A multifunctional modular shaft

A modular and multi-functional technology, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., can solve the problems of not being able to install electromagnetic brakes, affecting the compactness of size, and complicated design of limit parts, etc. Modular, easy to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

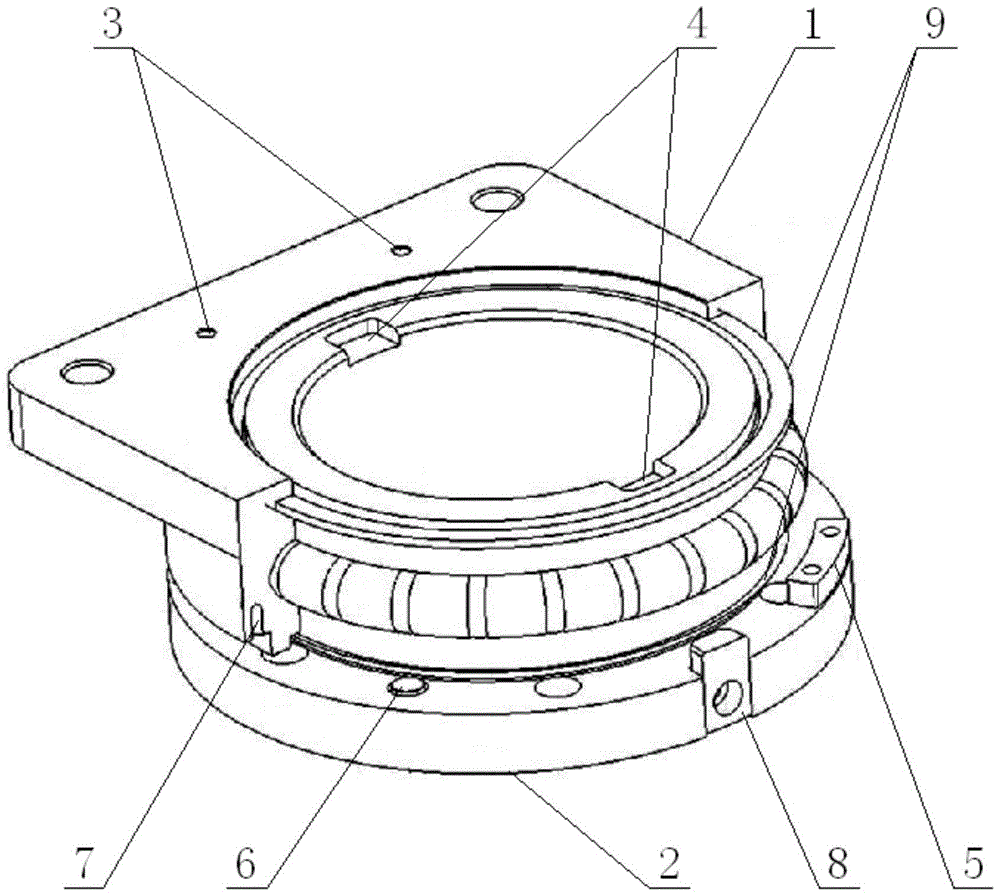

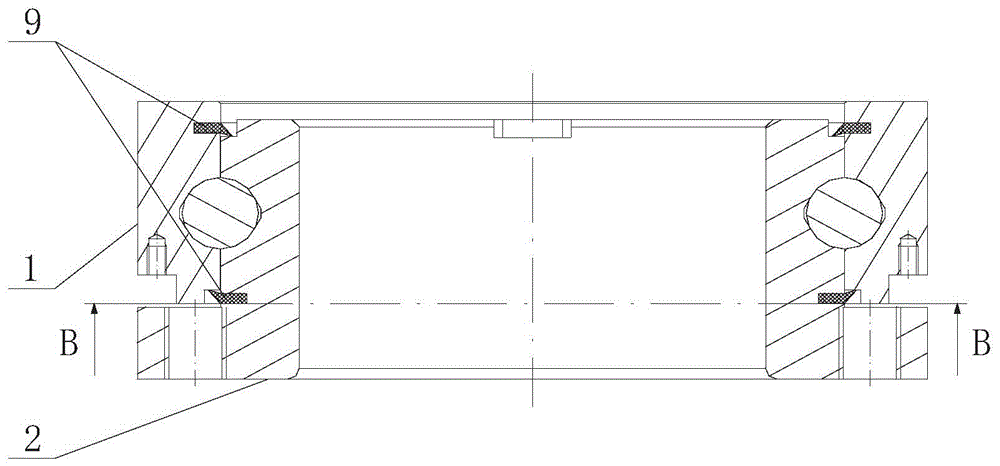

[0020] Such as Figure 1 ~ Figure 4 As shown, a multifunctional modular rotating shaft includes an outer ring of the rotating shaft 1 and an inner ring of the rotating shaft 2, wherein the outer ring of the rotating shaft 1 is an integral forged structure with a flange; the inner ring of the rotating shaft 2 is a An integral forged structure with a flange; the flange top surface of the outer ring of the rotating shaft 1 is provided with four connecting holes 3 for fixing the brake assembly; the bottom surface of the outer ring of the rotating shaft 1 is provided with a number of limit points Degree hole 4, the limit block 5 is installed on the limit index hole 4; the radial inner side of the bottom surface of the outer ring of the rotating shaft 1 is the mechanical braking action surface; the flange of the inner ring of the rotating shaft 2 is on the A number of mechanical brake holes 6 are arranged on the positions corresponding to the mechanical brake action surface; the top...

Embodiment 2

[0022] Such as Figure 5 As shown, an airbag brake is installed above the multifunctional modular rotating shaft.

Embodiment 3

[0024] Such as Image 6 As shown, an electromagnetic brake is installed above the multifunctional modular rotating shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com