Modular unginned cotton cleaning machine

A cleaning machine, modular technology, applied in mechanical processing, fiber processing, textiles and papermaking, etc., can solve the problems of difficult to clean seed cotton impurities, complicated connection process, and many accessories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

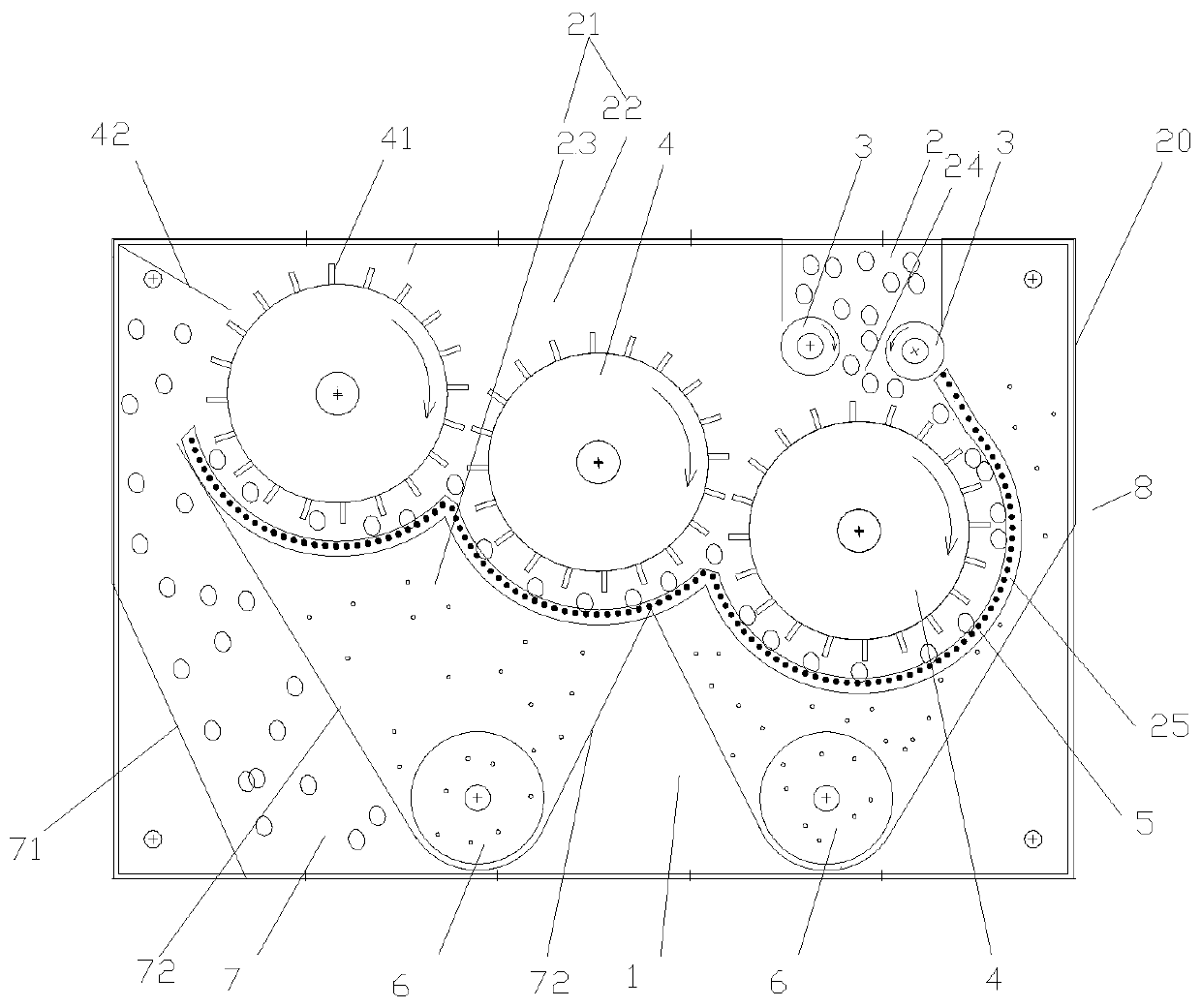

[0034] Such as figure 1, the modularized seed cotton cleaning machine 8 comprises a casing box 20, a housing cavity 21 is formed in the box body 20, and the arc-shaped grate bar frame 25 is arranged between the two side wall panels 1 parallel to each other in the box body 20, and the box body 20 is divided into a seed cotton cavity 22 and an impurity cavity 23. The top of the seed cotton cavity 22 is provided with a seed cotton inlet passage 2, and two feeding rollers 3 driven by a transmission device to rotate in opposite directions are installed below the seed cotton inlet passage 2. The two feeding rollers 3 are on opposite sides. The direction of the linear velocity moves away from the seed cotton inlet channel 2. The two feeding rollers 3 are connected between the wall panels 1 on both sides, and their axes are arranged parallel to each other. When the two feeding rollers 3 are far away from each other, a The transmission channel 24 through which the seed cotton in the in...

Embodiment 2

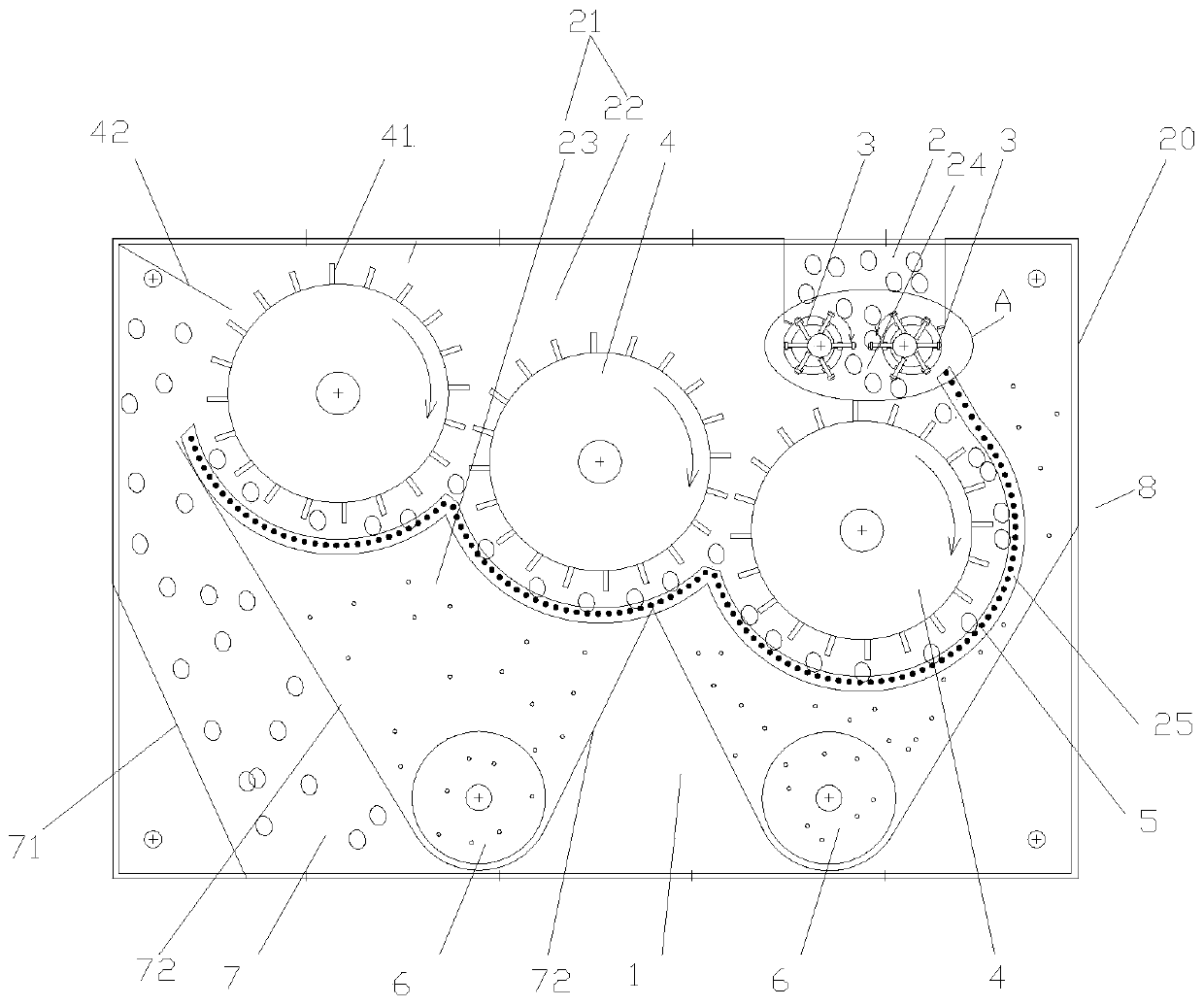

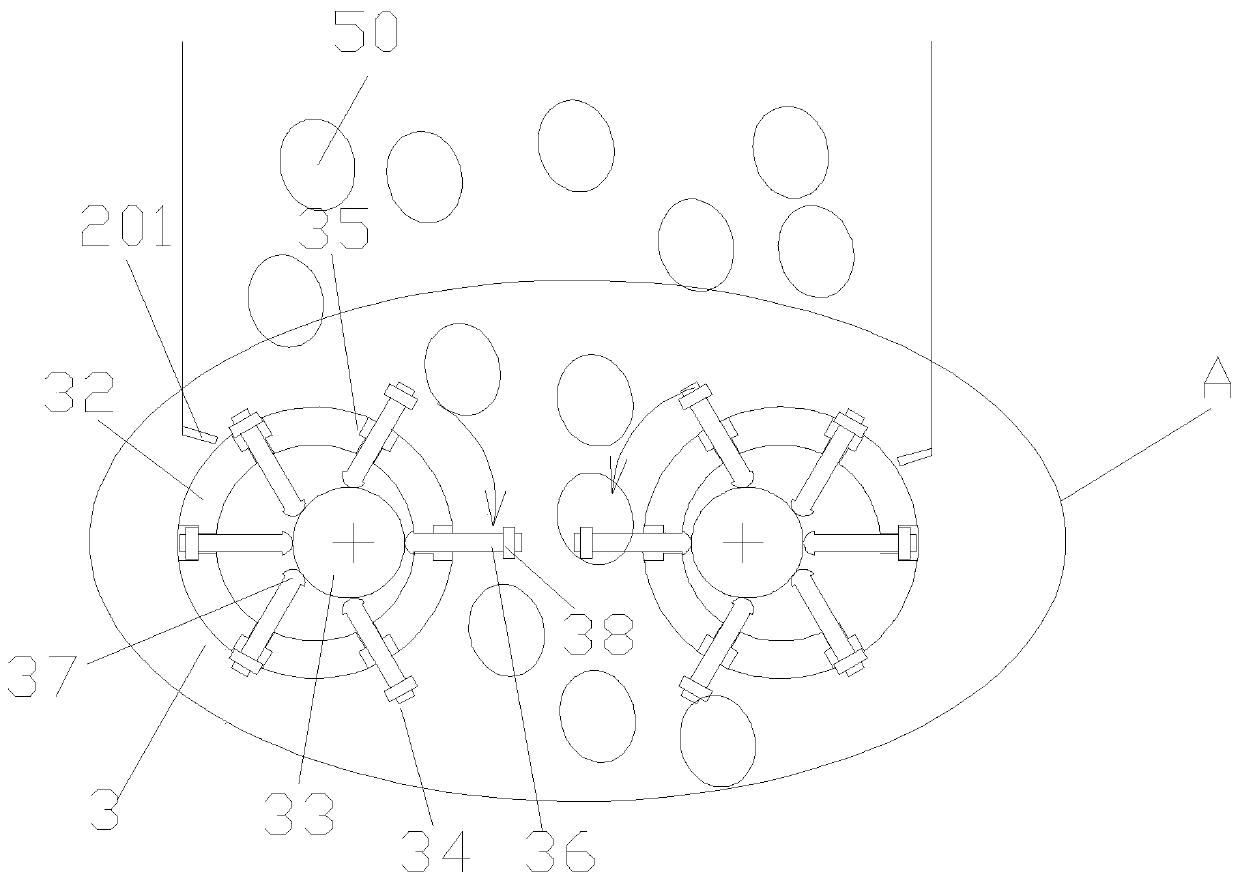

[0044] Such as figure 2 , the modularized seed cotton cleaning machine 8 comprises a casing box 20, a housing cavity 21 is formed in the box body 20, and the arc-shaped grate bar frame 25 is arranged between the two side wall panels 1 parallel to each other in the box body 20, and the box body 20 is divided into a seed cotton cavity 22 and an impurity cavity 23. The top of the seed cotton cavity 22 is provided with a seed cotton inlet passage 2, and two feeding rollers 3 driven by a transmission device to rotate in opposite directions are installed below the seed cotton inlet passage 2. The two feeding rollers 3 are on opposite sides. The direction of the linear velocity moves away from the seed cotton inlet channel 2. The two feeding rollers 3 are connected between the wall panels 1 on both sides, and their axes are arranged parallel to each other. When the two feeding rollers 3 are far away from each other, a The transmission channel 24 through which the seed cotton in the ...

Embodiment 3

[0054] Such as Figure 5 , using several modular seed cotton cleaning machines of embodiment 1 or embodiment 2 to assemble into a modular seed cotton cleaning machine unit sequentially from top to bottom, and the seed cotton outlet channel 7 of the modular seed cotton cleaning machine at the top communicates with the modular seed cotton cleaning machine at the bottom The seed cotton inlet channel 2 of the seed cotton cleaning machine is connected with the adjacent modularized seed cotton cleaning machines by bolts.

[0055] During use, the flow process of cleaning the seed cotton with higher impurity content: the seed cotton is fed by the seed cotton inlet passage 10-1 of the third modularized seed cotton cleaning machine 10, and the cleaned seed cotton is fed from the seed cotton outlet passage of the third modularized seed cotton cleaning machine 10 10-2 discharge, under the action of weight, the seed cotton directly falls into the seed cotton inlet channel 9-1 of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com