Chip connection method for rapidly generating high-strength and high-melting-point joint at low temperature

A connection method and high-strength technology, applied in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., to achieve the effects of high service temperature, high reliability, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

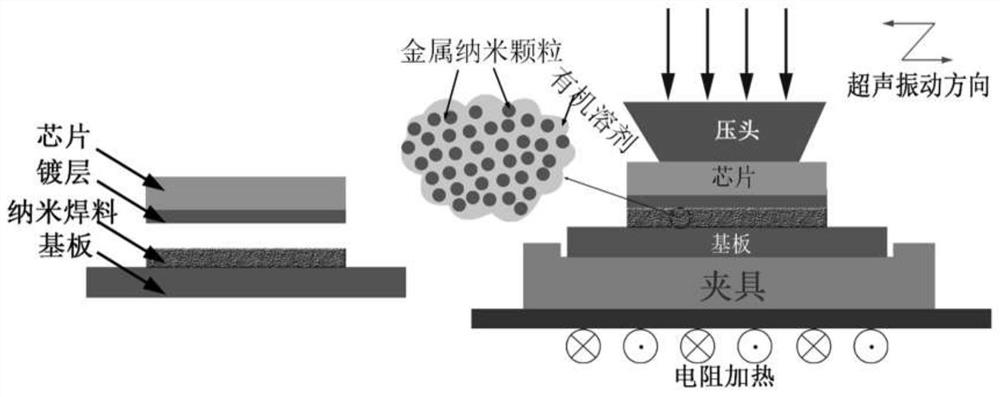

[0036] refer to figure 1 As shown, a chip connection method for quickly producing high-strength and high-melting point joints at low temperature, the connection materials mainly include: chip-1 with Ni / Ag plating layer, nano-silver-coated copper solder intermediate layer-2 and a copper substrate with a size of 10×10mm -3, is characterized in that comprising the following steps:

[0037] (1) Surface treatment of the material to be connected: According to the pre-set ion cleaning process: RF power 200W, RF time 150s, keep the cavity pressure at -100Pa, then chip-1 with Ni / Ag plating and copper Substrate-3 is cleaned with ions on the metal surface to remove the oxide layer and surface organic matter, and then ultrasonically cleaned for 30s to expose the clean metal surface for later use;

[0038] (2) After setting the height and basic level of the scraping head in advance, use the gravure printing process to evenly coat the configured nano silver-clad copper solder paste on the ...

Embodiment 2

[0045] refer to figure 1 As shown, a chip connection method for quickly producing high-strength and high-melting point joints at low temperature, the connection materials mainly include: chip-1 with Ni / Ag plating layer, nano-silver-coated copper solder intermediate layer-2 and a copper substrate with a size of 10×10mm -3, is characterized in that comprising the following steps:

[0046] (1) Surface treatment of the material to be connected: According to the pre-set ion cleaning process: RF power 200W, RF time 150s, keep the cavity pressure at -100Pa, then chip-1 with Ni / Ag plating and copper Substrate-3 is cleaned with ions on the metal surface to remove the oxide layer and surface organic matter, and then ultrasonically cleaned for 30s to expose the clean metal surface for later use;

[0047] (2) After setting the height and basic level of the scraping head in advance, use the gravure printing process to evenly coat the configured nano silver-clad copper solder paste on the ...

Embodiment 3

[0053] refer to figure 1 As shown, a chip connection method for quickly producing high-strength and high-melting point joints at low temperature, the connection materials mainly include: chip-1 with Ni / Ag plating layer, nano-silver-coated copper solder intermediate layer-2 and a copper substrate with a size of 10×10mm -3, is characterized in that comprising the following steps:

[0054] (1) Surface treatment of the material to be connected: According to the pre-set ion cleaning process: RF power 200W, RF time 150s, keep the cavity pressure at -100Pa, then chip-1 with Ni / Ag plating and copper Substrate-3 is cleaned with ions on the metal surface to remove the oxide layer and surface organic matter, and then ultrasonically cleaned for 30s to expose the clean metal surface for later use;

[0055] (2) After setting the height and basic level of the scraping head in advance, use the gravure printing process to evenly coat the configured nano silver-clad copper solder paste on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com