad, due to adoption of the structure of particular design, rigidity and reliability of the steel backboard are increased, the machining process and riveting process are simplified, the production cost of the brake pad is lowered, reliability of the brake pad is improved, the service life of the brake pad is prolonged, and the powder metallurgy brake pad can be widely applied to brake systems of various railway vehicles and high-speed D-series train sets.

Owner:湖南博科瑞新材料有限责任公司

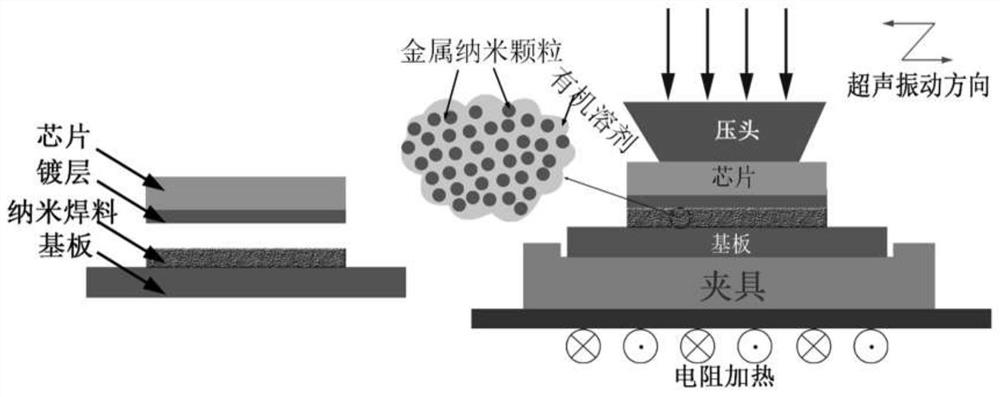

Chip connection method for rapidly generating high-strength and high-melting-point joint at low temperature

InactiveCN111627823ALow temperature connectionSolve the problem of long time and low efficiency of traditional brazingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipUltrasonic vibration

The invention discloses a chip connection method for rapidly generating a high-strength and high-melting-point joint at a low temperature. A self-designed resistance heating and power ultrasonic combined ultrasonic auxiliary hot-pressing device is adopted to realize low-temperature chip connection without damage on the chip. In the chip connection process, severe friction is generated between metal nanoparticles and between the particles and a substrate through a physical vibration effect of ultrasonic waves, the temperature of a solder layer is rapidly increased, atom diffusion is accelerated, and finally connection between the chip and the substrate is achieved at a lower temperature within an extremely short time. The joint obtained through the method has higher shear strength (70-90 MPa), high thermal conductivity (60-80 W / m.K) and wide service temperature, is an effective solution for third-generation semiconductor chip connection, and meanwhile meets the special application occasions of long-time high service temperature, high strength and high reliability.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

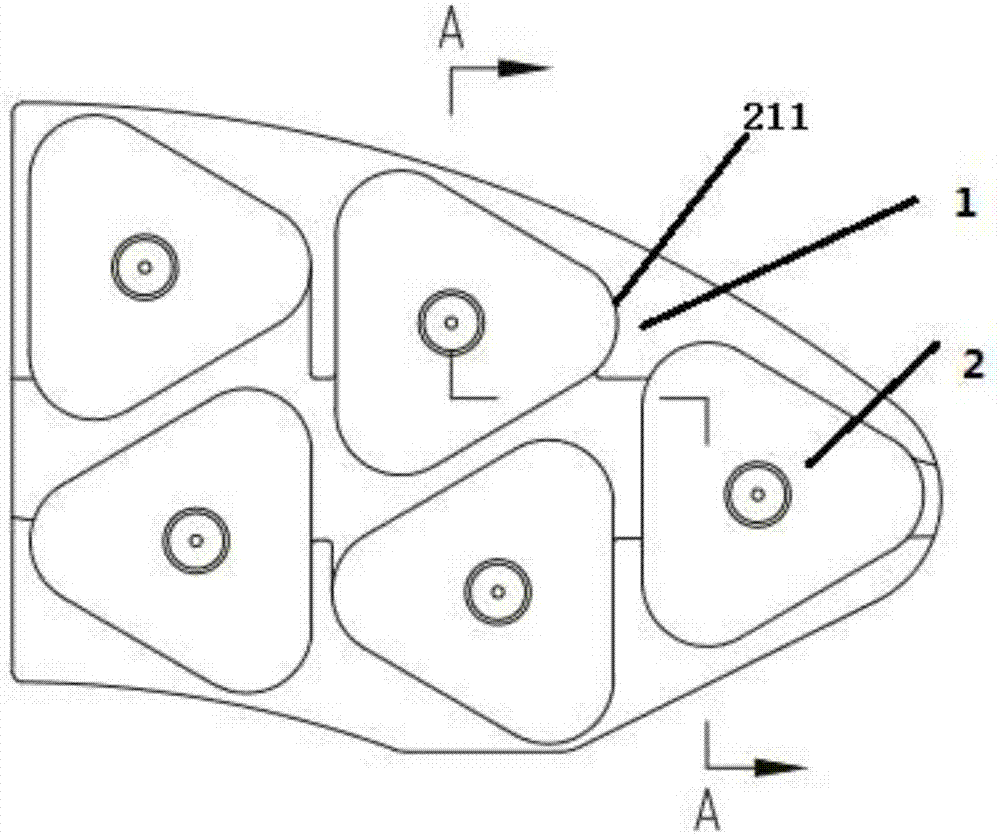

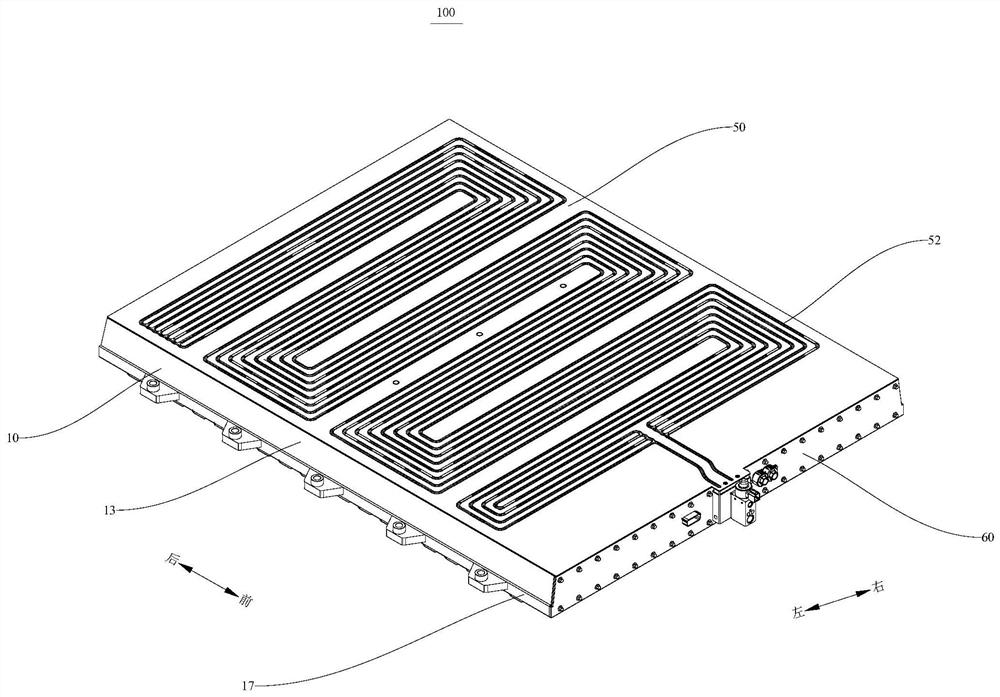

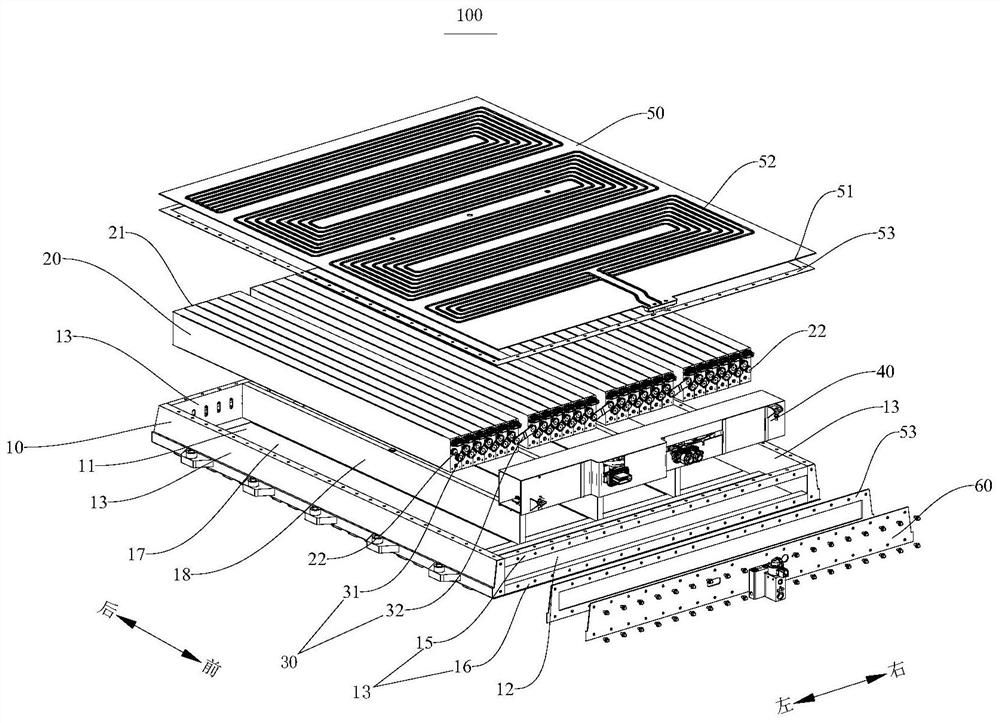

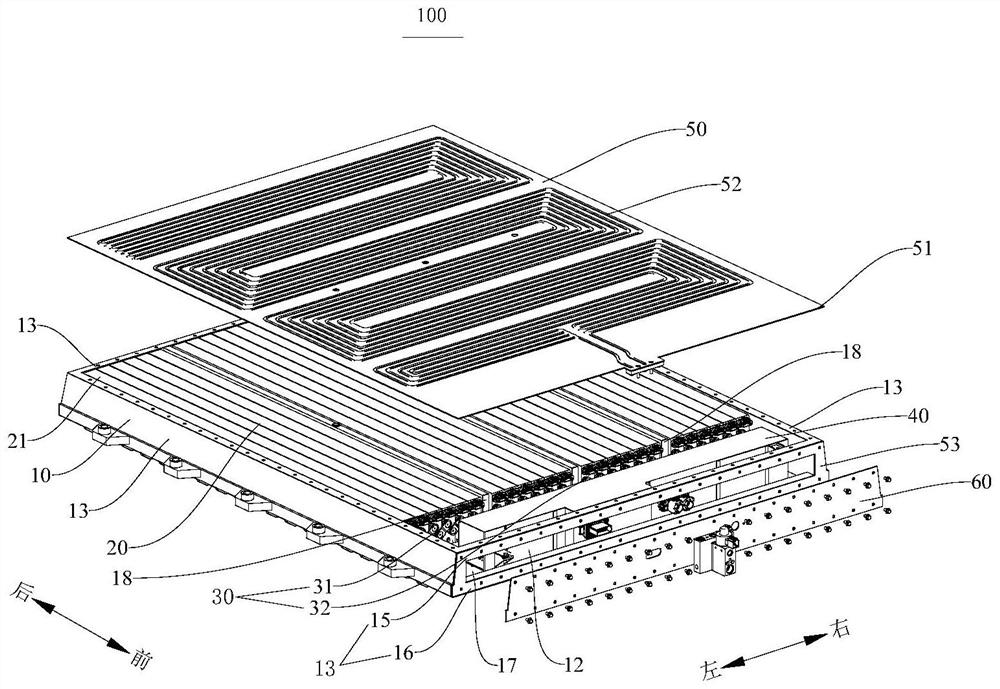

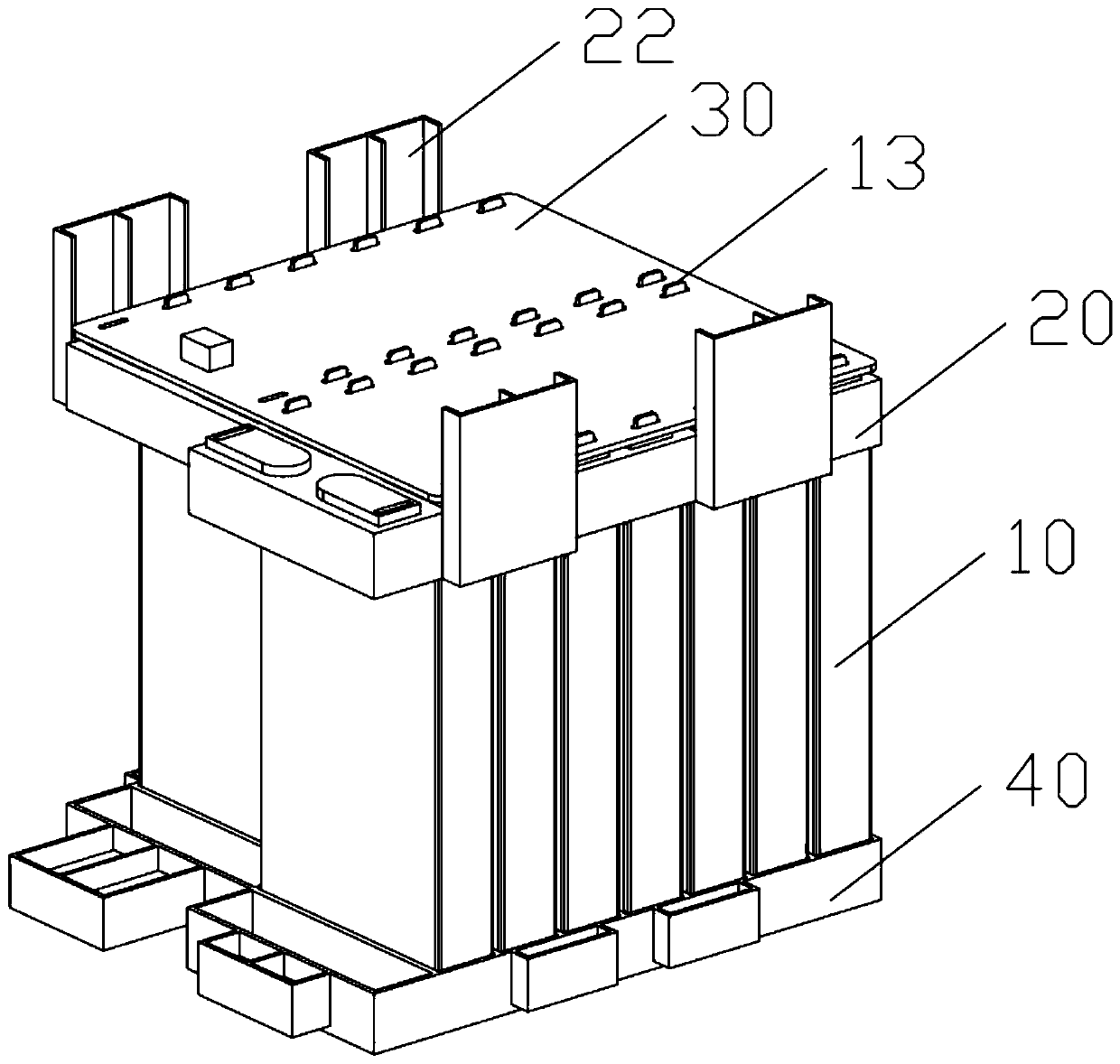

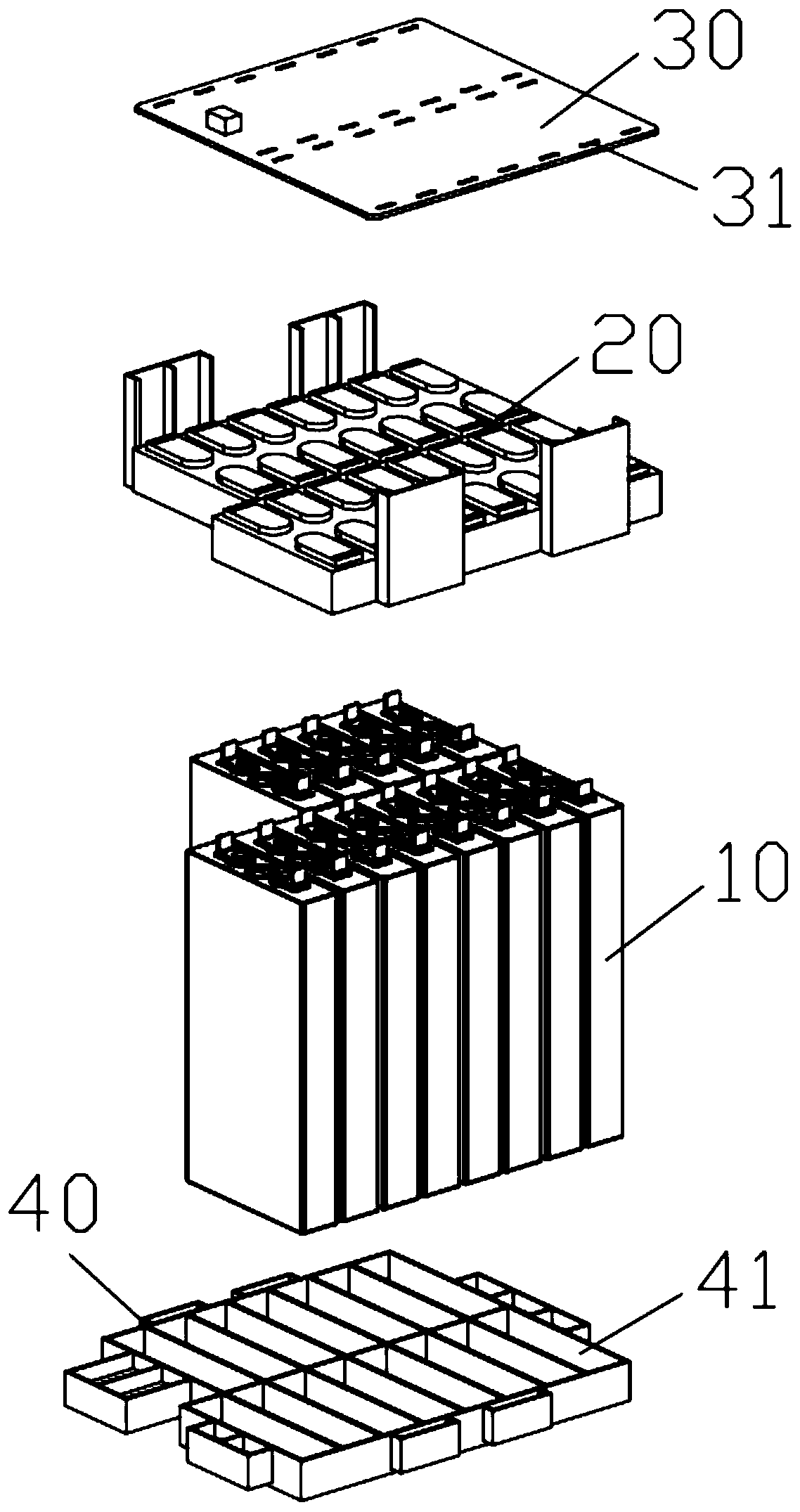

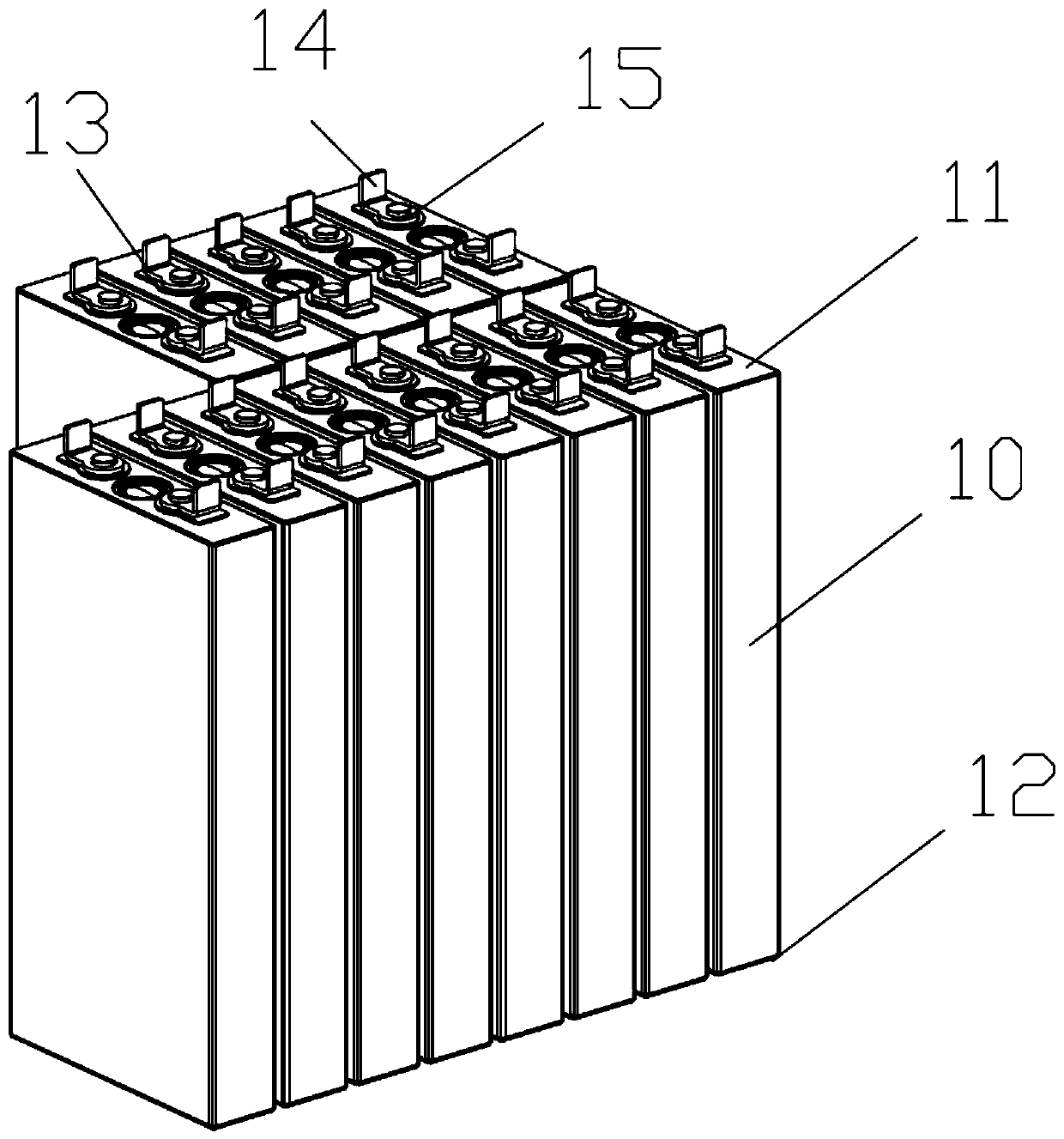

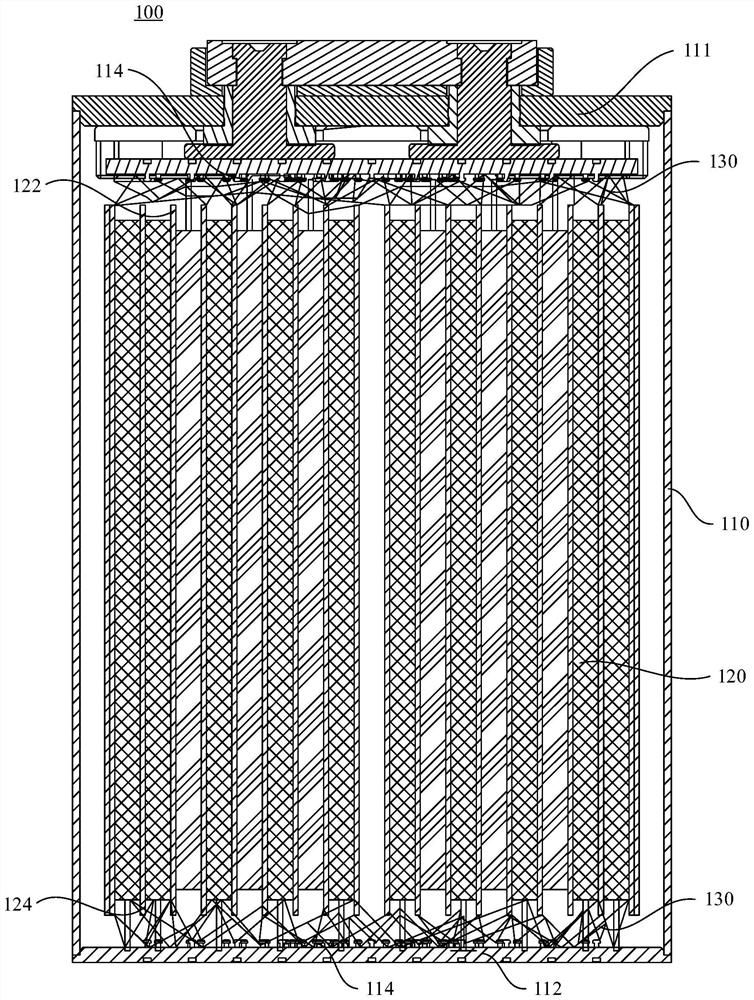

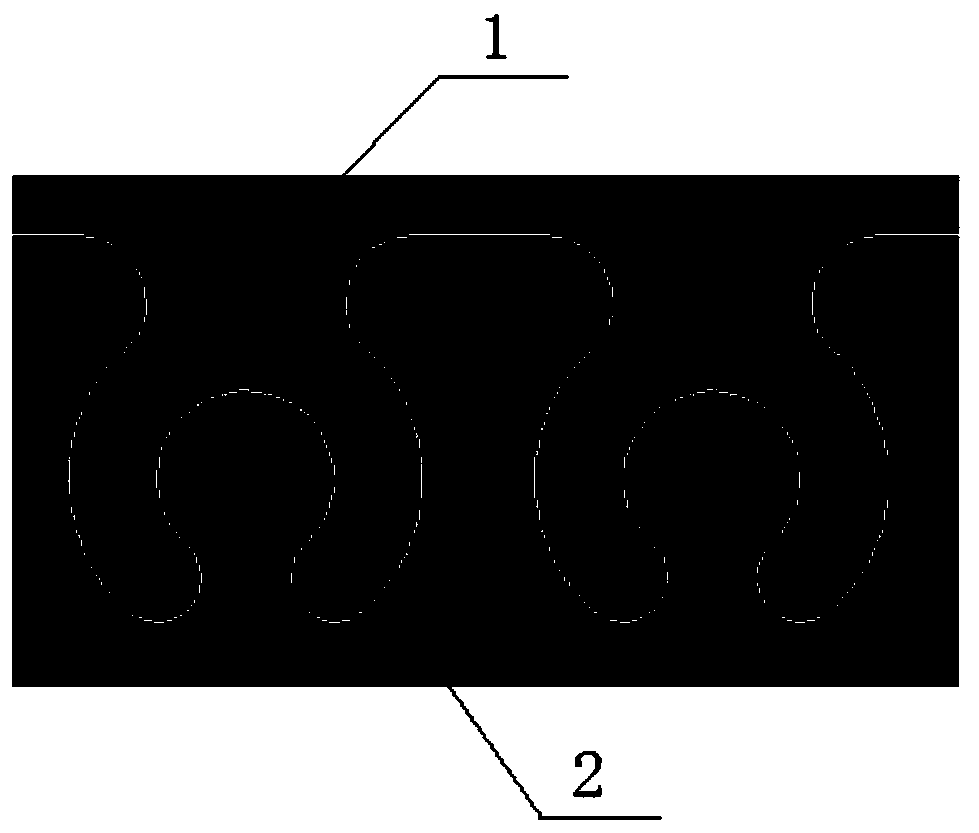

Battery pack and vehicle

ActiveCN113809479ASimple connection processOptimize process flowSecondary cellsCell lids/coversElectrical batteryElectrical connection

The invention discloses: a battery pack which comprises a tray, wherein a containing groove is formed in the tray, and a through hole is formed in the side wall of the containing groove; a battery array, wherein the battery array is arranged in the containing groove, the battery array comprises a plurality of batteries which are arranged in sequence, and an electrode terminal is arranged on the side, facing the through hole, of each battery; and an electric connecting piece, wherein the electric connecting piece is arranged in the accommodating groove and is connected with the electrode terminals of the at least two batteries, and the through holes can enable the electrode terminals and the electric connecting piece to be exposed. Therefore, the battery array can be firstly placed in the accommodating groove of the tray, and then the electrode terminal of the battery array in the accommodating groove and the electric connecting piece are connected together through the through hole in the tray, so that the connecting process of the electrode terminal of the battery array and the electric connecting piece does not need to be completed outside the tray, the assembling process of the battery pack can be reduced, and the technological process can be optimized.

Owner:BYD CO LTD

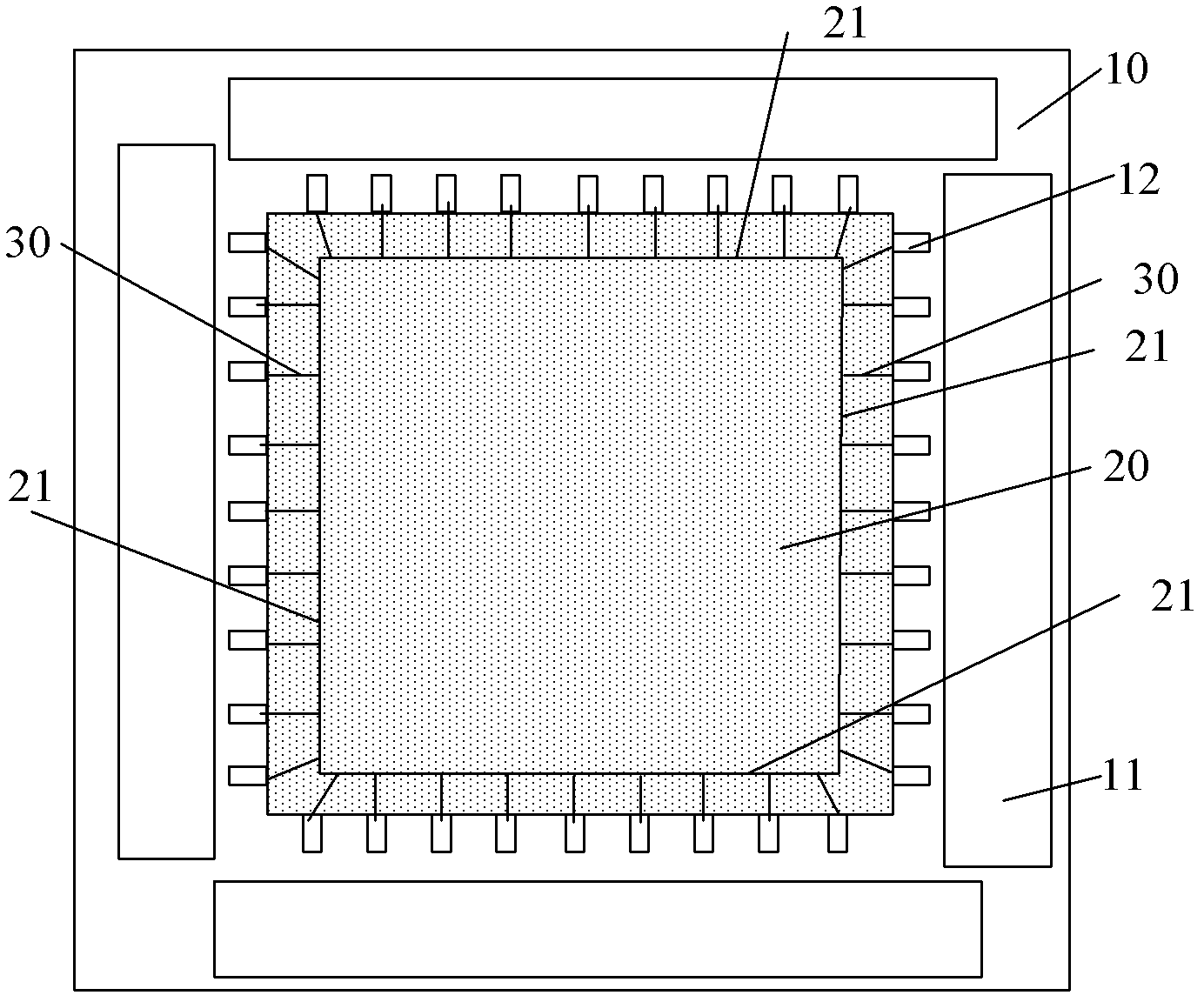

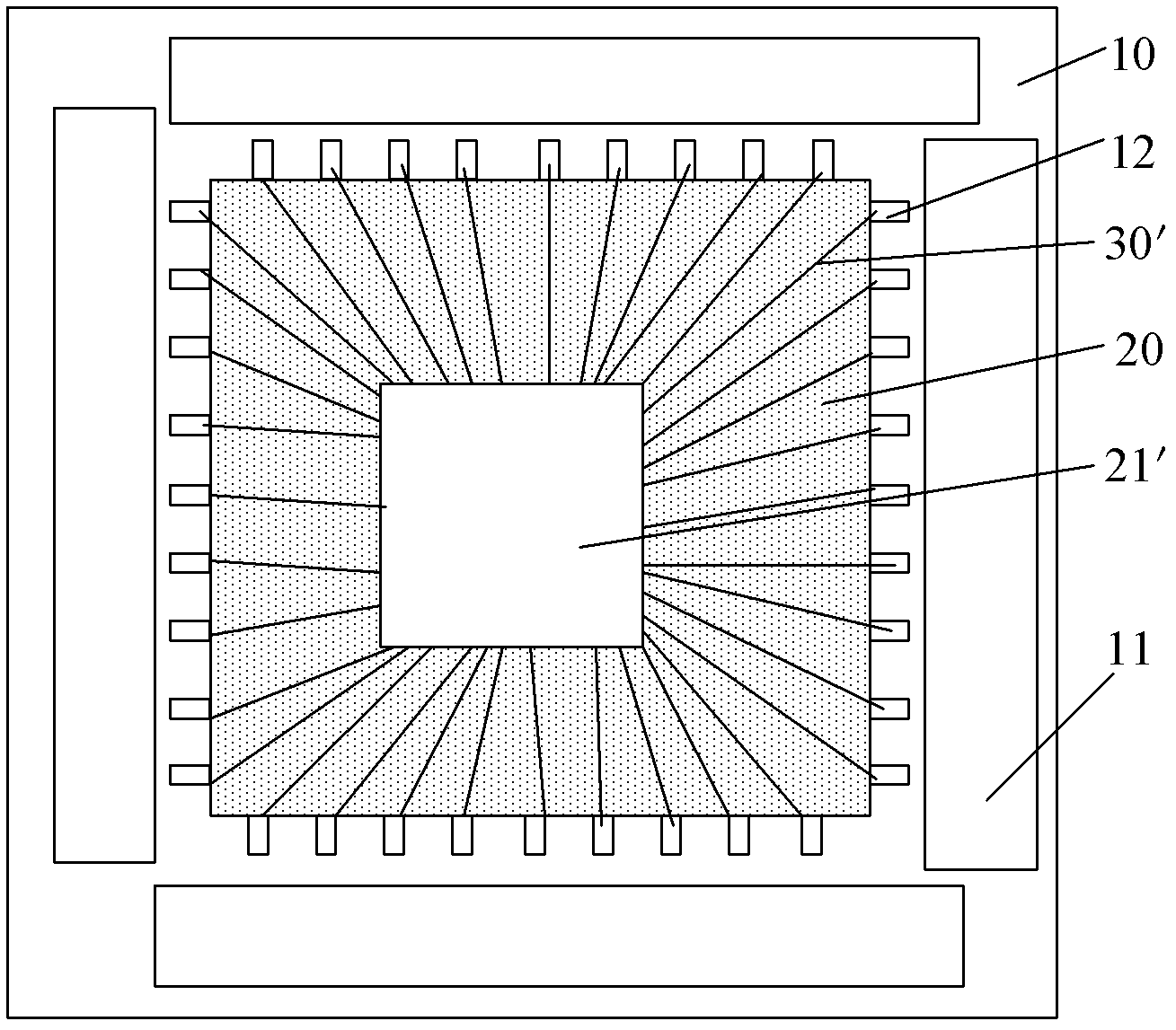

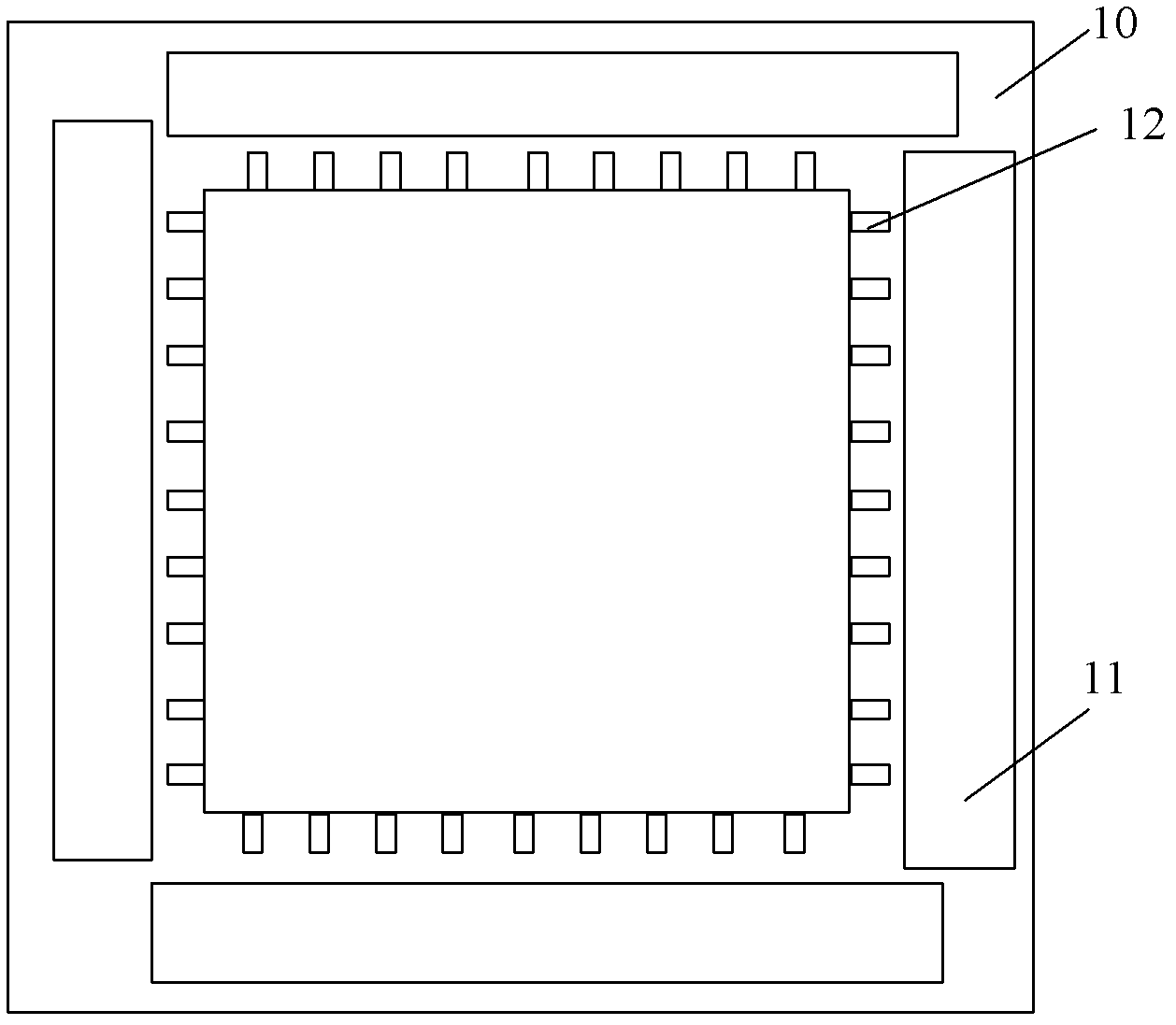

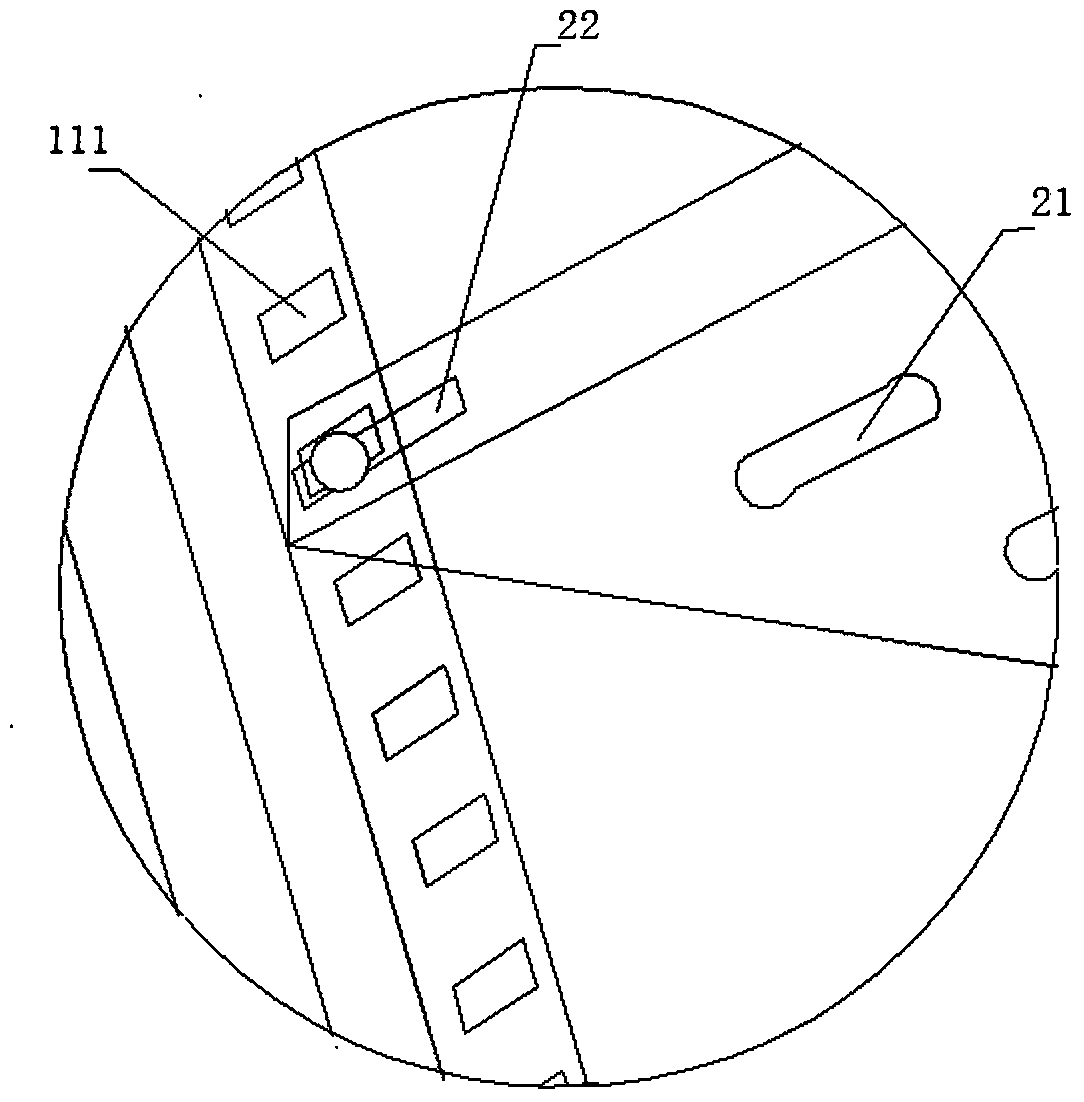

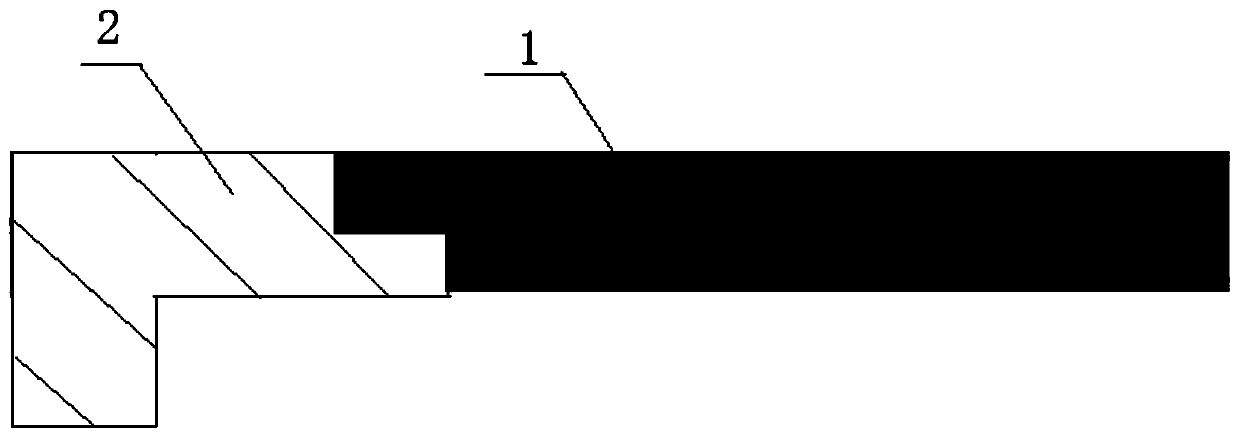

Printed circuit board and formation method thereof

ActiveCN103037615AAvoid short circuitSimple processSemiconductor/solid-state device detailsSolid-state devicesEngineeringPrinted circuit board

A printed circuit board comprises a substrate, wherein a first area and a second area are formed on the substrate, and the first area is arranged around the second area. A line is distributed at the first area, and a conductive area is formed at the second area. The line of the first area is electrically connected with the conductive area of the second area through wires, and the invention further provides a formation method of the printed circuit board. The line of the first area is electrically connected with the conductive area of the second area through the wires, and the second area is eliminated through adoption of a physical method so as to eliminate a short circuit. A method for eliminating the short circuit with the existing chemical process is replaced, and complexity of wire formation and wire elimination in the electroplating process is reduced. The electroplating process is simplified, process cost is reduced, technological process is simple, reliability of short circuit elimination is good, and efficiency is high.

Owner:JIANGNAN INST OF COMPUTING TECH

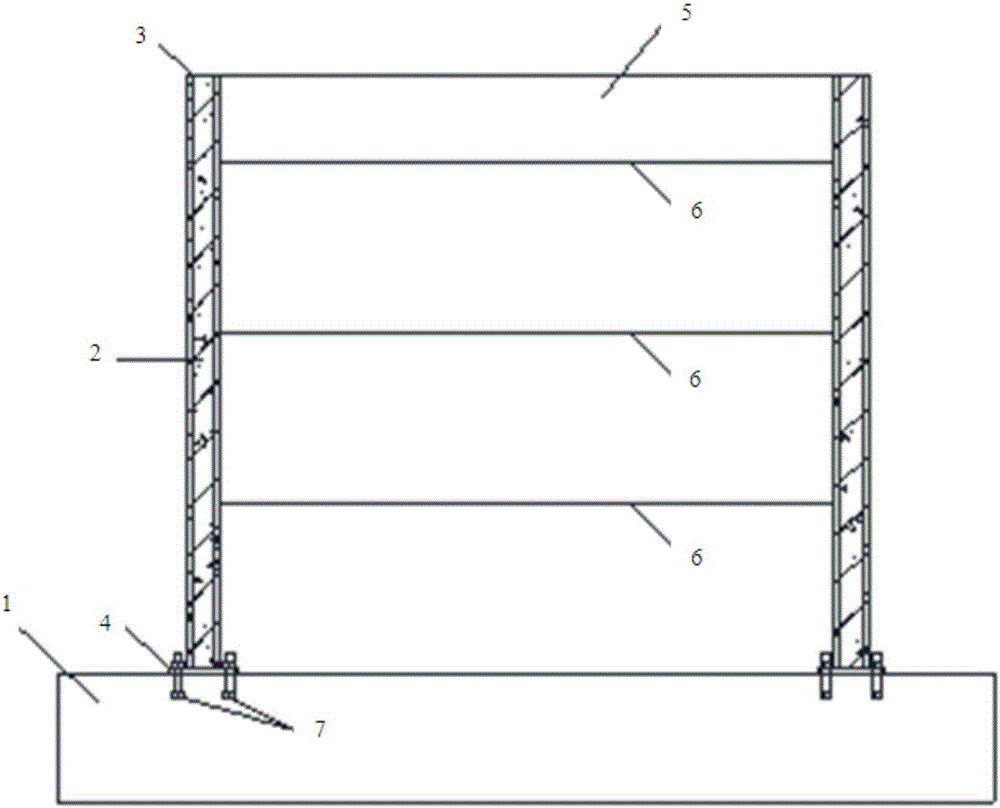

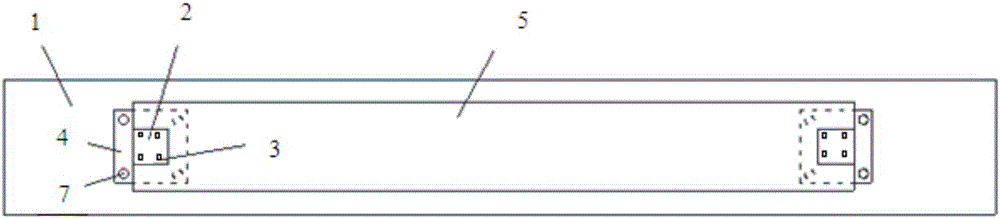

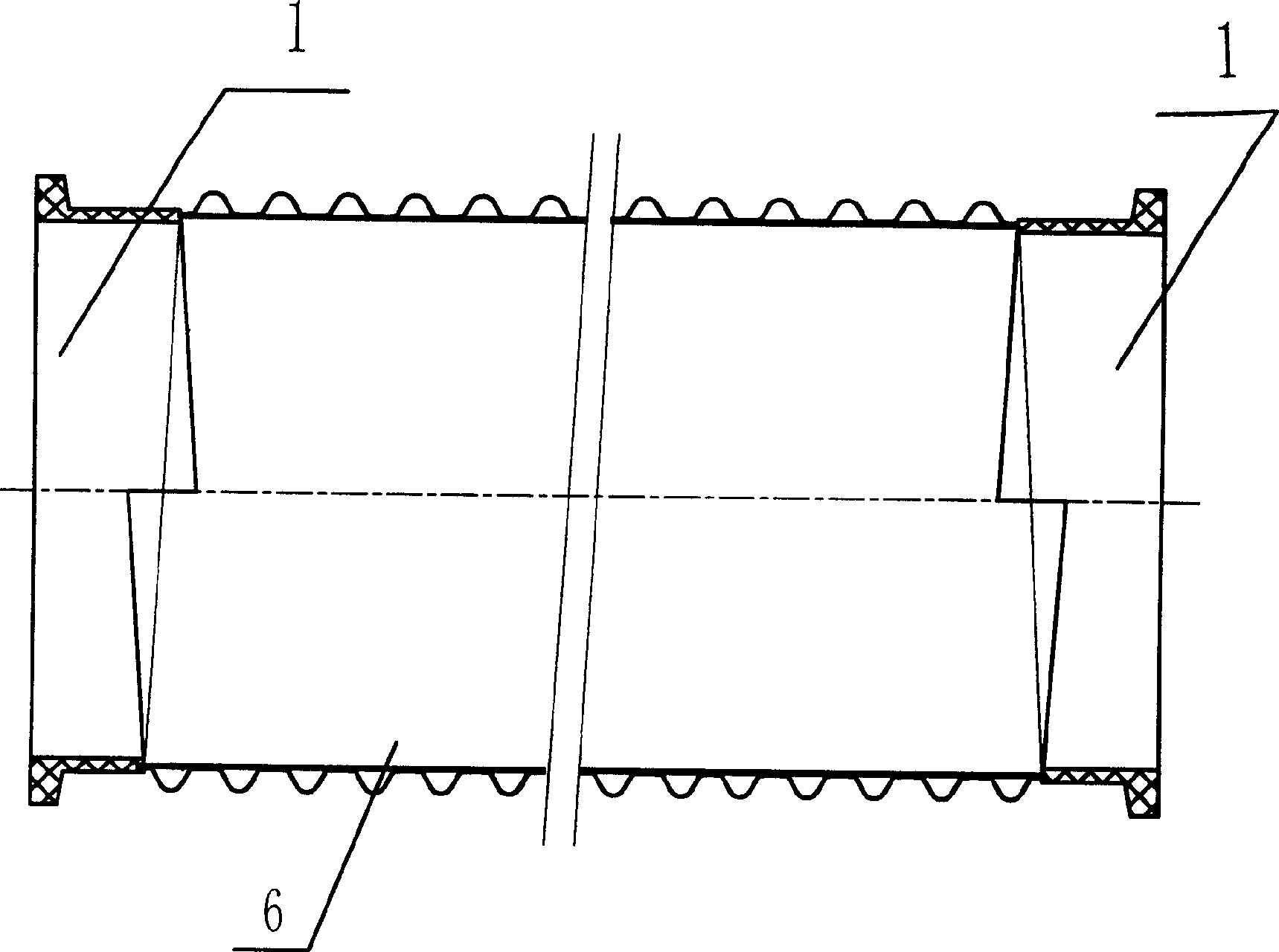

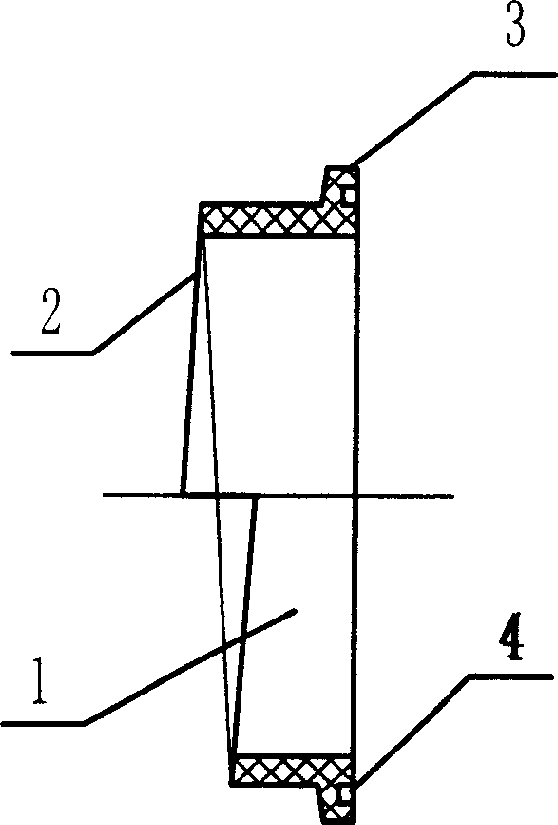

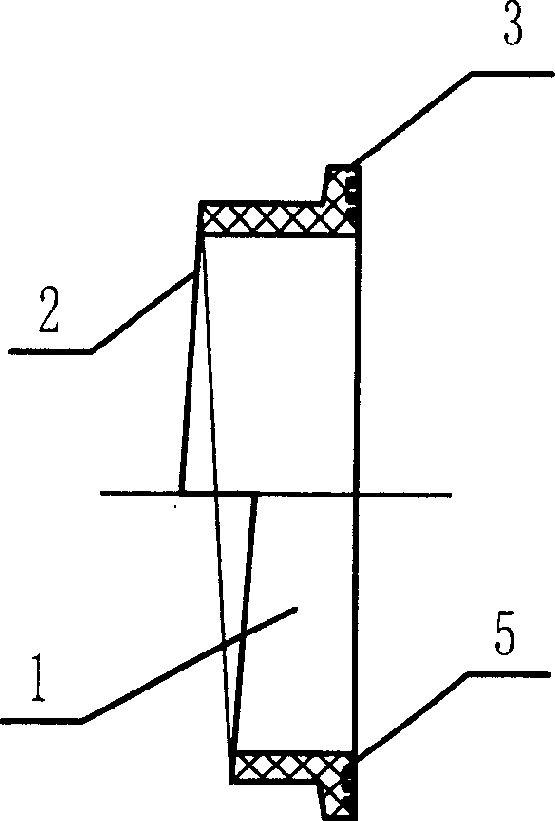

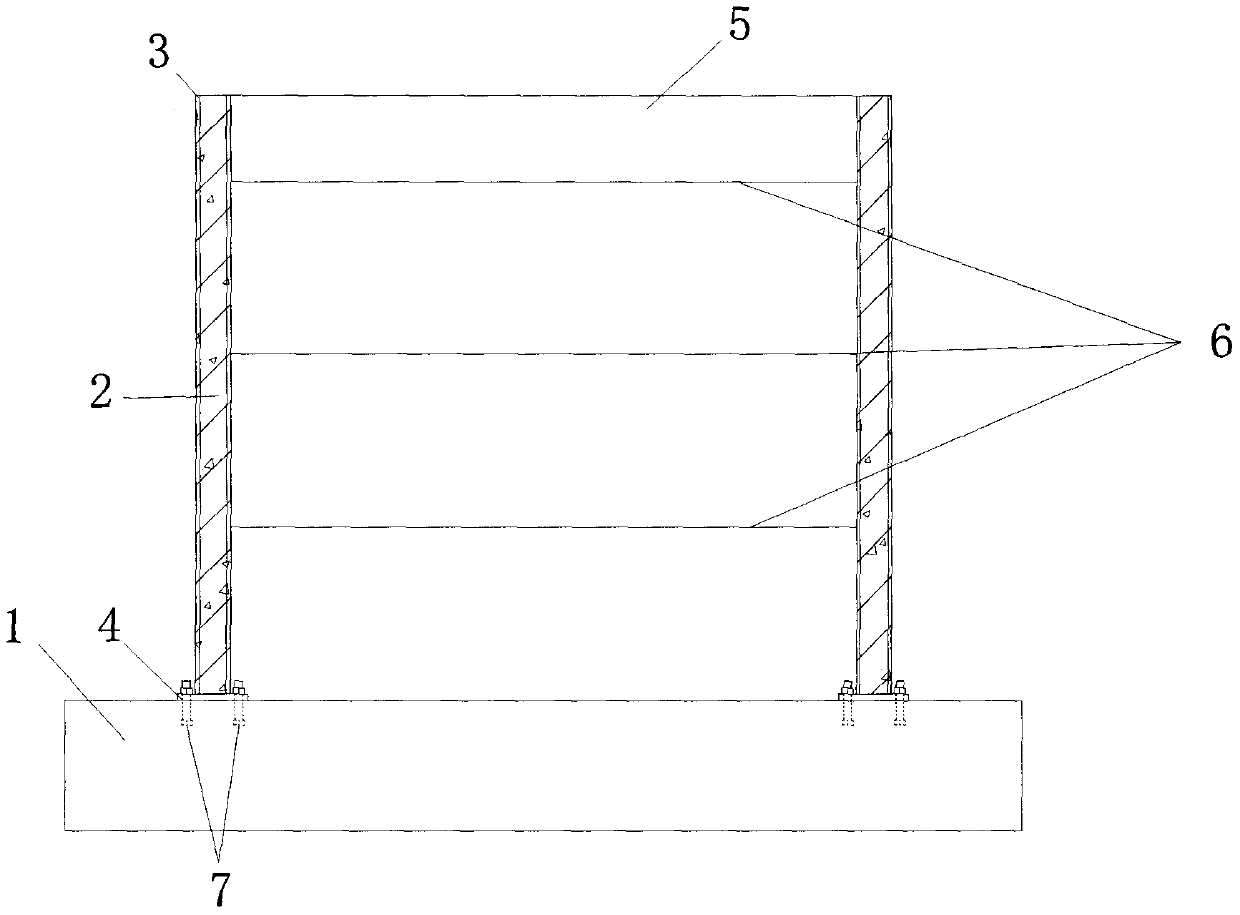

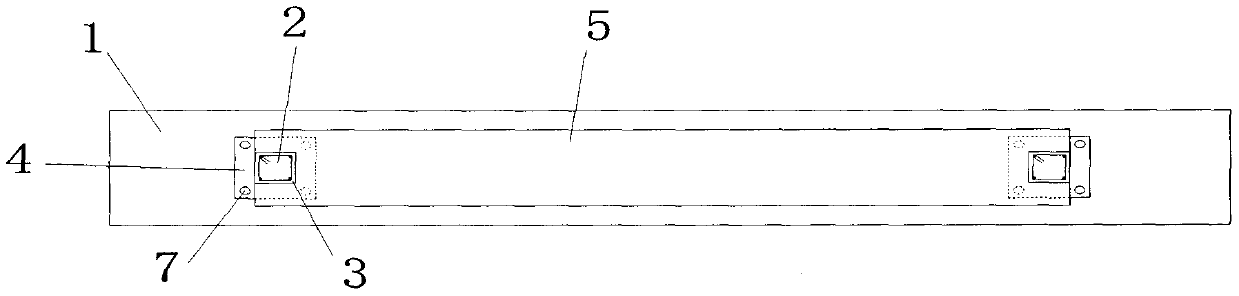

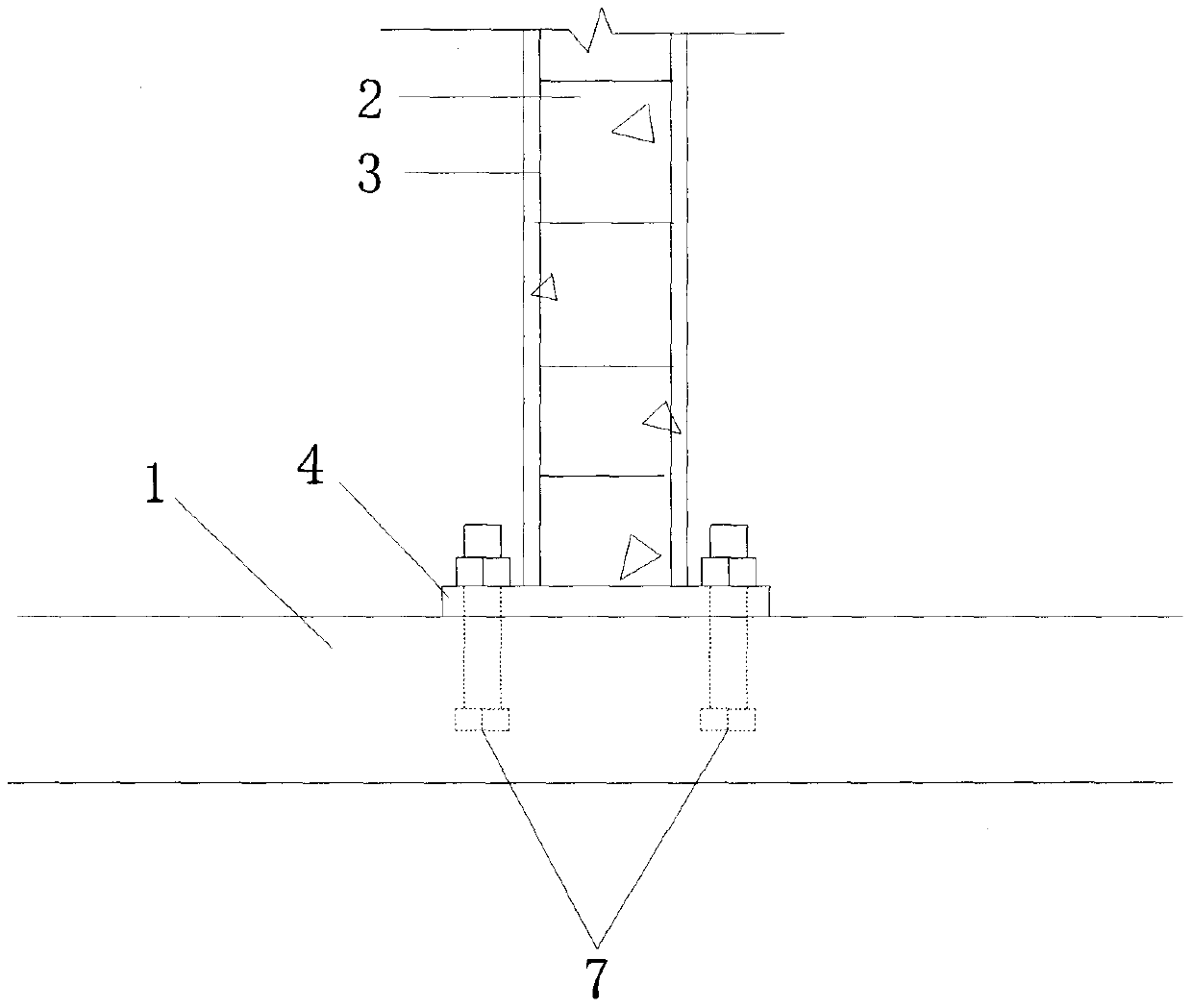

Rammed earth wall with precast concrete constructional columns

The invention discloses a prefabricated concrete structural column rammed earth wall, which is characterized in that it comprises a foundation ring beam (1), a prefabricated concrete structural column (2), a fixing plate (4), a rammed earth wall (5), and tie materials ( 6), pre-embedded bolts (7); said precast concrete construction column (2) is provided with four precast concrete construction column longitudinal bars (3), and said precast concrete construction column (2) is equipped with stirrups (8 ), the bottom of the precast concrete construction column (2) is provided with a fixing plate (4), and the precast concrete construction column (2) is fixedly connected with the foundation ring beam (1) with embedded bolts (7), the The fixed plate (4) is welded to the longitudinal reinforcement (3) of the precast concrete construction column, and the two sides of the rammed earth wall (5) are provided with tie materials (6) at intervals of a certain height, and the tie materials (6) The rammed earth wall (5) and the prefabricated concrete structural column (2) are formed as a whole.

Owner:TIANJIN CHENGJIAN UNIV

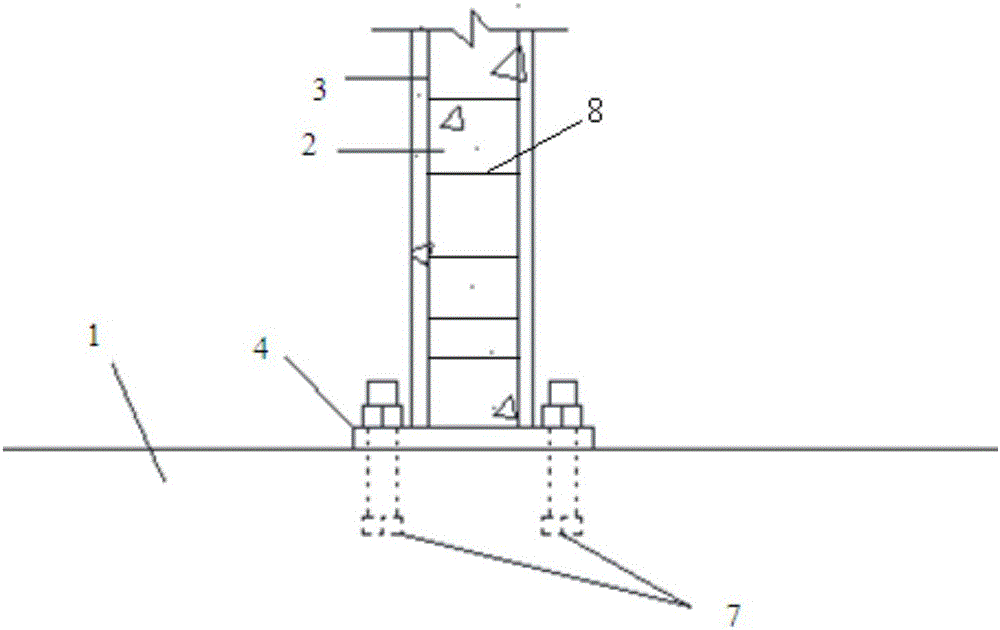

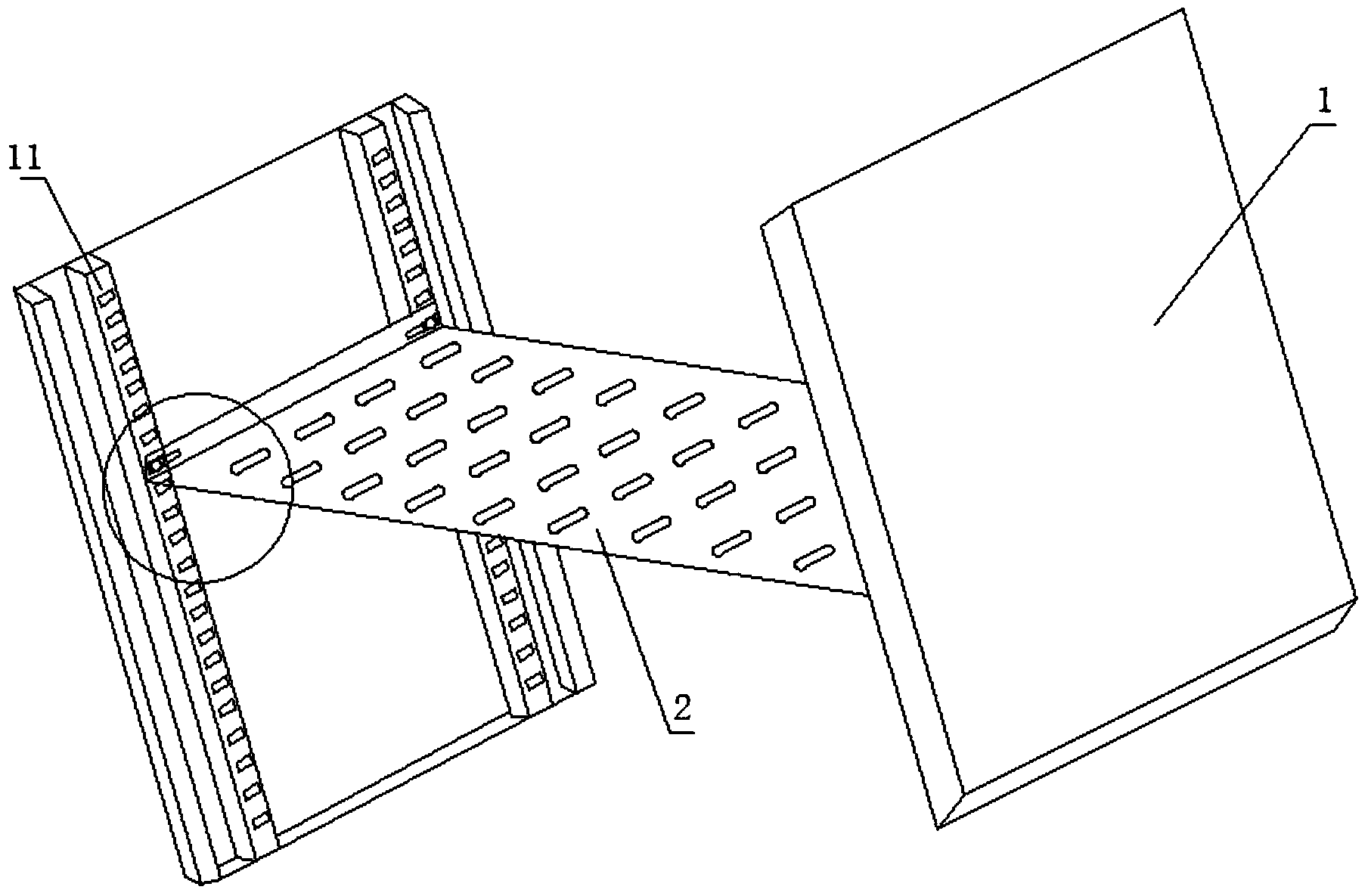

Case cabinet

InactiveCN104320947AEasy to organize and dischargeEasy to monitorMagnetic/electric field screeningCircuit arrangements on support structuresEngineeringMechanical engineering

The invention provides a case cabinet which comprises side boards, a back board, a door board, a top board and a bottom board. All the boards are detachably connected. The case cabinet further comprises a separation board. The separation board is detachably arranged between the two side boards and provided with multiple cable bunching holes. An opening is formed in the bottom board. Two to five detachable baffles are arranged in the opening. Due to the fact that the separation board is provided with the cable bunching holes and the bottom board is provided with the opening and the detachable baffles, cables near the cable bunching holes can conveniently penetrate through the cable bunching holes and the opening so as to be sorted and arranged, and the purpose of the reasonable layout of the cables is achieved; meanwhile, the adaptability is improved due to the multiple cable bunching holes and the requirements for bunching the cable in different positions can be met; due to the arrangement of the multiple detachable baffles, the different conditions of the cables with the number changing from small to large can be met, the number of the detached baffles is determined according to the number of the cables, and adaptability is further improved.

Owner:天津市晟宇金属制品有限公司

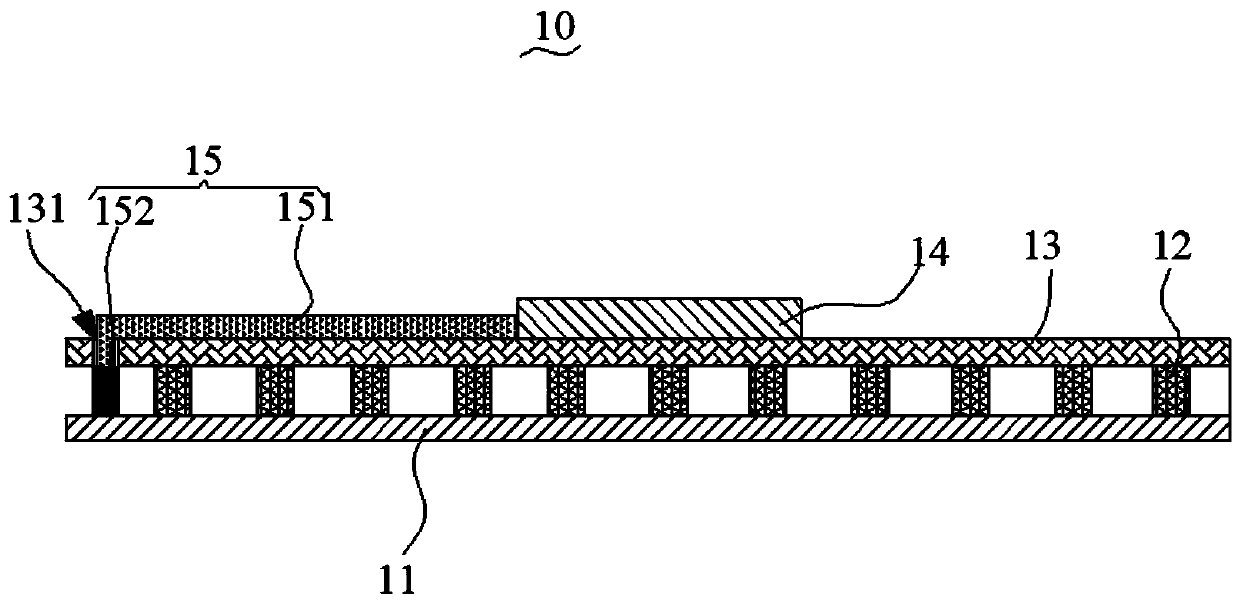

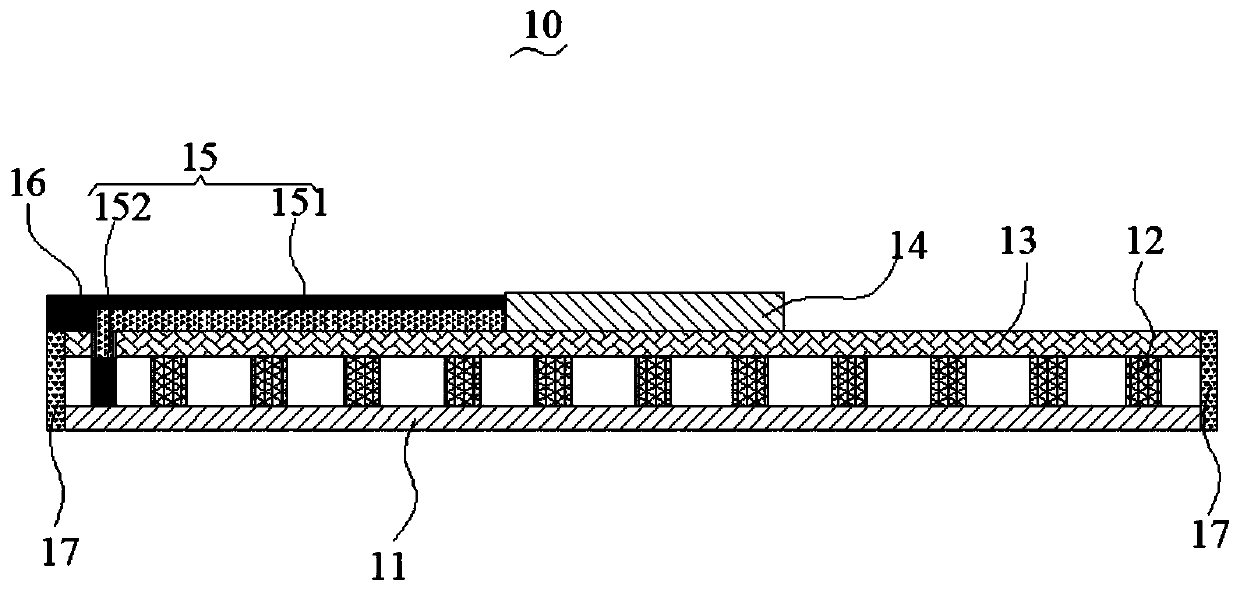

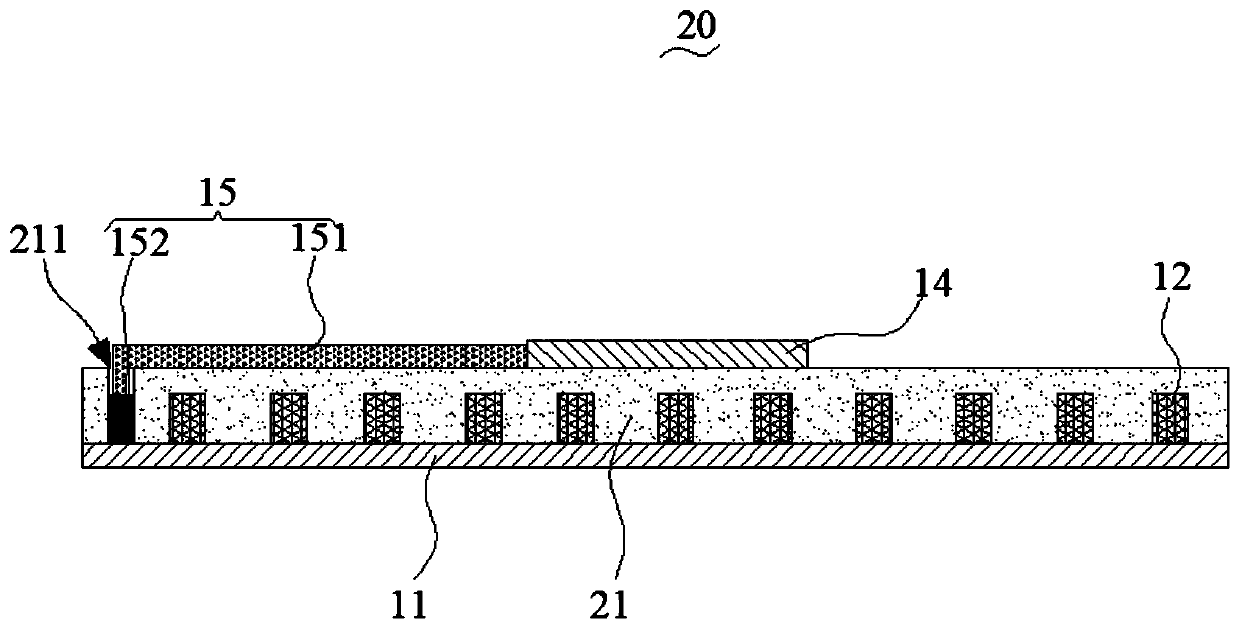

Display panel and manufacturing method thereof

InactiveCN110416242ASimple connection processSimple processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDriving circuit

The invention discloses a display panel and a manufacturing method thereof. The display panel includes a substrate; a plurality of LEDs which are arranged at one side of the substrate in an array manner; a flat layer which is arranged on one side of the substrate and covers the plurality of LEDs; a driving circuit chip which is arranged at one side, back to the plurality of LEDs, of the flat layer; and a bonding structure which penetrates through the flat layer and is connected with the driving circuit chip and the LEDs. According to the invention, the connection process between the driving circuit chip and the LEDs can be simplified, and the product yield is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

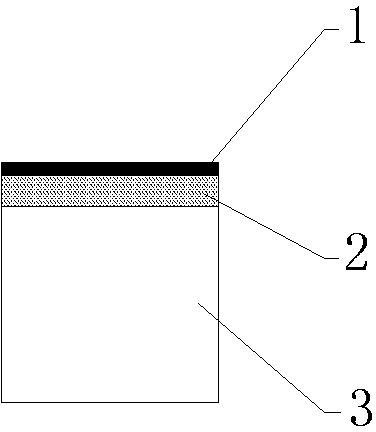

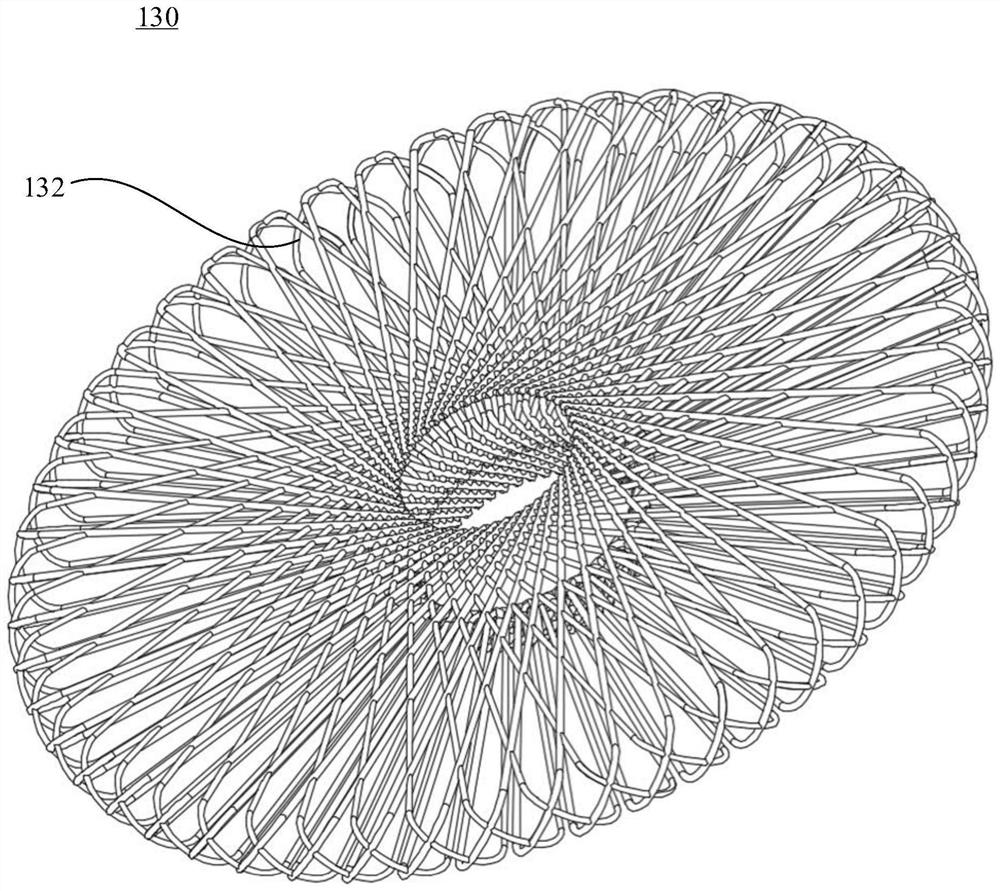

Battery cell combination and battery assembly using same

PendingCN110534678AOmit connectionSimple connection processBattery isolationBatteriesEngineeringChipset

The invention relates to a battery cell combination and a battery assembly using the battery cell combination. The battery cell combination comprises a chipset, an insulation board and a circuit board. The chipset is composed of a number of single battery chips. Each battery chip comprises an upper end face and a lower end face opposite to the upper end face. The insulation board covers the upperend face. The circuit board is placed on the insulation board. The upper end face is provided with positive and negative electrode tabs, and the electrode tabs are fixedly connected with the circuit board through the insulation board. The battery cell assembly not only omits a tab fixing plate and an auxiliary connecter between the electrode tabs and the tab fixing plate in the prior art, but alsoomits wire connection between the tab fixing plate and the circuit board, and has the advantages of simple connection process, low cost and high connection strength.

Owner:海睿能源科技(湖州)有限公司

Vacuum aluminized paper

InactiveCN103397573AModerate increaseHigh strengthFlexible coversWrappersEpoxyPulp and paper industry

The invention discloses a vacuum aluminized paper and relates to the package material field. The vacuum aluminized paper comprises a base layer and an aluminized layer. The vacuum aluminized paper is characterized in that the thickness of the aluminized layer is 0.05-0.075 micron; a pull-resisting layer is arranged between the base layer and the aluminized layer; the pull-resisting layer is made of composite materials of epoxy resins and phenyl ether. The vacuum aluminized paper can be applied in the food and medicine packaging fields, and has good flexibility and pull resistance. The intensity of the paper can be ensured and damage can be prevented. The vacuum aluminized paper is an environmental protection material with air blocking performances of aluminum foil composite papers.

Owner:KUNSHAN RONGAO WEIJIE TRADE

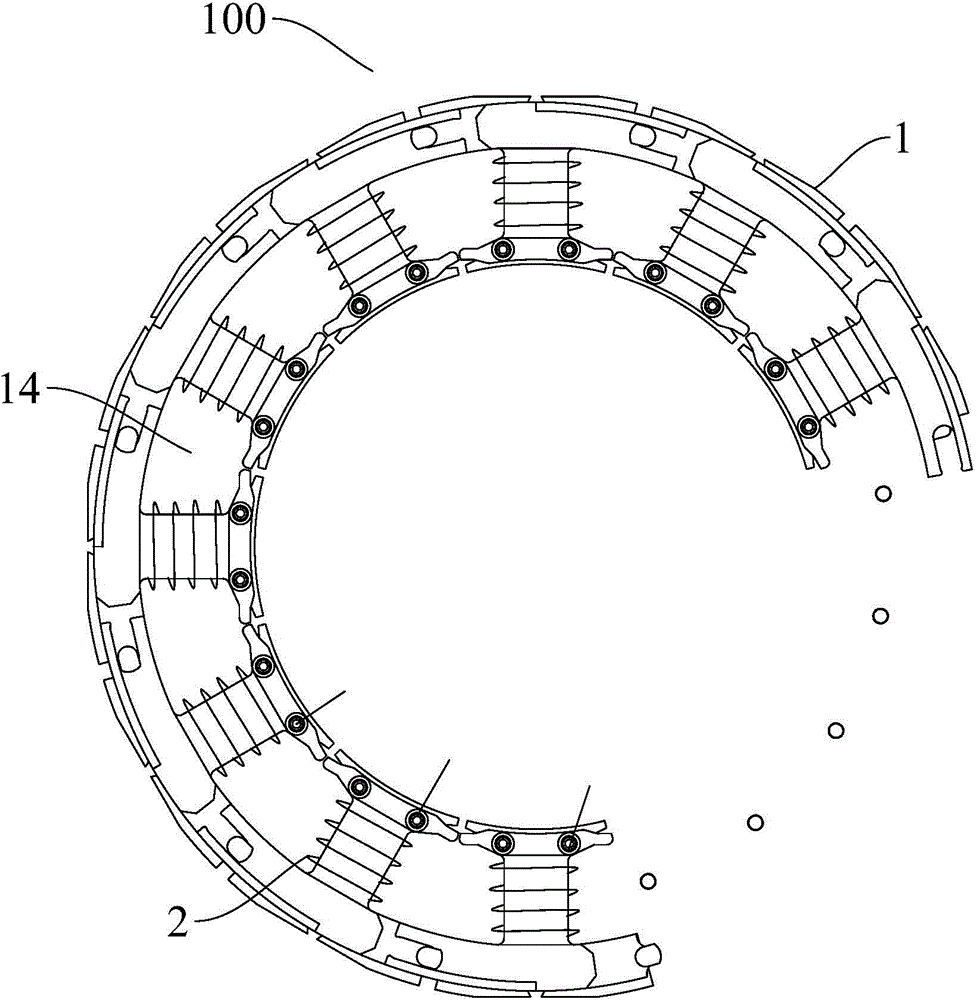

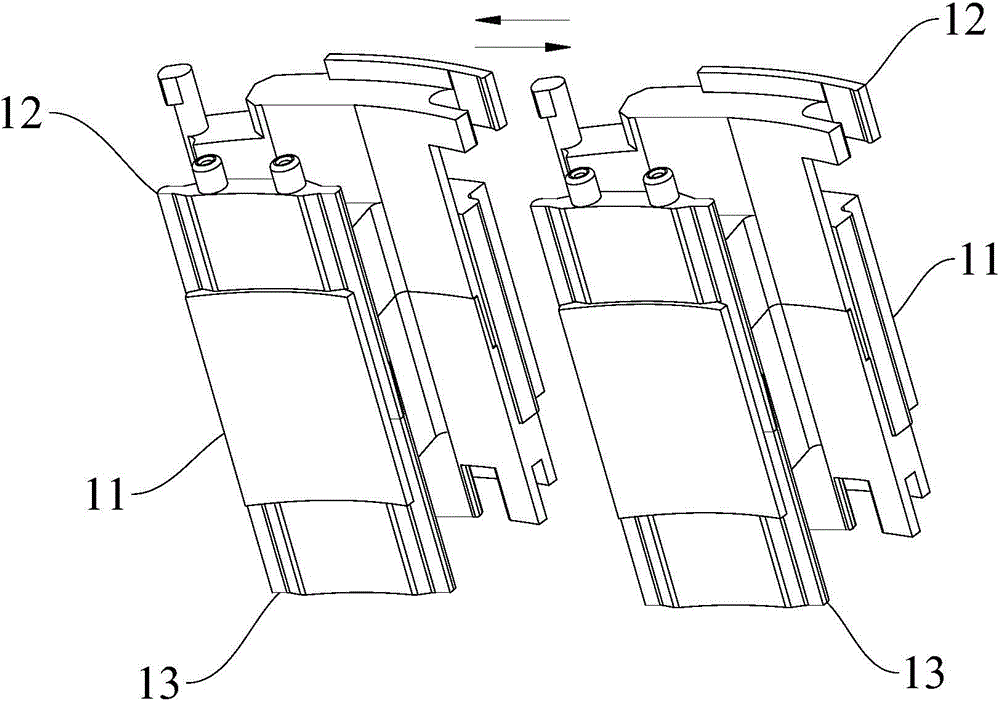

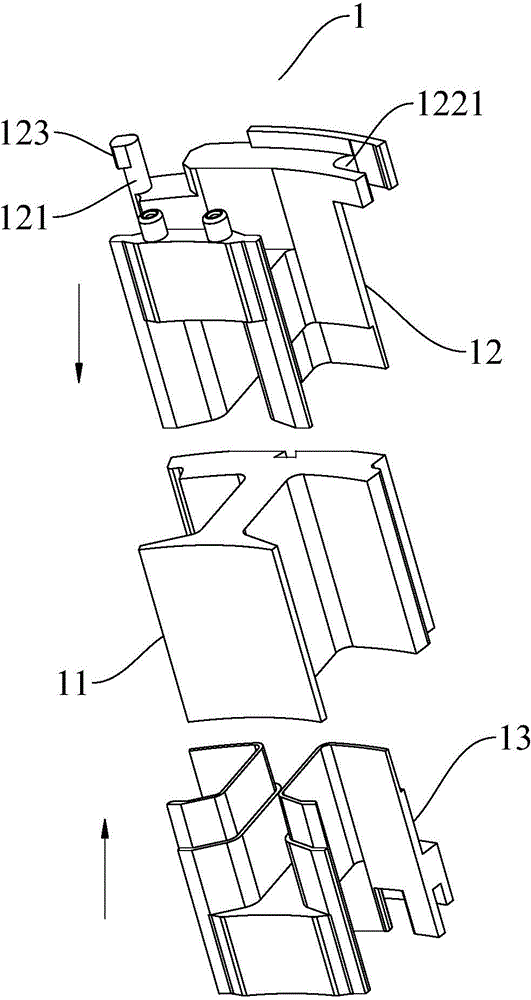

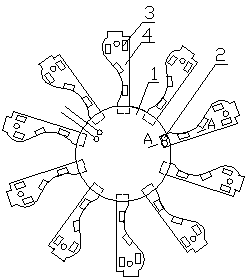

Motor stator and motor employing same

InactiveCN104901445AImprove winding efficiencyIncrease productivityWindings insulation shape/form/constructionMagnetic circuit stationary partsStator coilPhysics

The invention discloses a motor stator and a motor employing same. The motor stator comprises a partitioned stator and a stator coil, wherein the partitioned stator comprises a plurality of partitioned iron cores arranged on the circumferential direction, and the two axial ends of each partitioned iron core are provided with a first insulating frame and a second insulating frame. A first end and a second end are arranged on the circumferential direction of each first insulating frame, a receiving groove is formed on the first end of each first insulating frame, and the second end of each first insulating frame is provided with a connection projection which rotatably cooperates in a connection groove between adjacent first insulating frames. The stator coil winds on the partitioned stator, and comprises at least one-phase coil. The partitioned iron cores are connected into a linear shape through the first insulating frame, and each phase of coil is continuously wound on at least one part of the linear partitioned iron cores. According to the motor stator of the invention, the production efficiency and reliability of the motor stator are improved, and the cost is lowered.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Cylindrical battery and energy storage device

PendingCN114361466AEasy to storeFacilitated releaseFinal product manufactureElectrode carriers/collectorsStructural engineeringMechanical engineering

The invention discloses a cylindrical battery and an energy storage device, and relates to the technical field of energy storage. The cylindrical battery comprises a battery shell and a roll core arranged in the battery shell, the battery shell comprises a cover plate assembly and a bottom plate which are oppositely arranged, at least one end of the roll core is provided with a net-shaped current collector, the bottom plate and / or the cover plate assembly are / is provided with a plurality of protrusions corresponding to the current collector, and the protrusions are arranged on the bottom plate and / or the cover plate assembly. And the roll core is connected with the bulge through the current collector. The over-current capability at the confluence can be improved, so that the monomer capacity is improved, and the method is better suitable for a high-magnification application scene.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

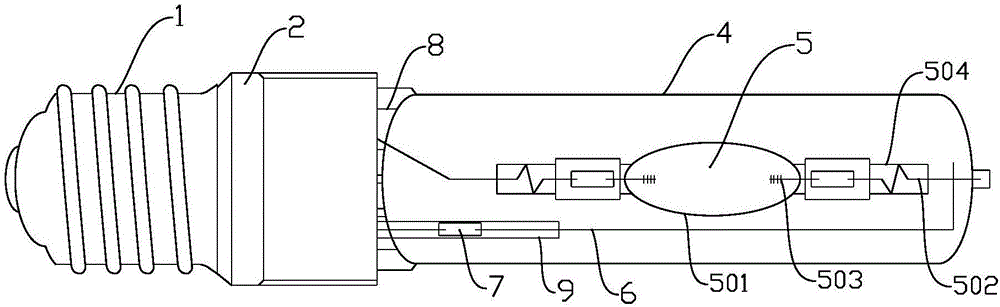

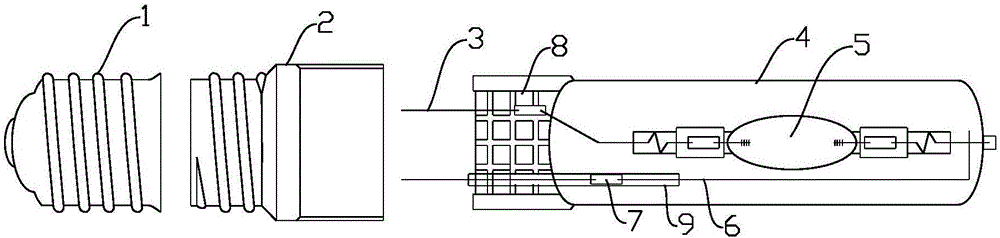

Xenon lamp and manufacturing technology thereof

ActiveCN106373859AAvoid arcingEasy to installElectric discharge tubesGas discharge lamp detailsManufacturing technologyBiochemical engineering

The invention relates to a xenon lamp and a manufacturing technology thereof. The xenon lamp comprises a lamp holder, a lamp tube and a luminescent tube arranged in the lamp tube, wherein the lamp holder comprises a fixed seat and a connector arranged at one end of the fixed seat; the connector is internally provided with a cavity for installing the lamp tube; the fixed seat is internally provided with two connecting passages; one end of each of the two connecting passages is communicated with the cavity respectively, and one of the other ends of the two connecting passages is communicated to the outside of the side wall of the fixed seat, and the other of the other ends of the two connecting passages is communicated to the lower end face of the fixed seat; two electrode leads of the luminescent tube are arranged in the two connecting passages respectively; one end of each of the two electrode leads is connected with a molybdenum sheet respectively, the molybdenum sheets of the two electrode leads are arranged in a staggered manner and are arranged in a clamping and sealing port and the lamp tube respectively, an insulating sleeve is arranged on the molybdenum sheet positioned in the lamp tube in a sleeving manner, and one end of the insulating sleeve stretches out of the clamping and sealing port along the corresponding electrode lead. By using a clamping and sealing technology, the required time of the manufacturing process is short, and the manufacturing qualified rate is high; the connecting process between the lamp tube and the lamp holder is simple, and the reliability of connection between the lamp tube and the lamp holder is improved.

Owner:四川梦天节能科技有限公司

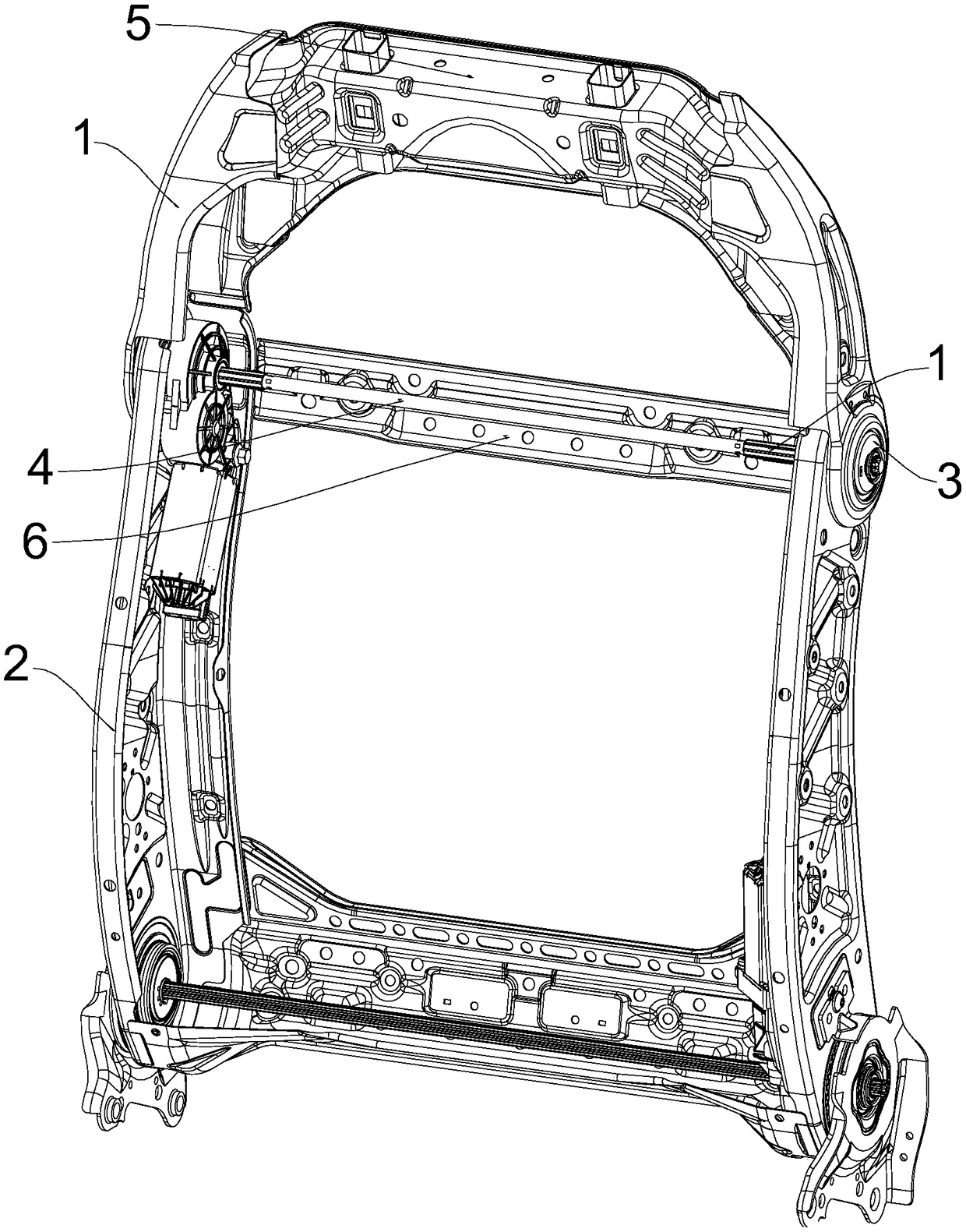

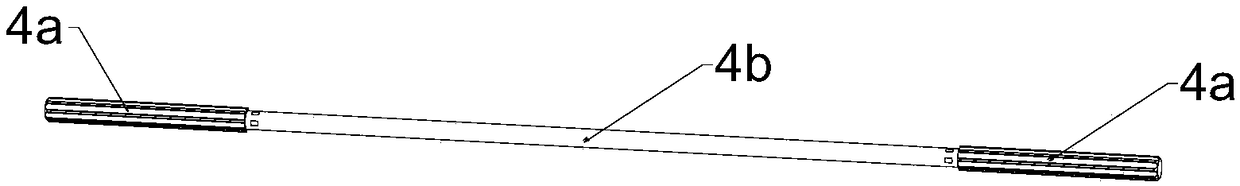

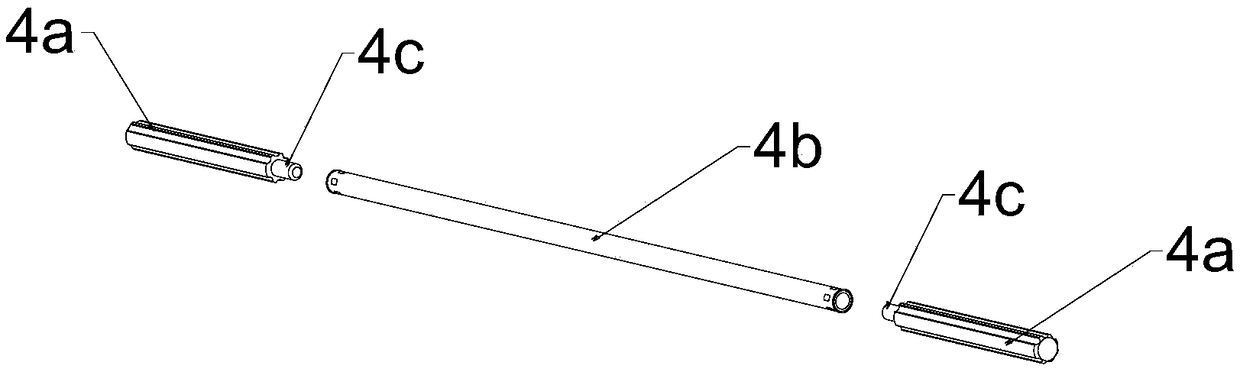

An angle adjuster type seat back shoulder adjusting structure

An angle adjuster type seat back shoulder adjusting structure includes two backrest retaining side panels positioned facing each other, An upper part of that two backrest fix side plates is respectively connected with a backrest rotate side plate, the backrest rotating side plate is hinged with the corresponding backrest fixing side plate, At least one angle adjuster is connected with the backrestrotation side plate and the backrest fixing side plate on either side, and a synchronous rotation transmission shaft is connected with the backrest rotation side plate on the opposite side between the center shaft of the angle adjuster and the synchronous rotation transmission shaft, and the synchronous rotation transmission shaft comprises an assembly section and a failure section arranged alongthe same axial direction. The invention has the advantages that, When the angle adjuster is unlocked, the rotating side plates of the backrest on both sides can realize synchronous rotation under thecoordination of synchronous rotation transmission shafts, and the left and right sides can balance each other. When the synchronous rotation transmission shafts are subjected to a certain bending force, damage can occur to avoid damage to passengers, thus realizing shoulder adjustment and meeting the seat safety requirements.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

Plain end screw pipe and processing method thereof

InactiveCN1888506AReasonable designConvenient and cost-effective electrofusion welding connectionRigid pipesPipe connection arrangementsPlastic pipeworkEngineering

The inventive spiral pipeline consists of a spiral pipeline body and a connecting member fixed at one end or two ends of the spiral pipeline body for connecting the end ports. One end of the screw end port connecting member is a screw end port and the other end is a flat port. The inventive manufacture method includes the following steps of heating melting the screw end ports of the connecting member and the spiral pipeline body and welding two screw end ports together under a certain pressure to be a integral one, at last changing the screw end port of the spiral pipeline body into the flat port to realize the flat port connection between the pipelines.

Owner:枫叶控股集团有限公司

Prefabricated concrete construction column rammed earth wall provided with horizontal tie bars

Owner:TIANJIN CHENGJIAN UNIV

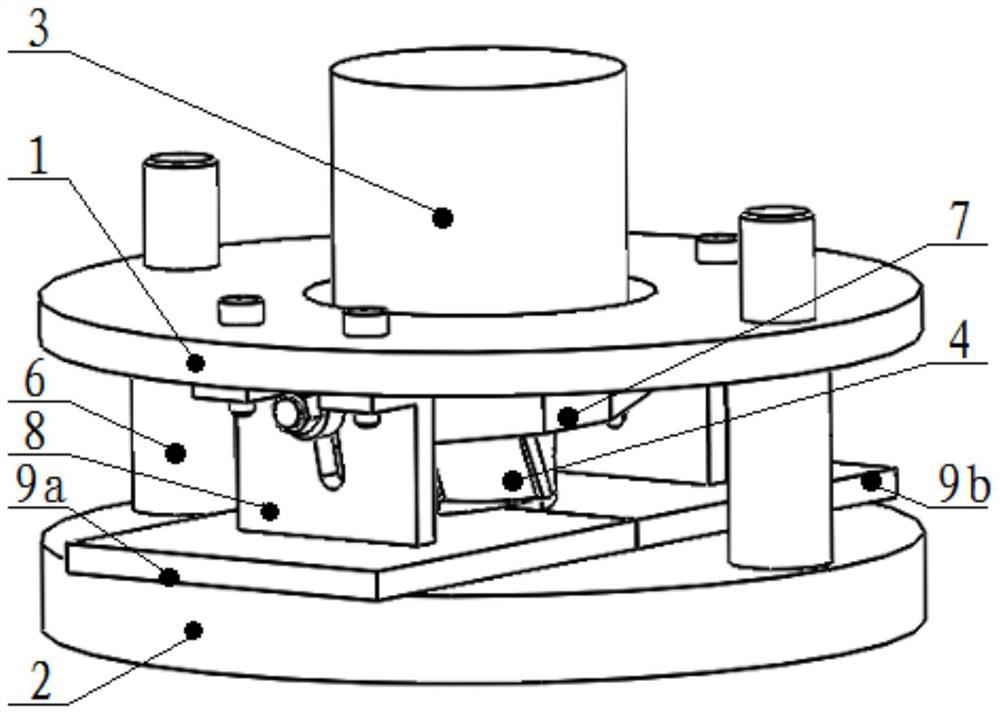

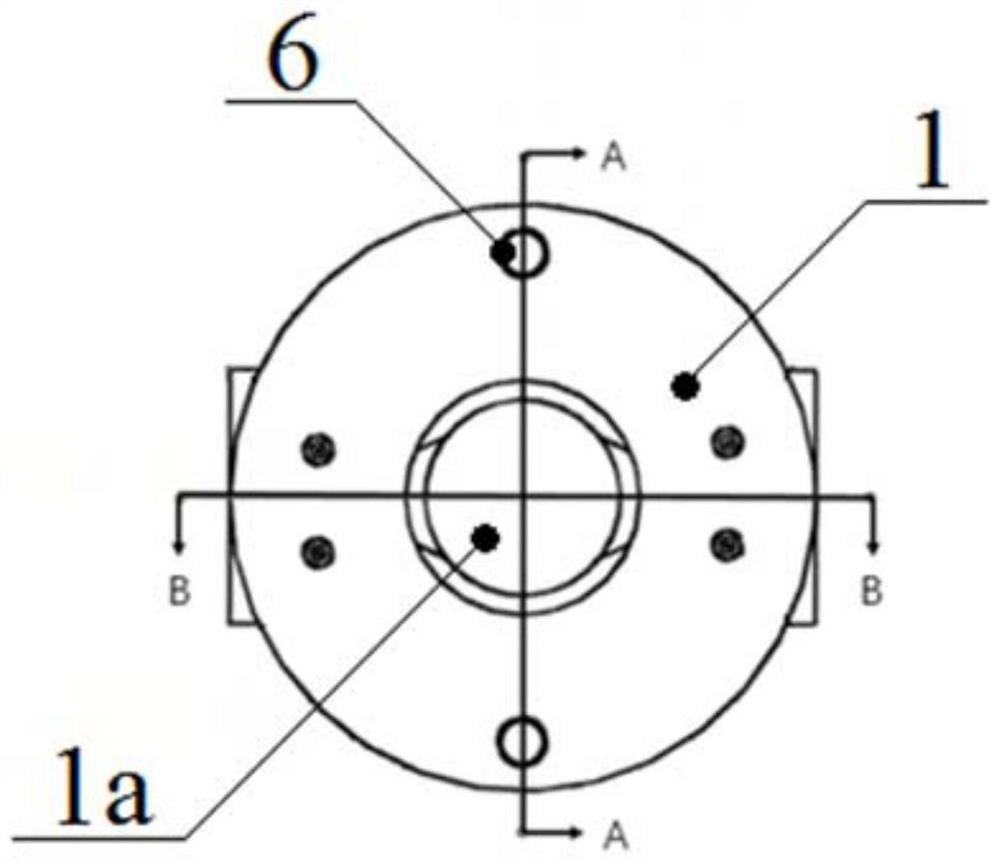

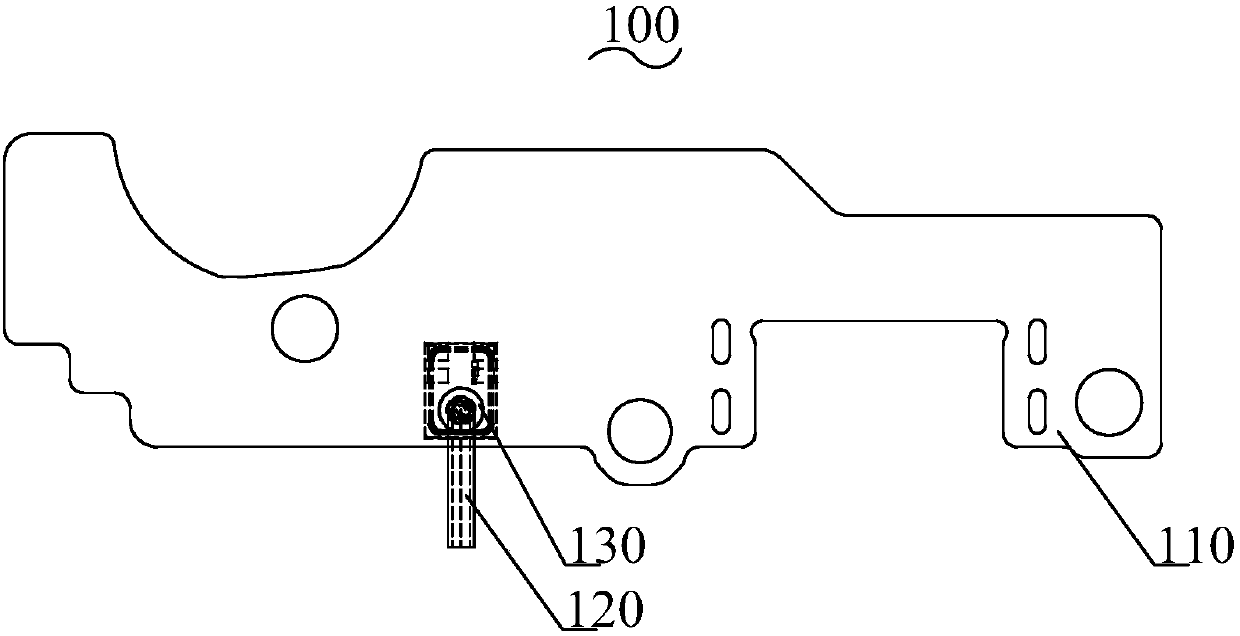

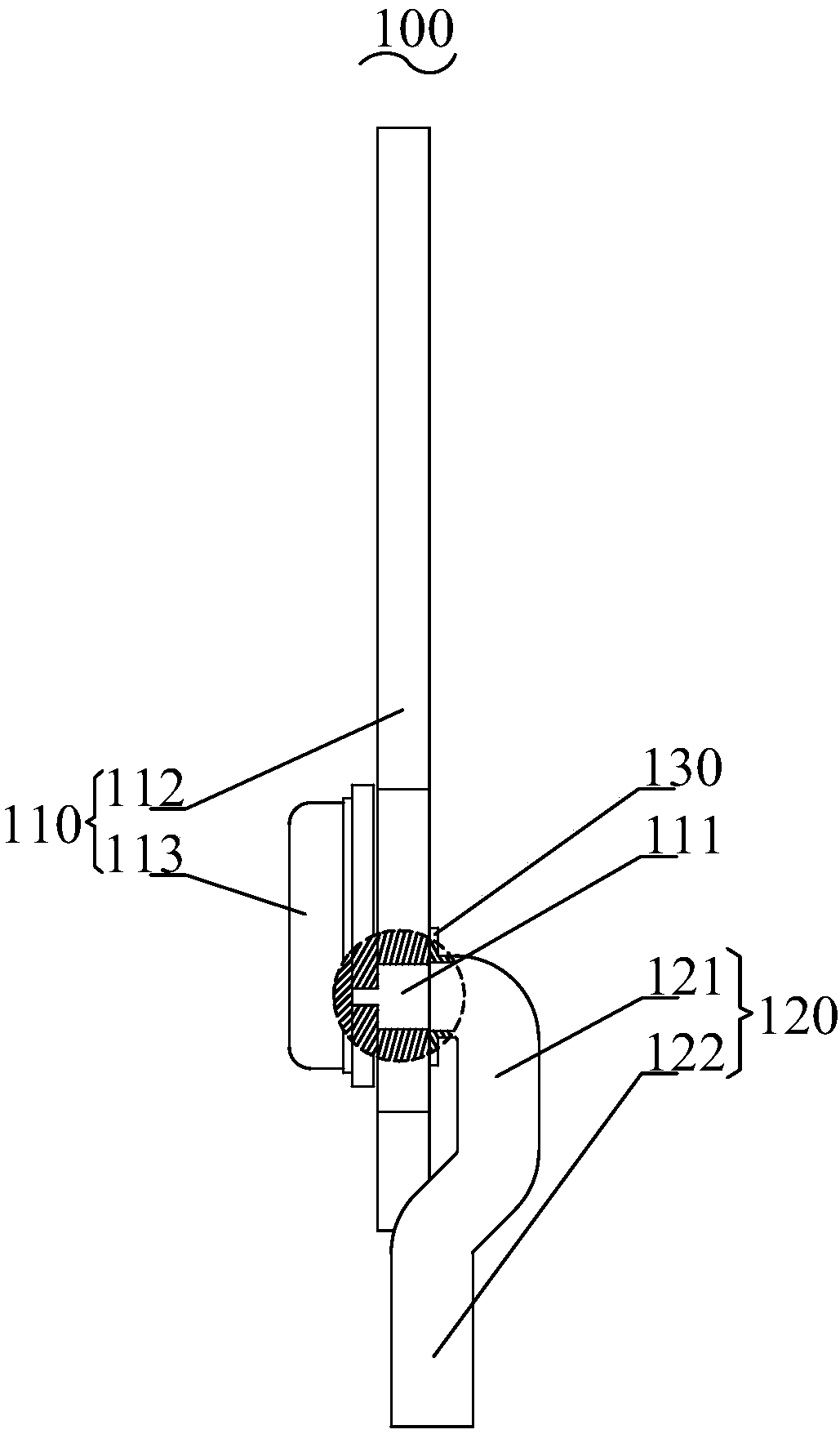

Stamp-formed crossed spin rivet interlocking type plate butting device and method

ActiveCN111659844ASimple connection processImprove processing efficiencyRivetsManufacturing engineeringRivet

The invention provides a stamp-formed crossed spin rivet interlocking type plate butting device. The device comprises a top support plate, a bottom support plate, a stamping head, an upper rivet and alower rivet; the top support plate is connected with the bottom support plate through a guide column; a stamping guide mechanism is arranged between the top support plate and the bottom support plate; the upper rivet is arranged on the stamping guide mechanism through a rivet clamping machine; the lower rivet is embedded into a lower rivet mounting groove of the bottom support plate; the lower rivet and the upper rivet are coaxially arranged; and the top surface of the lower rivet and the top surface of the bottom support plate are used for placing butted plates. The invention further provides a stamp-formed crossed spin rivet interlocking type plate butting. The stamp-formed crossed spin rivet interlocking type plate butting device provided by the invention is reasonable in structural design; the implementation steps of the method are convenient; the implementation process is free of harms; the device and the method can efficiently realize connection of the butted plates; the connected points are high in mechanical strength and high in capability of bearing load; and the surfaces of the plates are prevented from damages.

Owner:CENT SOUTH UNIV

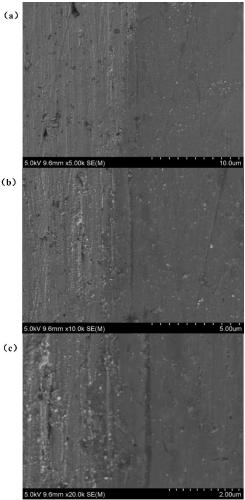

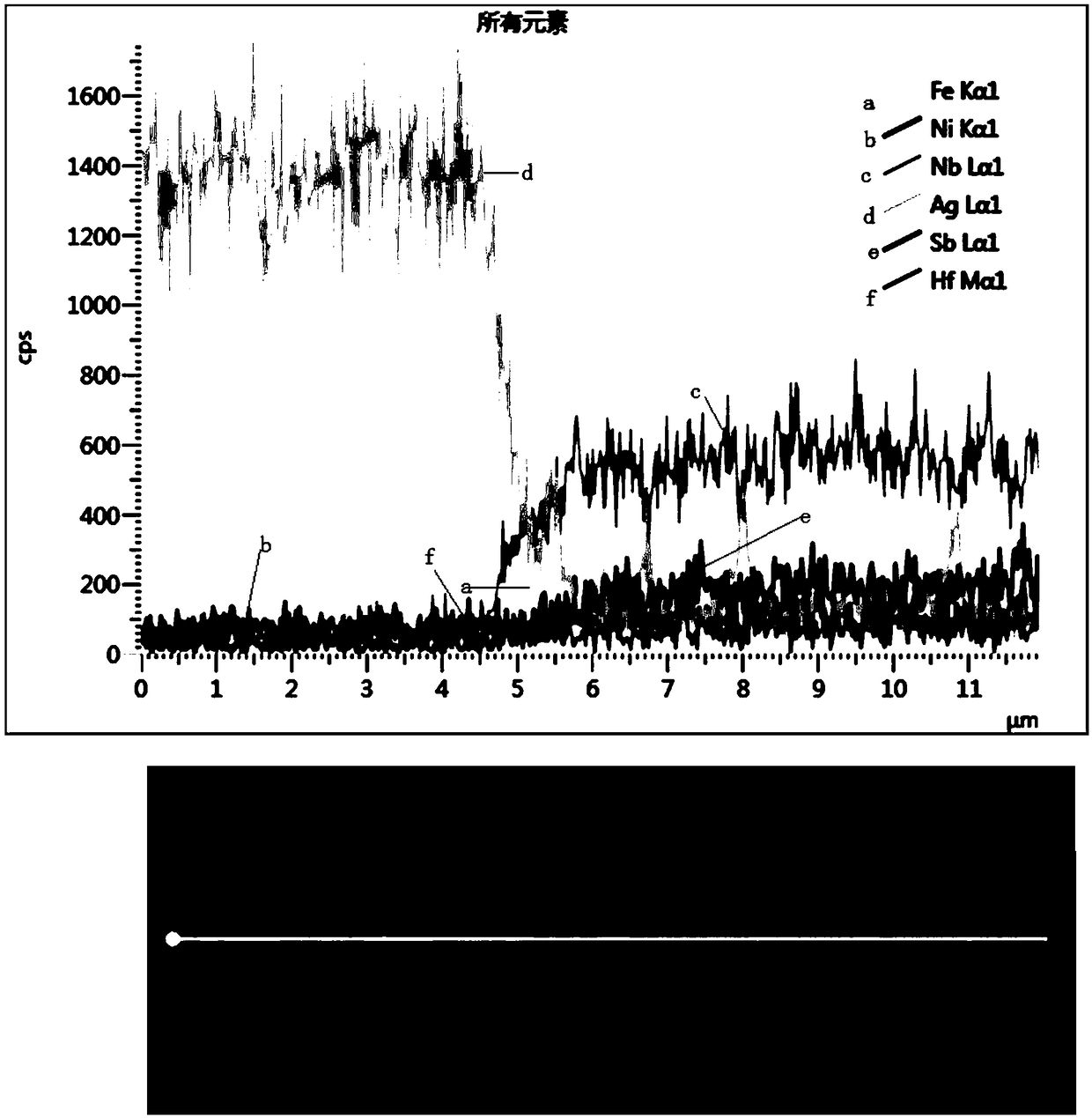

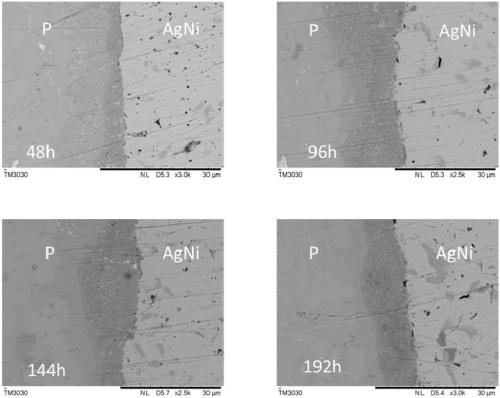

Electrode matched with thermoelectric material and connecting method thereof

ActiveCN109285940AImprove performanceImprove conductivityThermoelectric device manufacture/treatmentThermoelectric device detailsThermoelectric materialsNickel alloy

The invention belongs to the field of electrochemical technologies, and specifically relates to an electrode matched with a thermoelectric material and a connecting method thereof. The electrode matched with the thermoelectric material is a silver-nickel alloy, and the thermoelectric material is a FeNb0.88Hf0.12Sb-based thermoelectric material. After the silver-nickel alloy is connected with the FeNb0.88Hf0.12Sb-based thermoelectric material, a metal compound formed at the connection interface after aging remains stable and does not further diffuse to affect the performance of the thermoelectric material. Compared with the existing common Cu electrode material, the silver-nickel alloy does not reduce the performance of the thermoelectric material after the high temperature aging. In addition, the silver-nickel alloy is better in conductivity, so that the additional resistance is smaller, and the efficiency of the device is higher. Therefore, the silver-nickel apply is very suitable forserving as an electrode of the FeNb0.88Hf0.12Sb-based thermoelectric material.

Owner:SHENZHEN UNIV

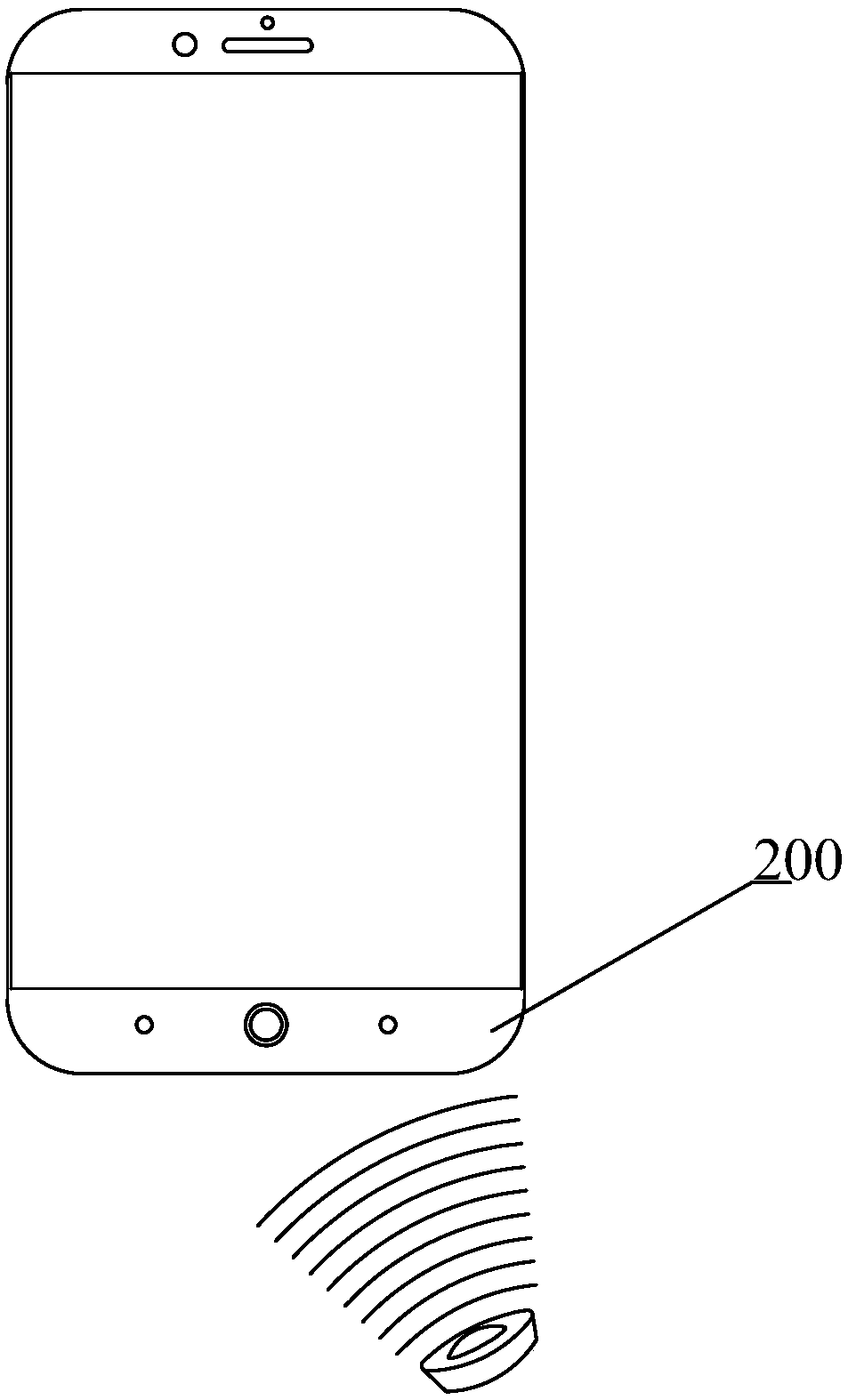

Microphone and mobile terminal

InactiveCN108055603AImprove sealingImprove yield rateMouthpiece/microphone attachmentsEngineeringGuide tube

The invention discloses a microphone and a mobile terminal. The microphone is arranged inside the mobile terminal. The microphone comprises a function module and a sound guide tube, wherein the function module is used for realizing a microphone function and is provided with a recording hole for transmitting sound, one end of the sound guide tube is connected with the recording hole, and the otherend of the sound guide tube extends outwards. The sealing yield rate of the microphone is improved.

Owner:NUBIA TECHNOLOGY CO LTD

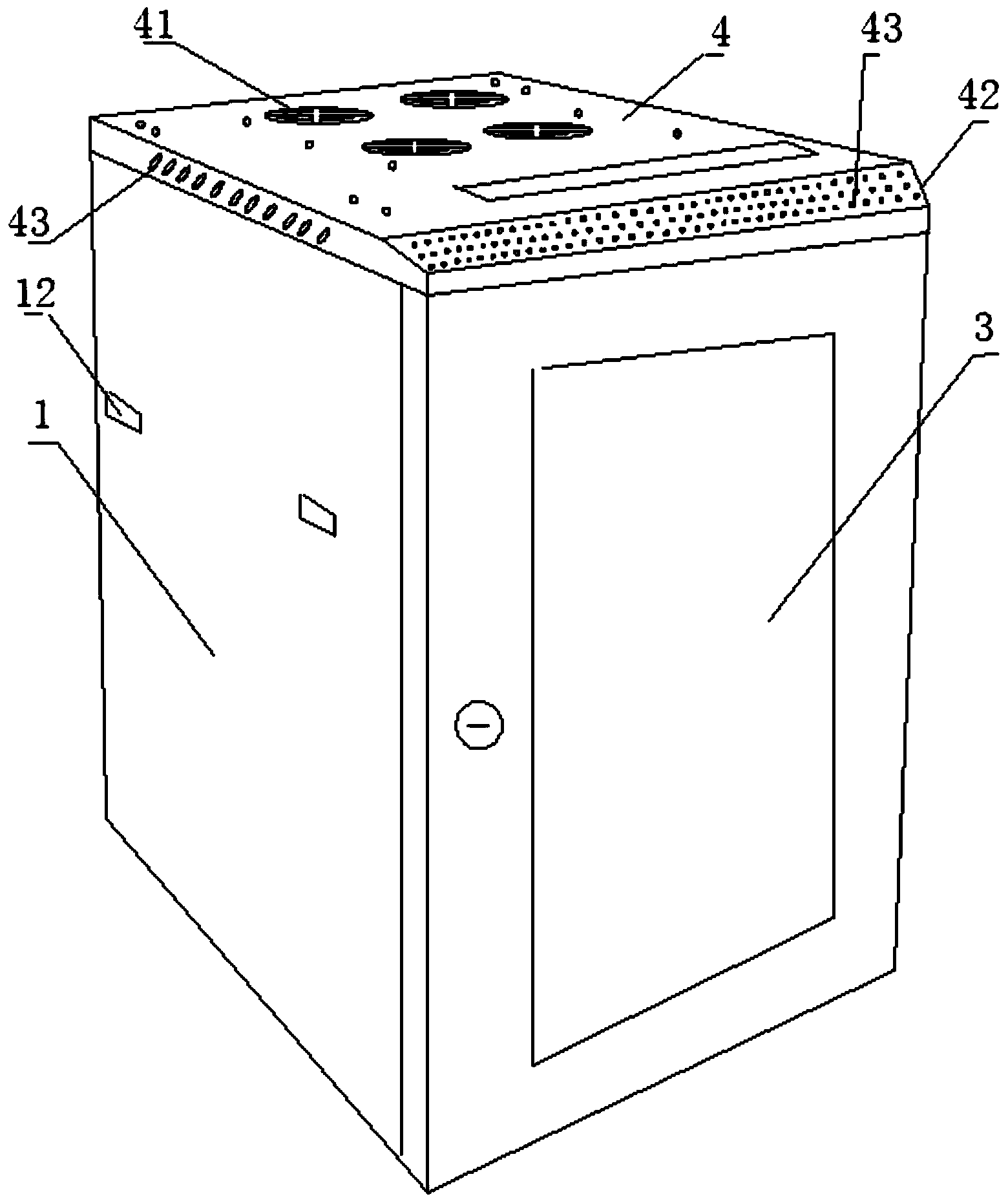

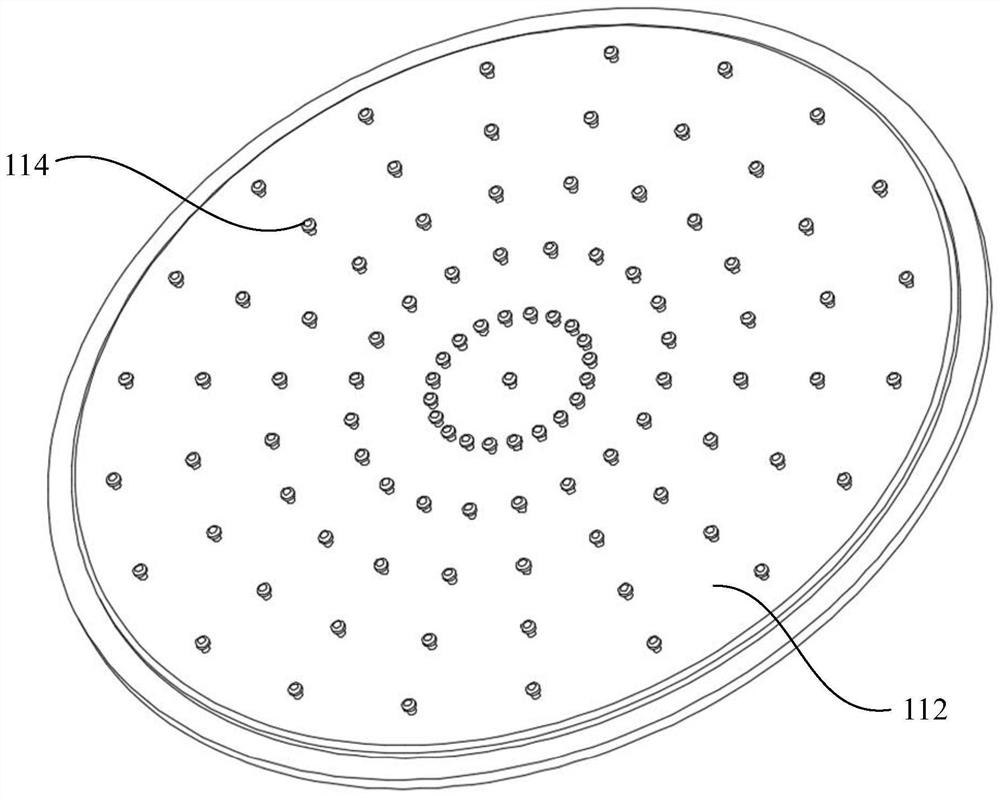

LED lamp with bonding pads of driving board or connection board and bonding pads of aluminum substrates being in butt welding connection

InactiveCN103994403AQuick connectionSimple connection processPoint-like light sourceSoldering apparatusElectrical conductorButt welding

The invention discloses an LED lamp with bonding pads of a driving board or a connection board and bonding pads of aluminum substrates being in butt welding connection. The LED lamp comprises the driving board (1) or the connection board (1) and the aluminum substrates (4), wherein the aluminum substrates are provided with lamp beads (3); the driving board or the connection board is provided with the bonding pads (2) connected with the direct current output ends; the aluminum substrates are provided with the bonding pads which are consistent with and correspond to the bonding pads on the driving board or the connection board in position, shape and size in a mirroring mode; the two kinds of bonding pads are attached tightly face to face through the tin spraying process, the bonding pads are fused into a whole through locating and heating, the bonding pads are combined into a whole due to fusion and solidification of soldering tin on the upper faces of the bonding pads, and consequently the aluminum substrates and the driving board or the connection board are combined into a whole. The aluminum substrates and the driving board or the connection board are connected together, the connection process is simplified, man-hour cost and connection conductor materials are saved, production efficiency is improved, and manufacturing cost is lowered.

Owner:谢绍刚

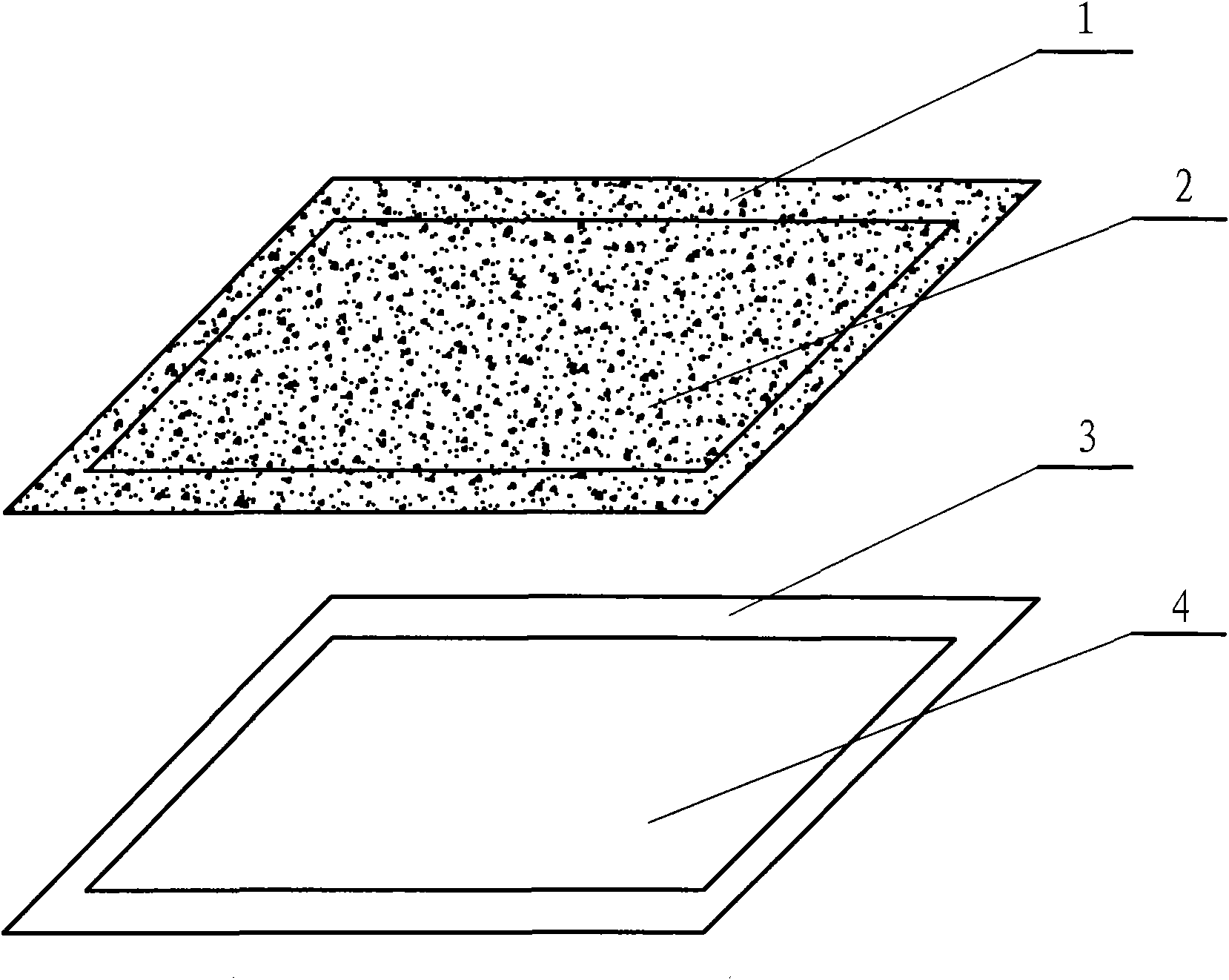

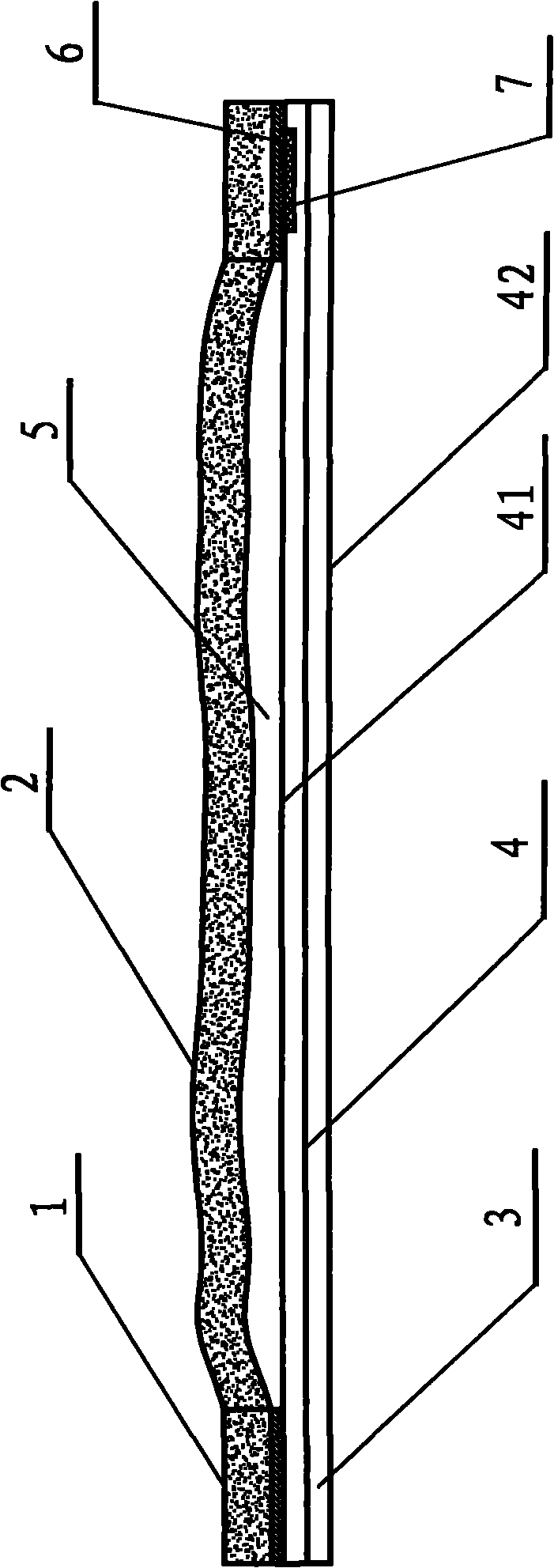

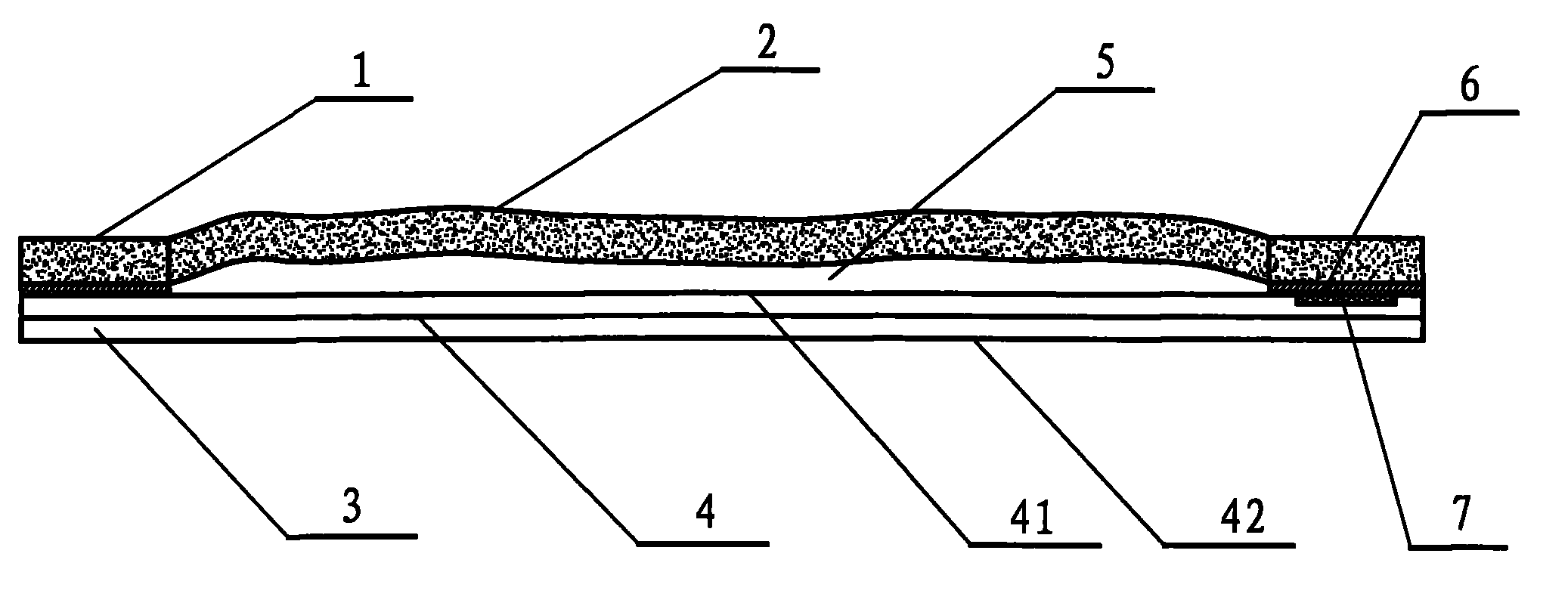

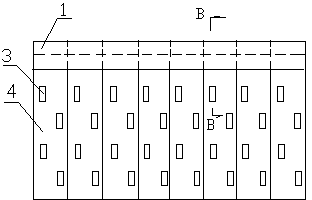

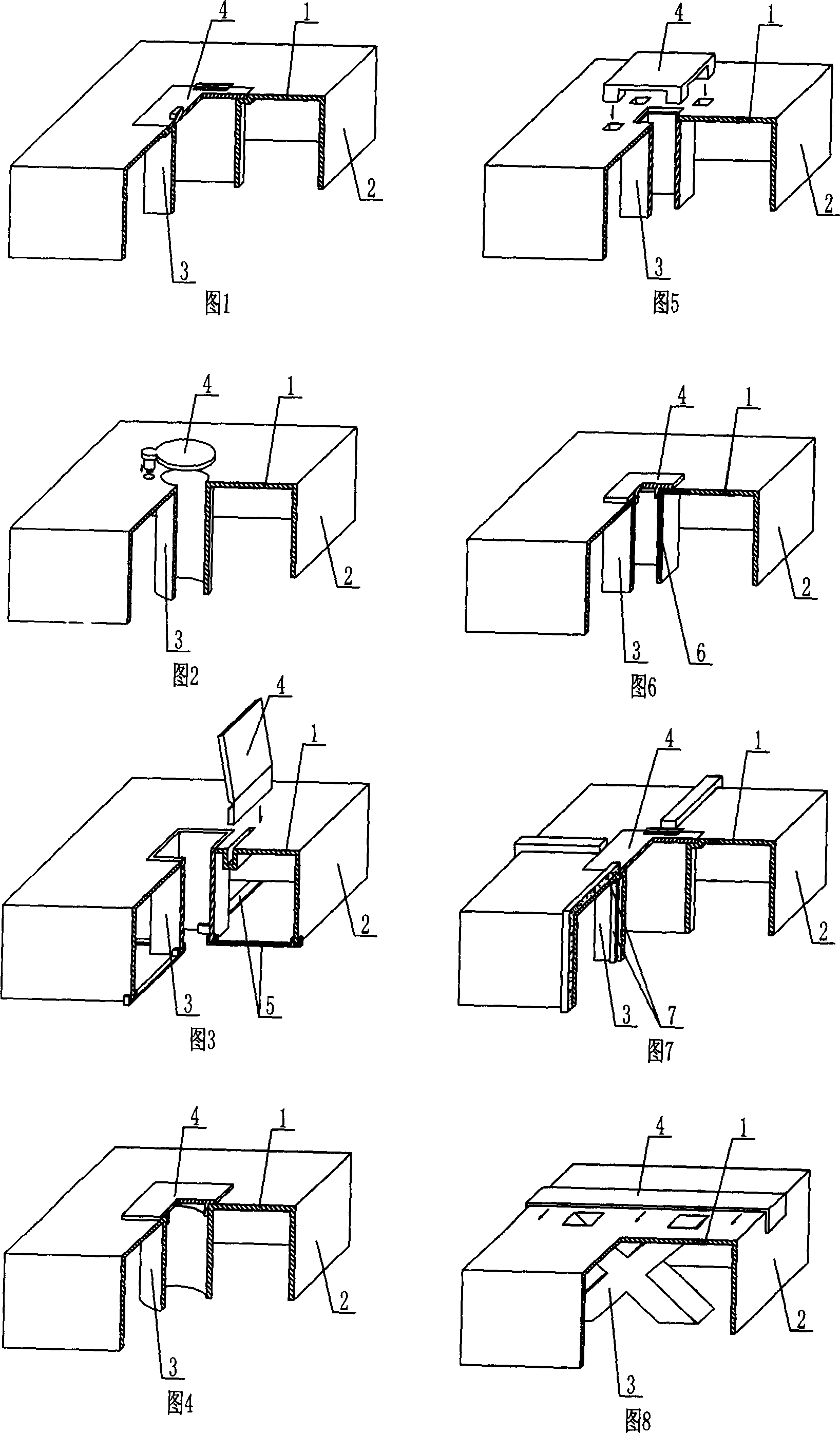

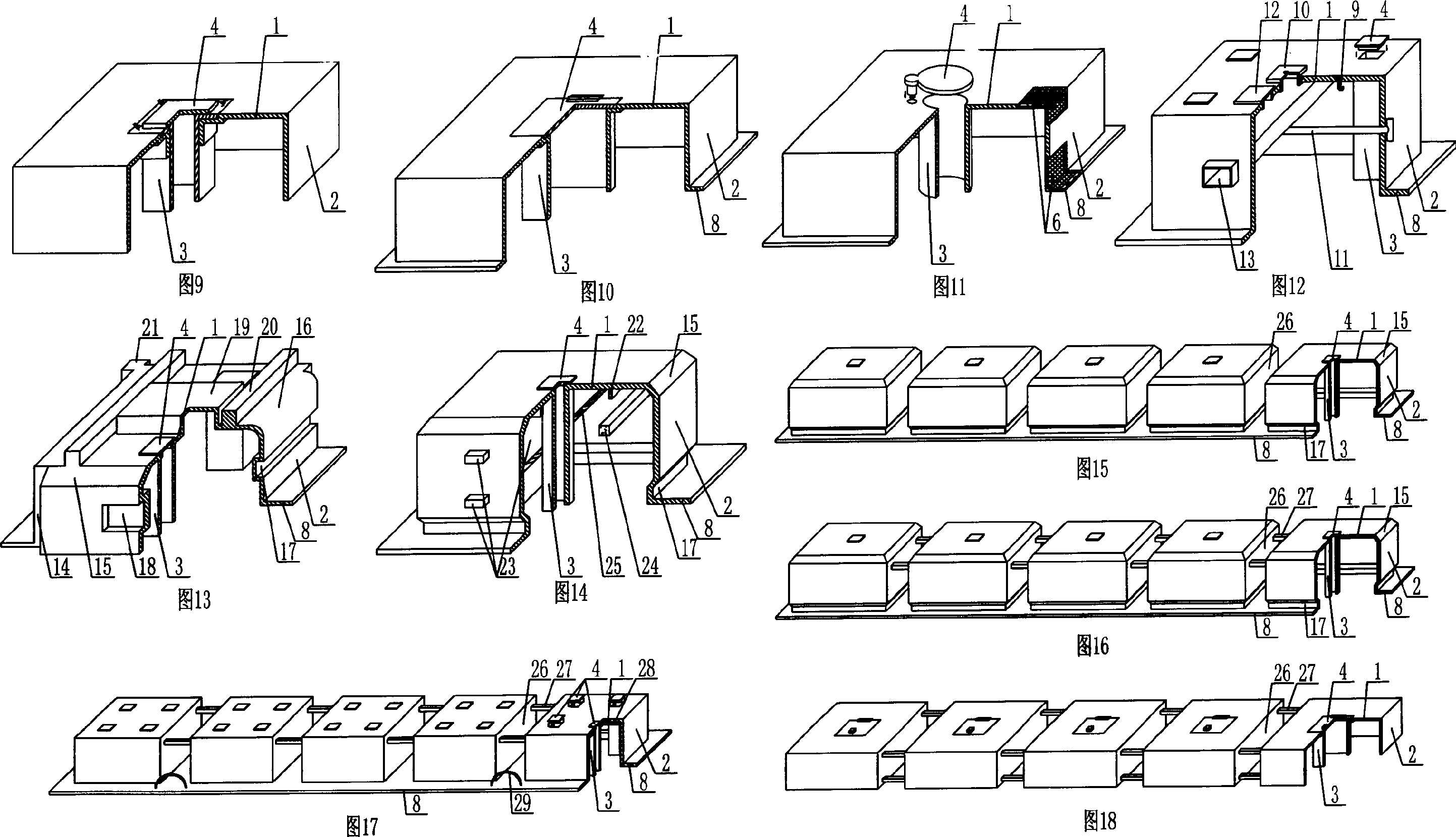

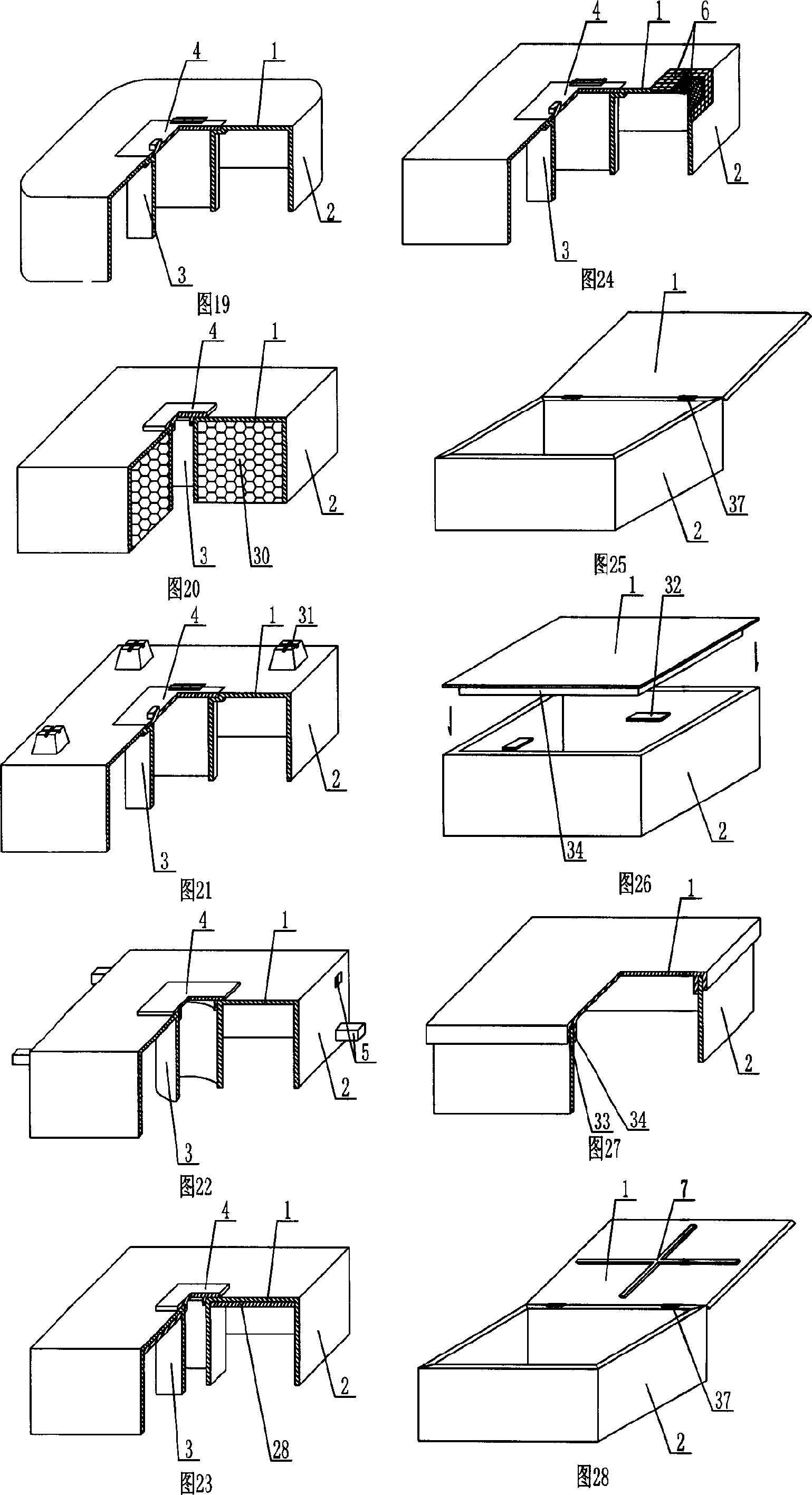

Mould-shell structural component

A mold-shell member is composed of top plate(1) and circular side walls(2). Said top plate(1) is arranged on said circular side walls(2) to enclose an open basin-shaped member, supporting device(44) of said top plate(1) or / and positioning device(45) are arranged at circular side wall(2) top opening, aerial foot(46) is arranged at circular side wall bottom opening. It can be used for various hollow and beamless building roofs of cast-in-situ reinforced concrete or pre-stressed reinforced concrete, basic baseboard, wall and bridges.

Owner:湖南邱则有专利战略策划有限公司

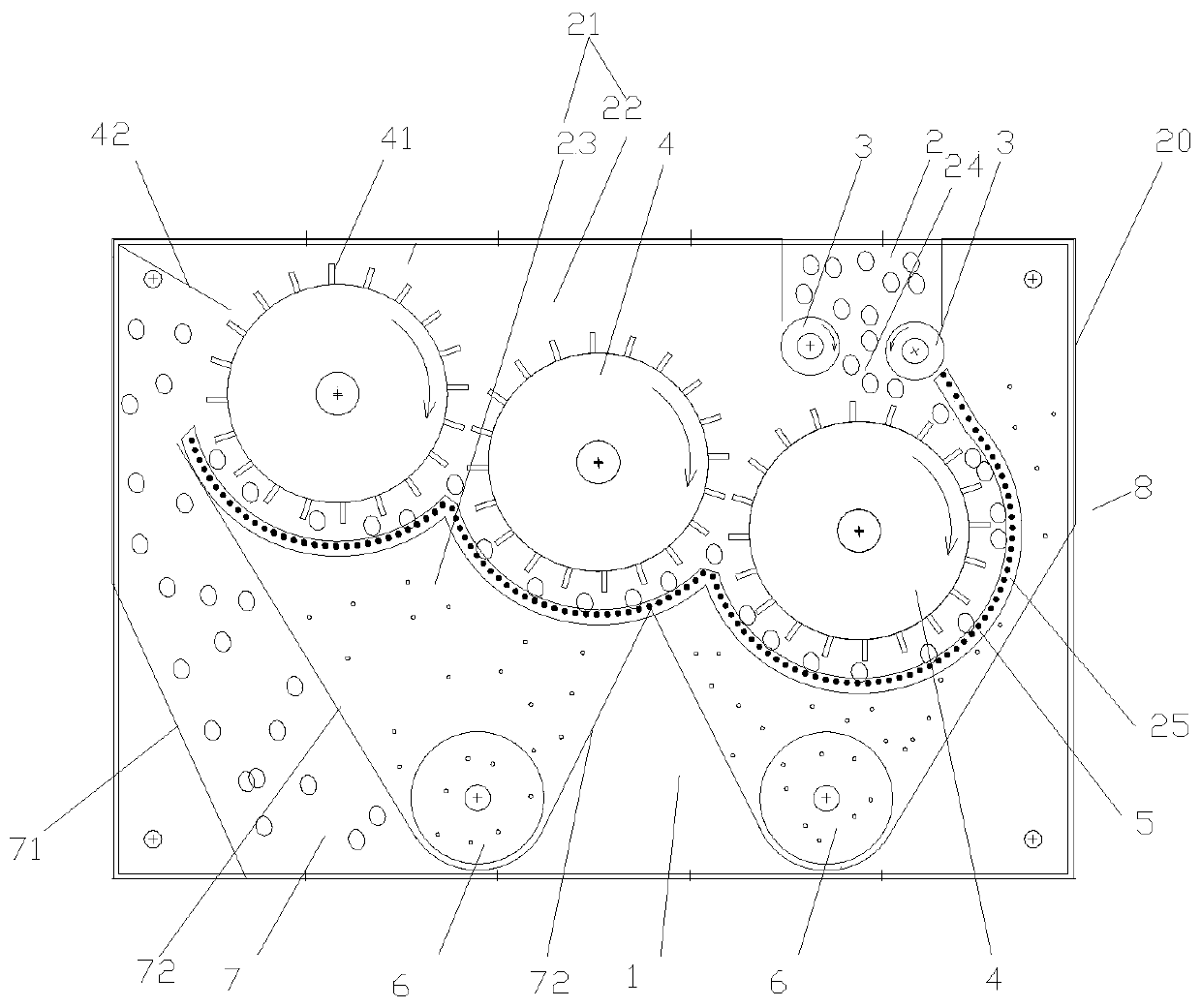

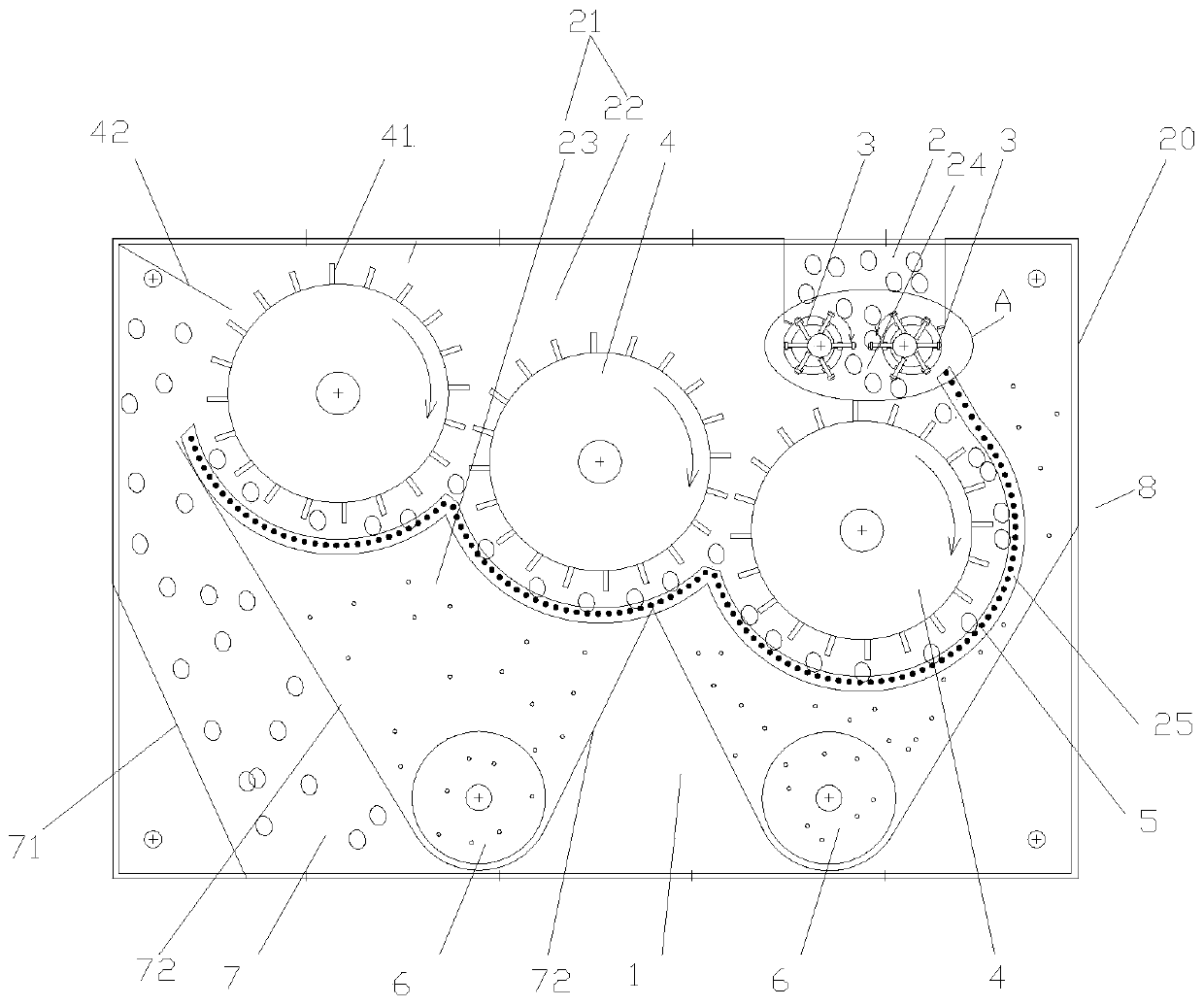

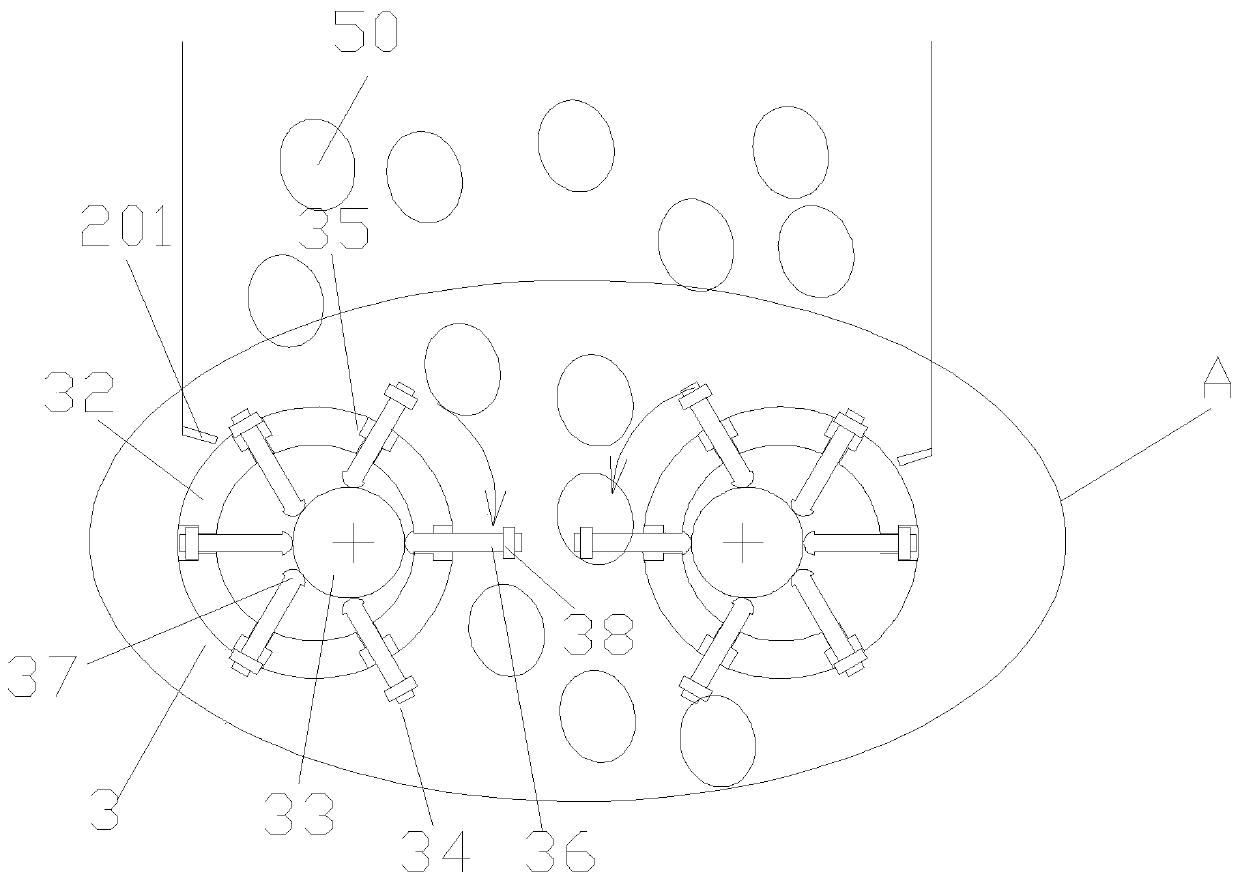

Modular unginned cotton cleaning machine

PendingCN110117819ASimple connection processReduce construction costsMechanical treatmentEngineeringMultiple function

The invention discloses a modular unginned cotton cleaning machine. The modular unginned cotton cleaning machine comprises a machine case body, an arc grating separates the machine case body, one sideof the arc grating is provided with an unginned cotton inlet channel, a first unginned cotton outlet channel, cotton feeding rollers and unginned cotton cleaning drums, the other side of the arc grating is provided with a V-shaped enclosing plate, and the bottom of the V-shaped enclosing plate is communicated with the outside of the machine case body through a screw feeder. The invention also discloses a modular unginned cotton cleaning machine group composed of the modular unginned cotton cleaning machines, a cotton sliding hopper, a working case and a cotton gin. The modular unginned cottoncleaning machine achieves multiple functions within one machine, and can clean low-impurity-content unginned cotton, or through simple combination, clean high-impurity-content unginned cotton; also,the modular unginned cotton cleaning machine can be directly mounted above the cotton gin to achieve unginned cotton cleaning and cotton ginning integration.

Owner:HUBEI BAIAO TECH

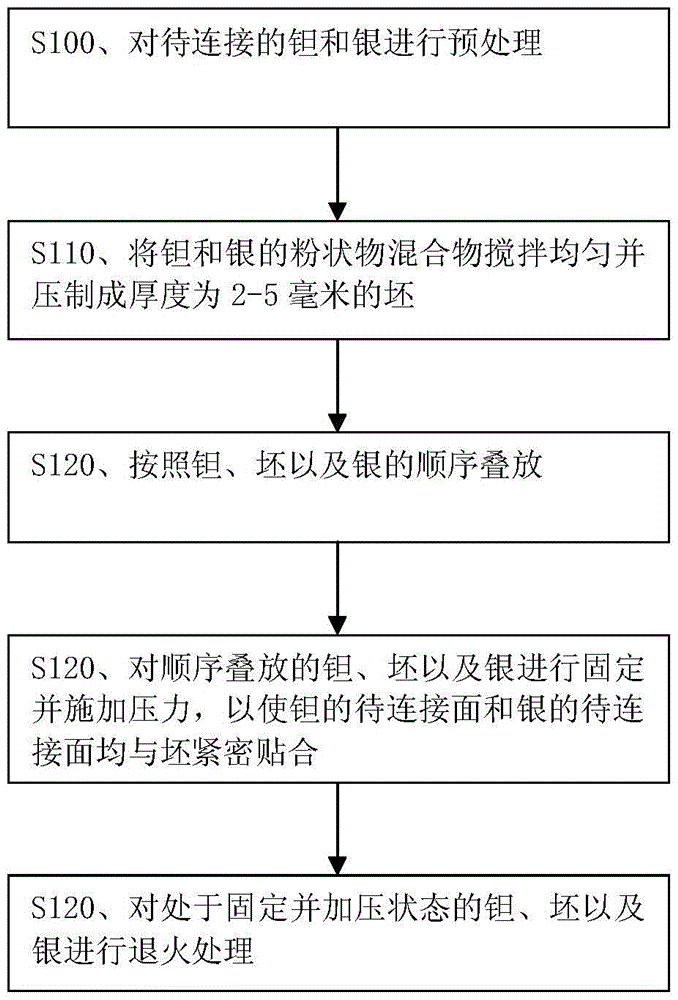

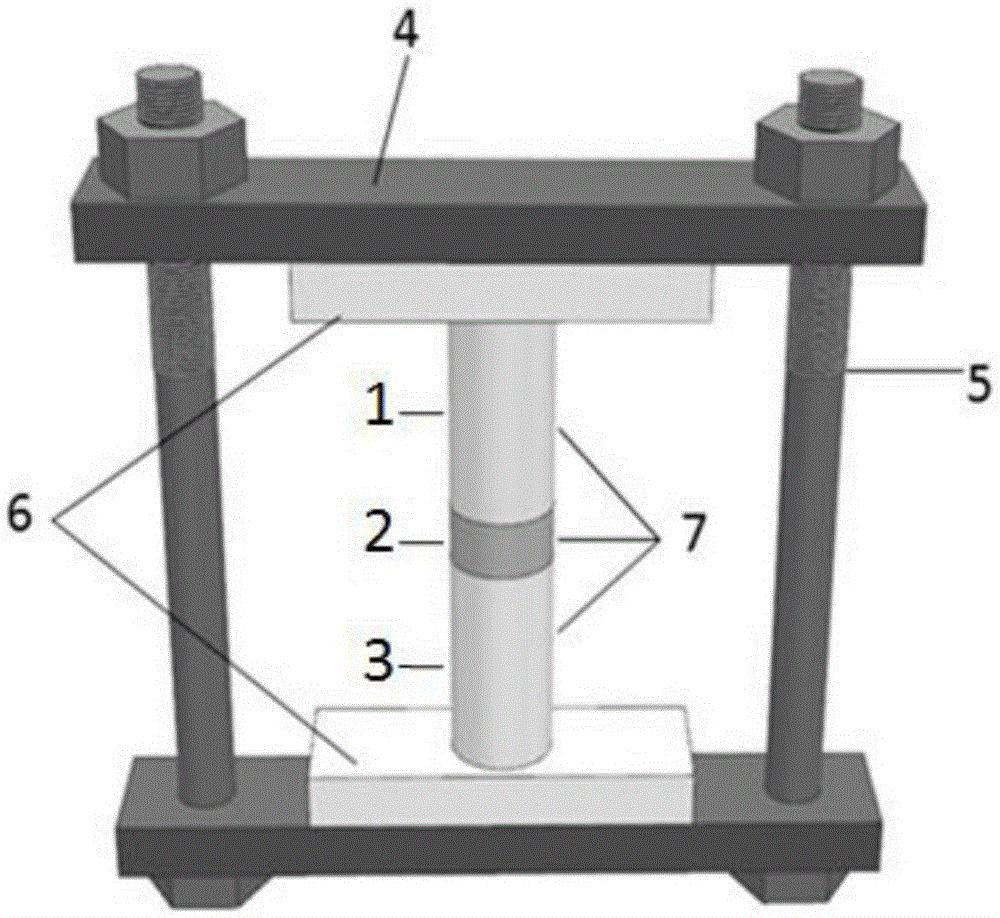

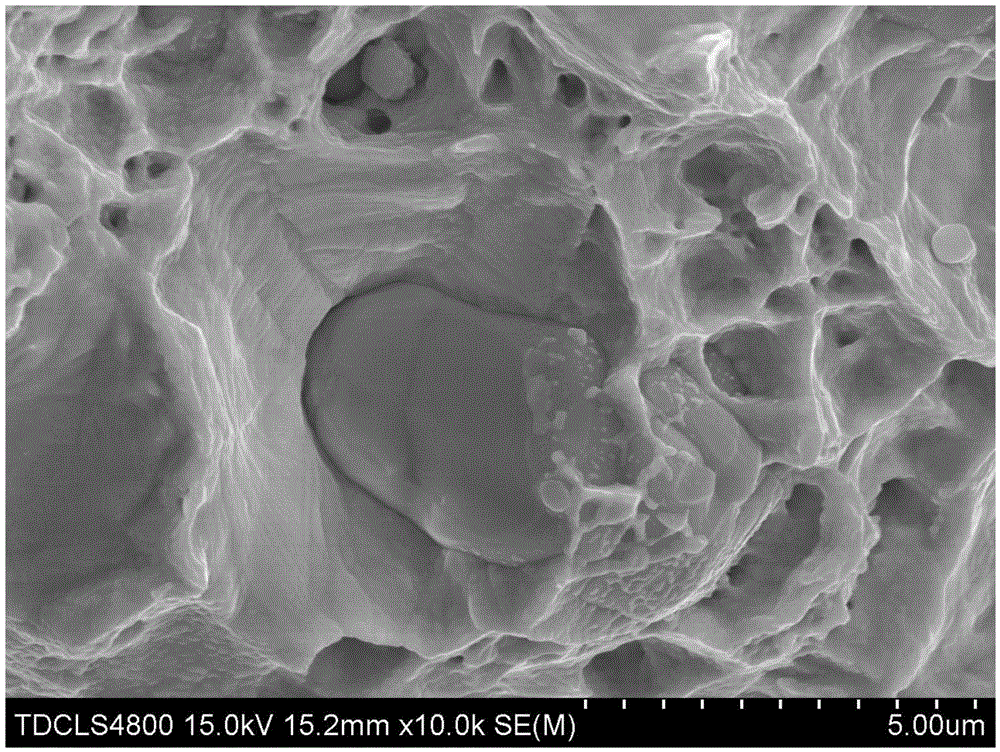

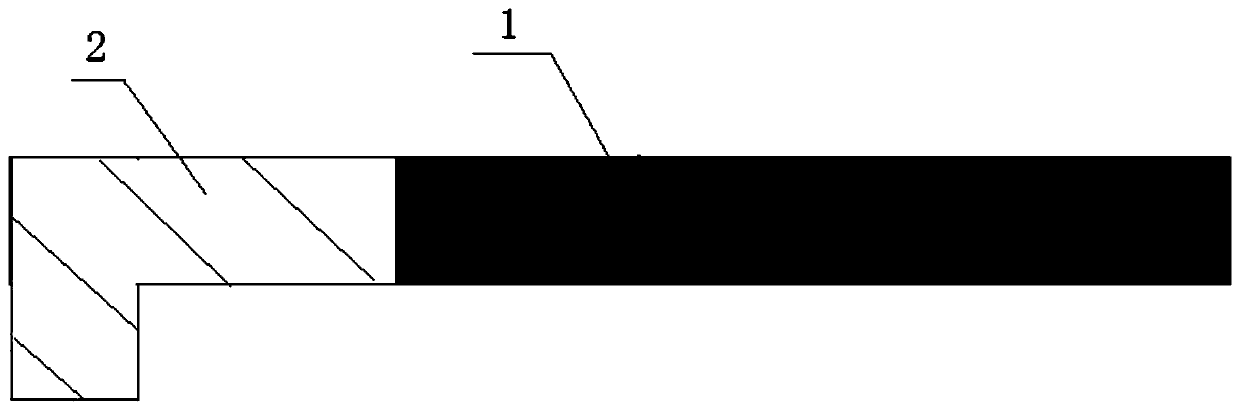

Connection process for metal silver and tantalum not capable of being dissolved in each other in solid mode

InactiveCN105537751ANo deformation and melting phenomenonContinuous and uniform spreadWelding/soldering/cutting articlesNon-electric welding apparatusPre treatmentUltimate tensile strength

The invention relates to a connection process for metal silver and tantalum not capable of being dissolved in each other in a solid mode. The connection process mainly includes the steps of preprocessing tantalum and silver which are to be connected, pressing a mixture of tantalum powder and silver powder into blanks with the thickness of 2-5 mm, stacking the blanks according to the sequence of tantalum, the blanks and silver, fixing tantalum, the blanks and silver which are stacked according to the sequence and applying pressure on tantalum, the blanks and silver so that to-be-connected faces of tantalum and to-be-connected faces of silver can be tightly attached to the blanks, and conducting annealing on fixed and pressurized tantalum, the fixed and pressurized blanks and fixed and pressurized silver, wherein the annealing temperature of annealing is lower than the melting point of silver by 10-50 DEG C. By means of the technical scheme, the process has the advantages of being simple, low in connection cost and the like, the bonding interfaces of metal silver and tantalum not capable of being dissolved in each other in the solid mode are uniform and continuous, and tantalum and silver not capable of being dissolved in each other in the solid mode can have good bonding strength.

Owner:MICCOOL YUEMEI TIANJIN TECH CO LTD

Strong-combined composite material plate

PendingCN110744871AImprove bindingStable structureSynthetic resin layered productsGlass/slag layered productsUltimate tensile strengthMaterials science

The invention discloses a strong-combined composite material plate. The strong-combined composite material plate comprises a composite material plate (1) and a thermoplastic material frame (2) connected to the periphery of the composite material plate (1) in an injection molding mode; the end surface of the composite material plate (1) is cut to form a concave-convex surface, and the concave-convex surface of the end surface is filled with a thermoplastic material and then is combined with the composite material plate (1); the composite material plate (1) or the thermoplastic material frame (2) is provided with sawtooth grooves, and the composite material plate (1) and the thermoplastic material frame (2) are connected in a meshed mode through the sawtooth grooves; the shapes of two adjacent sawtooth grooves in the composite material plate (1) or the thermoplastic material frame (2) are the same or different; and one or more grooves with the opening size larger than that of the openings of the sawtooth grooves are formed in the sawtooth groove. The strong-combined composite material plate has a reasonable structural design, and has the advantages of high bonding strength, firm structure, simple connecting process and good environmental protection property due to the fact that the one or more sawtooth-shaped grooves are adopted for meshed connection.

Owner:合肥山秀碳纤科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com