Stamp-formed crossed spin rivet interlocking type plate butting device and method

A stamping forming and docking device technology, applied in the direction of rivets, etc., can solve the problems of personnel injury operation, complicated efficiency, difficult performance guarantee, etc., and achieve the effect of high processing efficiency, good comprehensive ability, and strong ability to resist bending force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

[0043] Aiming at the problems of difficulty in guaranteeing the performance of the existing plate butting mode, easy injury to personnel and complicated operation and low efficiency, the invention provides a stamping and forming cross-riveting interlocking plate butting device and method.

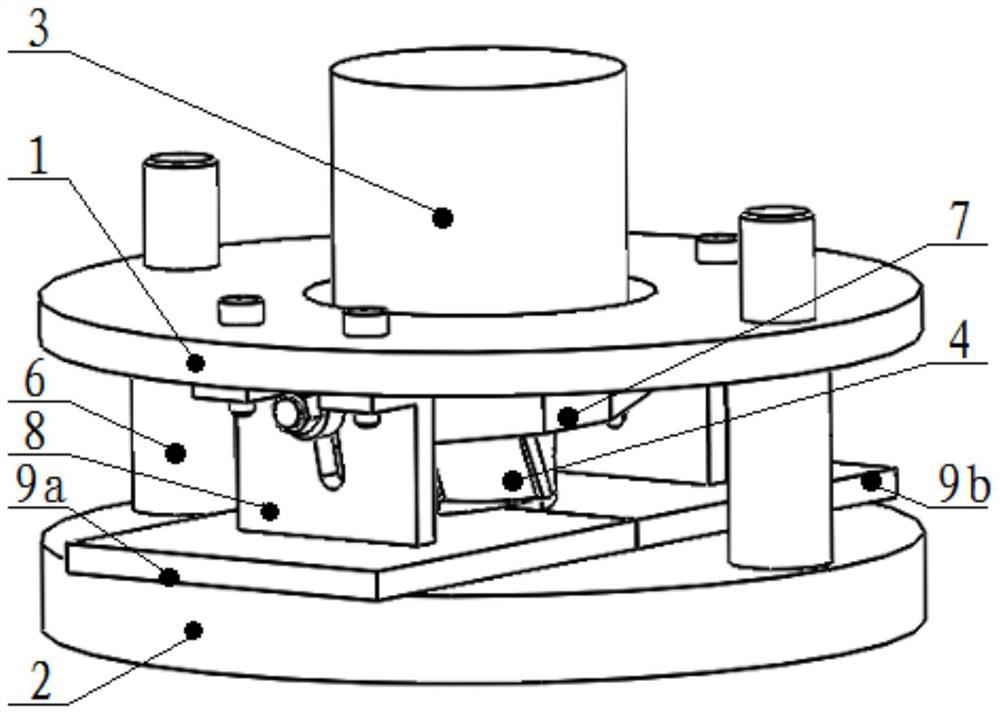

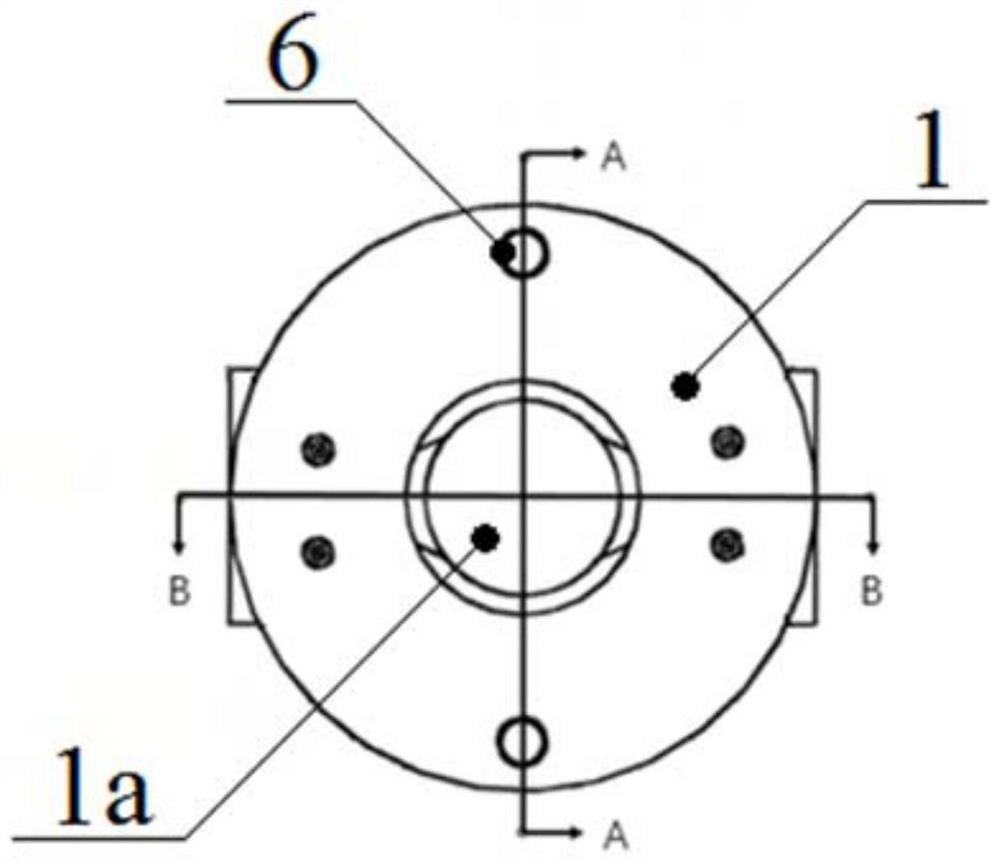

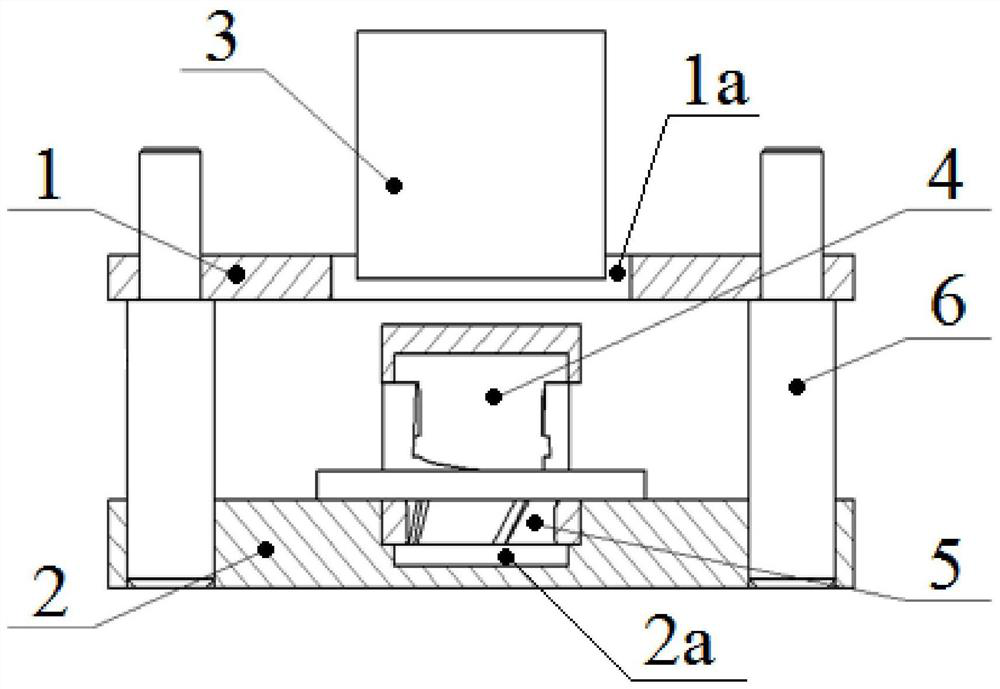

[0044] like Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a stamping and forming cross-riveting interlocking plate butting device, including: a top support plate 1, a bottom support plate 2, a punching head 3, an upper rivet 4 and a lower rivet 5; The top support plate 1 is symmetrically provided with two through holes, the bottom support plate 2 is provided with through holes at the same position, the through holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com