Electrode matched with thermoelectric material and connecting method thereof

A thermoelectric material and connection method technology, applied in the field of electrochemistry, can solve the problems of thermoelectric material matching and electrode material difficulty, and achieve the effect of small external resistance, good conductivity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

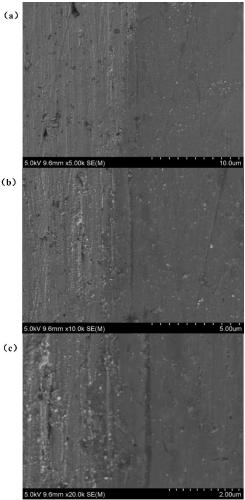

[0036] FeNb 0.88 f 0.12 Preparation of Sb-based thermoelectric material matrix:

[0037] a) FeNb 0.88 f 0.12 The stoichiometric ratio of Sb is measured by each metal source (accurate to 4 decimal places), and the elemental elements required for thermoelectric materials are weighed according to the ratio and put into the sample tank of the suspension melting furnace for suspension melting. Sb is weighed more than 5 on the basis. % mass fraction, the ingot obtained after suspension smelting;

[0038] When the vacuum reaches 10 -3 When the Pa is below, it is filled with argon as a protective gas, and then discharged at a current of 50A to suspend and smelt the sample until the raw materials of each metal source are melted into a liquid state. In order to ensure uniform smelting, each sample was smelted at least 3 times for 5 minutes each time, and the sample was turned over to the other side after each smelting, and then the smelted sample was sealed.

[0039] b) Put the ab...

Embodiment 2

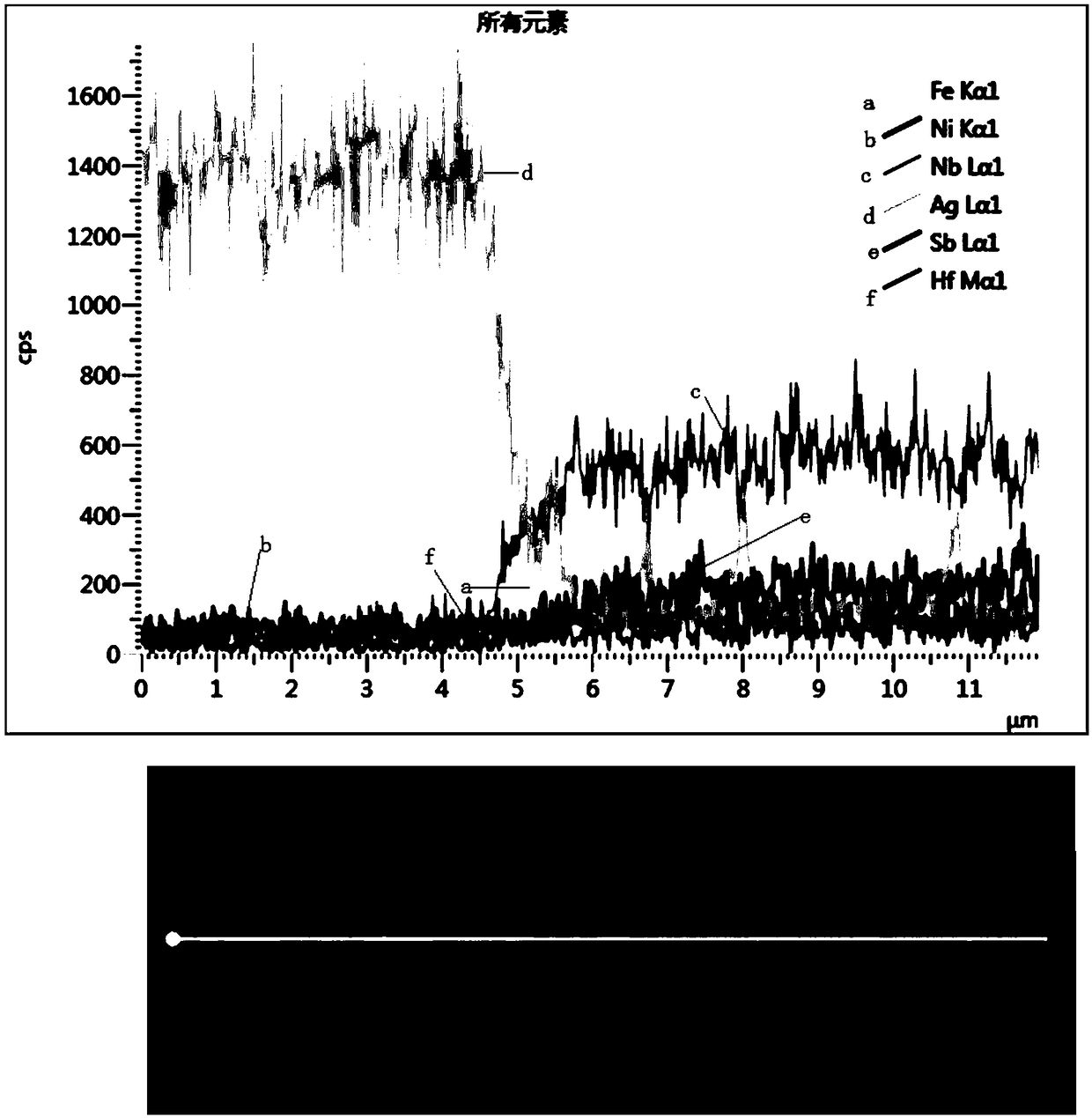

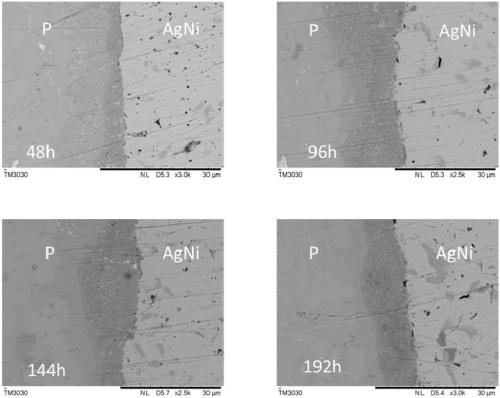

[0044] FeNb 0.88 f 0.12 Connection Technology of Sb-Based Thermoelectric Materials and Silver-Nickel Alloy Electrodes

[0045] a) Electrode material mixed powder: silver powder (200 mesh), nickel powder (200 mesh), wherein the mass percentage of metal element Ag is 90wt%, and the balance is Ni (10wt%);

[0046] b) In a graphite mold with a diameter of 15 mm, the electrode material mixed powder, the FeNb of Example 1 are successively filled 0.88 f 0.12 Sb-based thermoelectric material block, electrode material mixed powder, FeNb was sintered by SPS hot pressing 0.88 f 0.12 The Sb-based thermoelectric material block and the electrode material are sintered together; wherein, the vacuum degree during sintering is 1×10 - 3 MPa, the sintering pressure is 40Mpa, and the sintering temperature is 680°C.

[0047] c) The sample body formed by sintering is polished to remove the surface graphite paper and then cut into the specified length and width of the device by diamond wire cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com