LED lamp with bonding pads of driving board or connection board and bonding pads of aluminum substrates being in butt welding connection

A LED lamp and butt welding connection technology, which is applied in the direction of welding equipment, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problem of labor-intensive production and placement of springs, variety of types, and unfixable connections. Carry out automation design and other issues to achieve the effects of improving production efficiency, saving connecting conductor materials, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

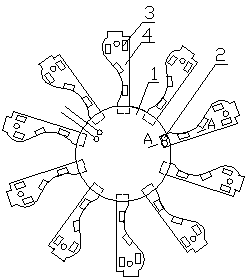

[0015] Example 1, such as figure 1 and figure 2 As shown, the driver board 1 in the LED ceiling lamp in which the driver board or the connection board pad and the aluminum substrate pad are butt-welded is made into a circle, and the diameter of the circle depends on the length of the aluminum substrate 4 and the size and size of the lamp panel. The area occupied by the driving electronic components. In Example 1, a 300mm disc with a 20W power LED ceiling lamp is used. The diameter of the driving board is 65mm. After the constant current driving electronic components are arranged, there is still about 6mm of space around the disc , Ten pairs of welding pads connected to the current output end are evenly arranged on the circular space, which are mirror images of the 4 butt welding pads of the aluminum substrate, and each group has two pads 2. Two pads are arranged side by side at the corresponding positions of the substrate, such as figure 1 , ten pieces of aluminum substrate...

Embodiment 2

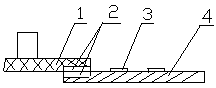

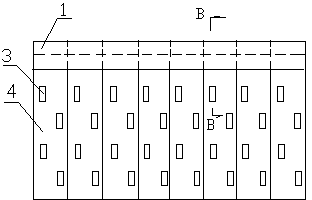

[0017] Example 2, such as image 3 and Figure 4 As shown, the connection board (specially used as the circuit board for butt welding connection) in the LED energy-saving lamp with butt welding connection of the driver board or the connection board pad and the aluminum substrate pad is made into a strip shape, and the width of the strip is to accommodate two The occupied positions of the root jumper and the jumper pad and the butt welding pad are determined. In this embodiment 2, the total length of the strip is the product of the width of the aluminum substrate 4 and the number of aluminum substrates. The aluminum substrate consists of eight rectangles and can be formed In the shape of a regular octagonal prism, one side of the long strip is set to mirror the butt welding pads of the aluminum substrate, and the same number and shape of the pads are used as butt welding pads, and the other side is set to be connected in series and parallel between the butt welding pads Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com