Ceramic and metal field self extending combustion connecting method

A technology of self-propagating combustion and connection method, which is applied to the field of laying ceramic protective layers on the high-temperature wear surface of metal parts, which can solve the problems of complex process, low connection strength, and low density of ceramic layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

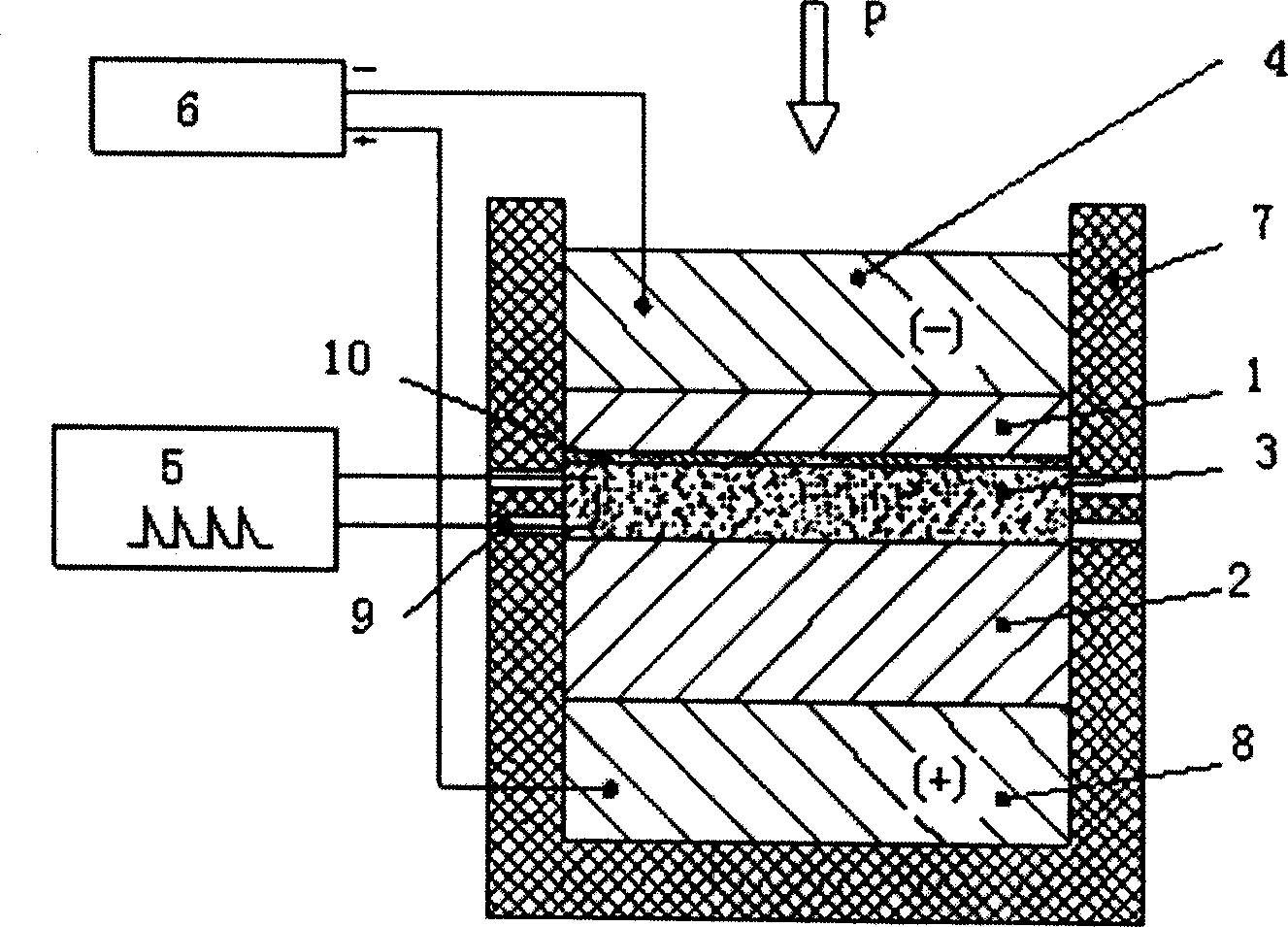

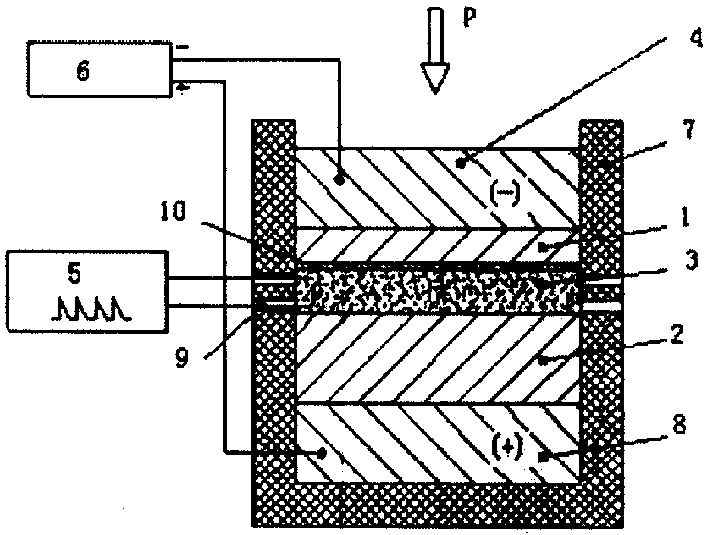

Method used

Image

Examples

Embodiment approach 1

[0017] Ceramic material Al 2 o 3 Plate, thickness 1.5mm; metal material 20 steel, thickness 12mm; mixed filler components: aluminum powder 35%, iron oxide red 45%, silicon oxide 10%, the rest is sodium borate and calcium fluoride; ceramic nickel plating layer thickness 5μm . Connect according to the method described in the manual, the voltage is 300V, and the pressure is 5Mpa. The shear strength of ceramic and metal connection is 29.5Mpa.

Embodiment approach 2

[0019] Ceramic material ZrO 2 Plate, thickness 2.0mm; metal material 13CrMo44 steel, thickness 8mm; mixed filler components: aluminum powder 40%, iron oxide red 35%, chromium oxide 10%, the rest is silicon oxide and calcium fluoride; ceramic nickel plating layer thickness 3μm . Connect according to the method described in the manual, the voltage is 500V, and the pressure is 3Mpa. The shear strength of ceramic and metal connection is 32Mpa.

Embodiment approach 3

[0021] Ceramic material TiC plate, thickness 1.0mm; metal material stainless steel, thickness 6mm; mixed filler components: titanium powder 40%, iron oxide red 25%, chromium oxide 10%, graphite powder 25%, ceramic nickel plating layer thickness 3μm. According to the method described in the manual, the connection voltage is 300V, the pressure is 5Mpa, and the shear strength of ceramic and metal connection is 28Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com