Battery pack and vehicle

A battery pack, battery technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve problems such as increased production costs, damage to electrical connectors, and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

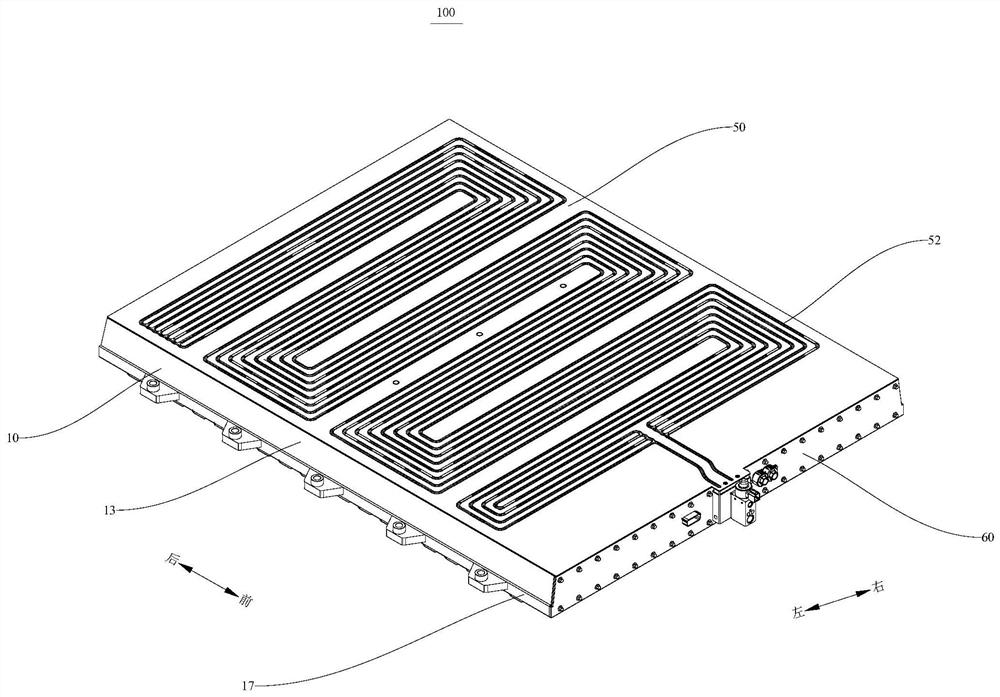

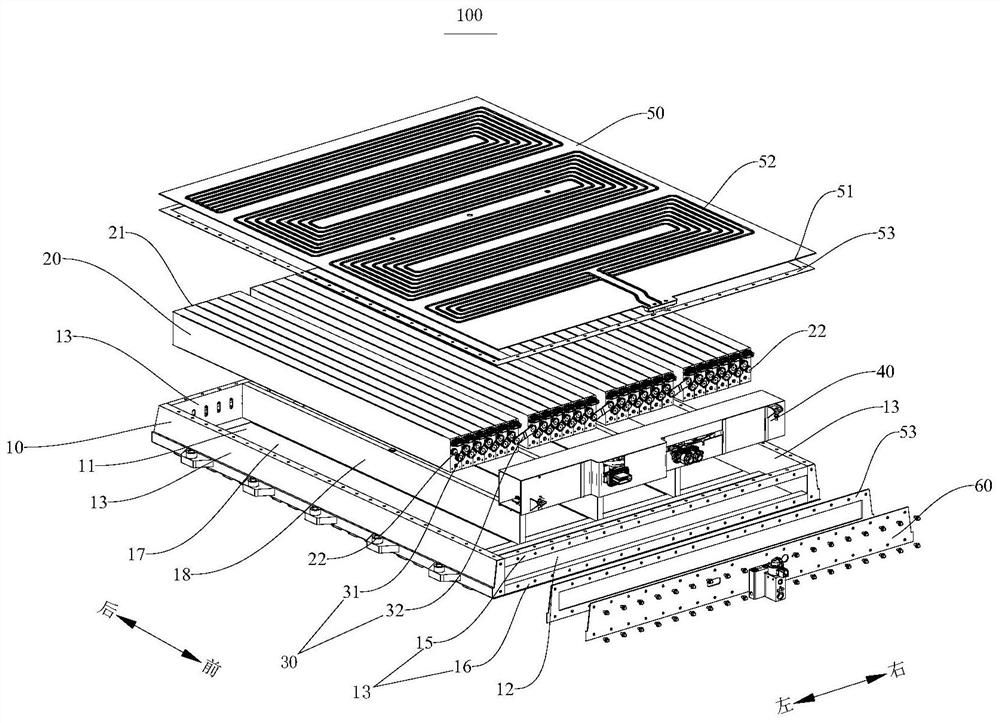

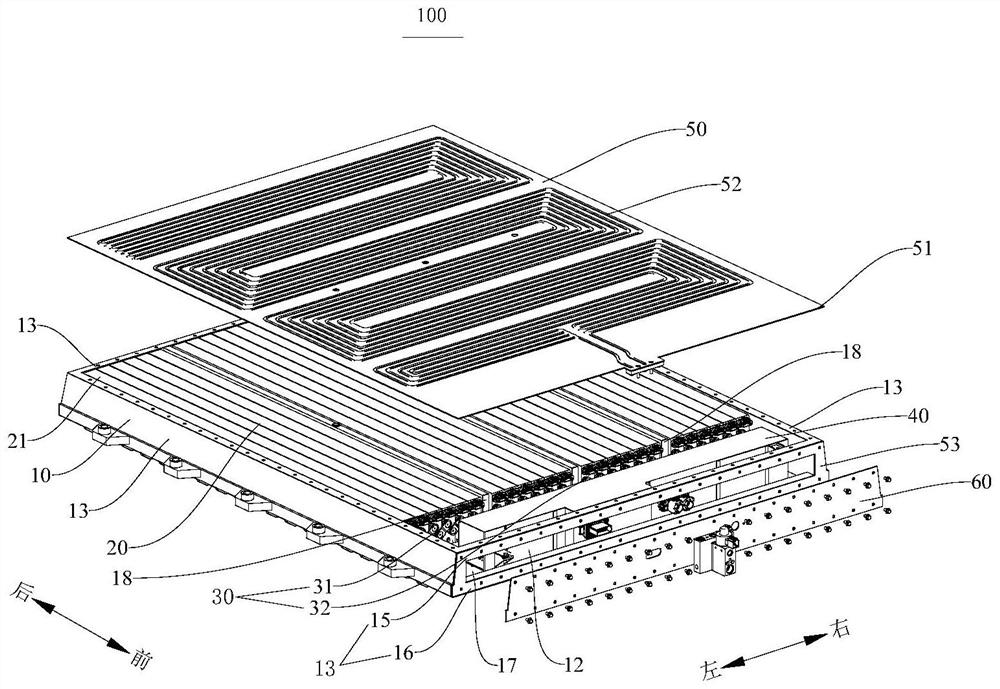

[0035] Refer below Figure 1-Figure 5 The battery pack 100 according to the embodiment of the present invention is described, and the battery pack 100 can be applied to a vehicle.

[0036] combine figure 1 and figure 2 As shown, the battery pack 100 according to the embodiment of the present invention may include: a tray 10, a battery array 20, and an electrical connector 30. The tray 10 is designed with an accommodating groove 11, and the accommodating groove 11 is used to accommodate the battery array 20, that is, In other words, the battery array 20 is installed in the accommodating groove 11 of the tray 10, and the battery array 20 is mainly composed of a plurality of batteries 21, and the battery array 20 composed of a plurality of batteries 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com