Strong-combined composite material plate

A composite material board and composite material technology, applied in the field of composite material boards, can solve the problems of high process cost, weak impact resistance, large environmental pollution, etc., and achieve the effect of simple connection process, reasonable structure design and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

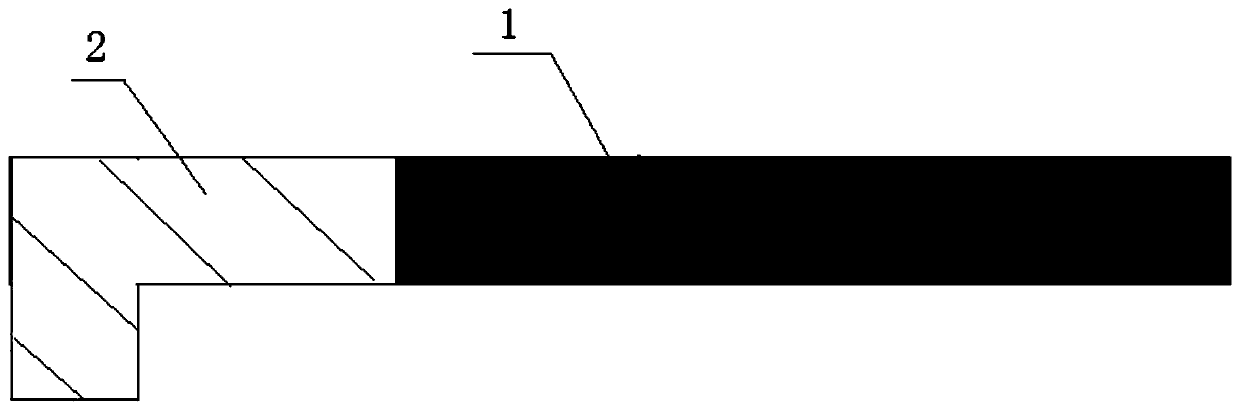

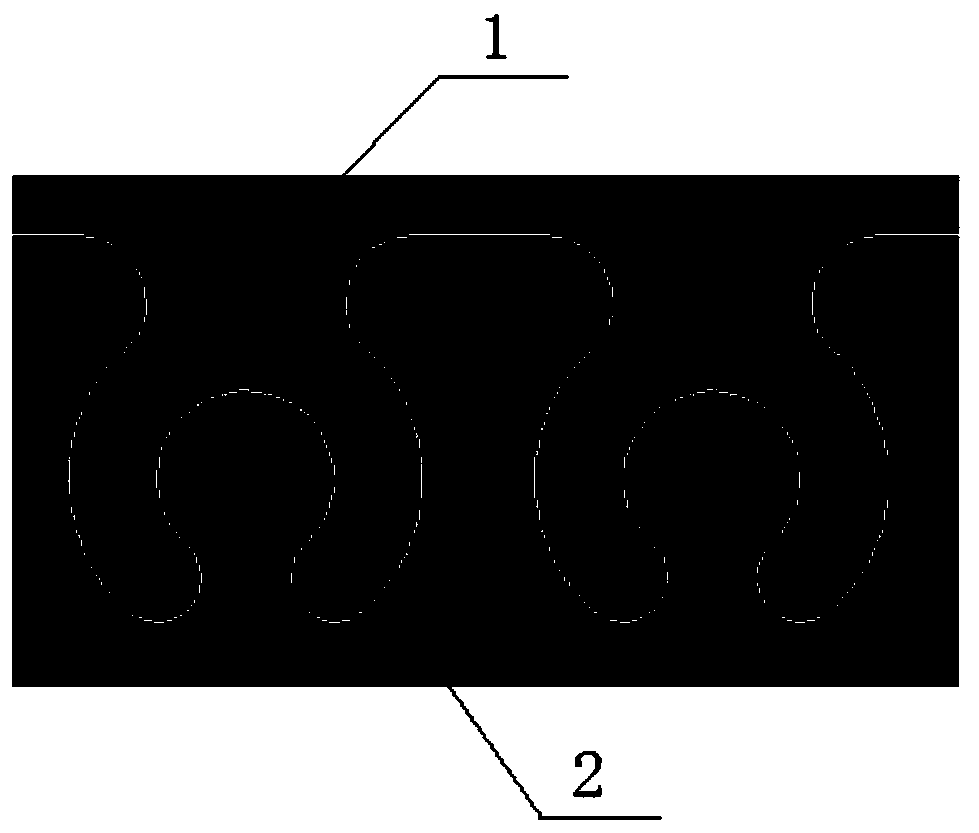

[0029] Such as figure 1 with image 3 As shown, a composite material plate with strong combination includes a composite material plate 1, a thermoplastic material frame 2 connected to the outer periphery of the composite material plate 1 by injection molding; the end surface of the composite material plate 1 is cut with concave and convex surfaces, and the thermoplastic material The concave-convex surface of the filling end surface is combined with the composite material plate 1;

[0030] The composite material plate 1 is provided with a sawtooth groove 3, and the composite material plate 1 and the thermoplastic material frame 2 are connected to each other through the sawtooth groove 3; the shapes of the two adjacent sawtooth grooves on the composite material plate 1 are the same; The inside of the sawtooth groove 3 is provided with a groove whose opening size is larger than the opening of the sawtooth groove;

[0031] The composite material board 1 includes a solid board an...

Embodiment 2

[0036] Such as figure 1 , Figure 4 with Figure 5 As shown, a composite material plate with strong combination includes a composite material plate 1, a thermoplastic material frame 2 connected to the outer periphery of the composite material plate 1 by injection molding; the end surface of the composite material plate 1 is cut with concave and convex surfaces, and the thermoplastic material The concave-convex surface of the filling end surface is combined with the composite material plate 1;

[0037] The composite material plate 1 is provided with a sawtooth groove 3, and the composite material plate 1 and the thermoplastic material frame 2 are connected to each other through the sawtooth groove 3; the shapes of the two adjacent sawtooth grooves on the composite material plate 1 are different; The inside of the sawtooth groove 3 is provided with a groove whose opening size is larger than the opening of the sawtooth groove;

[0038] The composite material board 1 includes a...

Embodiment 3

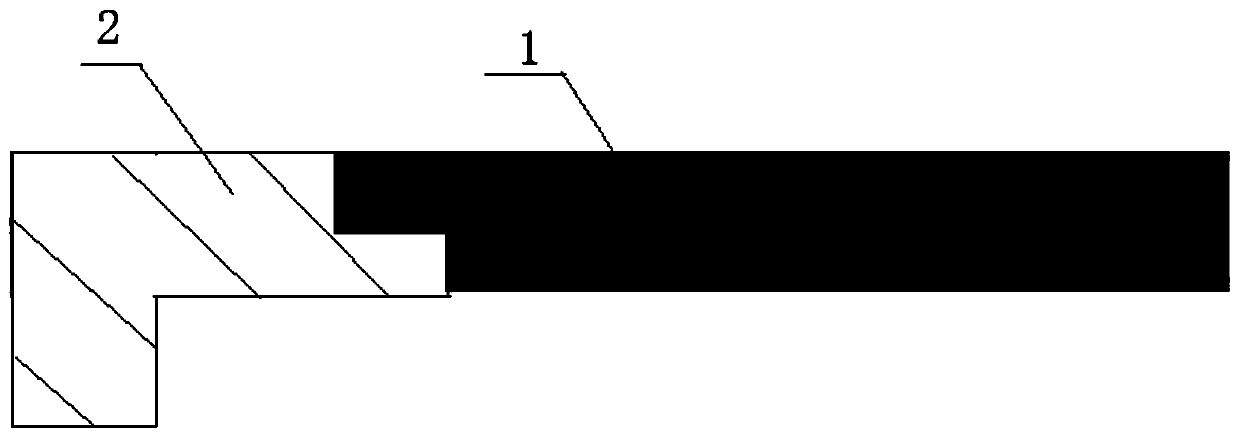

[0042] Such as figure 2 with Image 6 As shown in the figure, a solidly combined composite material plate includes a composite material plate 1, and a thermoplastic material frame 2 connected to the outer periphery of the composite material plate 1 by injection molding;

[0043] The composite material plate 1 is provided with a sawtooth groove 3, and the composite material plate 1 and the thermoplastic material frame 2 are connected to each other through the sawtooth groove 3; the shapes of the adjacent two sawtooth grooves 3 on the composite material plate 1 are the same ; The inside of the sawtooth groove 3 is provided with two grooves whose opening size is larger than the opening of the sawtooth groove 3;

[0044] The composite material board 1 includes a solid board and a sandwich board; wherein the sandwich board includes a solid sandwich and a foamed structure sandwich. The solid sandwich core and the foam structure sandwich core are provided with skins made of fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com