Battery cell combination and battery assembly using same

A technology for battery components and cells, applied in battery pack parts, batteries, electrical components, etc., can solve problems such as wire breakage, complex structure, and easy short-circuit safety hazards, and achieve convenient disassembly and assembly, simple overall structure, and broad market. and the effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

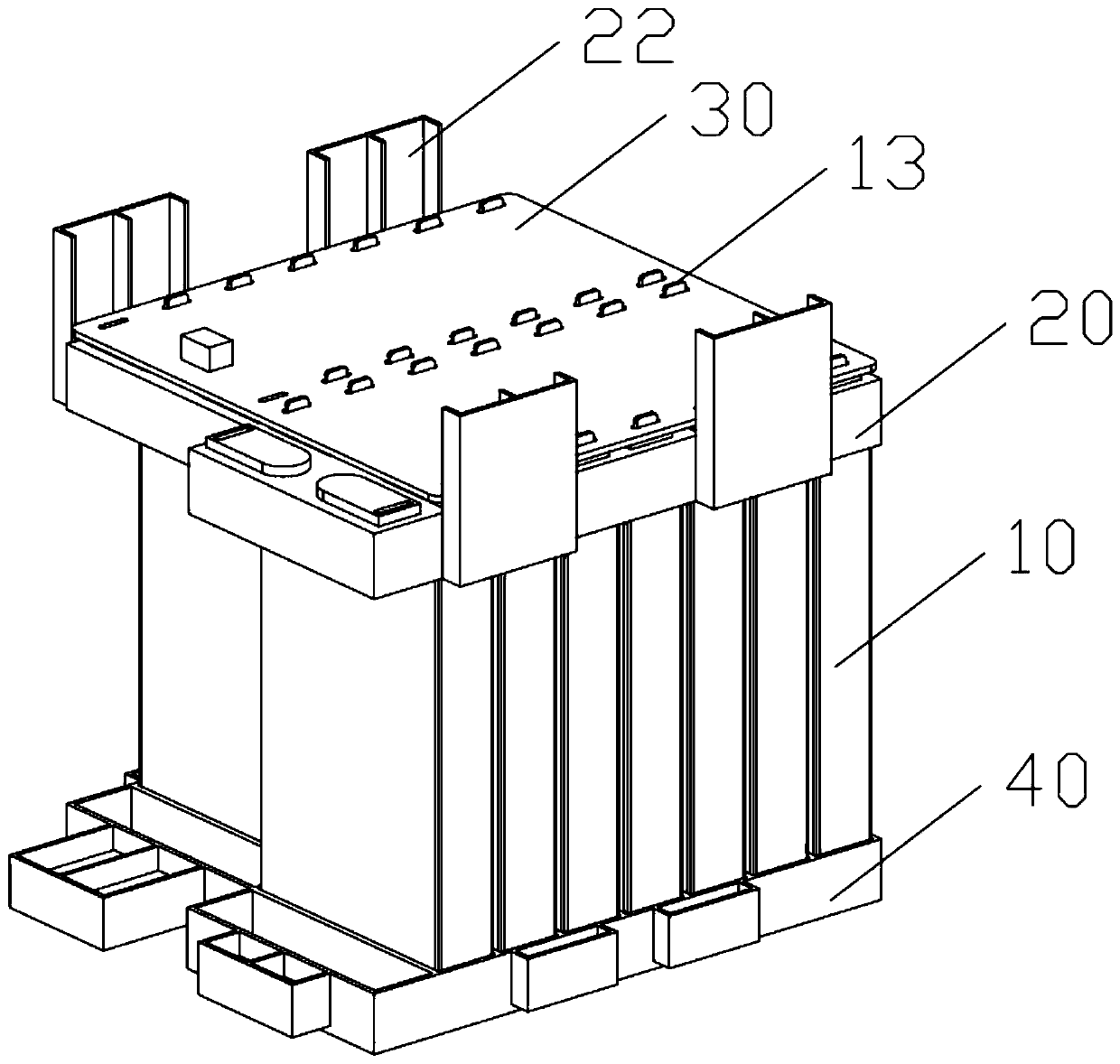

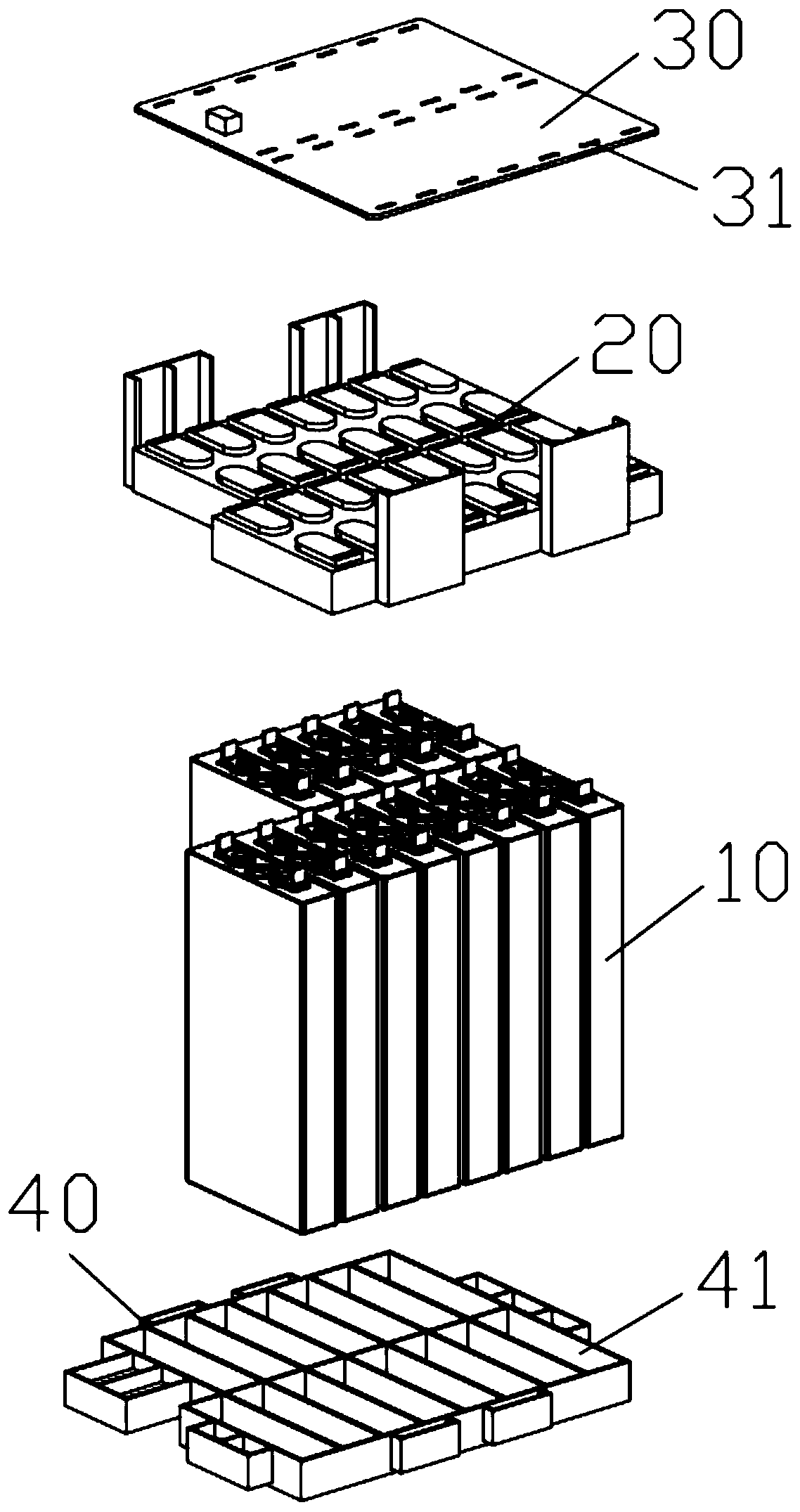

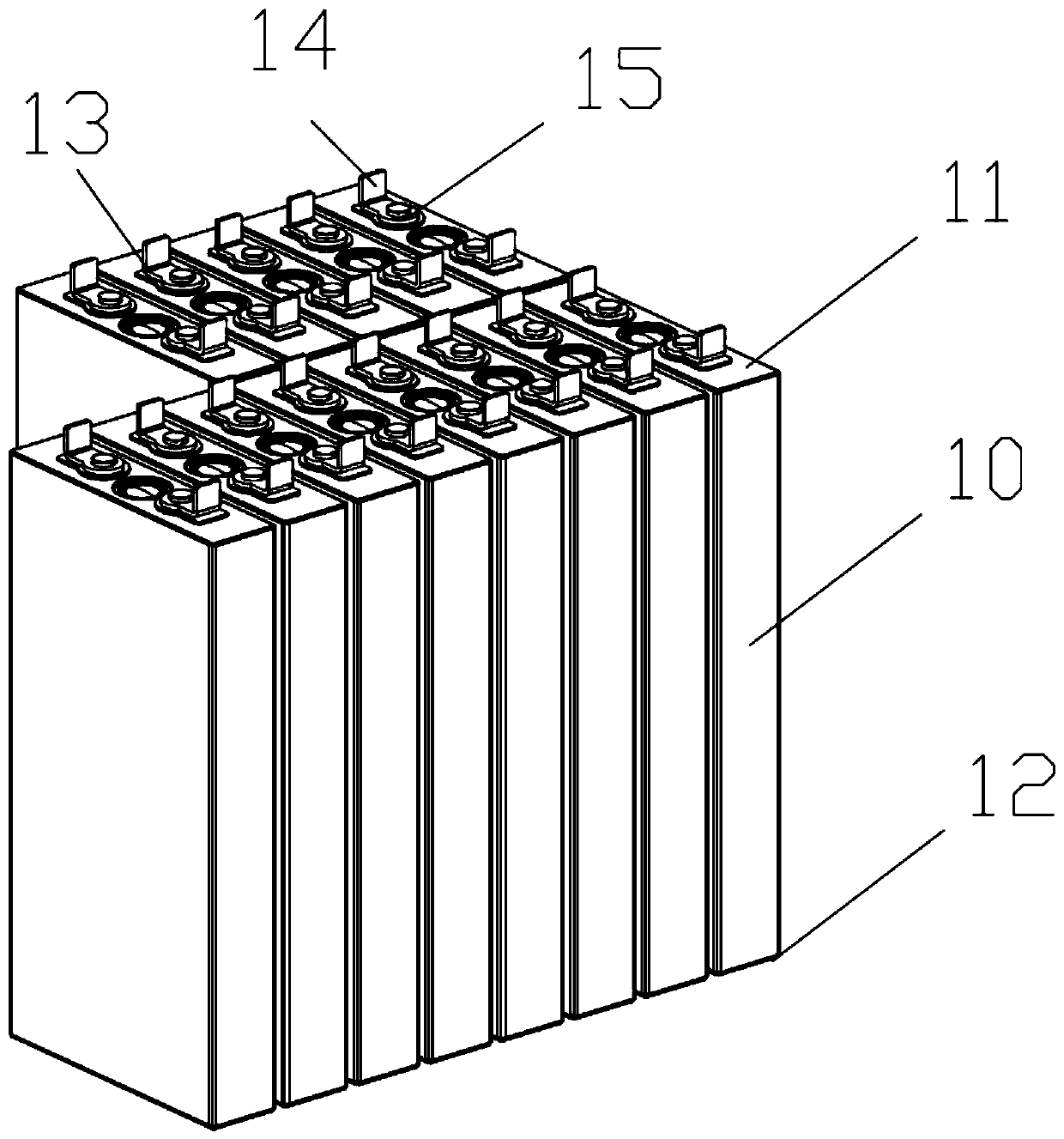

[0030] Example: such as Figure 1-4 As shown, a battery cell combination includes a chipset 10, an insulating plate 20 and a circuit board 30. The chipset 10 is composed of a number of single battery chips, and each battery chip has an upper end surface 11 and an upper end surface opposite to the upper end surface. The lower end face 12, the insulating plate 20 is covered on the upper end face 11, the circuit board 30 is placed on the insulating plate 20, the upper end face 11 is provided with positive and negative pole lugs 13, the pole lugs 13 Pass through the insulating board 20 and be fixedly connected to the circuit board 30 , the shell of the battery chip is made of hard material, and the tab 13 is copper sheet. In the present invention, the tabs 13 in the battery chip are directly connected to the circuit board 30, which not only omits the tab connection plate in the traditional process, but also does not need to be connected by wires, thus reducing the cost of battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com