An angle adjuster type seat back shoulder adjusting structure

A technology for seat back and adjustment structure, which is applied to vehicle seats, movable seats, vehicle parts, etc., can solve problems such as trauma in the neck and shoulders, and achieve the effect of realizing shoulder adjustment, meeting safety requirements, and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

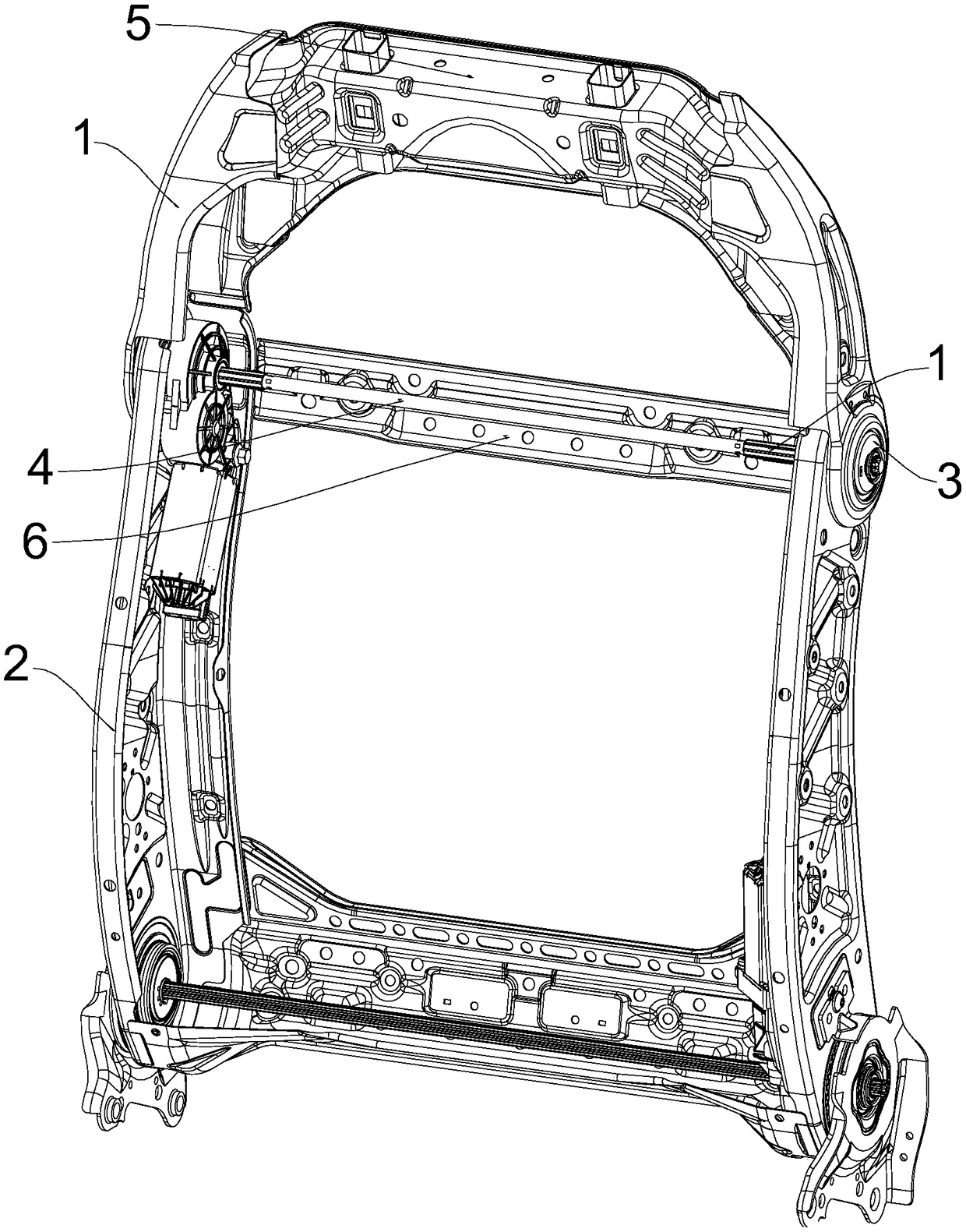

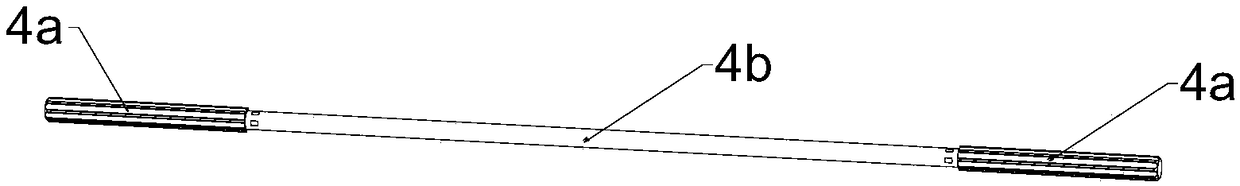

[0031] Such as figure 1 As shown, a recliner-type seat back shoulder adjustment structure includes two backrest fixed side panels 2 facing oppositely, and the upper parts of the two backrest fixed side panels 2 are respectively connected with backrest rotating side panels 1, The backrest rotating sideboard 1 is hinged to the corresponding backrest fixed sideboard 2, and also includes two recliners 3, and the two recliners 3 are respectively connected to the same side of the backrest rotating sideboard 1 and the backrest fixed sideboard. Side plate 2, wherein the backrest rotates side plate 1 to form the upper connecting plate of the recliner, the backrest fixed side plate 2 forms the lower connecting plate of the recliner, and a synchronously rotating transmission shaft is connected between the central shafts of the two recliners 3 4. An upper crossbeam 5 is connected between the upper parts of the two backrest rotating side plates 1, and a baffle plate 6 is arranged behind t...

Embodiment 2

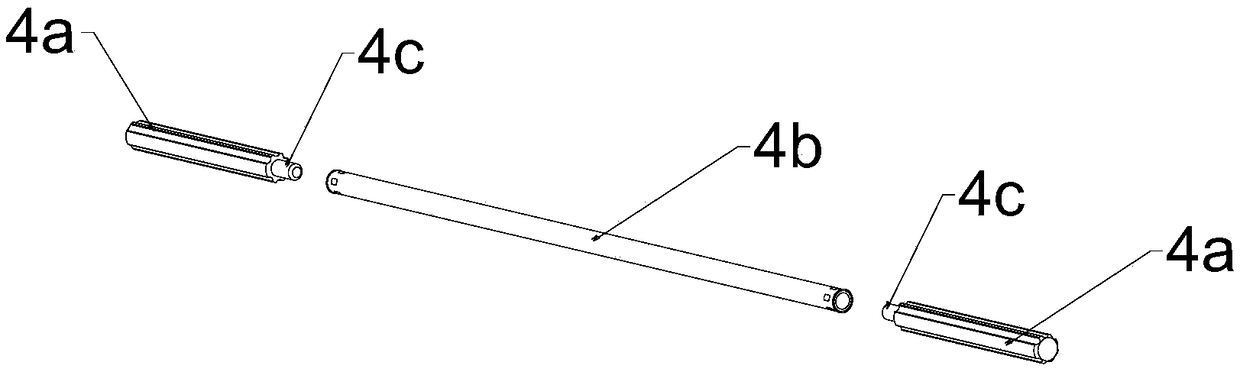

[0035] The difference from Example 1 is that, as image 3 As shown, the end of the assembling section 4a protrudes toward the destroying section 4b and is provided with a connector 4c, and the connecting head 4c extends into the inner cavity of the destroying section 4b, and the two ends of the destroying section 4b are respectively sheathed in On the corresponding connecting head 4c, the barrel wall of the breaking section 4b is pressed against the corresponding connecting head 4c. This not only facilitates forming, but also makes the assembly section 4a and the breaking section 4b relatively fixed, transmit rotation, and fall off each other under a certain bending force.

Embodiment 3

[0037] The difference from Embodiment 1 is that the broken section 4b is a plastic rod whose flexural strength is lower than that of the assembled section 4a, and fracture failure also occurs during collision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com