Vacuum aluminized paper

A technology of vacuum aluminized paper and aluminized layer, applied in the direction of wrapping paper, wrapping paper, flexible covering, etc., can solve the problems of poor carafe performance, limit printing performance, reduce paper strength, etc., and achieve good printing effect , the connection process is easy, and the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

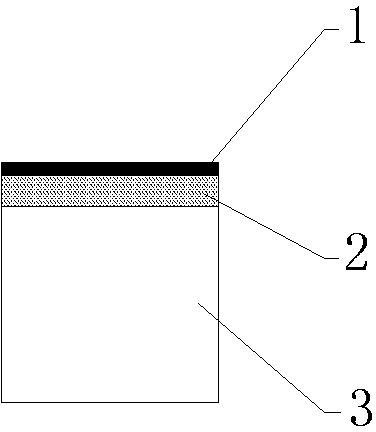

[0014] A vacuum aluminized paper, comprising a base layer 3 and an aluminum coating layer 1, the thickness of the aluminized layer 1 is 0.05um to 0.075um, a tensile layer 2 is also provided between the base layer 3 and the aluminized layer 1, the Tensile layer 2 is a composite material of epoxy resin and polyphenylene ether, which moderately increases the traditional aluminum-coated layer, improves the strength of the paper, is simple to make, and has better printing effect. It is easy to handle and recycle, and is an environmentally friendly product. The tensile layer enhances the tensile properties of the aluminized paper. Both epoxy resin and polyphenylene ether have good tensile strength, and the connection process with the paper base is easy t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com